Abstract

An operationally simple method for synthesis of benzimidazole and 3H-imidazo[4,5-c]pyridine from o-phenylenediamine or pyridine-3, 4-diamine and N,N-dimethylformamide (DMF) in the presence of hexamethyldisilazane (HMDS) as a reagent is described. To evaluate the scope of application of this reagent, it was also used to prepare benzothiazole, 1H-perimidine, and benzoxazole, which was successful for benzothiazole and 1H-perimidine but benzoxazole was not formed. This reaction complies with the principles of green chemistry as it does not use toxic solvents, transition metals, or strong acids. The products are obtained in moderate to excellent yields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

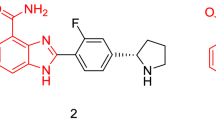

Benzimidazole is a bicyclic heteroaromatic compound containing an imidazole ring, where a benzene ring fused to the 4- and 5-position of the imidazole ring. The imidazole is an important heterocyclic compound that is found in several natural compounds such as purine, vitamins (B12), some of the amino acids same as histidine. This compound shows a vital role in the metabolism of all living cells. Benzimidazole derivatives exhibit numerous significant medical and biological activities such as antiallergic (Nakano et al. 1999), anticancer (Tong et al. 2009), antibacterial (Menteşe et al. 2014), antiulcer (Iwahi et al. 1991), antifungal (Ke et al. 2014), antihistaminic (Iemura et al. 1987), antiviral (Tonelli et al. 2014), anti-inflammatory (Sondhi et al. 2006), antidepressant (Siddiqui et al. 2011), and antidiabetic (Bansal and Silakari 2012) (Fig. 1). The literature survey reveals that the presence of a substitution at 1, 2 and 5 positions of benzimidazole ring causes to exhibit a wide range of pharmacological activities (Maryanoff et al. 1995).

Today, different strategies are used to synthesize organic compounds (Yang et al. 2004, 2017). With regard to the application of benzimidazole and its derivatives in chemistry and pharmacy, various methods have been used for the synthesis of benzimidazole such as, reaction of 1,2-arylenediamines with aldehydes, ketones, acid anhydrides, acid chlorides, esters, amides, nitriles, urea, in the presence of a catalyst such as In(OTF)3 (Trivedi et al. 2006), Na3AlF6 (Grigorjeva et al. 2014), Zn(OTF)2 (Srinivasulu et al. 2014), Na2S2O5 (Alaqeel 2017), CdCl2 (Sammaiah et al. 2012), NH4OAc (Sharghi et al. 2008a), BF3-etherate (Nagawade and Shinde 2006), Au-CeO2 (Ruiz et al. 2010), NaHSO3 (Austen and Kane 2001), MnO2 (Bhatnagar and George 1968), copper complex (Sharghi et al. 2008c), ceric ammonium nitrate (CAN) (Kidwai et al. 2010), K4[Fe(CN)6] (Shaikh and Patil 2012), zinc chloride (Mahajan et al. 2013), silica boron sulfonic acid (SBSA) (Sajjadifar et al. 2012), lanthanum chloride (Venkateswarlu et al. 2013), TsOH/graphite (Sharghi et al. 2008b), and hydrogen peroxide (Gadekar et al. 2010). Some of these methods suffer from disadvantages such as environmental damage, the use of strong acids, high temperatures, and use of toxic metal catalysts and hazardous reagents that is in conflict with green chemistry. Therefore, a research for new reagent and the development of new methods are still of practical importance in synthetic chemistry. Recently, DMF was used for the synthesis of benzimidazole derivatives in the presence of an activation reagent such as metal catalysts, PhSiH3 (Zhu et al. 2017), chlorotrimethylsilane (Ryabukhin et al. 2006). N,N-Dimethylformamide (DMF) is a clear liquid that has been widely used in industries as a solvent, an additive, or an intermediate. N,N-Dimethylformamide (DMF) can be easily synthesized from CO2 with dimethylamine in the presence of H2 and suitable catalyst (Liu et al. 2010). This compound has been employed as a widely utilized reactant in organic transformations such as formylation, amination, and cyanation reactions. (Ding and Jiao 2012). In one of its main uses in organic synthesis, DMF is a reagent in the Vilsmeier–Haack reaction, which is used to formylate aromatic compounds.

