Abstract

We present an extensive review of different techniques, such as x-ray magnetic circular dichroism, Mössbauer spectroscopy, and x-ray absorption spectroscopy, for determining the cation distribution in ferrites, and a comparison between these techniques is established. We describe the basic principles of these techniques to find the cation occupancies and highlight the important results obtained from these measurements on ferrite nanoparticles and thin films. Cation distribution, an important characteristic that controls the structural, electrical, and magnetic properties of ferrites, is strongly affected by the synthesis methods. Therefore, various synthesis techniques are reported for preparing ferrite nanoparticles and thin films. A summary correlating these techniques and the cation distribution in ferrite nanoparticles and thin films is presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The wide range of technological applications of ferrite nanoparticles and thin films in various fields has brought enormous interest by researchers. Ferrites are found to be applicable in various fields, such as sensors,1 memory,2 and microwave devices,3 due to their electrical and magnetic properties. These materials are chemically stable and can be easily synthesized. Recently, ferrite materials with a spinel structure have shown a strong potentiality both academically and technically. Ferrites are mostly known for their magnetic applications in refrigerators, and in loudspeakers as permanent magnets, and soft ferrites are used in electronic devices, such as inductors and transformers. The magnetic behavior and interaction are strongly influenced by the occupancies of metal ions in the spinel structure.4 The magnetic properties of ferrites are governed by the antiferromagnetic superexchange interaction by Fe3+ ions at tetrahedral (A) and octahedral (B) sites. These Fe3+ ions create three antiferromagnetic superexchange interactions via O ions, denoted as A-O-A, B-O-B, and A-O-B. In an inverse spinel, Fe3+ is present at both A and B sites, whereas Fe3+ is present only at the B sites for a normal spinel structure. In the case of normal spinel ferrite, only the B-O-B interaction is present. Thus, the cation occupancies at the A and B sites determine the antiferromagnetic superexchange interactions that control the properties of the ferrites, so that determining the exact cation occupancy in ferrites is important to obtain the origin of their magnetic behavior. For doped spinel ferrites, knowing the occupation sites of the doping ions is crucial for tailoring and improving their magnetic properties.5 In the case of Zn-doped MgFe2O4, the Zn2+ ions prefer to occupy Fe3+ sites and enhance the Fe3+-O2−-Fe3+ superexchange interaction, leading to an enhancement of the magnetization. Thus, the growth and characterization of spinel ferrite materials are an emerging area of research. Currently, various methods are available for preparing spinel ferrite nanoparticles and thin films. The structural, magnetic, and electrical properties of the spinel ferrites are controlled by the synthesis methods that introduce various cation distributions in the system. Synchrotron radiation-based x-ray magnetic circular dichroism (XMCD) is a powerful technique for studying cation distribution.6 This method, along with x-ray absorption spectroscopy measurements, provides information related to the electronic and magnetic properties of nanoparticles and thin films under various temperatures and magnetic fields. The element-selective nature of the measurements facilitates the estimation of the spin and orbital magnetic moments of an atom. Element-specific magnetic hysteresis loops suggest changes in the magnetic properties of ferrite nanoparticles and thin films. Therefore, XMCD studies are crucial for understanding the atomistic origin of magnetization in ferrites, and the effect of cation distribution on their structural, electrical, and magnetic properties. Apart from XMCD studies, other techniques, such as x-ray diffraction,7 Mössbauer spectroscopy,8 x-ray absorption spectroscopy,9 and neutron diffraction,10 are used to find the cation distribution in ferrites.

XMCD studies have been carried out on various ferrite nanoparticles and thin films prepared by different methods. Room-temperature XMCD studies were performed at Fe and Co L2,3 edges on high-quality CoFe2O4 nanoparticles in total electron yield mode.11 The Fe and Co cation distribution and their spin and orbital magnetic moments are calculated by simulating the experimental curves and using the sum rule. So, the XMCD is an efficient technique that can provide both cation distribution and magnetic moments of ions. XMCD studies on CoFe2O4 nanoparticles showed a partial inverse spinel structure with similar cation distribution and stoichiometry for a series of samples.12 Combined studies of XMCD and magnetization showed different cation distribution and oxygen vacancy concentrations which create local ferromagnetism in ZnFe2O4 nanoparticles and thin films.13 It has been reported that the magnetic properties alter with the synthesis methods, and that nanoparticle size depends on the cation distribution in the systems.14,15 Apart from the XMCD studies, Mössbauer spectroscopy and x-ray absorption spectroscopy are also widely used to determine the cation occupancies in ferrites. Mössbauer spectroscopy is utilized to find the degree of inversion in bulk and nano-sized particles of CuFe2O4, MnFe2O4, and NiFe2O4.15 This technique was used to confirm the structural changes from inverse spinel to normal spinel in the case of NiFe2−xCrxO4 and CoFe2−xCexO4 ferrites with increasing the content of Cr and Ce.16,17 X-ray absorption spectroscopy is used to find the degree of inversion in MnFe2O4 and CoFe2O4 and their variation with varying the particle sizes and synthesis methods.18,19,20

In this review article, various synthesis methods for preparing ferrite nanoparticles and thin films, and their effects on structural, physical, and cation distribution properties, are discussed. The variation of cation occupancies in ferrites is reported in terms of various synthesis parameters. Since the cation distribution is an important parameter in defining the physical properties and structural changes of ferrites, various techniques, such as XMCD, Mössbauer spectroscopy, and x-ray absorption spectroscopy, are illustrated in terms of discovering the cation distribution. A detailed discussion of each technique and their comparison are made in this article.

