Abstract

A unique surface texturing methodology has been used for controllably modulating and improving the optical absorption, scattering, and field intensity distribution of copper, silver, gold, and titanium nitride nanodiscs. The finite-difference time-domain (FDTD) method has been employed for this electromagnetic simulation study. We added roughness to the lateral surface of the nanodisc and found that the magnitude and line width of the optical spectra can be tuned simultaneously by simply varying the root mean square (RMS) amplitude of the rough surface. In addition, it makes a significant contribution to the enhancement of the field intensities. A comparative study has been performed and it was observed that the gold nanodisc (100 nm size), having a smooth lateral surface exhibiting optical absorption at the resonant wavelength ~ 554 nm, shifted to ~ 621 nm when the roughness was induced at the lateral surface. The electric field intensity was also enhanced from 23 (V/m)2 to 300 (V/m)2. Silver, exhibiting the highest scattering with a broad line width at 450 nm, shifted to 525 nm due to the addition of nanoscale roughness. A significant red shift was observed in the absorption and scattering spectra of the copper and titanium nitride nanodiscs when roughness was incorporated into these nanostructures. Additionally, we achieved an extraordinary enhancement in both the electric and magnetic field intensity distribution in comparison to their smooth counterparts. We strongly believe that this research can help experimentalists to fabricate roughness-induced metal nanorods, because this type of surface-texturing methodology is experimentally feasible. Therefore, it may help in the development of highly efficient solar energy harvesting systems, plasmonics, photovoltaic devices, etc.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metal nanoparticles show a variety of extraordinary optical properties in comparison with their bulk alternatives as a consequence of localized surface plasmons (LSPs).1,2 Whenever electromagnetic (EM) waves interact with these kinds of nanoparticles, intense excitation within the visible or near-infrared wavelengths is observed due to the coherent oscillations of the conduction electrons. In addition, it provides a significant electric field within the controlled resonance wavelengths.3 Noble metal nanostructures, along with their broad-spectrum response and photosensitivity, result in excellent platforms for very hypersensitive optical nanosensors and photonic elements, plus other applications.4,5 Silver (Ag) and gold (Au) possess unique optical properties throughout the visible as well as near-infrared (NIR) regions of the spectrum which are especially valuable for many applications, such as nanoscale optical elements and systems,6 biomolecular, as well as chemical sensing,7 medical imaging,8 and surface-enhanced spectroscopies.9 Copper (Cu) is yet another very used metal in electronic applications due to its higher conductivity and affordable cost. The continuing development of Cu-based miniaturized nanodevices that include optical, electronic, chemical, and biological characteristics, is primarily important for near-future sensing products.10 Titanium nitride (TiN), combined with other transition metal nitrides, has nowadays emerged as being a phenomenal alternate selection of plasmonic materials in the visible as well as the near-infrared regions.11 It provides tunable optical properties, is inexpensive, chemically plus thermally stable, and is additionally appropriate for modern-day silicon fabrication technological innovations.

Recently, available research indicates that TiN can facilitate plasmonic properties similar to that of Au, as well as being a much better material for photothermal energy transformation.12 In these nanoparticles, the position of the optical spectrum is strongly sensitive to their size, shape, and dielectric environment.13 Although the influence of particle dimensions and structure, as well as the variation of the localized dielectric function on the resonance, have been commonly studied,14 the effect of surface roughness has received comparatively little interest. Recently, several research reports have proved the relationship between surface roughness and the plasmonic behavior of metal nanoparticles. The impact of the surface, or of imperfections in the optical characteristics of sub-micrometer Au nanoshells and Au meatballs, were investigated by Wang and colleagues.15,16 The influence of roughness has additionally been studied in highly corrugated as well as porous Au rods.17 Each one of these works has demonstrated that surface roughness can cause red shifts to surface plasmon resonance (SPR) peaks. This means it can be employed as an additional method to tune the SPR responses of Au nanoparticles. Mahmoud and co-workers examined the optical and electrical properties associated with a roughened silicon nanowire photovoltaic cell using the three-dimensional finite-difference time-domain (FDTD) as well as the finite element method. They discovered that the surface roughness promotes a higher efficiency of 32.51%, with an improvement of 15.98% more than that of the smoothed silicon nanowire solar cell.18 The research work carried out by Kondorskiy and co-workers revealed that the localized surface plasmon resonance (LSPR) wavelength does not only depend on size but also depends on the shape of the nanoparticles.19

The geometrical structure also plays a very important role in the enhancement of optical cross-sections as well as the line widths of the plasmon peak. For spherical geometry, the optical cross-section, as well as the line width of the plasmon peak, increases with increasing size. However, in the case of metallic nanorods, the line width of the resonance in fact decreases, opposite to what occurs with nanospheres of identical diameter.20 In other work, Ahmadivand and co-workers revealed that the peak of the resonance spectrum shifted to longer wavelengths whenever the radius of the Cu nanodisc increased, while at the same time the scattering efficiency decreased.21 Therefore, when it comes to cylindrical metallic nanostructures, it is a challenging issue to simultaneously improve the optical cross-section and line width of the plasmon peak to a greater extent. In this work, we have used the FDTD simulation method to individually design and optimize the cylindrical structures of Cu, Ag, Au, and TiN nanodiscs. Furthermore, we have induced nanoscale roughness to the lateral surface of these nanodiscs, and increased their root mean square (RMS) roughness amplitude from the lower order (0 nm) to the highest order (5 nm) for each individual structure. The results obtained from the simulation have revealed that roughness simultaneously improves the bandwidth and optical cross-sections, as well as the field intensity distribution around all these nanostructures in comparison to their smooth counterparts.