Here we wish to report the synthesis of benzimidazole by treatment of o-phenylenediamine with N,N-dimethylformamide (DMF) or N,N-diethylformamide (DEF) in the presence of hexamethyldisilazane (HMDS) as a new reagent under solvent-free conditions at 120 °C (Scheme 1).

Experimental

Chemicals and methods

The materials were purchased from commercial suppliers and were of analytical grade. The progress of the reactions was monitored by thin layer chromatography (TLC) using a mixture of 80% n-hexane, 20% ethyl acetate as eluent. All products were purified by column chromatography. The products are known and the structures of those characterized by IR, 1H NMR and 13C NMR. The FT-IR spectra were recorded as KBr pellets by a Nicolet IR 100 instrument. 1H NMR and 13C NMR spectra were recorded on a Bruker INOVA 500 (500 and 125 MHz) spectrometer using TMS as internal standard and DMSO-d6 as a solvent and chemical shifts are reported in ppm.

General procedure for the synthesis of benzimidazole

HMDS (2 mmol) was added to in a 10-ml flask containing 1,2-phenylenediamine (1 mmol) and 3 ml of DMF. The reaction mixture was stirred and heated for 12 h at 120 °C and then was cooled to room temperature. The excess DMF was removed under reduced pressure. The benzimidazole was purified by silica chromatography using 4:1 n-hexane/EtOAc as the eluent. All of the products are known. Their structures were verified by their IR, 1H NMR, and 13C NMR spectral data.

1H-benzod]imidazole

Yellow solid (114.6 mg, 97%); spectral data: 1H NMR (500 MHz, DMSO-d6): δ 12.45 (s, 1H), 8.17 (s, 1H), 7.53 (t, J = 4 Hz, 2H), 7.11 (m, 2H), 13C NMR (125 MHz, DMSO-d6): δ 142.42, 136.50, 122.19, and 115.93 ppm.

6-Methyl-1H-benzo[d]imidazole

Yellow solid (115 mg, 87%); spectral data: 1H NMR (500 MHz, DMSO-d6): δ 12.24 (s, 1H), 8.06 (s, 1H), 7.39 (d, J = 4 Hz, 1H), 7.29 (s, 1H), 6.92 (d, J = 8 Hz 1H), 2.32 (s, 1H, CH3), 13C NMR (125 MHz, DMSO-d6): δ 142.18, 138.37, 137.36, 131.44, 123.77, 115.96, 115.16, 21.85 ppm.

6-Nitro-1H-benzo[d]imidazole

Yellow solid (110.9 mg, 68%); spectral data: 1H NMR (500 MHz, DMSO-d6): δ 13.02 (s, 1H), 8.47 (s, 1H), 8.43 (s, 1H), 8.03 (d, J = 8 Hz, 1H), 7.69 (d, J = 8 Hz, 1H). 13C NMR (125 MHz, DMSO-d6) δ 147.35, 134.23, 136.44, 133.86, 132.18, 126.96, 118.21 ppm.

3H-imidazo[4,5-c]pyridine

Yellow solid (53.6 mg, 45%); spectral data: 1H NMR (500 MHz, DMSO-d6): δ 12.79 (s, 1H), 8.86 (s, 1H), 8.31 (s, 1H), 8.22 (d, J = 4 Hz, 1H), 7.51 (d, J = 4 Hz, 1H), 13C NMR (125 MHz, DMSO-d6) δ 148.56, 144.56, 141.58, 133.17, 113.16, 107.92 ppm.

