Abstract

UV and solar radiation photocatalytic degradation of basic dye Rhodamine B (RhB) using ZnAl-layered double hydroxide photocatalyst was investigated. ZnAl-layered double hydroxide (ZA4-HT) with a molar ratio of 4:1 was synthesized from zinc and aluminum salts by co-precipitation methods, followed by heat treatment at 500 °C (CZA4). Powder X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR) and scanning electron microscopy (SEM) revealed that after heat treatment of ZA4-HT, the pristine structure collapsed resulting in ZnO particles and ZnAl2O4 spinel. The discoloration rate of RhB was lower than 8% through direct photolysis. The calcined ZA4-HT showed high photocatalytic efficiency with a discoloration rate of about 100% after 90 min exposure time to UV or sunlight radiation. The optimal catalyst loading was found to be 1 g/L and the discoloration time increased with the dye concentration. The photodiscoloration and the photodegradation kinetics data were described by pseudo-first-order and Langmuir–Hinshelwood models. The reusability study of the calcined material showed a stable efficiency after four successive uses.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is vital for life. However, it is more and more contaminated by various toxic organic and inorganic substances. The industrial discharges are heavily charged with these pollutants, which affect aquatic life as well as human life (Mekasuwandumrong et al. 2010). Synthetic dyes are considered as an important class of organic pollutants due to their extensive uses in several industries, low biodegradability, high solubility in water and high toxicity (Ameen et al. 2013). For example, Rhodamine B (RhB), a cationic xanthene dye, has been used in several areas including textile and food industries. However, many studies reported the carcinogenic activity of RhB in rats and mice (Su et al. 2015). In this work, RhB was chosen as a pollutant model.

Many chemical and physical processes have been applied to remove dyestuffs including coagulation, adsorption, precipitation and filtration. In this case, the pollutant is only transferred from the liquid phase to the solid phase. Moreover, an appropriate treatment is further necessary to purify the obtained sludge (Hachem et al. 2001).

Recently, novel methods such as advanced oxidation processes (AOPs) have attracted considerable attention in the depollution of wastewater (Phaltane et al. 2017; Lian et al. 2017). They are based on the generation of reactive oxygen species (ROS) with high oxidation power. Typical examples are hydroxyl radicals \( {}^{ \bullet }{\text{OH}} \), singlet oxygen and peroxyl radicals. The ROS are able to degrade and convert persistent organic pollutants (POP) such as dyes into water, carbon dioxide and harmless products (Mohapatra and Parida 2012). Heterogeneous photocatalysis is one typical example of AOPs for removing dyes which exhibit particular advantages including high efficiency, low cost and non-toxicity (Xia et al. 2013). In this process, ROS are generated when a semiconductor is radiated (with UV, visible light or sunlight) in aqueous solution in the presence of air or oxygen (Chen et al. 1995). Various semiconductors have been used in photocatalytic degradation of dyes including TiO2 (Carriazo et al. 2011; Kaplan et al. 2016), ZnO (Lu et al. 2009; Kian et al. 2016), SnO2 (Kansal et al. 2007) and layered double hydroxides (LDHs) (Mantilla et al. 2009; Morimoto et al. 2011).

Layered double hydroxides (LDHs), also known as anionic clays, are natural or synthetic, non-toxic, available or easily prepared materials (Carja et al. 2011). They have the general formula: \( \left[ {M_{1 - x}^{2 + } M_{x}^{3 + } \left( {\text{OH}} \right)_{2} } \right]^{x + } A_{{{\raise0.7ex\hbox{$x$} \!\mathord{\left/ {\vphantom {x n}}\right.\kern-0pt} \!\lower0.7ex\hbox{$n$}}}}^{n - } \; \bullet \;m{\text{H}}_{2} {\text{O}} \), where M 2+ and M 3+ are di- and trivalent metal cations, A n− denotes exchangeable organic or inorganic anion with negative charge n, m is the number of interlayer water molecules and x = M 3+/(M 2+ + M 3+) is the LDH layer charge density (Xia et al. 2013). However, the structure of LDHs is destroyed by heat treatment and transformed into mixed oxides with high light absorption and high surface area (Mantilla et al. 2009; Carja et al. 2011). These metal oxides can be used as photocatalysts to degrade organic pollutants.