Structure of Ferrites and Metal Ion Occupancy

Ferrite nanoparticles are metal oxides with spinel structure having the general formula, MFe2O4 , where M represents divalent metallic cations (M = Co, Ni, Cu, Zn, Mn, or other metals). The word spinel is derived from the mineral MgAl2O4 due to its structural similarity.21 In this mineral, oxygen ions are placed at the face centers of a cubic structure. However, Mg2+ and Al3+ ions occupy tetrahedral and octahedral voids surrounded by oxygen ions (Fig. 1). These metallic cations are positioned at two different crystallographic sites: tetrahedral (A) and octahedral (B). There are 64 tetrahedral and 32 octahedral sites in the spinel structure. One-eighth of the A sites and one-half of the B sites are occupied by metal ions, the rest remain empty. Thus, in the structure, a unit cell contains 8 molecules. In the case of spinel ferrites, Al3+ ions are replaced by Fe3+, making the chemical formula MFe2O4.22

In the case of ferrites, transition metal can occupy either the A or B sites. There are two factors on which the site preference of metals may be determined.

-

(a)

Large ions having low charge prefer A sites.

-

(b)

The difference in the electronic configuration of the cations leads to another set of preference criteria for the A and B sites:

-

(i)

Ions with filled 3d shells like Zn2+ tend to form covalent bonds with sp3 orbitals. Therefore, they occupy the A sites in the spinel.

-

(ii)

Ions with noble gas structures show no preference for either A or B sites.

-

(iii)

For a half-filled 3d shell with spherical symmetry, the preference will be decided by the influence of the crystalline electric field originating from the neighboring ions on the average energy levels and the spatial distribution of the 3d charges.

In ferrites, the chemical bond is assumed to be ionic, to a first approximation. Therefore, the main part of the lattice energy is Coulomb energy and Born repulsive energy. Other factors, such as polarization, individual preference of certain ions for 4-fold and 6-fold coordination, and magnetic interaction, also contribute to lattice energy. These energies depend on the lattice parameter, ‘a’, oxygen parameter, ‘u’, and the cation distribution. According to the cation distribution among the A and B sites, the spinel structure may be classified in the following categories:

-

(i)

Normal spinel structure: 8 M2+ ions at A sites and 16 Fe3+ ions at B sites. Example: ZnFe2O4

-

(ii)

Inverse spinel structure: 8 Fe3+ ions at A sites and (8 Fe3+ + 8 M.2+) ions at B sites. Example: NiFe2O4

-

(iii)

Intermediate or mixed spinel structure: Fe1−x3+Mx2+ at A sites and Fe1+x3+ M1−x2+ at B sites. Example: MnFe2O4

Although categories (i) and (ii) are defined, the examples also show slight deviations from the crystal structure. Thus, most of the ferrites are characterized by a general formula as (Fe1−x3+Mx2+)A{Fe1+x3+M1−x2+}B to show the distribution of ferrite. This distribution not only affects the structure but also leads to significant changes in the magnetic properties of the ferrite. According to cation distribution, the magnetic moment of ferrite is given as

This makes the determination of this distribution extremely important. In general, the distribution is characterized by the presence of Fe3+ ions on the A site and is widely termed cation inversion, which is defined as

where x = 1 for the normal spinel structure, and 0 for the inverse spinel structure, while the value is 0 < x < 1 for the mixed spinel structure. Keeping in mind the necessities of cation inversion, numerous efforts are being made by researchers to precisely control this factor by synthesis processes. More than this, significant attention is being given to determining this factor by suitable methods. So this review article discusses various synthesis approaches to prepare ferrite nanoparticles and thin films, and their cation distribution studies.

Ferrite Nanoparticle Synthesis

Spinel ferrite nanoparticles are synthesized by various methods, such as mechanical milling, ultrasonics, hydrothermal/solvothermal, micro-emulsion, co-precipitation, microwave-assisted, and sol–gel. The preparation of ferrite nanoparticles by each method is described below.