1H-perimidine

Yellow solid (84.1 mg, 50%); spectral data: 1H NMR (500 MHz, DMSO-d6): δ 10.48 (s, 1H), 7.23 (s, 1H), 7.00 (t, J = 6 Hz, 2H), 6.90 (d, J = 8 Hz, 2H), 6.29 (s, 2H). 13C NMR (125 MHz, DMSO-d6) δ 146.96, 138.26, 135.91, 128.99, 126.89, 123.57, 119.08 ppm.

Benzothiazole

Colorless liquid (121 mg, 90%); spectral data: 1H NMR (500 MHz, CDCl3): δ 8.97 (s, 1H), 8.14 (d, J = 10 Hz, 1H), 7.92 (d, J = 5 Hz, 1H), 7.49 (t, J = 5 Hz, 1H), 7.41 (t, J = 5 Hz, 1H), 13C NMR (125 MHz, CDCl3): δ 153.90, 153.23, 133.70, 126.15, 125.52, 123.62, 121.87 ppm.

Results and discussion

Initially, we performed the reaction of o-phenylenediamine with DMF in the presence of SiO2, PdCl2, TEOS (tetraethyl orthosilicate) as a catalyst and in the absence of any catalyst. As shown in Table 1, no product was found in all four cases (Table 1, entries 1–4). The yield of the same reaction in the presence of HMDS (1 mmol) as a reagent at 85 °C for 6 h was traced (Table 1, entry 5). The same reaction was then carried out at 120 °C and the yield increased to 8% (Table 1, entry 6). Subsequently, under the same conditions, the amount of HMDS was increased to 2 and 3 mmol therefore, the yield of the product increased to 90 and 91% (Table 1, entries 7, 8). The best reaction conditions for the synthesis of benzimidazole were obtained in the presence of HMDS at 120 °C for 12 h and the yield of the product increased to 97% (Table 1, entry 9). Increasing temperature up to 130 °C reduced the yield of the reaction to 90% (Table 1, entry 10). The reaction time was increased to 15 h, but no significant change was observed in the reaction efficiency (Table 1, entry 11). Finally, the number of reactants was increased to 3 mmol and the product was obtained in 96% yield (Table 1, entry 12).

On the basis of optimized reaction conditions, we carried out the reactions of o-phenylenediamine derivatives with DMF and DEF in the presence of HMDS, and the results are presented in Table 2. To evaluate the scope of application of this reagent, it was also used to prepare 3H-imidazo[4,5-c]pyridine, benzothiazole, 1H-perimidine, and benzofuran. The reaction was successful for preparing of 3H-imidazo[4,5-c]pyridine, benzothiazole and 1H-perimidine but benzoxazole was not formed (Table 2, entries 4–7). Benzothiazole was formed in the reaction of o-aminothiophenol with DMF and DEF in the optimized reaction conditions with 90 and 80% yields, respectively (Table 2, entries 7, 13). The reaction of DMF and DEF with 1,8-diaminonaphthalene was successful and 1H-Perimidine was formed in 50 and 38% yields, respectively (Table 2, entries 5, 12). When 3,4-pyridinediamine was used instead of o-phenylenediamine, 1H-imidazo[4,5-c]pyridine was obtained in 45 and 40% yields, respectively (Table 2, entries 4, 11).

A reasonable mechanism for the mentioned reaction is depicted in Scheme 2. Initially, the carbonyl group of DMF is activated by the HMDS and then the –NH2 group of o-phenylenediamine attacks to the activated carbonyl group and intermediate (I) is formed. Then a proton exchange takes place between the two amine groups followed by removing ammonium salt. Then the second NH2 group attacks to the carbon having Si–O group and the intermediate (II), a two-ring heterocyclic compound, is formed. Aromatization of new ring was performed by removing of Me3SiOH and benzimidazole is formed as a final product (Scheme 2).