In the present study, a ZnAl-layered double hydroxide (ZA4-HT) was synthesized by the co-precipitation method at constant pH with a molar ratio of 4:1 and subsequently calcined at 500 °C. The photocatalytic efficiency of the calcined and uncalcined materials was tested for the degradation of Rhodamine B (RhB) in aqueous solution under UV and solar radiation in batch mode. The effect of the catalyst dose and the initial dye concentration on the photodiscoloration process was investigated. The calcined material was also reused four times under UV and solar radiation.

Experimental

Photocatalyst synthesis

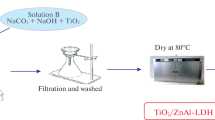

Layered double hydroxide Zn/Al with a molar ratio of 4:1 was prepared by co-precipitation method at constant pH. The metals were zinc chloride (ZnCl2; 98%, Merck) and aluminum chloride hexahydrate (AlCl3·6H2O; 99%, Aldrich). 54.512 g of ZnCl2 and 24.143 g of AlCl3·6H2O were dissolved in 200 mL of deionized water to prepare solution A. Twenty grams of sodium hydroxide was dissolved in deionized water to obtain solution B. Under vigorous stirring, solution A was added dropwise to solution B while maintaining the pH of the suspension at 7.5 using NaOH (0.1 M). The resulting slurry was aged for 72 h at 70 °C under magnetic stirring and reflux. The material was centrifuged and washed several times with deionized water until the precipitate was Cl− free (checked with AgNO3). It was then washed with acetone, dried at 100 °C for 12 h, ground and finally 0.250 mm sieved. The latter material was labeled ZA4-HT. Calcination of ZA4-HT at 500 °C for 4 h yielded a material designated CZA4.

Catalyst characterization

The ZA4-HT and CZA4 samples were characterized by X-ray diffraction (XRD). The patterns were recorded using a Phillips X’Pert MPD diffractometer with monochromatic CuKα = 1.5418 Å (40 kV, 30 mA). FT-IR spectra were obtained in transmission mode on a Nicolet Avatar 330 Fourier Transform IR spectrometer using KBr disks containing 1 wt% of samples. The spectra were recorded with 2 cm−1 resolution in the range of 4000–400 cm−1. Thermogravimetric analysis (TGA) of solid samples was conducted using a NETZSCH STA 409 PC/PG simultaneous thermal analyzer, heated from 20 to 900 °C at a heating rate of 5 °C/min under N2 flow rate of 50 mL/min. The BET specific surface areas and pore sizes of the samples were determined by N2 adsorption–desorption isotherms using a Micromeritics ASAP 2010 sorptiometer. ZA4-HT and CZA4 SEM micrographs were obtained using a Hitachi S-2600N microscope.

Photocatalytic experiments

The performance of ZA4-HT and CZA4 as photoctalysts was tested for the degradation of the dye Rhodamine B (Fig. 1) in aqueous solution using UV radiation and solar light. The experiments under solar radiation were carried out in successive sunny days (June 2016) between 9 am and 5 pm. On these days, the solar intensity ranges from 0.08 to 0.13 W/cm2 and the temperature varies from 26 to 32 °C. Magnetic stirring under direct solar light was used in the solar photoreactor. The UV photocatalytic chamber was equipped with two 15 W Hg lamps (Philips) emitting at 365 nm under magnetic stirring to ensure homogeneity of the suspension. The distance between the UV lamps and the surface of the suspension was kept at 10 cm. The inside surface of the photocatalytic chamber was covered with mirrors to reflect all radiation emitted by UV lamps.