Methods and Description

FDTD is considered as probably one of the most well-established numerical methods, developed by Yee to solve Maxwell’s equations for a given material having a complicated geometrical structure.22 Here, commercial software, Ansys Lumerical FDTD solutions,23 has been used to model the geometries and visualization of optical cross-sections, as well as electric field distributions around smooth and roughness-induced disc-like nanostructures. The same software package has been used widely by many researchers, including our group.24,25,26,27,28,29,30,31,32 In this method, the physical space near the material is divided into smaller-sized compact cubic cells, which are called Yee cells. This algorithm starts with some guessed values, with both the electric as well as the magnetic fields being computed by using Maxwell’s equations, and then the first-order approximation values were evaluated. These values are then provided to Maxwell’s equations to obtain the second-order approximation. This procedure will continue further up to the level at which a convergent limit is obtained that signifies the real physical value of the fields. The convergence factor is at the same time dependent upon the size of the Yee cell cube, which is recognized as the mesh size. Extinction, scattering, and absorption parameters, along with the local electric and magnetic field distribution properties, were selected to study the optical response of the material. The detailed arrangement of the simulated region is provided in supplementary Figure S1. The absorption cross-section (σabs) was calculated by an analysis group present inside the total field scatter field (TFSF) source. The analysis group determines the net power flowing into the system and by normalizing it to the source intensity (Iinc). Likewise, the scattering cross-section (σscat) is also determined by an analysis group positioned outside the TFSF source. The absorption as well as the scattering of the nanoparticles, which relates the absorbed power \(\left( {P_{{{\text{abs}}}} } \right)\), as well as the scattered power \(\left( {P_{{{\text{scat}}}} } \right)\) , to that of the incident light, is given by33:

where the addition of σabs and σscat gives the extinction cross-section (σext) of the nanoparticles.

The surfaces which appeared naturally, as well as those developed artificially and with proper care, continue to be rough to some extent. Therefore, it is significant and sometimes crucial to have an understanding of the degree to which this roughness controls the physical processes taking place at the surface. Typically, a fascinating class of physical processes taking place on a rough surface stands out as the scattering and absorption of EM waves. When it comes to metal nanostructures, the effective dielectric characteristics are usually affected by the surface morphology due to their small skin depth. Since light is incident mainly on the outer layer of the surface, the nanoscale roughness therefore greatly influences the interaction of the light with the metal. In general, the roughness is defined via a correlation length (Lc) and RMS roughness amplitude (σ), also called sigma RMS. A total of six parameters were chosen to describe the surface roughness: a seed for generating random numbers, the roughness amplitude (σ), correlation length (Lc), height (h), and diameter (d) of the nanodisc, and the resolution parameter (δ). The roughness amplitude (σ) is the vertical deviation of a real surface from a mean plane, while the correlation length (Lc) shows the horizontal magnitude of the roughness originating from a point up to a distance where the heights of a rough surface are correlated with each other. δ is the resolution parameter which defines the frequency of radius modulation. The value of δ, as well as Lc, are taken as a number and considered to be 100 and 0.1, respectively. These values are kept fixed for all the structures. Computationally, the roughness of a surface can be viewed as a 2-D image in which each point (pixel) has different random correlated intensities. The relationship of these types of distributed arbitrary intensities present in the image is characterized by an appropriate autocorrelation function, which describes the way in which random variables are statistically related. Here, the Gaussian autocorrelation function R(r) is chosen for the simulation, due to the fact that this model is realistic and is used for the statistics of surface roughness of multiple waveguides.34,35 The roughness parameters, i.e., Lc and δ are related to the correlation function R(r), where r signifies all the positions on that particular surface and is given by36:

By altering the value of σ, the overall pattern of surface roughness can be regulated. Equation 2 is implemented under Ansys Lumerical FDTD solutions by using a Lumerical script environment.37 In the scripting code, a random number vector is initially generated in the k-space with a gaussian distribution to ensure that it keeps all the information of the surface. Then, it is filtered in accordance with the required input parameters, and the actual surface is accomplished by applying a Fourier transform within the filtered k-space.38 The resulting surface roughness is finally applied to the sidewalls of the nanodisc. A flow chart of the surface roughness algorithm is provided in supplementary Figure S2. The value of roughness amplitude is then changed from 0 nm (lower-order roughness) to 5 nm (highest-order roughness) under the same Lumerical code written in a scripting language. The code of the rough cylindrical structure can be found in the cylinder category under the object library of the Lumerical FDTD software package.

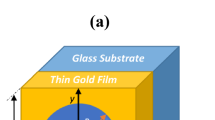

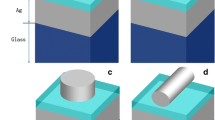

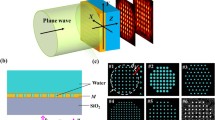

Both single (as shown in Fig. 1), and multiple (as shown in Fig. 2) metal nanodiscs are considered during the simulation. For a single metal structure, we measured the light absorption, scattering, extinction, and field intensities of the nanodiscs by changing the polarization angle of 90° and 0° (where 90° represents s-polarized radiation and 0° represents p-polarized radiation) (Figs. 3, 4, 5, and 6). The results, obtained from s-polarized radiation, are included in the main text and the results obtained from the p-polarized radiation is presented in the supplementary data file (see supplementary Figures S3–S17). For multiple nanodiscs, to study the polarization dependence, we have simulated the optical responses by considering different polarization angles, i.e., 0°, 45° 90°, and 135°, etc. Among all of these polarization angles, initially, 45° is used to present the resultant extinction spectra of the individual group of nanodiscs with respect to the different values of roughness amplitudes, which are shown in Figs. 7, 8, 9, 10, and 11. The same angle of polarization is used to simulate the field intensity values, as provided in Tables IV and V. The variation of the peak scattering wavelength with respect to the diameter to the thickness aspect ratio of the individual metal nanodisc is presented in the supplementary data file (see supplementary Figures S18–S21). Furthermore, Figs. 12, 13, 14, and 15 show the overall polarization-dependent optical spectra, i.e., absorption, scattering cross-sections, etc., considering the highest order of roughness amplitude (i.e., RMS = 5 nm). The rest of the optical responses with different values of roughness amplitudes are presented in supplementary Figures S22–S25).

