Abstract

The thermodynamic modeling of the ternary system C-Cr-Zr has been obtained by modeling the Gibbs energy of all individual phases using the CALPHAD (CALculation of PHAse Diagrams) approach. There is no ternary compound in this system. The liquid is modeled as a substitutional solution phase, while the solid solution phases including ZrC, (αZr), (βCr), (βZr), Cr3C2, Cr7C3, Cr23C6, C14, C15 and C36 are described by sublattice models. The modeling covers the whole composition and temperature ranges. A set of self-consistent thermodynamic parameters for the C-Cr-Zr system is obtained by considering the phase diagram data in the ternary system. Comprehensive comparisons between the calculated and measured phase diagram and thermodynamic data show that the experimental information is satisfactorily accounted for by the present thermodynamic description. The liquidus projection and reaction scheme of the C-Cr-Zr system are also presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

By introducing refractory metal elements such as Cr and Zr into carbon steel, dispersed carbides can be formed during the aging process, so as to obtain excellent mechanical properties and heat-resistance.[1,2] In addition, Cr- and Zr-based carbides are also identified as the effective reinforcing particles to fabricate the outstanding cutting tools. It has been proven that ZrC can significantly improve the hardness and high-temperature properties of WC-based cemented carbides.[3] The introduce of Cr3C2 to the TiC-based cermets can not only facilitate the formation of finer microstructure and better mechanical performance, but also improve their ability of oxidation resistance, rust resistance and corrosion resistance.[4] Thus, it is of technological interest to study the formation of the carbides in the C-Cr-Zr system.

The CALPHAD (CALculation of PHAse Diagrams) approach is a useful tool to establish thermodynamic databases, which are the bases for the prediction of thermodynamic properties, phase diagrams, diffusion[5] and phase-field simulations.[6] In order to develop the thermodynamic databases of multicomponent cemented carbides,[7] knowledge concerning phase equilibria and thermodynamic properties of the C-Cr-Zr ternary system is of fundamental importance. The present work is thus intended to (I) critically evaluate the experimental phase diagram information and thermodynamic data in the C-Cr-Zr ternary system and its constituent binary systems from the literature, and (II) develop self-consistent thermodynamic description for the C-Cr-Zr system by means of the CALPHAD approach.

2 Evaluation of Phase Diagram Data in the Literature

In the present assessment, the published phase diagram, and thermodynamic data of C-Cr-Zr system are critically reviewed. To facilitate reading, the symbols to denote the stable phases in the C-Cr-Zr system are summarized in Table 1.

2.1 Binary Systems

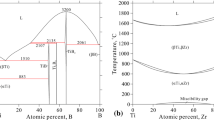

The thermodynamic descriptions of the C-Cr binary system were firstly performed by Andersson[8] and Kajihara and Hillert.[9] However, the thermodynamic parameters obtained by these two groups of authors, could not meet the demand for a reasonable extrapolation to the Fe-Cr-V-C system. Consequently, Lee[10] reassessed the C-Cr system by considering both the C-Cr-Ni and Fe-Cr-V-C systems. Most recently, Khvan et al.[11] found that the calculated temperature of the eutectic reactions in the C-Cr system by using the parameters from Lee’s work[10] is even lower than the reported temperature of the corresponding ternary eutectic reaction.[12] For this reason, they reassessed the parameters of the liquid phase in C-Cr system on the basis of absorbing other solid phase parameters from Lee.[10] As discussed above, the modeling reported by Khvan et al.[11] is adopted in the present work.

The thermodynamic description from Guillermet[13] is generally admitted as the major contribution on the C-Zr binary system, which proposed a reliable assessment of the system based on a wide compilation of experimental data from previous works.[14,15,16,17] In the present optimization, the description of the C-Zr system derives from Guillermet’s work,[13] which has been widely used in the thermodynamic database of cemented carbides.