Experiments were carried out at room temperature and under atmospheric pressure in a Pyrex glass vessel containing the photocatalysts (CZA4 or ZA4-HT) and 50 mL of a 10 mg/L (20.9 μM) RhB solution without adjusting the initial pH (pH i = 5.8). The suspension was stirred in dark for 30 min in the absence of light after adsorption took place. This time was necessary to reach adsorption–desorption equilibrium between the photocatalyst and the dye molecules. Then, the suspension was exposed to UV radiation or sunlight. At a given contact time, the light was turned off and the suspension centrifuged and analyzed with HACH DR/4000 U spectrophotometer at 555 nm.

The process efficiency R% was calculated using Eq. (1):

where C 0.Cor (mg/L) is the concentration of the dye after adsorption, and C t (mg/L) is the concentration of the dye solution at t (min) radiation time.

Reusability study

The reusability study of CZA4 for the photodegradation of RhB under UV radiation and sunlight was carried out with an initial dye concentration of 10 mg/L, at pH 5.8 and at a material/solution ratio of 1 g/L. After the first use of CZA4 where the suspension was radiated for 90 min under UV or solar radiation, the photocatalyst was separated by centrifugation, washed three times with acetone, dried at 100 °C for 4 h and then added to 10 mg/L of RhB solution under the same conditions as above. The procedure was repeated three times.

Results and discussion

Characterization

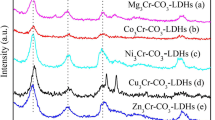

Figure 2 depicts the XRD patterns of the synthesized materials. A strong reflection (003) was noted in the ZA4-HT XRD patterns. Reflections of (006), (009), (101), (110) and (113) can be assigned typically to layered double hydroxide materials (Gardner et al. 2001). The unit cell parameters of ZA4-HT and the basal spacing d (003)were calculated and compared with other works (Table 1). The obtained results are similar to the values reported by Seftel et al. (Seftel et al. 2008). After heat treatment of ZA4-HT, the original structure of LDH collapsed and transformed into a mixture of ZnO phase and ZnAl2O4 spinel (Fig. 2) (Ali Ahmed et al. 2012; Guan et al. 2013). The ZnO phase is illustrated by the presence of strong and sharp diffraction peaks at 2θ = 31.77°, 34.43°, 36.33°, 47.63°, 56.66°, 62.88° and 67.96° corresponding to the reflections (100), (002), (101), (102), (110), (103) and (112) planes, respectively (Marottia et al. 2004). The lattice parameters of ZnO phase were calculated using standard relations (Table 1). The c/a ratio value is 1.601 (lower than 1.633). This value corresponds to a closed-packed hexagonal (wurtzite) structure of ZnO showing some strains in the crystals (Seftel et al. 2008; Ali Ahmed et al.2012). The calcination at 500 °C induced the formation of ZnAl2O4 spinel, but aluminum oxide crystals (Al2O3) were not obtained at this temperature (Guan et al. 2013). Thus, the aluminum compound is present presumably as AlO(OH) (Seftel et al. 2008; Carriazo et al. 2011).

The IR spectra of ZA4-HT and CZA4 are presented in Fig. 3. A strong broad absorbance band is visible at 3500 cm−1 for both materials. It is ascribed to the stretching mode of hydrogen-bonded hydroxyl groups of the hydroxide layer and the interlayer water, ν(OH) (Bouraada et al. 2008). The vibration bands of water deformation, δ(H2O), is observed at 1609 and 1623 cm−1 for ZA4-HT and CZA4, respectively. After LDH calcinations, the absorption bands at 1510 and 1365 cm−1, assigned to the carbonate vibration ν(CO3 2−) (El Gaini et al. 2009), are absent suggesting their decomposition. The presence of carbonate species in ZA4-HT might result from the dissolution of carbon dioxide of the air into deionized water during the preparation of the material.

Figure 4 shows scanning electron microscopy (SEM) images of the materials prepared. ZA4-HT is composed of planar particles of few hundred nanometers, while for CZA4 the particles are smaller. The ZnO phase is probably presented by the shining particles (Fig. 4b) as described elsewhere (Seftel et al. 2008; Morimoto et al. 2011).