The geometrical structure shows (a) cross-sectional view and (b) three-dimensional view of a smooth nanodisc (roughness amplitude = 0 nm), (c) roughness amplitude = 1 nm, (d) roughness amplitude = 2 nm, (e) roughness amplitude = 3 nm, (f) roughness amplitude = 4 nm, (g) roughness amplitude = 5 nm, and (h) cross-sectional view of the rough surface.

Permittivity profile of (a) copper (real part), (b) copper (imaginary part), (c) silver (real part), (d) silver (imaginary part), (e) gold (real part), (f) gold (imaginary part), (g) titanium nitride (real part), (h) titanium nitride (imaginary part), and comparison plot shows (i) absorption, (j) scattering, and (k) extinction cross-sectional spectra of individual smooth single metal nanodisc with roughness amplitude = 0 nm.

Simulated spatial distribution of electric field intensity (|E|)2 in (V/m)2 around smooth (a) Cu, (b) Ag, (c) Au, and (d) TiN nanodiscs with RMS = 0 nm, and roughness-induced (e) Cu, (f) Ag (g) Au, and (h) TiN with RMS = 5 nm nanodiscs at their respective LSPR excitation wavelengths using s-polarized light.

Elements from Group 11 of the periodic table (Cu, Ag, and Au) and also TiN were selected for the present simulation. The list of the refractive indices of Cu, Ag, and Au were obtained from the Lumerical database to calculate the real and imaginary parts of the permittivity values.39,40,41 However, the experimental refractive index data of TiN were obtained from a recently available publication.42 The permittivity profiles of these metals are presented in Fig. 3a–h. A smooth nanodisc was designed (with diameter and thickness defined by ‘d’ and ‘h’, respectively), as shown in Fig. 1a and b, with the complete FDTD simulation set up, and initially Cu was added to this geometry in order to create the Cu nanodisc. The simulation was then performed by optimizing the structure in a vacuum. After that, the absorption, scattering, and extinction cross-sectional spectra were calculated as a function of the wavelength. To observe the field distribution, both the electric field and magnetic field intensities associated with the nanodisc were also computed. In order to incorporate random roughness into the sidewall of the cylindrical geometry, the Gaussian autocorrelation function (R(r)) was considered. The RMS roughness amplitude was then changed from 0 nm to 5 nm by an increment of 1 nm in order to design additional structures of roughness-induced Cu nanodiscs. All these structures were then optimized and individual absorption and scattering spectra, as well as field intensities, were simulated. The other structures of smooth and roughness-induced nanodiscs made up of Ag, Au, and TiN were also created in the same way and a comparative study provided. Figure 1c–g represents the increasing order of the RMS roughness amplitude parameter from 1 to 5 nm, respectively. Figure 1h shows the variation of the roughness pattern with respect to the mean surface. Figure 2a shows the group of smooth nanodiscs with 25-nm interparticle distance and Fig. 2b shows a group of roughness-induced metal nanodiscs. To observe the impact of roughness on the multiple structures, two types of nanoclusters (groups of nanodiscs) were created. In the first cluster, a group of smooth nanodiscs were designed and the diameter of each nanodisc was considered in such a way that it overall represented the smooth counterpart of the entire series of roughness-induced nanoclusters. Initially, Cu was added to the nanoclusters in order to create a Cu nanocluster. The other structures of smooth Ag, Au, and TiN nanoclusters were created in the same way, and a comparative study of the smooth nanoclusters with the roughness-induced nanoclusters is provided in Figs. 8, 9, 10, and 11.

Results and Discussion

Spectral Response and Field Intensity Distribution of Smooth Nanodisc with Single Structure

Figure 3i–k shows the optical absorption, scattering, and extinction cross-sectional spectra of Cu, Ag, Au, and TiN nanodiscs without applying any surface roughness. The absorption of light by these metals occurs through plasmon excitation and interband transitions which take place in different energy ranges. Electrons present in the conduction band are considered as free electrons creating an electron gas, in addition, their positions are treated as collective oscillations at the plasma frequency of the system in general. Plasmon transitions occur at low energies (high wavelength) from visible to infrared EM wave absorption of free electrons, as given in the Drude model. In this model, the incident radiation of frequencies below the plasma frequency is reflected, due to the fact that electrons in the metal screen the electric field of the EM wave. EM radiation of frequencies above the plasma frequency is transmitted because the electrons are unable to react fast enough to screen it.43,44 At lower wavelengths, interband transitions are taking place from an occupied energy state below the Fermi level to an unoccupied energy state in a higher band. In cases like this, the hot carriers usually have much lower kinetic energies but higher populations. From Fig. 3i, it can be seen that the optical absorption cross-section of Au is the highest (~ 0.03 µm2) at the wavelength of 554 nm. This dominating feature of a single peak representing the LSPR appears due to the plasmon excitation of conduction electrons within the sp band.45 These hot carriers produced by the LSPR with higher energies frequently have a short lifetime. Alternatively, at the lower wavelength, another small peak is observed around 370 nm due to d → sp interband transitions which need photons with energies higher than 2.3 eV (less than 539-nm wavelength).46 In the case of Ag, the interband contribution is associated with the electron transitions between the valence band, d, the conduction band, p, and also the upper band, s. It relates to electron transitions involving the d, p, and s bands in the vicinity of the first Brillouin zone.47 The electronic excitation threshold energy, which is located at 4 eV (close to ~ 300 nm wavelength) for interband transition, is present for Ag metal at room temperature.48 That is why, when Ag is illuminated with visible light, hot electrons can only be generated by plasmon excitation.49 Additionally, in this case, electronic excitation does not overlap with plasmon excitation. In Fig. 3i, the absorption cross-section of smooth Ag is located at 0.021 µm2 at the plasmon excitation wavelength of 450 nm. This wavelength is found to tally with the results reported in the standard publication.50 The plasmon contribution relates to electron transitions within the conduction band of Ag. For Cu, both plasmon and interband excitations are found to result in large differences in the spectral response in the visible wavelengths. The promotion of d-band electrons to the unoccupied energy states above the Fermi level (Ef) leads to interband absorptions. For the Cu nanodisc shown in Fig. 3i, the increase in the absorption cross-section at wavelengths less than 475 nm signifies the interband absorption which is found to be a good agreement with the previously reported results.51 Under plasmon excitation, the spectral response is quite different: the structure indicates a relatively strong photoinduced absorption feature at 554 nm. As far as TiN is concerned, the plasmon peak and absorption due to interband transition were 608 nm and 370 nm, respectively. This absorption spectrum is satisfactory with the reported absorption spectrum.11 The absorption cross-section of TiN is 0.022 µm2. These results reveal that the plasmon excitation in the absorption spectra corresponding to the Au nanodisc is more dominant when compared to Cu, Ag, and TiN.