To highlight the importance of this research, a number of reagents and catalysts which was used to synthesize of benzimidazole from the reaction of DMF with o-phenylenediamine have been studied. As shown in Table 3, Zhu et al. presented an efficient way to synthesize benzimidazole using PhSiH3 (Zhu et al. 2017). Although the practical approach presented in this article is very similar to the Zhu method and there is not much difference in the efficiency of two reactions but phenylsilane is very expensive so that, the price of 30 g of PhSiH3 is approximately equal to the price of 1 l of HMDS. Therefore, this protocol is economically better than the Zhu method and is preferable to other methods due to the lack of use a toxic solvent and strong acids.

In conclusion, we used HMDS as a reagent for the synthesis of benzimidazole, benzothiazole, 3H-imidazo[4,5-c]pyridine and 1H-perimidine from DMF or DEF and o-phenylenediamine, 2-aminothiophenol, 3,4-pyridinediamine and 1,8-naphthalene diamine. The yield of the products was moderate to excellent and this reaction can take place in the category of green chemistry reactions because the reaction does not contain strong acids, toxic metal catalyst, and an organic solvent.

References

Alaqeel SI (2017) Synthetic approaches to benzimidazoles from o-phenylenediamine: a literature review. J Saudi Chem Soc 21:229–237. https://doi.org/10.1016/j.jscs.2016.08.001

Austen SC, Kane JM (2001) A short synthesis of the parp inhibitor 2-(4-trifluoro-methylphenyl) benzimidazole-4-carboxamide (NU1077). J Heterocycl Chem 38:979–980. https://doi.org/10.1002/jhet.5570380427

Bansal Y, Silakari O (2012) The therapeutic journey of benzimidazoles: a review. Bioorgan Med Chem 20:6208–6236. https://doi.org/10.1016/j.bmc.2012.09.013

Bhatnagar I, George M (1968) Oxidation with metal oxides—II: oxidation of chalcone phenylhydrazones, pyrazolines, o-aminobenzylidine anils and o-hydroxy benzylidine anils with manganese dioxide. Tetrahedron 24:1293–1298. https://doi.org/10.1016/0040-4020(68)88080-9

Ding S, Jiao N (2012) N,N-Dimethylformamide: a multipurpose building block. Angew Chem Int Ed 51:9226–9237. https://doi.org/10.1002/anie.201200859

Gadekar LS, Arbad BR, Lande MK (2010) Eco-friendly synthesis of benzimidazole derivatives using solid acid scolecite catalyst. Chin Chem Lett 21:1053–1056. https://doi.org/10.1016/j.cclet.2010.03.038

Gao X, Yu B, Mei Q, Yang Z, Zhao Y, Zhang H, Liu Z (2016) Atmospheric CO2 promoted synthesis of N-containing heterocycles over B (C 6 F 5) 3 catalyst. New J Chem 40:8282–8287. https://doi.org/10.1039/C6NJ01721E

Grigorjeva L, Liepinsh E, Razafimahefa S, Yahorau A, Yahorava S, Rasoanaivo P, Wikberg JE (2014) Semisynthesis of libiguin a and its analogues by trans-lactonization of phragmalin. J Org Chem 79:4148–4153. https://doi.org/10.1021/jo500318w

Iemura R, Kawashima T, Fukuda T, Ito K, Tsukamoto G (1987) Synthesis of benzimidazole derivatives as potential H1-antihistaminic agents. J Heterocycl Chem 24:31–37. https://doi.org/10.1002/jhet.5570240107

Iwahi T, Satoh H, Nakao M, Iwasaki T, Yamazaki T, Kubo K, Imada A (1991) Lansoprazole, a novel benzimidazole proton pump inhibitor, and its related compounds have selective activity against Helicobacter pylori. Antimicrob Agents Chemother 35:490–496. https://doi.org/10.1128/AAC.35.3.490

Kattimani PP, Kamble RR, Meti GY (2015) Expedient synthesis of benzimidazoles using amides. RSC Adv 5:29447–29455. https://doi.org/10.1039/C5RA00021A