Mechanical Milling Method

The top–down approach of mechanical milling is used for large-scale production of nanoparticles. A high-energy shaker or ball mill or sometimes tumbler mills are used. The nanoparticles prepared by this method have a random shell and an ordered ferromagnetic core. The limitation of this method is the contamination of the nanoparticles by the milling tools during the milling process, which results in non-stoichiometry in the nanoparticles. Nanocrystalline NiFe2O4 was successfully synthesized by the reactive milling method using a stoichiometric mixture of commercial nickel and iron oxides.23 The NiFe2O4 nanoparticles were found to be disordered and to incorporate defects. It is reported for NiFe2O4 nanoparticles that the magnetization depends on the milling time and annealing temperature due to the cation reordering in the crystal structure. Magnetization increases initially up to a milling time of 12 h, and reduces with further increasing the milling time after completion of the reaction between the starting oxides.23 CuFe2O4 crystals have been prepared by the combined methods of reactive milling, heat treatment, and mechanical milling.24 The reactive milling contained a stoichiometric mixture of CuO, and α-Fe2O3 hematite. CuFe2O4 was formed at a temperature of 600–1000°C. Finally, mechanical milling was carried out using the same mill, vial, and disc rotational speed to refine the crystalline size of the CuFe2O4. The magnetization of CuFe2O4 decreased due to the partial redistribution of the cations in the spinel by increasing the milling time.24 A mechanochemical process of synthesizing ferrite nanoparticles using a ball mill was investigated by Todaka et al.25 Different ferrites, such as Fe3O4, CoFe2O4, and Ni0.5Zn0.5Fe2O4 nanoparticles, were prepared by taking aqueous solutions of various chlorides, FeCl3, CoCl2, or NiCl2/ZnCl2, and NaOH, in a horizontal ball mill (SUS304). The pH of the solution was controlled by varying the amount of NaOH, and a centrifuge was used to separate the nanoparticles from the solution. A combined approach of microwave-assisted ball milling was introduced for the synthesis of nanocrystalline NiFe2O4 particles with a mean size of about ~ 20 nm.26 Nickel carbonate and iron powders were used as precursors. Initially, an intermediate product, Fe2Ni2(OH)8CO3.2H2O, was formed during the milling process, and this product further reacted to form NiFe2O4 nanocrystals. ZnFe2O4 nanoparticles were prepared by mechanical milling using ZnO and α-Fe2O3 powder.27 The powders were placed in a stainless steel vial with a ball-to-powder weight ratio of 10:1. The milling process was carried out at 275 rpm for 50 and 35 h. The effect of lattice constant, inversion degree, and crystallite size on the variation of magnetization was demonstrated. It was reported that cation inversion is the most significant parameter that can most effectively tune the magnetic properties. The saturation magnetization was found to be 79 emu/g at 5 K, with the degree of inversion varying from 0.56 to 0.61.27 ZnFe2O4 and MgFe2O4 nanocrystalline powders were prepared by high-energy milling using a planetary ball mill with a 2 × 150 grinding chamber and balls made of α-Al2O3.28 The degree of inversion for the MgFe2O4 decreased with the increasing the milling time. The inversion was found to be 0.904(1) for bulk MgFe2O4 and changed to 0.856(3) and 0.756(1) with increasing the milling time to 15 and 30 min, respectively. With further increasing the milling time, the degree of inversion saturated at 0.73. In the case of ZnFe2O4, the degree of inversion was reported to be 0.41.28 Synthesis parameters for preparing various ferrite nanoparticles by mechanical milling are listed in Table I.

Ultrasonic Method

This method is very popular because of the control of the reaction conditions and particle size distribution. The temperature and intensity of the ultrasonic waves are the two major factors that control the particle size of nanocubes. Here, high-energy collisions between the particles forms the nanocubes which undergo in situ calcination. Ultrasonication is responsible for the mixing at the atomic level and the formation of the crystalline phase at low temperatures. Some examples are cobalt and manganese ferrites.29,30 Magnetization is shown to be decreased to 21.58 emu/g in Gd3+ -substituted CoFe2O4 compared to 40.19 emu/g in pure CoFe2O4 nanoparticles. On the other hand, electrical properties, such as dielectric constant and ac conductivity, increased in Gd3+ -substituted CoFe2O4 nanoparticles. The cation distribution in Gd3+ -substituted CoFe2O4 nanoparticles prepared by the sonochemical method plays a significant role in determining these physical properties.29 The cation distribution was found to be varied in MnFe2O4 nanoparticles with the variation of sonication time. The formula of MnFe2O4 is reported as (Mn0.29Fe0.42)[Mn0.71Fe1.58]O4 and (Mn0.28Fe0.54)[Mn0.72Fe1.46]O4 for sonication times of 20 and 80 min, respectively. The saturation magnetization was enhanced from 1.9 emu/g to 52.5 emu/g with increasing sonication time from 20 to 80 min. These changes are attributed to the cation occupancies in the MnFe2O4 nanoparticles.30 Sonochemical syntheses of CoFe2O4 were carried out in which cobalt acetate and iron acetate were placed (1:2 ratios) in millipore water.31 The solution was kept on a sonicator for 30 min at 70°C. The pH ~ 4.5 was maintained with 0.1 N NaOH or 0.1 N HCl. The chemical reactions of CoFe2O4 synthesis were:31

A simple and easy technique of ultrasonic cavitation-induced water in vegetable oil emulsion droplets was used to synthesize manganese zinc ferrite nanocrystals.32 This method consists of rapeseed oil as an oil phase and an aqueous solution of Mn2+, Zn2+, and Fe2+ acetate. The reaction was performed at 300°C for 3 h, so that the small amount of oil present on the surface of the ferrite could be eliminated. The prepared manganese zinc ferrite was nanocrystalline. Another method of ultrasonic-assisted synthesis of self-assembled CuFe2O4 nanoparticles was also reported by Abbasian et al., 33 in which FeCl3.6H2O, CuCl2.2H2O, and sodium acetate were used as precursors. The solution was stirred and exposed to ultrasonic waves. Finally, centrifuging, washing, and drying were carried out to obtain CuFe2O4 nanoparticles. The ferrites synthesized by ultrasonic methods are listed in Table II.