To investigate the different transformation processes during calcination, thermoanalytical measurements of ZA4-HT were performed (Fig. 5). The weight loss in the temperature ranges from 60 to 180 °C and from 200 to 270 °C is due to elimination of water molecules from the external surfaces and the internal gallery surfaces of the LDH (Parida and Mohapatra 2012). However, at higher temperatures (from 460 to 600 °C), the second weight loss might result from carbonate decomposition and dehydroxylation (Parida and Mohapatra 2012). The endothermic weak peak observed corresponds to the conversion of the layered structure into mixed metal oxides.

Heat treatment effect on the specific surface area of the material was studied by nitrogen adsorption–desorption isotherm analysis (Fig. 6). ZA4-HT and CZA4 samples exhibit type IV isotherms according to IUPAC classification. The H3 hysteresis loops indicate the existence of mesoporous solid and some pore asymmetry. These results are similar to those found by Carriazo et al. (Carriazo et al. 2011). The values of the BET specific surface area and the pore volume for both materials are gathered in Table 1. The calcined material (CZA4) presents a specific surface area twice as large as that reported by Seftel et al. (Seftel et al. 2008).

Catalytic performance of synthesized materials

Semiconductors TiO2 and ZnO are widely used in heterogeneous photocatalytic processes due to their high photocatalytic capacity to degrade organic compounds (Laohaprapanona et al. 2015). The CZA4 material has been used as a photocatalyst in various researches using UV radiation (Carriazo et al. 2011), whereas its catalytic performance has never been tested under sunlight.

Effect of the photocatalyst dose

The photocatalyst dose is an important factor influencing the dye degradation rate. In this case, different CZA4 doses were tested (0, 0.25, 0.5, 1, 1.5 and 2 g/L) for the removal of RhB (10 mg/L) under UV radiation. The samples were analyzed after 1 h of treatment (Fig. 7). In the range from 0 to 1 g/L, the discoloration rate increased with CZA4 amount. This is ascribed to the increase of the total surface of the photocatalyst exposed to radiation which produces more ROS responsible for the degradation of RhB (Hasnat et al. 2007). A CZA4 dose larger than 1 g/L raised the turbidity of the suspension which affected negatively the light penetration. As a result, the discoloration rate remained unchanged. The optimum dose of CZA4 was 1 g/L with 99.63% of RhB photodiscoloration.

Photodiscoloration study

Different treatments were applied to degrade 50 mL of RhB with an initial concentration of 10 mg/L. Photolysis experiments on the dye by UV radiation and sunlight were carried out without catalyst, while the photocatalytic activity of ZA4-HT and CZA4 was tested under both radiation sources by adding 50 mg of the catalyst into the solution of RhB. Before radiation tests, 30 min contact time was sufficient to obtain equilibrium for adsorption–desorption in darkness. The adsorption capacities were 8.9% (0.79 mg/g) for CZA4 and 0.1% (0.01 mg/g) for ZA4-HT. Figure 8 shows the photodiscoloration results expressed by the ratio C t /C 0, where C t and C 0 are the dye concentration at time t and initial state, respectively. It is obvious that the removal of Rhodamine B was much faster and higher in the presence of CZA4, where after 90 min exposure time the photocatalytic reaction reached almost 100% under UV and solar radiation. However, the discoloration rate R% varied from 5.43 to 8.01% with direct photolysis treatments (UV or solar light) and with photodegradation by UV-ZA4-HT. These results show that RhB is a persistent pollutant and cannot be oxidized under both lights. The presence of ZnO and ZnAl2O4 spinel in CZA4 improved significantly the photodiscoloration of RhB.