Many researchers have performed thermodynamic modeling of the Cr-Zr system.[18,19,20] Recently, Pavlů et al.[21] carried out the first-principles calculations on the total energies of Laves phases in all three structures, i.e. C14, C15 and C36. Then they derived a thermodynamic description of the Cr-Zr system based on the calculation results. In addition, Lu et al.[22] performed the experimental study at different temperatures to determine the phase boundaries and supplemented the literature with new experimental and calculated data to re-evaluate the Cr-Zr system. On the basis of the work form Lu et al.[22] Liu et al.[23] conducted a modified description of the C15 phase and adjusted the invariant reaction from C36 = C15 + L (1547 °C) to L + C36 = C15 (1562 °C), in order to better fit the phase relationships in the Cu-Cr-Zr ternary system. The parameters of Cr-Zr system are adopted from the works of Lu et al.,[22] and Liu et al.[23]

2.2 Ternary Systems

The first investigation on the phase equilibria of the C-Cr-Zr system was reported by Fedorov and Kuz’ma[24] at 1300 °C. The isothermal section is characterized by the ZrC phase with a NaCl-type crystalline structure, which forms six three-phase regions: ZrC + (C) + Cr3C2, ZrC + Cr3C2 + Cr7C3, ZrC + Cr7C3 + Cr23C6, ZrC + Cr23C6 + (βCr), ZrC + (βCr) + C15 and ZrC + C15 + (βZr). The solubility of Cr in the ZrC reaches up to 6 at.%, while Cr-based carbides dissolve negligible amounts of Zr. It should be noted that the phase boundaries of the three-phase regions were determined by the methods of x-ray diffraction and microstructural analyses and the detailed alloy compositions were not reported in their work. Obviously, their work cannot accurately determine the solubility of Cr in the ZrC phase with different carbon contents. Since the relevant data is very limited, these phase equilibria are also given the certain weight in the present modeling.

The invariant equilibria of the C-Cr-Zr system were investigated by Eremenko et al.[25,26] using chemical analysis (CA), x-ray diffraction (XRD), scanning electron microscopy (SEM), differential thermal analysis (DTA) and Pirani-Alterthum method. The investigated specimens were prepared by arc-melting, followed by homogenization treatment. The primary crystallization phases, namely those of ZrC, Cr3C2, Cr7C3, Cr23C6, (βCr), (βZr), C14 and (C) are detected in the as-cast alloys. Eremenko et al.[26] given the invariant equilibria of L + (C) = ZrC + Cr3C2 at 1805 °C, L = ZrC + Cr3C2 + Cr7C3 at 1730 °C, L + Cr7C3 = ZrC + Cr23C6 at 1605 °C, L = ZrC + Cr23C6 + (βCr) at 1575 °C, L = ZrC + (βCr) + C14 at 1595 °C, and L = ZrC + C14 + (βZr) at 1320 °C. They also reported three ternary eutectic maxima reactions, i.e., L = ZrC + Cr7C3 at 1750 ± 10 °C, L = ZrC + (βCr) at 1740 ± 10 °C and L = ZrC + C14 at 1630 ± 10 °C.

Based on the obtained thermodynamic data, Eremenko et al.[26] also constructed two vertical sections of Cr75Zr25-Cr75C25 and Zr-Cr52C48. Using DTA method, Shurin and Dmitrieva[27] determined the Cr-ZrC vertical section with a eutectic temperature of 1785 ± 20 °C and composition of 4.2 at.% ZrC, which is consistent with the result from Eremenko et al.[26] According to Shurin and Dmitrieva,[27] the solubility of ZrC in (Cr) at 1785 °C is measured to be 1.3 at.%. The data mentioned above are all considered in the present optimization.

3 Thermodynamic Models

In the present modeling, the Gibbs energy functions for the elements C, Cr and Zr are taken from the SGTE compilation by Dinsdale.[28] The thermodynamic parameters in the C-Cr, C-Zr and Cr-Zr binary sub-systems are taken from Khvan et al.,[11] Guillermet,[13] and Liu et al.[23] Different thermodynamic models are applied depending on the crystal structure and thermodynamic property of each phase.

3.1 Liquid

The liquid phase is described as substitutional solution, and the Gibbs energy is expressed by the Redlich-Kister-Muggianu polynomial[29,30]:

where R is the gas constant, and xC, xCr and xZr are molar fractions of the elements C, Cr and Zr, respectively. The standard element reference (SER) state,[28] i.e. the stable structure of the element at 25 °C and 1 bar, is used as the reference state of Gibbs energy. The parameters \(L_{i,j}^{L} \, (i,j = C,Cr,Zr)\) are the interaction parameters from the binary constituent systems. The ternary excess Gibbs energy \({}^{ex}G_{C,Cr,Zr}^{L}\) is expressed as follows:

in which the interaction parameters \({}^{0}L_{C,Cr,Zr}^{L}\), \({}^{1}L_{C,Cr,Zr}^{L}\) and \({}^{2}L_{C,Cr,Zr}^{L}\) are linearly temperature-dependent. These parameters will be evaluated in the present work.