Hydrothermal/Solvothermal Method

This method is well known because different sizes, shapes, and morphologies of ferrite nanoparticles can be prepared by controlling the experimental parameters.37 It is also known as an economical and eco-friendly method, due to the use of water as a solvent. Using this method, various ferrites nanoparticles, such as multiwalled carbon nanotube CoFe2O4, Fe3O4, CoFe2O4, Ni-Zn ferrite, MnFe2O4, and metal-doped MgFe2O4 have been synthesized.38,39,40 Co1−xNixFe2O4 nanoparticles were successfully prepared by this method using ethylene glycol as solvent.41 Co(NO3)2.6H2O/Ni(NO3)2.6H2O, and Fe(NO3)3.9H2O as precursors were taken in a 1:2 molar ratio and dissolved in ethylene glycol. Anhydrous sodium acetate and polyethylene glycol were added to the mixture and stirred continuously for 30 min. The mixture was kept in an autoclave at 200°C for 12 h and then cooled to room temperature. The final product was washed with distilled water and anhydrous ethanol and dried at 70°C for 12 h under vacuum.41 Cobalt ferrite nanoparticles have been synthesized by the solvothermal method.42 Co(NO3)2.6H2O and Fe(NO3)3.9H2O were mixed with 3 M NaOH solution in deionized water. The solution was mixed by simultaneous heating and stirring, then transferred into an autoclave. Finally, the nanoparticles were washed, dried, and calcinated. Various nanoparticles of MFe2O4 (M = Mn, Co, Ni) have been synthesized by the hydrothermal method.43 For the preparation of 0.1 g ferrite, MnAc2 was mixed with FeAc2 and dissolved in a suitable solvent, such as benzyl alcohol or hexanol. The resulting solution was stirred and crystallized at 180°C for 24 h. Finally, the autoclave was cooled to room temperature and the sample was centrifuged at 5000 rpm for 30 min. The product was washed with ethanol and dried at room temperature.43 A facile synthesis of α-Fe2O3 and Fe3O4 nano- and microstructures by the hydrothermal/solvothermal process is shown in Fig. 2.44 The process involved in the morphology and size-control with the role of the reaction medium was also studied.

Superparamagnetic ZnFe2O4 submicron spheres were prepared by the one-pot solvothermal method.45 In this preparation, ZnCl2, FeCl3, and CH3COONa were used as precursors and ethylene glycol was taken as a solvent. The solution was kept in an autoclave at 200–215°C for 4–8 h. The autoclave was cooled to room temperature before collecting the ZnFe2O4 nanocrystals, which were finally washed with deionized water and ethanol and dried at 60°C. A one-step hydrothermal method for the synthesis of CuFe2O4/reduced graphene oxide aerogel was reported by Yao et al.46 The observed properties, such as high efficiency, good reusability, and a simple synthesis process, make this aerogel a promising catalyst for wastewater treatment. Saturation magnetization increases in Cu-substituted CoFe2O4 nanoparticles with increasing Cu content up to 0.3, and decreases with larger Cu content. These changes are attributed to the crystallinity, cation distribution, misbalance of Fe3+ ions in tetrahedral and octahedral sites, and super-exchange interaction.47 A list of different ferrite nanoparticles prepared by the hydro(solvo) thermal method is given in Table. III.

Micro-emulsion Method

This method of ferrite nanoparticle synthesis is known for its environmentally friendliness and the size-controlled nature of the nanoparticles. It requires a low temperature and a large amount of solvent, reuses the surfactant several times. One of the main drawbacks of this method is the poor crystalline nature of the nanoparticles. Preparation of nanoparticles of barium ferrite using the micro-emulsion method was investigated by Palla et al.48 The precursor carbonate and hydroxide can be precipitated by the aqueous cores of the water-in-oil micro-emulsion method. The prepared precursor was calcinated at 925°C for 12 h. After 12 h, the product was transferred to hexagonal ferrite. The pH of the reaction was maintained between 5 and 12, affecting the magnetic properties of the particles. It was reported that the barium ferrite crystals prepared by the micro-emulsion method had both higher intrinsic coercivity and saturation magnetization. Neodymium-doped LiNi0.5Fe2O4 nano-crystalline was prepared via micro-emulsion.49 The preparation of ferrite nanoparticles by the oil-in-water micro-emulsion method was carried out by organometallic precursors by mixing with a surfactant, oil component, and Milli-Q-water.50 All the components were mixed at 25°C and stirred until a brown transparent micro-emulsion was formed. Finally, centrifugation and washing were carried out with a water and ethanol mixture (1:1) and drying in the oven at 70°C for 2 days to obtain Mn-Zn ferrite nanoparticles. In Mg1−xCaxNiyFe2−yO4 nanoparticles synthesized by the micro-emulsion method, the saturation magnetization increased from 9.84 to 24.99 emu/g with increasing Ca and Ni content up to x = 0.2 and y = 0.4, while the dielectric constant decreased with increasing Ca-Ni concentration. These changes were attributed to the cation distribution in Mg1−xCaxNiyFe2−yO4 with changing the Ca-Ni content. It has been shown that Ca and Ni prefer to occupy octahedral sites, while Fe3+ migrates from octahedral to tetrahedral sites.51 Similarly, magnetization values increased from 20.5 to 47.6 emu/g with increasing x in Ni0.5Sn0.5CoxMnxFe2−2xO4 ferrites. The origin of the magnetization is the imbalance of the magnetic moments at the tetrahedral and octahedral sites. As the cation distribution depends on the ionic radii of the cations, introducing different cations into the structure causes changes in the magnetic moments.52 A list of different ferrite nanoparticles prepared by the micro-emulsion method is given in Table IV.