Ke Y, Zhi X, Yu X, Ding G, Yang C, Xu H (2014) Combinatorial synthesis of benzimidazole-azo-phenol derivatives as antifungal agents. Comb Chem High. https://doi.org/10.2174/13862073113166660058

Kidwai M, Jahan A, Bhatnagar D (2010) Polyethylene glycol: a recyclable solvent system for the synthesis of benzimidazole derivatives using CAN as catalyst. J Chem Sci 122:607–612. https://doi.org/10.1007/s12039-010-0095-7

Liu J, Guo C, Zhang Z, Jiang T, Liu H, Song J, Han B (2010) Synthesis of dimethylformamide from CO2, H2 and dimethylamine over Cu/ZnO. Chem Commun 46:5770–5772. https://doi.org/10.1039/C0CC00751J

Mahajan T, Dhimant K, Kapse G, Hugar M (2013) ZnCl2-SiO2 catalyzed solvent free synthesis of benzimidazole derivatives under microwave irradiation. J Appl Chem 2:50–54

Maryanoff BE, Ho W, McComsey DF, Reitz AB, Grous PP, Nortey SO, Gardocki JF (1995) Potential anxiolytic agents. Pyrido [1, 2-a] benzimidazoles: a new structural class of ligands for the benzodiazepine binding site on GABA-A receptors. J Med Chem 38:16–20

Menteşe E, Bektaş H, Ülker S, Bekircan O, Kahveci B (2014) Microwave-assisted synthesis of new benzimidazole derivatives with lipase inhibition activity. J Enzyme Inhib Med Chem 29:64–68. https://doi.org/10.3109/14756366.2012.753880

Nagawade RR, Shinde DB (2006) BF3· OEt2 promoted solvent-free synthesis of benzimidazole derivatives. Chin Chem Lett 17:453–456

Nakano H, Inoue T, Kawasaki N, Miyataka H, Matsumoto H, Taguchi T, Satoh T (1999) Synthesis of benzimidazole derivatives as antiallergic agents with 5-lipoxygenase inhibiting action. Chem Pharm Bull 47:1573–1578

Nale DB, Bhanage BM (2015) N-substituted formamides as C1-sources for the synthesis of benzimidazole and benzothiazole derivatives by using zinc catalysts. Synlett 26:2835–2842. https://doi.org/10.1055/s-0035-1560319

Ruiz VR, Corma A, Sabater MJ (2010) New route for the synthesis of benzimidazoles by a one-pot multistep process with mono and bifunctional solid catalysts. Tetrahedron 66:730–735. https://doi.org/10.1248/cpb.47.1573

Ryabukhin SV, Plaskon AS, Volochnyuk DM, Tolmachev AA (2006) Synthesis of fused imidazoles and benzothiazoles from (hetero) aromatic ortho-diamines or ortho-aminothiophenol and aldehydes promoted by chlorotrimethylsilane. Synthesis 2006:3715–3726. https://doi.org/10.1055/s-2006-950289

Sajjadifar S, Mirshokraie SA, Javaherneshan N, Louie O (2012) SBSA as a new and efficient catalyst for the one-pot green synthesis of benzimidazole derivatives at room temperature. AJOC 2:1–6. https://doi.org/10.5923/j.ajoc.20120202.01

Sammaiah B, Sumalatha D, Reddy GS, Rajeswari M, Sharada L (2012) Cadmium chloride (CdCl2): a mild and efficient catalyst for the synthesis of benzimidazoles. IJIC 3:11. https://doi.org/10.5923/j.ajoc.20120202.01

Shaikh KA, Patil VA (2012) An efficient solvent-free synthesis of imidazolines and benzimidazoles using K4 [Fe(CN)6] catalysis. Org Commun 5:12–17

Sharghi H, Asemani O, Khalifeh R (2008a) New one-pot procedure for the synthesis of 2-substituted benzimidazoles. Synth Commun 38:1128–1136. https://doi.org/10.1080/00397910701863657