The kinetic data of RhB photodiscoloration was described by the pseudo-first-order model expressed in its linear form by:

where k app (min−1) is the apparent rate constant, C 0.Cor is the dye concentration after adsorption in dark and C t is the concentration at time t. The determination coefficient values R 2 ranged from 0.764 to 0.994 (Table 2) confirming good linearity. The apparent constant and half-time t 1/2 of the photodiscoloration reaction were calculated and are presented in Table 2. The half-time is the time required to decompose half of the RhB present in the irradiated solution. The highest value of apparent constant was obtained in the presence of CZA4 under artificial UV light (0.0668 min−1). The shortest half-time value was 10.38 min, obtained under the same conditions. Moreover, to demonstrate the photocatalytic activity of CZA4, the initial photocatalytic discoloration rates of RhB were calculated using Eq. (3) and are sketched in Fig. 9 for each process:

where r 0 is the initial rate of the photocatalytic discoloration (mg/L min). Figure 9 shows the huge difference in the initial photocatalytic discoloration rate between the heterogeneous photocatalytic process with and without CZA4. CZA4 material presented high photocatalytic activity under UV radiation and solar light. Using solar radiation, the heterogeneous photodegradation process becomes cheaper and ready to be applied.

Effect of dye concentration

The initial concentration of RhB was varied to evaluate its influence on the discoloration rate. Different initial concentrations (4, 7, 10, 13 and 16 mg/L) were used with a reaction time ranging from 5 to 90 min under UV radiation and in the presence of 50 mg of CZA4. Figure 10a shows that the discoloration time increased with the dye concentration. Furthermore, the plot of ln (C 0.Cor/C t ) versus radiation time yielded straight lines with good values of the determination coefficient (R 2 > 0.985) (Fig. 10b). Photodiscoloration kinetic data fitted very well the pseudo-first-order model. The values of apparent rate constant for the different initial concentrations were calculated and are reported in Table 2.

The Langmuir–Hinshelwood kinetic model is an appropriate model commonly used to describe the photodegradation of organic pollutants in aqueous solution (Hentit et al. 2014). It relates the initial photocatalytic discoloration rate r 0 with the initial concentration of the dye after sorption in dark C 0.Cor by the following formula:

The linearization form of Eq. (4) is given in Eq. (5):

where k L–H (mg/L min) is the Langmuir–Hinshelwood rate constant and K ad (L/mg) is the adsorption constant. Figure 11 shows the good linearity between the variation of \( r_{0}^{ - 1} \) and \( C_{{0.{\text{Cor}}}}^{ - 1} \) (R 2 = 0.998). Using the slope and intercept of Eq. (5), L–H model constants were calculated and found as: k L-H = 0.8387 mg/L min and K ad = 0.3112 L/mg.

Photodegradation study of RhB

The degradation of RhB on CZA4 at different times was followed spectrophotometrically under UV radiation and sunlight (Fig. 12a and b, respectively). The intensity of absorption bands of RhB, located at 260, 355 and 555 nm, decreased gradually with radiation time. It attained nearly zero after 90 min of radiation time with both light sources. The removal of the dye by UV radiation is slightly faster than that by solar light radiation. The photodegradation mechanism of RhB until the mineralization state has been proposed by several studies (Rasalingam et al. 2015). In our case, the possible steps of the dye degradation under UV radiations can be expressed as follows.

Firstly, when the CZA4 is irradiated, photoelectron and photohole pairs are generated as in Eq. (6):

Secondly, these electron–hole pairs (e−/h+) can react immediately with dye molecules as in Eq. (7), or with adsorbed water and dissolved oxygen as in Eqs. (8–14). The radical species produced, such as •OH, •O2 −, •HO2 and H2O2, are responsible for the degradation of RhB into less harmful organics and minerals.

The proposed mechanism of the oxidation of Rhodamine B by CZA4 catalyst under natural sunlight is presented in Fig. 13. The adsorbed RhB can be photoexcited (RhB*) by visible light. An electron is injected into the conduction band (CB) of the catalyst causing RhB *Desb desorption (Subash et al. 2013; Akir et al. 2016). The latter can react with the adsorbed oxygen to produce superoxide radicals \( {\text{O}}_{2}^{ - \bullet } \), which oxidize the dye molecules in the solution and/or the \( {\text{O}}_{2}^{ - \bullet } \) radicals can be protonated to form hydroperoxyl radicals OOH˙. Meanwhile, the coloration of the RhB solution decreases allowing for a deeper sunlight penetration. The photocatalyst CZA4 absorbs photon energy equal to or greater than its band gap energy producing more electron–hole pairs. The electron–hole pairs react with various adsorbed species including O2 and H2O to form oxidative radicals (•OH, •O2 −,•HO2 and H2O2). Subsequently, the RhB or RhBDesb*molecules decompose via radical attack until mineralization (Li et al. 2011).