3.2 Solid Solution Phases

The Gibbs energies of the ZrC, (βCr), (βZr) and (αZr) phases are described using two-sublattice models developed by Hillert and Staffansson[31] as (Cr, Zr)a(C, Va)c. In this model, it is assumed that Cr and Zr atoms occupy one sublattice while C atoms and vacancies occupy the other one, since C atoms are generally known to occupy only interstitial sites in these phases. The symbols a and c denote the numbers of sites on each sublattice and have values of a = 1 and c = 1 for the ZrC phase with fcc structure; a = 1 and c = 3 for the (βCr)) and (βZr) phases with bcc structure; a = 1 and c = 0.5 for the (αZr) phase with hcp structure. For one formula unit (Cr, Zr)a(C, Va)c, the Gibbs energy of a phase is expressed as follows:

where \(y_{C}^{{\prime }}\) and \(y_{Zr}^{{\prime }}\) are the site fractions of Cr and Zr in the first sublattice, and \(y_{C}^{\prime \prime }\) and \(y_{Va}^{\prime \prime }\) are the site fractions of C and Va in the second sublattice. The parameter \({}^{0}G_{i:Va}^{\varphi } \, (i = Cr\;{\text{or}}\;Zr)\) is the Gibbs energy of pure element i, and the parameter \({}^{0}G_{i:C}^{\varphi } \, (i = Cr\;{\text{or}}\;Zr)\) is the Gibbs energy of a hypothetical state where all the interstitial sites are completely filled with C. \(L_{Cr,Zr:Va}^{\varphi }\), \(L_{Cr:C,Va}^{\varphi }\) and \(L_{Zr:C,Va}^{\varphi }\) are the binary parameters from the sub-binary systems, while the \(L_{Cr,Zr:C}^{\varphi }\) and \(L_{Cr,Zr:C,Va}^{\varphi }\) are the ternary parameters that will be optimized in the present assessment.

Considering the limited experimental data on the solubility of the third element, the binary phases Cr3C2, Cr7C3, Cr23C6, C14, C15 and C36 are considered as pure binary stoichiometric phases. It is presumed that the sublattice of graphite is totally filled by C due to the negligible solubility of Cr and Zr in graphite. The Gibbs energy of graphite is taken from the SGTE database.[28]

4 Results and Discussion

The evaluation of the model parameters was carried out using the optimization program PARROT,[32] which works by minimizing the sum of the square of the differences between measured and calculated values. The step-by-step optimization procedure described by Du et al.[33] was utilized in the present assessment. Each piece of selected information was given a certain weight based on the uncertainties of the experimental data. The weights were changed by trial and error during the assessment until most of the selected experimental information was reproduced within the expected uncertainty limits.

Based on the experimental sections of 1300 °C,[24] the modeling of the C-Cr-Zr system proceeds with the solid phase. Therefore, the thermodynamic parameters of ZrC phase are firstly evaluated. For the fcc-ZrC phase with large homogeneity ranges varying from 37.3 to 50.0 at.% C, two ternary parameters \({}^{0}L_{Cr,Zr:C}^{Fcc}\) and \({}^{2}L_{Cr,Zr:C}^{Fcc}\) are introduced to model the ZrC with higher C contents, while one ternary parameters \({}^{1}L_{Cr,Zr:C,Va}^{Fcc}\) are adopted to model the ZrC with lower C contents. During the optimization, it is found that the parameter \({}^{0}G_{Cr,Zr:C}^{Fcc}\) is used to limit the solid solubility of Cr in the ZrC phase. When the parameter \({}^{0}G_{Cr,Zr:C}^{Fcc}\) reaches up to +161,903.988, the solubility solid solubility of Cr in the ZrC phase is reduced to 7.35 at.%. The parameter \({}^{2}G_{Cr,Zr:C}^{Fcc}\) is used to increase the stability of the ZrC phase. Only by setting the parameter to − 323,421.99 or below, the assessment can fit well with the experimental data and avoid the formation of fcc#1 + fcc#2 for the ZrC phase in the high C region. No ternary parameters of (αZr) with hcp structure and (βCr) and (βZr) with bcc structure are introduced in the present assessment. Subsequently, \({}^{0}L_{C,Cr,Zr}^{Liquid}\) and \({}^{2}L_{C,Cr,Zr}^{Liquid}\) for liquid are assessed by using the experimental data including liquidus, primary crystallization fields and invariant equilibria.[25,26] The parameter \({}^{0}L_{C,Cr,Zr}^{Liquid}\) is mainly to assess the temperatures of the invariant reactions related to the C-Cr binary system and the parameter \({}^{2}L_{C,Cr,Zr}^{Liquid}\) is mainly to assess the temperatures of the invariant reactions related to the Cr-Zr binary system. Finally, the thermodynamic parameters obtained above are optimized at the same time by considering all selected phase diagram information.