Sharghi H, Asemani O, Tabaei SMH (2008b) Simple and mild procedures for synthesis of benzimidazole derivatives using heterogeneous catalyst systems. J Heterocycl Chem 45:1293–1298. https://doi.org/10.1002/jhet.5570450506

Sharghi H, Hosseini-Sarvari M, Moeini F (2008c) Copper-catalyzed one-pot synthesis of benzimidazole derivatives. Can J Chem 86:1044–1051. https://doi.org/10.1139/v08-153

Siddiqui N, Andalip SB, Ali R, Afzal O, Akhtar MJ, Azad B, Kumar R (2011) Antidepressant potential of nitrogen-containing heterocyclic moieties: an updated review. J Pharm Bioallied Sci 3:194–212. https://doi.org/10.4103/0975-7406.80765

Sondhi SM, Singh N, Kumar A, Lozach O, Meijer L (2006) Synthesis, anti-inflammatory, analgesic and kinase (CDK-1, CDK-5 and GSK-3) inhibition activity evaluation of benzimidazole/benzoxazole derivatives and some Schiff’s bases. Bioorgan Med Chem 14:3758–3765. https://doi.org/10.1016/j.bmc.2006.01.054

Srinivasulu R, Kumar KR, Satyanarayana PVV (2014) Facile and efficient method for synthesis of benzimidazole derivatives catalyzed by zinc triflate. GSC 4:33

Tonelli M, Novelli F, Tasso B, Vazzana I, Sparatore A, Boido V, Giliberti G (2014) Antiviral activity of benzimidazole derivatives. III. Novel anti-CVB-5, anti-RSV and anti-Sb-1 agents. Bioorgan Med Chem 22:4893–4909. https://doi.org/10.1016/j.bmc.2014.06.043

Tong Y, Bouska JJ, Ellis PA, Johnson EF, Leverson J, Liu X, Przytulinska M (2009) Synthesis and evaluation of a new generation of orally efficacious benzimidazole-based poly (ADP-ribose) polymerase-1 (PARP-1) inhibitors as anticancer agents. J Med Chem 52:6803–6813. https://doi.org/10.1021/jm900697r

Trivedi R, De SK, Gibbs RA (2006) A convenient one-pot synthesis of 2-substituted benzimidazoles. J Mol Catal Chem 245:8–11. https://doi.org/10.1016/j.molcata.2005.09.025

Venkateswarlu Y, Kumar SR, Leelavathi P (2013) Facile and efficient one-pot synthesis of benzimidazoles using lanthanum chloride. Org Med Chem Lett 3:3–7. https://doi.org/10.1186/2191-2858-3-7

Yang X, Zhang S, Qiu Z, Tian G, Feng Y, Xiao FS (2004) Stable ordered mesoporous silica materials templated by high-temperature stable surfactant micelle in alkaline media. J Phys Chem B 108:4696–4700. https://doi.org/10.1021/jp0380226

Yang XY, Chen LH, Li Y, Rooke JC, Sanchez C, Su BL (2017) Hierarchically porous materials: synthesis strategies and structure design. Chem Soc Rev 46:481–558. https://doi.org/10.1039/C6CS00829A

Zhu J, Zhang Z, Miao C, Liu W, Sun W (2017) Synthesis of benzimidazoles from o-phenylenediamines and DMF derivatives in the presence of PhSiH 3. Tetrahedron 73:3458–3462. https://doi.org/10.1016/j.tet.2017.05.018

Acknowledgements

We are grateful to the Shahid Bahonar University of Kerman for the financial of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mostafavi, H., Islami, M.R., Ghonchepour, E. et al. Synthesis of 1H-1,3-benzimidazoles, benzothiazoles and 3H-imidazo[4,5-c]pyridine using DMF in the presence of HMDS as a reagent under the transition-metal-free condition. Chem. Pap. 72, 2973–2978 (2018). https://doi.org/10.1007/s11696-018-0540-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-0540-5