Scattering processes take place instantaneously. Scattering related to the structure when the dimensions of the material are lower than the wavelength of the incident radiation is usually known as Rayleigh scattering.52 This scattering is also referred to as elastic scattering, in which the scattered light has the same frequency as the incident light. The study of scattering cross-sections in Fig. 3j reflects that, at the lower wavelength, the magnitude of the scattering cross-section of Ag is the highest compared to the other nanodiscs, due to the Ag nanostructures having the strongest affinity towards light. It has a large plasma frequency and a large carrier concentration. Subsequently, the large plasma frequency results in a greater enhancement in overall performance.53 The plasma frequency of Au is less than that of Ag but higher than those of Cu and TiN. That is why its highest scattering wavelength is shifted to the longer wavelength of 564 nm compared to Ag, which has the highest scattering wavelength of 455 nm. In the case of Cu, the plasma frequency is less than that of Ag and Au but greater than that of TiN. Therefore, its highest scattering wavelength is even more shifted to the longer wavelength of 591 nm compared to Ag and Au. On the other hand, TiN has the lowest plasma frequency in comparison to Ag, Au, and Cu, and therefore its maximum scattering wavelength is located at around 626 nm. At further higher wavelengths, the scattering cross-sections of all the metal nanostructures overlap with each other. The decreasing trend of the scattering cross-section with increasing wavelength is due to the fact that, for nanostructure sizes less than the wavelength of the incident radiation, the scattering is inversely proportional to the 4th order of the incident wavelength. Comparing both the absorption and scattering spectra of these metal nanodiscs, it is observed that, at the excitation wavelength, the scattering of Ag is higher than its absorption. When it comes to the Cu, Au, and TiN nanodiscs, it is found that these nanostructures act better as light absorbers than as scatterers. The extinction cross-sections (σext) of the nanodiscs are shown in Fig. 3k. The study of extinction spectra also reveals that, for Ag, the scattering contribution towards the total extinction cross-section turns out to be more dominant when compared to the absorption. However, for the Au, Cu, and TiN nanodiscs, an expected dominance is observed of the absorption contribution over the scattering contribution to the total extinction spectrum.

The variation of electric field intensities with respect to the different wavelengths associated with the smooth Cu, Ag, Au, and TiN nanodiscs are presented in Table I, in which the results reveal that the optical wavelengths do not participate equally in the increase of the electric field intensity. For all the metal nanostructures, the highest total field intensity is obtained at their resonance wavelengths. At the lower 450-nm wavelength, Ag shows the highest total electric field (~ 29 (V/m)2) and magnetic field (5.75 × 10−5 (A/m)2) intensity. At the middle 554-nm and 578-nm wavelengths, Au and Cu exhibit the highest electric (~ 23 (V/m)2 and 21 (A/m)2) and magnetic field intensity (3.27 × 10−5 (A/m)2 and (2.33 × 10−5 (A/m)2), respectively. However, at the higher 700 nm wavelength, TiN shows a strong electric (~ 15 (V/m)2 ) field intensity.