Reusability study of CZA4

The CZA4 was reused four times under UV and solar radiation (Fig. 14). The photocatalyst exhibited good efficiency under both radiation sources. As compared to the first use, the discoloration rate of RhB remained stable at about 80% after 90 min of exposure time.

Conclusions

A layered double hydroxide (ZA4-HT) and its calcined product (CZA4) were synthesized and characterized. Then, they were used as photocatalysts in the degradation of a xanthene dye type Rhodamine B (RhB) under UV and solar radiation. The optimum photocatalyst loading was 1 g/L. The photodiscoloration of RhB was studied with and without the photocatalyst. After 90 min of radiation time, the discoloration rates attained were 5.43, 5.62 and 8.01% for the processes UV-ZA4-HT, direct photolysis using UV radiation and sunlight, respectively. However, in the presence of CZA4, the RhB solution was completely discolored after 90 min radiation time under both light sources (UV or sunlight). Discoloration time increased with dye concentration. Photodiscoloration and photodegradation kinetics data were well described by pseudo-first-order and Langmuir–Hinshelwood models. The reusability study of CZA4 showed that its efficiency was stable after four uses. This study shows that anionic clays can be used successfully in the treatment of persistent organic pollutant-laden water.

References

Akir S, Barras A, Coffinier Y, Bououdina M, Boukherroub R, Omrani AD (2016) Eco-friendly synthesis of ZnO nanoparticles with different morphologies and their visible light photocatalytic performance for the degradation of Rhodamine B. Ceram Int 42:10259–10265. https://doi.org/10.1016/j.ceramint.2016.03.153

Ali Ahmed AA, Talib ZA, Bin Hussein MZ, Zakaria A (2012) Improvement of the crystallinity and photocatalytic property of zinc oxide as calcination product of Zn–Al layered double hydroxide. J Alloys Compd 539:154–160. https://doi.org/10.1016/j.jallcom.2012.05.093

Ameen S, Akhtar MS, Nazim M, Shin HS (2013) Rapid photocatalytic degradation of crystal violet dye over ZnO flower nanomaterials. Mater Lett 96:228–232. https://doi.org/10.1016/j.matlet.2013.01.034

Bouraada M, Lafjah M, Ouali MS, Menorval LC (2008) Basic dye removal from aqueous solutions by dodecylsulfate- and dodecyl benzene sulfonate intercalated hydrotalcite. J Hazard Mater 153:911–918. https://doi.org/10.1016/j.jhazmat.2007.09.076

Carja G, Husanu E, Gherasim C, Iovu H (2011) Layered double hydroxides reconstructed in NiSO4 aqueous solution as highly efficient photocatalysts for degrading two industrial dyes. Appl Catal B Environ 107:253–259. https://doi.org/10.1016/j.apcatb.2011.07.020

Carriazo D, del Arco M, Garcia-Lopez E, Marci G, Martin C, Palmisano L, Rives V (2011) ZnAl hydrotalcites calcined at different temperatures: preparation, characterization and photocatalytic activity in gas–solid regime. J Mol Catal A Chem 342–343:83–90. https://doi.org/10.1016/j.molcata.2011.04.015

Chen HY, Zahraa O, Bouchy M, Thomas F, Bottero JY (1995) Adsorption properties of TiO2 related to the photocatalytic degradation of organic contaminants of water. J Photochem Photobiol A Chem 85:179–186. https://doi.org/10.1016/1010-6030(94)03900-F

El Gaini L, Lakraimi M, Sebbar E, Meghea A, Bakasse M (2009) Removal of indigo carmine dye from water to Mg–Al–CO3-calcined layered double hydroxides. J Hazard Mater 161:627–632. https://doi.org/10.1016/j.jhazmat.2008.04.089