Co-precipitation Method

Co-precipitation is an easy method to perform economically to obtain high mass production in less time. Various spinel ferrite nanoparticles have been synthesized by this method to get uniform-sized nanoparticles. A careful observation of the pH in the solution is needed to get good quality nanocubes. For the preparation of nickel ferrite nanoparticles, the co-precipitation method is very popular and easy.57 The flow chart of nickel ferrite preparation by this method is as follows (Fig. 3).

Nano-spinel ferrites (Ni0.4Cu0.2Zn0.4Fe2O4) were prepared by co-precipitation assisted by ultrasonic irradiation produced by an ultrasonic cleaner with a frequency of 20 kHz.58 Chlorinated salts and KOH were used as the initial materials. The microstructure and magnetic properties dependence on the ultrasonic power and reaction temperature were studied. X-ray diffraction studies confirmed the formation of pure (NiCuZn)Fe2O4 ferrite nano-spinel with crystallite sizes of less than 40 nm and a lattice constant of 8.39 Å. Nanoparticles of MnFe2O4 with different sizes by varying the pH have been prepared by chemical co-precipitation.59 These nanoparticles were modified on their surfaces with polysaccharide chitosan to discover the characteristics of hyperthermia and magnetic resonance imaging (MRI). The sizes of the MnFe2O4 particles varied from 5 to 15 nm at pH 9–12. The hydrodynamic sizes were less than 250 nm, with a polydispersity index of 0.3, and zeta potentials were higher than 30 mV, which proved the electrostatic repulsion for a stable colloidal suspension. The MRI properties at 7 T described that the transverse relaxation (T2) doubled as the size of the CS-coated MnFe2O4 nanoparticles tripled in vitro. However, through the study of in vivo positive contrast MRI angiography, the longitudinal relaxation (T1) was strongest for the smallest CS-coated MnFe2O4 nanoparticles. Finally, the results showed the exciting potential of CS-coated MnFe2O4 nanoparticles in MRI and of hyperthermia studies for biomedical research. CoFe2O4 and ZnCoFe2O4 have been prepared by a modified co-precipitation method,60 which was reported to be a simple, environment-friendly, and low-temperature process in which no oxidizing or coating agent was used. The composition of the precursor materials was also changed (molar ratio of Fe+3:Fe+2:Co+2/Zn+2 of 3:2:1). Ferrites synthesized by the co-precipitation method are listed in Table V. Sn1−xMnxFe2O4 nanoparticles, synthesized by co-precipitation method, showed increasing magnetization and coercive fields with increasing the content of Mn in SnFe2O4. These changes were attributed to the increasing degree of inversion of Fe3+ and the decreasing degree of inversion for Mn2+ ions.61

Microwave-Assisted Method

This method is a new technique, that is fast, simple to use, has a high yield, low cost, and shorter reaction time, in which microwave energy is used for the combustion of precursors. During the reaction, the microwave energy is converted into thermal energy and the temperature rises for a shorter period at 100–200°C. The common ferrites prepared by this method are Fe3O4, NiFe2O4, CoFe2O4, Mn1−xNixFe2O4, and ZnFe2O4.64,65 Nanocrystalline NiFe2O4 and CoFe2O4 have been prepared by the microwave-assisted combustion process. The stoichiometric proportion of nickel nitrate hexahydrate (Ni(NO3)2.6H2O), ferric nitrate nonahydrate (Fe(NO3)3.9H2O), and urea NH2CONH2 were dissolved in deionized water. The solution was kept in a crucible in a microwave oven. At first, the solution boiled and underwent dehydration and decomposition with a large number of gases. As a point of spontaneous combustion was achieved, the solution began to burn, a great deal of heat was released, and all the solution was vaporized and became a solid. The reaction of combustion reaction to getting NiFe2O4 is:

Nanoplatelets of nickel ferrite were synthesized through a microwave-assisted combustion process with the help of trisodium citrate as fuel.66 Cobalt ferrite nanoparticles by the microwave-assisted solvothermal method were investigated by Kozakova et al.67 For the synthesis of CoFe2O4 nanoparticles, CoCl2 and FeCl3 were dissolved in ethylene glycol and mixed. The resulting solution was placed into the microwave at 220°C and at a pressure of about 900 kPa for 30 min. A black product was obtained after cooling to room temperature. The product was rinsed with demineralized water or ethanol and dried at 60°C for 6 h. The microwave-assisted synthesis of water-soluble styrylpyridine dye-capped zinc oxide nanoparticles was investigated by Giridhar et al.68 MxFe3−xO4 magnetic ferrite (M = Fe, Mn, Co) spherolites of high surface area have been successfully prepared by a facial microwave-assisted reflux method.69