Table 2 presents the thermodynamic parameters of the C-Cr-Zr system obtained from the present modeling. Based on these thermodynamic parameters, all phase equilibrium data are calculated to demonstrate the reasonability of the present assessment including isothermal sections, vertical sections and liquidus projection (Fig. 1).

The calculated sections of the C-Cr-Zr system at 1300 °C in comparison with the experimental results from Fedorov and Kuz’ma[24] are shown in Fig. 2. It can be seen that the calculated phase relationships fit well with the experimental ones. The ZrC phase forms six three-phase regions with the (C), Cr3C2, Cr7C3, Cr23C6, (βCr), C15 and (βZr) phases. The maximum solid solubility of Cr in ZrC is calculated to be 7.35 at.%, which occurs at 47.2 at.% C. In the present modeling, the solubilities of Zr in the Cr3C2, Cr7C3 and Cr23C6 phases and C in the C15 phase is set to be zero, which is very close to the experimental results.

Calculated isothermal section of the C-Cr-Zr system at 1300 °C compared with the experimental data reported by Fedorov and Kuz’ma[24]

To better illuminate the phase relationship of the C-Cr-Zr system, Fig. 3a–f shows the calculated sections at 500, 1500, 1600, 1700, 2000 and 3000 °C. It can be seen that the solubility of Cr in the ZrC phase does not change significantly with the increasing temperature. The liquid phase firstly forms in the Zr-rich corner and gradually extends to the whole Cr-Zr sub-binary side, as the temperature increases to 2000 °C. In this temperature ranges, the Laves phase undergoes the following transformations: C15 → C36 → C14. When the temperature reaches up to 3000 °C, liquid has dominated the ternary system and the ZrC phase shrinks adjacent to the C-Zr side.

The calculated vertical sections Cr75Zr25-Cr75C25, Zr-Cr52C48 and Cr-Cr60Zr20C20 of the C-Cr-Zr system together with the experimental data from Eremenko et al.[26] and Shurin and Dmitrieva[27] are shown in Fig. 4a–c. Most experimental data are in good agreement with the present calculation results. The calculated liquidus projection of the C-Cr-Zr ternary system is given in Fig. 5, while Fig. 6 presents the reaction scheme in the range of melting/solidification for this system. Table 3 presents the comparison between the calculated and experimental invariant equilibria.[26] The invariant reaction types, temperatures and compositions reported in the literature are well reproduced by the present calculations. Compared with the experimental results reported by Eremenko et al.,[26] the present modeling predicts three primary crystallization regions including one C15 and two C36, and three invariant reactions of U2: L + C14 = ZrC + C36, P1: L + ZrC + C14 = C36 and U4: L + C36 = ZrC + C15.

For the other C-Cr-X (X = Refractory metal elements) systems, the reciprocal parameter of \(G_{Cr,X:C,Va}^{Fcc}\) is not adopted to describe the fcc phase in the C-Cr-Ti[34] system, and the reciprocal parameters of \(G_{Cr,X:C,Va}^{Fcc}\) are introduced to model the fcc phase in the C-Cr-Ta[35] and C-Cr-Nb[36] systems. Therefore, it is meaningful to discuss the role of the reciprocal parameter \(G_{Cr,X:C,Va}^{Fcc}\) in the C-Cr-Zr system. Based on the obtained parameters in the present work, the reciprocal parameter \({}^{1}G_{Cr,Zr:C,Va}^{Fcc}\) for fcc is set to be 0, and the other parameters \({}^{0}G_{Cr,Zr:C}^{Fcc}\) and \({}^{2}G_{Cr,Zr:C}^{Fcc}\) are remodeled and changed from + 161,903.988 and − 323,421.995 to + 50,558.5 and − 429,563.4, respectively. Using the remodeled parameters, the isothermal section of 1300 °C and the Cr-ZrC vertical section are represented in Fig. 7a and b. It can be found the phase relationship is consistent with the previous results, however the phase equilibria information related to ZrC phase cannot be described very well. So it is meaningful to introduce the reciprocal parameter of \(G_{Cr,X:C,Va}^{Fcc}\) to model the fcc phase in the C-Cr-Zr system.