Effect of Roughness

The absorption, scattering cross-sections and resonant wavelengths (Table II) are significantly influenced when the roughness is incorporated in the sidewall of the nanodiscs. When the roughness amplitude (\(\sigma\)) increases from 0 nm to 5 nm, it automatically changes the autocorrelation function, R(r), and increases the average diameter (d) of the nanodiscs; however, the overall increase of the average diameter is not very significant compared to the initial diameter of the nanodisc. Table III represents the overall increase in the average diameter of the nanodiscs with respect to the increase in roughness amplitude. The RMS roughness amplitude was gradually increased from 0 nm to 5 nm with an increment of 1 nm and corresponding absorption and scattering spectra were simulated for each nanodisc. The addition of roughness in the side wall reduces the symmetry of the overall structure and increases the average diameter to the thickness aspect ratio of the nanodisc. When an EM wave interacts with a rough surface, it causes a decrease in the reflectivity of the surface by improving the diffusion of the incident energy. Geometrically, the roughness creates a corner curvature which gives rise to a sharp tip along with lower apex angles when the RMS roughness amplitude is increased to a higher order. The sharp metallic tip has a higher charge density. Therefore, these two parameters, i.e., the apex angle associated with sharp tips and the corner curvature, control the spectra of the plasmonic resonances. In general, dipoles induce throughout the pits and bumps on the rough surface. The spectra, as well as the spatial structure of the plasmonic modes, seem to be greatly affected by the corners. Therefore, the number of resonances strongly increases when the symmetry decreases.54,55 The visualizations of the overall roughness pattern in the side wall of the nanodisc are presented in Fig. 1c–g. As observed in the spectra in Fig. 4a–d, a linear increment in the optical absorption cross-section of the Cu, Au, and TiN nanodiscs is found when the roughness amplitude changes from 1 to 2 nm and from 2 nm to 3 nm. Further, a sufficiently large exponential enhancement is observed when the higher-order roughness is induced (4 nm to 5 nm) to the nanodiscs. The multiple reflections from the rough surface may increase the absorption over the smooth surface and the LSP extinction peaks shift to longer wavelengths. Furthermore, the full width at half-maximum of the spectra was also sufficiently increased in each case, covering the wide range of the bandwidth of the incident radiation. In the case of the Ag nanodisc, as presented in Fig. 4b, the higher-order surface roughness (4 nm to 5 nm) give rise to the formation of another peak in the absorption. The scattering cross-sectional spectra are shown in Fig. 5. In the case of the Cu nanodisc shown in Fig. 5a, the cross-sectional area corresponding to the plasmon peak is enhanced from 0.01 µm2 to 0.35 µm2 when the roughness amplitude is increased from 0 nm to 5 nm. For the Ag nanodisc, the scattering cross-sectional area is enhanced from 0.05 µm2 to 0.07 µm2 , as shown in Fig. 5b. Similarly, when it comes to the Au nanodisc, the scattering cross-section is increased from 0.017 µm2 to 0.036 µm2 , as shown in Fig. 5c. Furthermore, in the case of the TiN nanodisc, as shown in Fig. 5d, no significant enhancement is observed in the scattering cross-sectional area whenever the roughness amplitude is raised from 0 nm to 5 nm. However, in all these cases, the wavelength where the absorption and scattering are maximum is significantly red-shifted because the surface roughness causes an additional reduction of the resonant frequency, plus a broadening of the width of the resonance.56 This phenomenon takes place as a result of the roughness-induced plasmon damping.57 The damping of surface plasmons in the surface roughness occurs as a consequence of an imaginary part of the permittivity of the metal. The imaginary part contributes an additional factor to the plasma frequency and therefore causes the roughness-induced frequency shift. Furthermore, it also provides retardation effects in which the phase of the exciting field varies across the surface. As far as the Ag nanodisc is concerned, an additional small peak is observed in the visible range in the scattering cross-sectional spectra, as shown in Fig. 5b for the roughness amplitude of 5 nm, which is not seen in any other nanodiscs. In the case of Ag, small peaks in both of the absorption and scattering spectra are observed due to the fact that, at the higher order RMS amplitude values, the surface plasmon resonance mode of vibrations give rise to splitting of the plasmon resonances into unique dipole and quadrupole plasmon modes.58 The presence of a small peak in Ag, which normally corresponds to the quadrupole excited mode of vibration in the absorption (Fig. 4b) as well as scattering (Fig. 5b) spectra, is more dominant in comparison with the other metals. This is due to the fact that, in Ag, the quadrupole intensity improves more quickly compared to the dipole intensity59 with the increase of average diameter to thickness aspect ratio. Therefore, more than one single resonance can be excited in this kind of roughness-induced non-regular structure.

The variation of electric as well as magnetic field intensities at the higher-order roughness RMS amplitude of 5 nm has also been simulated, as set out in Table II. The existence of sharp tips along with corners in the metal cause corner singularities, which give rise to a strong local enhancement of the EM fields. A comparison of Tables I and II shows a significant enhancement of electric field intensity of the rough surface over the smooth surface. This enhancement of field intensities is observed with respect to the shifting of the resonant condition to longer wavelengths. Figure 6 shows the visualization of the local electric field intensity in the vicinity of the nanodiscs as a function of wavelengths. Here, the electric field of the incident wave is polarized along the y-axis (due to the s-polarization nature of the incident wave), and therefore the total electric field is localized at the upper and lower surfaces of the nanodiscs. We have also provided the simulated field intensity values using p-polarized light (see supplementary data file). The highest extinction cross-section of the smooth Ag nanodisc gives rise to the highest electric field intensity of 29 (V/m)2 at the resonant wavelength of 450 nm, as shown in the color bar of Fig. 6b, compared to Cu (21 (V/m)2) (Fig. 6a), Au (23 (V/m)2) (Fig. 6c), and TiN (12 (V/m)2 (Fig. 6d). Comparing the distribution of electric field intensities of the smooth nanodiscs with the roughness-induced nanodiscs, (having a RMS roughness amplitude of 5 nm), it is found that the rough surface creates a non-uniform distribution of the electric fields with higher field intensity compared to the smooth surface. This extraordinary field enhancement is observed at the very sharp borders and edges on the rough surface. It can be seen that the field intensity of the roughness-induced Cu (Fig. 6e) and TiN (Fig. 6h) nanodiscs at their resonance wavelengths of 628 nm and 750 nm are 280 (V/m)2 and 60 (V/m)2 , respectively. However, the electric field distribution associated with both Ag (Fig. 6f) and Au (Fig. 6g) reaches the highest value (300 (V/m)2) when these structures are excited with the designed resonant wavelengths of 537 nm and 628 nm, respectively.

Spectral Response and Field Intensity Distribution of Smooth and Roughness Induced Nanodisc with Multiple Structures