Sol–Gel Method

This method is commonly used for synthesizing ferrite nanoparticles because of its simplicity and cost-effectiveness. The distribution of the nanoparticle sizes can be easily controlled using this method. For the preparation of ferrite nanoparticles by the sol–gel method (Fig. 4), the nitrates of the particular metal ions and a suitable chelating agent, e.g., urea/citric acid, and glycine were taken in the ratio of 1:x (where x = 1–3 in most cases). First, the metal nitrate was dissolved in deionized water. Then, the aqueous solution of citric acid was mixed into the metal nitrates. Finally, the mixture was kept on a hot plate at 100°C with continuous stirring until it became gel-like. After some time, the gel itself ignited and burnt at a high temperature. The ignition and decomposition process gives chromium-substituted cobalt ferrite.70

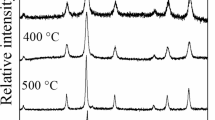

Magnetic MnFe2O4 spinel ferrite nanoparticles were synthesized from metal nitrates by the sol–gel method.71 A 50% solution of Mn(NO3)2 and Fe(NO3)3.9H2O powders were mixed with deionized water. The complexing agent (citric acid) was added to the metal nitrate solution with a 1:1 molar ratio. The solution was evaporated and decomposed at 200°C by forming a gel. Finally, calcination was carried out in air at a different temperature to obtain the MnFe2O4 nanoparticles. An aqueous glycolate sol–gel method was used to synthesize transition metal ferrite ceramic samples (YFeO3, Y3Fe5O12, CoFe2O4, NiFe2O4, and ZnFe2O4).72 Different spinel metal ferrites have been synthesized through the sol–gel combustion method, and the effect of these ferrite nanoparticles on the growth of the microalgae Picochlorum sp. has been examined.73 The prepared metal ferrites were found to possess a high crystalline structure, and the average crystallite sizes of FeCr2O4, CoFe2O4, NiFe2O4, CuFe2O4, and ZnFe2O4 were determined as 34, 33, 36, 35, and 52 nm, respectively. The microalgae culture of Picochlorum sp. treated with different ferrite nanoparticles showed a significant difference in viable cell concentrations at 48 h and 72 h of incubation as compared to the control samples. However, the growth pattern of both treated and untreated samples was similar. This could indicate that the synthesized nanoparticles may reduce the growth of the microalgae, but will not cause severe inhibition when used at the proper concentration. NiFe2O4 nanoparticles, synthesized by honey-mediated sol–gel combustion show, an enhanced magnetization with increasing the crystallite size. The magnetization was shown to increase from 32.3 emu/g to 49.9 emu/g and the coercivity decreased from 162 to 47 Oe with the crystallite size increasing from 20 to 163 nm during annealing. This enhancement has also been attributed to the cation occupancies obtained for the as-prepared and air-annealed NiFe2O4 nanoparticles.74 The variation of conductivity with increasing the annealing temperature of ZnFe2O4 nanoparticles has been demonstrated as the variation of the microstructure and mobility associated with cation redistribution.75 A few selected ferrites prepared by the sol–gel method are listed in Table VI.

Other frequently employed synthesis techniques, such as solid-state,80 sonochemical,30 and template methods81 were used to prepare ferrite nanoparticles.

Ferrite Thin Films Synthesis

Spinel ferrite thin films are grown by using two major techniques. These techniques are based on (1) physical, and (2) chemical deposition methods.

Physical Deposition Method

The extensively used physical deposition methods are sputter deposition and pulsed laser deposition (PLD) for spinel ferrite thin film fabrication. A rapid cooling process from the vapor phase to the solid-state phase in sputtering and PLD introduces a random distribution of metal cations in spinel ferrite thin films.

Sputter Deposition

The sputter deposition technique operated in direct current (DC) and radio frequency (RF) modes is a simple and straight forward process for depositing uniform and dense spinel ferrite compounds. Spinel ferrite ZnFe2O4 thin films were prepared on various substrates like glass, quartz, Si (100), SrTiO3 (100), and yttria-stabilized zirconia (111) using an RF magnetron sputtering system.82,83,84,85 A ceramic target of ZnFe2O4 was prepared by a solid-state reaction method from the starting materials, ZnO and Fe2O3. To achieve a highly dense target, this ceramic material was sintered at a high temperature. An appropriate amount of sputter gas (Ar) and reactive gas (O2) flowed through the sputtering chamber during the time of deposition. The RF reactive sputtering method was used to grow CoFe2O4 films on MgAl2O4 (110) and MgO (001) substrates from an iron-cobalt alloy target.86,87,88 Both DC and RF sputtering methods were employed to prepare CuFe2O4 thin films on glass and quartz substrates from a copper ferrite target.89,90,91 A Mn0.6Zn0.4Fe2 alloy target was used to deposit Mn-Zn ferrite thin films on glass substrates using the reactive sputter deposition technique.92 Various oxygen partial pressure and substrate temperatures have been used during the deposition of Mn-Zn ferrite films. Both MnFe2O4 and ZnFe2O4 targets were prepared to grow Mn-Zn ferrite thin films of varying Zn content by an alternate RF sputtering method.93 This method was used at room temperature for depositing Mn-Zn ferrite thin films on different substrates, including Si (100), MgO (100), and SiO2/Si (100) from two targets. Other doped ferrite thin films, such as Ni-Zn ferrite,94,95,96,97,98,99 and Cu–Zn ferrite,100 have also been deposited on glass, quartz, Si (100), and Pt substrates using the RF magnetron sputtering method. Among various spinel ferrite thin films, the investigation of cation distribution was carried out on ZnFe2O4, NiFe2O4, and Al-Zn-doped NiFe2O4 thin films deposited by RF and DC magnetron sputtering.101,102,103 The cation occupancies of Zn2+ and Fe3+ ions in a ZnFe2O4 spinel structure explain the ferrimagnetic nature at room temperature and spin-glass behavior.101 The ferrimagnetic behavior of NiFe2O4 thin films is due to the compensation of the magnetic moments of Fe at tetrahedral and octahedral sites, as expected in an inverse spinel structure.102 The magnetocrystalline anisotropy and the intrinsic magnetic damping in Zn/Al-doped NiFe2O4 thin films are affected by the cation distribution. The reduction of Ni2+ at tetrahedral sites with increasing the Zn content leads to a decrease in anisotropy, coercivity, and damping.103 A summary of ferrite thin films grown by the DC and RF sputter deposition method is provided in Table VII.