5 Conclusions

On the basis of sufficient experimental information, the C-Cr-Zr ternary system is modeled using the CALPHAD method, and a set of reasonable parameters for each phase in this system are obtained, which can well reproduce the phase equilibrium relationships of the ternary system over the whole composition and temperature ranges including vertical sections, isothermal sections and invariant reactions. The liquidus projection and reaction scheme of C-Cr-Zr system are also calculated according to the present optimization, which is very important for practical applications and basic material research.

References

J.R. Li, P.F. Zhang, T. He, L.J. Cheng, L.W. Wang, and H. Li, Effect of carbides on high-temperature aging embrittlement in 12%Cr martensitic heat-resistant steel, J. Mater. Res. Technol., 2019, 8, p 5833-5846

T.K. Bandyopadhyay and K. Das, Processing and characterization of ZrC-reinforced steel-based composites, J. Mater. Process. Tech., 2006, 178, p 335-341

C.C. Lv, X.Y. Ren, C.B. Wang, and Z.J. Peng, Spark plasma sintering of ultrafine WC-10Ni-ZrC hardmetals: effects of adding ZrC nano-powder, Int. J. Appl. Ceram. Technol., 2020, 17, p 932-940

T. Lin, Y. Guo, Z. Wang, H.P. Shao, H.Y. Lu, F.H. Li, and X.B. He, Effects of chromium and carbon content on microstructure and properties of TiC-steel composites, Int. J. Refract. Met. Hard Mater., 2018, 72, p 228-235

J.O. Andersson, T. Helander, L. Hoglund, P. Shi, and B. Sundman, Thermo-Calc and DICTRA, computational tools for materials science, Calphad, 2002, 26(2), p 273-312

L. Zhang, I. Steinbach, and Y. Du, Phase-field simulation of diffusion couples in the Ni-Al system, Int. J. Mater. Res., 2011, 102(4), p 371-380

Y.B. Peng, Y. Du, P. Zhou, W.B. Zhang, W.M. Chen, L. Chen, S.Q. Wang, G.H. Wen, and W. Xie, CSUTDCC1—a thermodynamic database for multicomponent cemented carbides, Int. J. Refract. Metals Hard Mater., 2014, 42, p 57-70

J.O. Andersson, Thermodynamic properties of Cr-C, Calphad, 1987, 11, p 271-276

M. Kajihara and M. Hillert, Thermodynamic evaluation of the Cr-Ni-C system, Metall Trans. A, 1990, 21A, p 2777-2787

B.-J. Lee, Thermodynamic assessment of the Fe-Nb-Ti-C-N system, Metall. Mater. Trans. A, 2001, 32A, p 2423-2439

A.V. Khvan, B. Hallstedt, and K. Chang, Thermodynamic assessment of Cr-Nb-C and Mn-Nb-C systems, Calphad, 2012, 39, p 54-61

V.N. Eremenko, T.Y. Velikanova, and A.A. Bondar, Phase diagram of the Cr-Mo-C system. I. Phase equilibria in the area of crystallization of alloys of the Mo-Mo2C-Cr7C3-C partial system, Poroshk. Metall., 1987, 293, p 70-76

A.F. Guillermet, Analysis of thermochemical properties and phase stability in the zirconium-carbon system, J. Alloys Compd., 1995, 217(1), p 69-89

R.V. Sara, The system zirconium-carbon, J. Am. Ceram. Soc., 1965, 48(5), p 243-247

L.M. Adelsberg, L.H. Cadoff, and J.M. Tobin, Group IVB and VB metal carbide-carbon eutectic temperatures, Trans. Metall. Soc. AIME, 1966, 236, p 972-977

E. Rudy, Ternary Phase Equilibria in Transition Metal-Boron-Carbon-Silicon Systems. Part 5. Comprendium of Phase Diagram Data, Air Force Materials Laboratory, WrightPatterson AFB, 1969, p 165–167