Figure 7 shows the extinction cross-sectional spectra of individual groups of the Cu, Ag, Au, and TiN nanodiscs with a roughness amplitude of 0 nm. From Figs. 7 and 3k, it can be seen that, in the case of multiple metal nanodiscs, the plasmon peaks are shifted to longer wavelengths compared to the single nanodiscs. The plasmon peak of Cu shifted from 578 nm to 604 nm, for Ag, from 450 nm to 501 nm, for Au, from 554 nm to 590 nm, and for TiN, from 608 nm to 664 nm. This shifting of the wavelength occurs due to the plasmonic coupling effect. When metal nanoparticles are put in the vicinity of other ones, the interparticle coupling impacts the overall optical response. The plasmonic mode of a single nanodisc couples with the plasmonic modes of other nearby nanodiscs, which produces a red shift of plasmon resonance in the optical spectrum. A comparative study has shown that, between smooth (with a roughness amplitude of 0 nm) and roughness-induced nanoclusters in which the roughness amplitude increases from 0 nm to 5 nm, the diameter of each nanodisc present in the smooth nanocluster is equal to the overall average diameter of each nanodisc present in the roughness-induced nanocluster. From Fig. 8b, it can be seen that the plasmon peak in the extinction spectra of the roughness-induced Cu nanocluster shifted to a much higher wavelength compared to the smooth Cu nanocluster (as shown in Fig. 8a). In the case of the highest order of roughness (where the roughness amplitude is 5 nm and the average diameter is 108.7 nm), two plasmon peaks are observed at 621 nm and 871 nm (Fig. 8b). However, only a single peak is observed in its smooth counterpart (Fig. 8a), in which the roughness amplitude is 0 nm but the average diameter is 108.7 nm. A similar trend can be seen in the case of the roughness-induced Au nanocluster in Fig. 10b, in which the excitation wavelength shifted to 882 nm for a RMS roughness amplitude of 5 nm and average disc diameter of 108.7 nm . For its smooth counterpart, the excitation wavelength of the smooth Au nanocluster in Fig. 10a shifted to 624 nm for the RMS roughness amplitude of 0 nm and average disc diameter of 108.7 nm. However, for the roughness-induced TiN nanocluster shown in Fig. 11b, no multimode excitation can be seen in the extinction spectra for the lower order roughness but, at the highest order roughness, two plasmon peaks can be seen and the excitation wavelength is further shifted to 970 nm wavelength for a RMS roughness amplitude of 5 nm and average disc diameter of 108.7 nm. Here, its smooth counterpart (as shown in Fig. 11a)also fails to provide significant shifting of the excitation wavelength. In the case of the Ag nanocluster for RMS roughness amplitude of 5 nm and average disc diameter of 108.7 nm, as shown in Fig. 9b, the incorporation of roughness into the individual nanodisc of the nanocluster produces multimode excitation between 400 nm and 600 nm wavelengths, and the excitation wavelength has also largely shifted to the longer wavelength. However, this type of optical response is not seen in its smooth counterpart having the RMS roughness amplitude of 0 nm and average disc diameter of 108.7 nm (as shown in Fig. 9a). Therefore, in the case of multiple metallic nanostructures, the resultant optical response is the composition of the conventional plasmon resonance due to a single structure and its interaction with the nearby structures. This is due to the fact that the internal coupling with the nearby structure is stronger than the coupling within the surrounding medium. Furthermore, the roughness results in complex extinction spectra by splitting of the single resonance as well as enhancing this interaction via exhibiting multimode excitation in the optical spectra. Tables IV and V represent the overall distribution of electric and magnetic field intensities at their respective resonant wavelengths. Comparing these two tables, it is found that the roughness-incorporated nanocluster exhibits much higher electric and magnetic field intensities compared to its smooth counterpart. The polarization-dependent study of the optical response is presented in Figs. 12, 13, 14, and 15. From those optical responses, it can be seen that the plasmon peaks of the roughness-induced group of metal nanodiscs are sensitive to the different angles of polarization. A significant change in the excited wavelength is observed in the absorption, scattering, and extinction spectra, whenever the polarization angle changes from 0° to 45° and from 45° to 90° in all of the nanodiscs. However, when the angle of polarization is changed to 135°, then it can be seen that the computed optical spectra are found to be similar to that of the 45°-polarization angle.

Conclusions

We have examined the absorption and scattering characteristics along with the electric field intensities associated with smooth and nanoscale roughness-induced Cu, Ag, Au, and TiN nanodiscs. Our investigations demonstrate that surface roughness plays a very important role in the high absorption and high scattering of the incident radiation over a wide range of wavelengths. Exceptional enhancement was observed, not only in the line width of the plasmon peak but also in the optical cross-sections when the surface roughness amplitude was serially varied from 0 nm to 5 nm. Moreover, FDTD simulations identified higher values of the field intensities which provide extraordinary enhancement when excited at the designed resonant wavelength compared to the nanodiscs having a smooth surface. The nanoscale roughness provides tunability of resonant peaks up to a particular excitation wavelength simply by adjusting the RMS amplitude of the rough surface. Our results conclude that roughness is furthermore an important parameter in understanding the control enhancement of the optical properties and field intensities. This electromagnetic enhancement, exhibited by the roughness-induced nanodiscs, is one of the mechanisms leading to surface-enhanced Raman scattering (SERS). Therefore, it makes them good candidates for optoelectronics, SERS detection, and other photonic crystal applications.

References

A.V. Kabashin, P. Evans, S. Pastkovsky, W. Hendren, G.A. Wurtz, R. Atkinson, R. Pollard, V.A. Podolskiy, and A.V. Zayats, Plasmonic nanorod metamaterials for biosensing. Nat. Mater. 8, 867 (2009).

L. Li, T. Hutter, U. Steiner, and S. Mahajan, Single molecule SERS and detection of biomolecules with a single gold nanoparticle on a mirror junction. Analyst 138, 4574 (2013).

S. Mubeen, S. Zhang, N. Kim, S. Lee, S. Krämer, H. Xu, and M. Moskovits, Plasmonic properties of gold nanoparticles separated from a gold mirror by an ultrathin oxide. Nano Lett. 12, 2088 (2012).

J. Zhao, A. Das, X. Zhang, G.C. Schatz, S.G. Sligar, and R.P. Van Duyne, Resonance surface plasmon spectroscopy: low molecular weight substrate binding to cytochrome P450. J. Am. Chem. Soc. 128, 11004 (2006).

C.R. Yonzon, E. Jeoung, S. Zou, G.C. Schatz, M. Mrksich, and R.P. Van Duyne, A comparative analysis of localized and propagating surface plasmon resonance sensors: the binding of concanavalin A to a monosaccharide functionalized self-assembled monolayer. J. Am. Chem. Soc. 126, 12669 (2004).

S.A. Maier, M.L. Brongersma, P.G. Kik, S. Meltzer, A.A.G. Requicha, and H.A. Atwater, Plasmonics—a route to nanoscale optical devices. Adv. Mater. 13, 1501 (2001).