Gardner EA, Huntoon KM, Pinnavaia TJ (2001) Direct synthesis of alkoxide-intercalated derivatives of hydrocalcite-like layered double hydroxides: precursors for the formation of colloidal layered double hydroxide suspensions and transparent thin films. Adv Mater 13:1263–1266. https://doi.org/10.1002/1521-4095(200108)13:16<1263:AID-ADMA1263>3.0.CO;2-R

Guan MY, Xu DM, Song YF, Guo Y (2013) ZnO/ZnAl2O4 prepared by calcination of ZnAl layered double hydroxides for Ethanol sensing. Sens Actuator B Chem 188:1148–1154. https://doi.org/10.1016/j.snb.2013.08.016

Hachem C, Bocquillon F, Zahraa O, Bouchy M (2001) Decolourization of textile industry wastewater by the photocatalytic degradation process. Dyes Pigm 49:117–125. https://doi.org/10.1016/S0143-7208(01)00014-6

Hasnat MA, Uddin MM, Samed AJF, Alam SS, Hossain S (2007) Adsorption and photocatalytic decolorization of a synthetic dye erythrosine on anatase TiO2 and ZnO surfaces. J Hazard Mater 147:471–477. https://doi.org/10.1016/j.jhazmat.2007.01.040

Hentit H, Ghezzar MR, Womes M, Jumas JC, Addou A, Ouali MS (2014) Plasma-catalytic degradation of anthraquinonic acid green 25 in solution by gliding arc discharge plasma in the presence of tin containing aluminophosphate molecular sieves. J Mol Catal A Chem 390:37–44. https://doi.org/10.1016/j.molcata.2014.03.003

Kansal SK, Singh M, Sud D (2007) Studies on photodegradation of two commercial dyes in aqueous phase using different photocatalysts. J Hazard Mater 141:581–590. https://doi.org/10.1016/j.jhazmat.2006.07.035

Kaplan R, Erjavec B, Drazic G, Grdadolink J, Pintar A (2016) Simple synthesis of anatase/rutile/brookite TiO2 nanocomposite degradation of water pollutants. Appl Catal B Environ 181:465–474. https://doi.org/10.1016/j.apcatb.2015.08.027

Kian ML, Chin WL, Koh SN, Joon CJ (2016) Recent developments of zinc oxide photocatalyst in water treatment technology: a review. Water Res 88:428–448. https://doi.org/10.1016/j.watres.2015.09.045

Laohaprapanona S, Matahumb J, Tayob L, You SJ (2015) Photodegradation of reactive black 5 in a ZnO/UV slurry membrane reactor. J Taiwan Inst Chem Eng 49:136–141. https://doi.org/10.1016/j.jtice.2014.11.017

Li WJ, Li DZ, Meng SG, Chen W, Fu XZ, Shao Y (2011) Novel approach to enhance photosensitized degradation of rhodamine B under visible light irradiation by the ZnxCd1-xS/TiO2 nanocomposites. Environ Sci Technol 45:2987–2993. https://doi.org/10.1021/es103041f

Lian J-Z, Tsai C-T, Chang S-H, Lin N-H, Hsieh Y-H (2017) Iron waste as an effective depend on TiO2 for photocatalytic degradation of dye waste water. Opt Intern J Light Electron Opt 140:197–204. https://doi.org/10.1016/j.ijleo.2017.04.023

Lu C, Wu Y, Mai F, Chung W, Wu C, Lin W, Chen C (2009) Degradation efficiencies and mechanisms of the ZnO-mediated photocatalytic degradation of basic blue 11 under visible light irradiation. J Mol Catal A Chem 310:159–165. https://doi.org/10.1016/j.molcata.2009.06.011

Mantilla A, Tzompantzi F, Fernandez JL, Dıaz Gongora JAI, Mendoza G, Gomez R (2009) Photodegradation of 2,4-dichlorophenoxyacetic acid using ZnAlFe layered double hydroxides as photocatalysts. Catal Today 148:119–123. https://doi.org/10.1016/j.cattod.2009.02.036