E.K. Storms and J. Griffin, Vaporization behavior of the defect carbides. IV. The zirconium-carbon system, High Temp. Sci., 1973, 5, p 291-310

L. Kaufman and H. Nesor, Treatise on Solid State Chemistry, Plenum Press, 1975

T. Chart and F. Putland, Thermodynamically calculated phase-diagram for the Co-Cr-Zr system, Calphad, 1979, 3, p 9-18

K. Zeng, C. Haemaelaeinen, and R. Luoma, A thermodynamic assessment of the Cr-Zr system, Z. Met., 1993, 84, p 23-28

J. Pavlů, J. Vřeštál, and M. Šob, Stability of laves phases in the Cr-Zr system, Calphad, 2009, 33, p 382-387

H.-J. Lu, W.-B. Wang, N. Zou, J.-Y. Shen, X.-G. Lu, and Y.-L. He, Thermodynamic modeling of Cr-Nb and Zr-Cr with extension to the ternary Zr-Nb-Cr system, Calphad, 2015, 50, p 134-143

Y.L. Liu, P. Zhou, S.H. Liu, and Y. Du, Experimental investigation and thermodynamic description of the Cu-Cr-Zr system, Calphad, 2017, 59, p 1-11

T.F. Fedorov and Y.B. Kuzma, Phase equilibria in the zirconium-chromium-carbon system, Poroshk. Metall., 1965, 3, p 75-79

V.N. Eremenko, T.Y. Velikanova, S.V. Sleptsov, and A.A. Bondar, Melting diagram of the Cr-Zr-C system, Dokl. Akad. Nauk Ukrain. SSR, 1990, A(1), p 70-72

V.N. Eremenko, T.Ya. Velikanova, S.V. Sleptsov, and A.A. Bondar, Phase equilibria at subsolidus temperatures and solidification behaviour of Cr-Zr-C alloys, Metally, 1992, 5, p 144-150

A.K. Shurin and G.P. Dmitrieva, Phase diagrams of the Cr-HfC and Cr-ZrC system, Akad. Nauk Ukr. SSR Metallofizika, 1974, 51, p 105-109

A.T. Dinsdale, SGTE data for pure elements, Calphad, 1991, 15(4), p 317-425

O. Redlich and A.T. Kister, Thermodynamics of nonelectrolytic solutions. Algebraic representation of thermodynamic properties and the classification of solutions, Ind. Eng. Chem., 1948, 40, p 84-88

Y.M. Muggianu, M. Gambino, and J.P. Bros, Enthalpies of formation of liquid alloys bismuth-gallium-tin at 723° K. Choice of an analytical representation of integral and partial excess functions of mixing, J. Chim. Phys. Phys. Chim. Biol., 1975, 72(1), p 83-88

M. Hillert and M. Jarl, A model for alloying effects in ferromagnetic metals, Calphad, 1978, 2, p 227-238

B. Sundman, B. Jansson, and J.O. Andersson, The thermo-calc databank system, Calphad, 1985, 9, p 153-190

Y. Du, R. Schmid-Fetzer, and H. Ohtani, Thermodynamic assessment of the V-N system, Z. Metallkd., 1997, 88, p 545-556

J.C. Schuster and Y. Du, Thermodynamic description of the system Ti-Cr-C, Calphad, 1999, 23, p 393-408

C.S. Sha, M.J. Bu, H.H. Xu, Y. Du, S.Q. Wang, and G.H. Wen, A thermodynamic modeling of the C-Cr-Ta ternary system, J. Alloys Compd., 2011, 509, p 5996-6003

Y.B. Peng, P. Zhou, M.J. Bu, W.B. Zhang, and Y. Du, A thermodynamic evaluation of the C-Cr-Nb system, Calphad, 2016, 53, p 10-19

Acknowledgments

The financial support from the National Natural Science Foundation of China (51901063), the Fundamental Research Funds for the Central Universities of China (JZ2019HGBZ0114 and PA2020GDGP0054), the Program for Guangdong Introducing Innovative and Entrepreneurial Teams (2016ZT06G025) and Guangdong Natural Science Foundation (2017B030306014) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, Y., Huang, L., Zhang, J. et al. Thermodynamic Description of the C-Cr-Zr System Over the Whole Composition and Temperature Ranges. J. Phase Equilib. Diffus. 41, 870–882 (2020). https://doi.org/10.1007/s11669-020-00850-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-020-00850-0