R. Elghanian, J.J. Storhoff, R.C. Mucic, R.L. Letsinger, and C.A. Mirkin, Selective colorimetric detection of polynucleotides based on the distance-dependent optical properties of gold nanoparticles. Science 277, 1078 (1997).

C. Loo, A. Lowery, N. Halas, J. West, and R. Drezek, Immunotargeted nanoshells for integrated cancer imaging and therapy. Nano Lett. 5, 709 (2005).

K. Kneipp, H. Kneipp, I. Itzkan, R.R. Dasari, and M.S. Feld, Ultrasensitive chemical analysis by raman spectroscopy. Chem. Rev. 99, 2957 (1999).

Y.V. Stebunov, D.I. Yakubovsky, DYu. Fedyanin, A.V. Arsenin, and V.S. Volkov, Superior sensitivity of copper-based plasmonic biosensors. Langmuir 34, 4681 (2018).

S. Podder and A.R. Pal, Hot carrier devices using visible and NIR responsive titanium nitride nanostructures with stoichiometry variation. Opt. Mater. 97, 109379 (2019).

A. Lalisse, G. Tessier, J. Plain, and G. Baffou, Quantifying the efficiency of plasmonic materials for near-field enhancement and photothermal conversion. J. Phys. Chem. C 119, 25518 (2015).

S. Link and M.A. El-Sayed, Size and temperature dependence of the plasmon absorption of colloidal gold nanoparticles. J. Phys. Chem. B 103, 4212 (1999).

J.J. Mock, M. Barbic, D.R. Smith, D.A. Schultz, and S. Schultz, Shape effects in plasmon resonance of individual colloidal silver nanoparticles. J. Chem. Phys. 116, 6755 (2002).

H. Wang and N.J. Halas, Mesoscopic Au “Meatball” particles†. Adv. Mater. 20, 820 (2008).

M.J. Banholzer, S. Li, J.B. Ketter, D.I. Rozkiewicz, G.C. Schatz, and C.A. Mirkin, Electrochemical approach to and the physical consequences of preparing nanostructures from gold nanorods with smooth ends. J. Phys. Chem. C 112, 15729 (2008).

H.M. Bok, K.L. Shuford, S. Kim, S.K. Kim, and S. Park, Multiple surface plasmon modes for a colloidal solution of nanoporous gold nanorods and their comparison to smooth gold nanorods. Nano Lett. 8, 2265 (2008).

A.H.K. Mahmoud, F.M.H. Korany, C. Tharwat, M. Hussein, M.A. Swillam, S.S.A. Obayya, and M.F.O. Hameed, Surface roughness effect on characteristics of Si nanowire solar cell. J. Photonics Energy 10, 045502 (2020). https://doi.org/10.1117/1.JPE.10.045502.

A.D. Kondorskiy, N.T. Lam, and V.S. Lebedev, Absorption and scattering of light by silver and gold nanodisks and nanoprisms. J. Russ. Laser Res. 39, 56 (2018).

C. Sönnichsen, T. Franzl, T. Wilk, G. von Plessen, J. Feldmann, O. Wilson, and P. Mulvaney, Drastic reduction of plasmon damping in gold nanorods. Phys. Rev. Lett. 88, 077402 (2002).

A. Ahmadivand and N. Pala, Plasmon resonance hybridization in self-assembled copper nanoparticle clusters: efficient and precise localization of surface plasmon resonance (LSPR) Sensing based on fano resonances. Appl. Spectrosc. 69, 277 (2015).

K. Yee, Numerical solution of initial boundary value problems involving maxwell’s equations in isotropic media. IEEE Trans. Antennas Propagat. 14, 302 (1966).

M. Taheri, M. Omoomi, and J. Mazloum, Slow light propagation in photonic crystal-based meandering delay lines using the PTS material. Arab. J. Sci. Eng. 44, 2335 (2019).

P. Mishra, V. Srivastava, and M. Kumar, Sunny, All-dielectric metasurface-enabled near-infrared switching based on Ge2Sb2Te5 phase-change material. J. Electron. Mater. 49, 3913 (2020).

S.M. Gan, P.S. Menon, N.R. Mohamad, N.A. Jamil, and B.Y. Majlis, FDTD simulation of Kretschmann based Cr-Ag-ITO SPR for refractive index sensor. Mater. Today Proc. 7, 668 (2019).

L. Budai, Z. Márton, P. Dombi, and K. Tőkési, Simulation of photoelectron emission from metallic nanoparticles under laser irradiation. Eur. Phys. J. D 73, 138 (2019).

A. Elrashidi, Electrophotonic improvement of polymer solar cells by using graphene and plasmonic nanoparticles. Mater. Express 7, 305 (2017).

Z. Lu, J. Jhoja, J. Klein, X. Wang, A. Liu, J. Flueckiger, J. Pond, and L. Chrostowski, Performance prediction for silicon photonics integrated circuits with layout-dependent correlated manufacturing variability. Opt. Express 25, 9712 (2017).

V. Demontis, A. Marini, F. Floris, L. Sorba, and F. Rossella, Engineering the optical reflectance of randomly arranged self-assembled semiconductor nanowires, in AIP Conference Proceedings (2020), p. 020009.

S. Podder, J. Bora, S. Thakur, D. Gogoi, B. Basumatary, S.M. Borah, N.C. Adhikary, and A.R. Pal, Interband transition in plasmonic titanium nitride and its contribution towards ZnO based pyro-phototronic application. Mater. Chem. Phys. 275, 125290 (2022).

B. Basumatary, S. Podder, S. Thakur, J. Bora, B. Sharma, S.M. Borah, NCh. Adhikary, D.S. Patil, and A.R. Pal, Synergistic effect of Au interband transition on graphene oxide/ZnO heterostructure: experimental analysis with FDTD simulation. ACS Omega 7, 7662 (2022).

S.D. Rezaei, J. Ho, R.J.H. Ng, S. Ramakrishna, and J.K.W. Yang, On the correlation of absorption cross-section with plasmonic color generation. Opt. Express 25, 27652 (2017).