Pulsed Laser Deposition (PLD)

PLD is a physical vapor deposition technique that uses a high-power pulsed laser, an ultra-high vacuum, a target material, and substrates for coating. MgFe2O4 thin films were coated on MgAl2O4 (100),104 SrTiO3 (100),105 and α-Al2O3 (0001)106 substrates using the PLD method. A solid-state reaction method was employed to prepare a dense MgFe2O4 ceramic target by sintering at high temperatures. In this method, a KrF excimer laser of wavelength 248 nm was used for film deposition with an energy density of 1.2 J/cm2 and a repetition rate of 10 Hz. The energy density and the pulse frequency of the laser can be varied, based on their requirements. Thin-film growth depends on various parameters, such as substrate temperature, target–substrate distance, and oxygen partial pressure into the chamber. Kim et al.105 found a decrease in the lattice constant of MgFe2O4 thin films with increasing the partial pressure of oxygen. CoFe2O4 thin films have been grown by the PLD technique on various substrates, such as quartz,107 MgO (001),108 SrTiO3 (100),109 and Si (100).110 A third harmonic Nd:YAG laser of wavelength 355 nm with an energy density 2.5 J/cm2, pulse duration 6 ns, and repetition rate 10 Hz has been used to irradiate a CoFe2O4 ceramic target.107 CoFe2O4 films were deposited by varying the repetition rate (2, 3, 5, 7, and 10 Hz) of the KrF excimer laser.108 On the other hand, in a Nd:YAG laser, different excitation wavelengths of 213, 532, and 1064 nm with fluence values of 0.8, 2.4, and 4 J/cm2 , respectively, has been applied for ablating the target.109 Other spinel ferrite ZnFe2O4,111,112 and NiFe2O4104 thin films have also been prepared by the PLD method. A site-doped spinel ferrites, such as Ni1−xCrxFe2O4,113 Ni1−xZnxFe2O4,114 Mn1−xZnxFe2O4,115 and Ni-Mn-Zn ferrite116 thin films, were deposited on Si and sapphire substrates from the bulk targets. Fe3+ ions were substituted by lanthanide group elements Dy, La, and Gd in CoFe2O4 spinel ferrite thin films grown by the PLD technique to investigate the changes in structural properties.117 Epitaxial MgAl2−xFexO4 (0.8 < x < 0.2) films were deposited on a single crystal (001) MgAl2O4 substrate by PLD.118 Cation distribution of spinel ferrite thin films has been studied on CuFe2O4,119 ZnFe2O4,120,121 and NiFe2O4122 deposited by the PLD method. The cation inversion decreases with increasing the magnetization, which is found to be increased in CuFe2O4 thin films with increasing the oxygen partial pressure during PLD. Thus, the cation occupancies in ferrite thin films vary with the oxygen partial pressure.119 The magnetization alters depending on the cation occupancies of Fe at tetrahedral and octahedral sites of ZnFe2O4 thin films with oxygen partial pressure during PLD and the annealing conditions.120,121 The cation inversion enhances with increasing the oxygen vacancies in NiFe2O4 thin films originated during PLD.122 Therefore, this technique is an efficient ferrite thin film deposition method to alter the cation occupancies in ferrite thin films. Various thin film deposition parameters, such as substrate temperature, target-substance distance, and oxygen partial pressure, are tabulated in Table VIII.

Chemical Deposition Method

In the chemical deposition method, spinel ferrite thin films are coated by both the gaseous and liquid phases of the materials.