Marottia RE, Guerra DN, Bello C, Machado G, Dalchiele EA (2004) Bandgap energy tuning of electrochemically grown ZnO thin films by thickness and electrode position potential. Solar Energy Mater Solar Cells 82:85–103. https://doi.org/10.1016/j.solmat.2004.01.008

Mekasuwandumrong O, Pawinrat P, Praserthdam P, Panpranot J (2010) Effects of synthesis conditions and annealing post-treatment on the photocatalytic activities of ZnO nanoparticles in the degradation of methylene blue dye. Chem Eng J 164:77–84. https://doi.org/10.1016/j.cej.2010.08.027

Mohapatra L, Parida KM (2012) Zn–Cr layered double hydroxide: visible light responsive photocatalyst for photocatalytic degradation of organic pollutants. Sep Purif Technol 91:73–80. https://doi.org/10.1016/j.seppur.2011.10.028

Morimoto K, Tamura K, Iyi N, Ye J, Yamada H (2011) Adsorption and photodegradation properties of anionic dyes by layered double hydroxides. J Phys and Chem of Solids 72:1037–1045. https://doi.org/10.1016/j.jpcs.2011.05.018

Parida KM, Mohapatra L (2012) Carbonate intercalated Zn/Fe layered double hydroxide: a novel photocatalyst for the enhanced photo degradation of azo dyes. Chem Eng J 179:131–139. https://doi.org/10.1016/j.cej.2011.10.070

Phaltane SA, Vanalakar SA, Bhat TS, Patil PS, Sartale SD (2017) Photocatalytic degradation of methylene blue by hydrothermally synthesized CZTS nanoparticles. J Mater Sci 28:8186–8191. https://doi.org/10.1007/s10854-017-6527-0

Rasalingam S, Peng R, Koodali RT (2015) An insight into the adsorption and photocatalytic degradation of rhodamine B in periodic mesoporous materials. Appl Catal B: Environ 174–175:49–59. https://doi.org/10.1016/j.apcatb.2015.02.040

Seftel EM, Popovici E, Mertens M, De Witte K, Van Tendeloo G, Cool P, Vansant EF (2008) Zn–Al layered double hydroxides: synthesis, characterization and photocatalytic application. Microporous Mesoporous Mater 113:296–304. https://doi.org/10.1016/j.micromeso.2007.11.029

Su X, Li X, Li J, Liu M, Lei F, Tan X, Li P, Luo W (2015) Synthesis and characterization of core–shell magnetic molecularly imprinted polymers for solid-phase extraction and determination of Rhodamine B in food. Food Chem 171:292–297. https://doi.org/10.1016/j.foodchem.2014.09.024

Subash B, Krishnakumar B, Swaminathan M, Shanthi M (2013) Highly efficient, solar active, and reusable photocatalyst: Zr-loaded Ag-ZnO for Reactive Red 120 dye degradation with synergistic effect and dye-sensitized mechanism. Langmuir 29:939–949. https://doi.org/10.1021/la303842c

Xia SJ, Liu FX, Ni ZM, Xue JL, Qian PP (2013) Layered double hydroxides as efficient photocatalysts for visible-light degradation of Rhodamine B. J Colloid Interface Sci 405:195–200. https://doi.org/10.1016/j.jcis.2013.05.064

Acknowledgements

The authors acknowledge help from the technical staff of Laboratory AIME-UMR, University Montpellier 2 (France) in XRD, SEM, BET, TG/DTA and FT-IR spectral measurements. This work was financially supported by the National Research Program (PNR). We would like to thank all the co-workers cited in the references below for their valuable contributions to the work described here.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bessaha, H., Harrats, C., Bouraada, M. et al. Photocatalytic efficiency of ZnAl-layered double hydroxide on degradation of a cationic dye under UV and solar radiation. Chem. Pap. 72, 1031–1040 (2018). https://doi.org/10.1007/s11696-017-0347-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-017-0347-9