M. Pelliccione and T.M. Lu, Evolution of Thin Film Morphology: Modeling and Simulations (New York: Springer, 2008).

E. Jaberansary, T.M.B. Masaud, M.M. Milosevic, M. Nedeljkovic, G.Z. Mashanovich, and H.M.H. Chong, Scattering loss estimation using 2-D fourier analysis and modeling of sidewall roughness on optical waveguides. IEEE Photonics J. 5, 6601010 (2013).

Y. Al Qazwini, A.S.M. Noor, P.T. Arasu, and A.R. Sadrolhosseini, Investigation of the performance of an SPR-based optical fiber sensor using finite-difference time domain. Curr. Appl. Phys. 13, 1354 (2013).

https://optics.ansys.com/hc/en-us/articles/360034382374-Tips-for-adding-surface-roughness-to.

W.P. Dong and K.J. Stout, Two-dimensional fast fourier transform and power spectrum for surface roughness in three dimensions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 209, 381 (1995).

E.D. Palik, Handbook of Optical Constants of Solids (Orlando: Academic Press, 1985).

H.J. Hagemann, W. Gudat, and C. Kunz, Optical constants from the far infrared to the x-ray region: Mg, Al, Cu, Ag, Au, Bi, C, and Al2O3. J. Opt. Soc. Am. 65, 742 (1975).

P.B. Johnson and R.W. Christy, Optical constants of the noble metals. Phys. Rev. B 6, 4370 (1972).

V. Schnabel, R. Spolenak, M. Doebeli, and H. Galinski, Structural color sensors with thermal memory: measuring functional properties of Ti-based nitrides by eye. Adv. Opt. Mater. 6, 1800656 (2018).

M.S. Dresselhaus, Solid State Physics, Lecture Notes, Part II, Optical Properties of Solids (Cambridge, MA: Massachusetts Institute of Technology, 2001).

F. Wooten, Optical Properties of Solids (Saint Louis: Elsevier, 2014).

X. Cui, F. Qin, Q. Ruan, X. Zhuo, and J. Wang, Circular gold nanodisks with synthetically tunable diameters and thicknesses. Adv. Funct. Mater. 28, 1705516 (2018).

R. Sundararaman, P. Narang, A.S. Jermyn, W.A. Goddard III., and H.A. Atwater, Theoretical predictions for hot-carrier generation from surface plasmon decay. Nat. Commun. 5, 5788 (2014).

B.R. Cooper, H. Ehrenreich, and H.R. Philipp, Optical properties of noble metals. II. Phys. Rev. 138, A494 (1965).

G.L. Eesley, Generation of nonequilibrium electron and lattice temperatures in copper by picosecond laser pulses. Phys. Rev. B 33, 2144 (1986).

M. Bernardi, J. Mustafa, J.B. Neaton, and S.G. Louie, Theory and computation of hot carriers generated by surface plasmon polaritons in noble metals. Nat. Commun. 6, 7044 (2015).

V. Amendola, O.M. Bakr, and F. Stellacci, A study of the surface plasmon resonance of silver nanoparticles by the discrete dipole approximation method: effect of shape, size, structure, and assembly. Plasmonics 5, 85 (2010).

C. Lee, Y. Park, and J.Y. Park, Hot electrons generated by intraband and interband transition detected using a plasmonic Cu/TiO2 nanodiode. RSC Adv. 9, 18371 (2019).

M. Pelton and G.W. Bryant, Introduction to Metal-Nanoparticle Plasmonics (Hoboken, NJ: Wiley Science Wise Publishing, 2013).

A. Maradudin ed., Modern Plasmonics (Amsterdam: Elsevier, 2014).

J. Tominaga and D.P. Tsai eds., Optical Nanotechnologies: The Manipulation of Surface and Local Plasmons (Berlin Heidelberg: Springer, 2003).

N.C. Lindquist, J. Jose, S. Cherukulappurath, X. Chen, T.W. Johnson, and S.H. Oh, Tip-based plasmonics: squeezing light with metallic nanoprobes. Laser Photonics Rev. 7, 453 (2013).

A.J. Bard and I. Rubinstein eds., Electroanalytical Chemistry: A Series of Advances (Boca Raton: CRC Press, 2003).

J. Rodríguez-Fernández, A.M. Funston, J. Pérez-Juste, R.A. Álvarez-Puebla, L.M. Liz-Marzán, and P. Mulvaney, The effect of surface roughness on the plasmonic response of individual sub-micron gold spheres†. Phys. Chem. Chem. Phys. 11, 5909 (2009).

E. Hao and G.C. Schatz, Electromagnetic fields around silver nanoparticles and dimers. J. Chem. Phys. 120, 357 (2004).

E. Hao, K.L. Kelly, J.T. Hupp, and G.C. Schatz, Synthesis of silver nanodisks using polystyrene mesospheres as templates. J. Am. Chem. Soc. 124, 15182 (2002).

Acknowledgments

The authors would like to extend their sincere appreciation to Dr Arup R. Pal of the Institute of Advanced Study in Science and Technology (IASST), Guwahati for fruitful discussions. One of the authors (Samir Thakur) would like to acknowledge the Director of Gauhati University Institute of Science and Technology, Head, Dept. of Applied Sciences, Gauhati University and MHRD, Govt. of India, for offering a Research Assistantship under TEQIP-III Project. The authors extend their sincere acknowledgement to IASST, Guwahati and the Department of Science and Technology, Government of India. Also, we would like to express our heartfelt thanks to the reviewers of the Journal of electronic materials for their valuable and important comments and suggestions which help us a lot in correcting the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thakur, S., Borah, S.M., Singh, A. et al. Roughness Effect on the Broadband Optical Performance and Extraordinary Local Field Enhancement in Metal Nanostructures. J. Electron. Mater. 52, 4878–4894 (2023). https://doi.org/10.1007/s11664-023-10422-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10422-w