Gaseous Phase Deposition

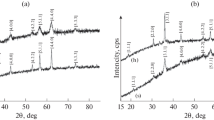

The gaseous phase of the materials is used mainly in chemical vapor deposition (CVD) and atomic layer deposition (ALD) techniques. In the CVD method, ZnFe2O4 thin films were deposited on Si (100) substrates at a substrate temperature in the range of 400–800°C at low chamber pressure.123 The precursor was heated to 120°C to vaporize the solution, and nitrogen gas was used to deliver the vapor to the substrate. NiFe2O4 films were deposited on MgO (100),124 MgAl2O4 (100),124,126 SrTiO3 (100),126 PZT-PT (001),127 PMN-PT (001),127 and Si (100)128 substrates by direct liquid injection CVD and metal–organic CVD. The surface morphology and chemical composition of NiFe2O4 thin films are controlled by the various parameters (solution injection rate, flow rate of carrier gas, temperature, and pressure) during liquid phase CVD.124 Substrates were cleaned thoroughly in acetone, ethanol, and isopropanol before being placed into the deposition chamber. Other spinel ferrites, such as CoFe2O4 thin films129,130, Ni-Zn ferrite,131,132 and Co-Zn ferrite133 films were also grown by a similar technique. A list of different ferrites prepared by CVD techniques with varying parameters is tabulated in Table IX.

The ALD technique has also been used to fabricate various spinel ferrite thin films. ZnFe2O4 thin films were grown using a sequential deposition of Fe3O4 and ZnO films on mono-crystalline Si (001) substrates.134 Initially, a layer of Fe3O4 was deposited at a temperature of 673 K followed by another coating of ZnO layer at 473 K. Finally, Si (001)/Fe3O4/ZnO was annealed at 873 K for 1 h in air atmosphere.134 Air-stable ferrimagnetic oxides NixFe3−xO4 (nickel ferrite) and CoxFe3−xO4 (cobalt ferrite) were directly prepared using the ALD technique.135 The stoichiometry and thickness of these thin films grown by ALD are highly controllable. Pure and smooth CoFe2O4 thin films of thickness 5–25 nm were grown on SrTiO3 (100) and SrTiO3 (110) single crystals by the ALD method.136 Pham et al.137 have demonstrated a radical enhanced ALD method to grow CoFe2O4 thin films on SrTiO3 (001) substrates at 200 ºC temperature. Apart from spinel ferrite, hexagonal orthoferrite h-ErFeO3 thin films were also fabricated on SiO2/Si substrates by using the ALD technique.138

Liquid Phase Deposition

The extensively used ferrite thin film deposition techniques based on liquid-phase precursors are spin-coating and spray pyrolysis. The initial precursor solutions for depositing thin films using these techniques are prepared by the sol–gel and metal–organic chemical methods. The concentration of the precursors plays a key role in obtaining a film of the desired thickness. Various ferrite thin films, such as ZnFe2O4,139,140 CoFe2O4,141,142 NiFe2O4,143 MnFe2O4,144 and MgFe2O4145 have been grown by the liquid-phase deposition method. Easy control of chemical compositions in these techniques also encourages fabricating doped ferrite films, such as Ni1−xZnxFe2O4,146,147 Ni1−xCoxFe2O4,148 Co1−xMnxFe2O4,149 Ni1−xCuxFe2O4,150 Ni1−xCdxFe2O4,151 and CoxRE1−xFe2O4 (RE: Nd, Eu).152 Another advantage of liquid phase deposition is the flexibility of choosing the substrates, which results in the deposition of thin films on different substrates, like glass,139 quartz,147 mono-crystalline Si,141 Pt,140 MgO, 142 and ITO/glass146. Finally, these films have been dried to remove the solvents and then annealed at high temperatures to obtain crystalline thin films. Ni0.15ZnyFe2.85−yO4 and NiFe2−xGdxO4 ferrite films have been studied to examine the distribution of cations of tetrahedral and octahedral sites.153,154 In Ni-Zn ferrite, Zn cations occupy only tetrahedral sites, while Ni and Fe cations occupy both the tetrahedral and octahedral sites. Magnetization is shown to be increased with increasing Zn concentration when Ni occupancy increases to 25% at tetrahedral sites. Gd doping in NiFe2O4 thin film show higher magnetization due to the Gd doping, exchange interaction, and redistribution of cations at octahedral and tetrahedral sites.154 The ferrite films prepared by the spin-coating and spray pyrolysis methods are listed in Table X.

Other thin-film deposition techniques such as electrochemical deposition155 and electrospinning156 can be employed to fabricate ferrite materials.

At the end of the various synthesis techniques described for preparing ferrite nanoparticles and thin films, a summary of the correlation between the synthesis methods and the cation distribution is established. In the case of ferrite nanoparticle synthesis, it has been found that the milling time and annealing temperature can alter the cation ordering in the mechanical milling method. The degree of inversion initially decreases and saturates with increasing the milling time. Sonication time also plays a major role in determining the cation occupancies in ferrite nanoparticles prepared by the ultrasonic method. The annealing temperature during the preparation of ferrite nanoparticles in the sol–gel method varies the cation distribution, resulting in the variation of different physical properties. Therefore, these techniques are efficient in modifying cation occupancies in ferrite nanoparticles. On the other hand, for ferrite thin film fabrication, the cation distribution predominantly depends on the oxygen partial pressure during the thin film growth using the PLD method. Thus, this technique is found to be an efficient method to alter the cation occupancies in ferrite thin films compared to other methods. The annealing temperatures of ferrite thin films always play a significant role in cation distribution.

X-ray Magnetic Circular Dichroism (XMCD) on Ferrites

XMCD is a technique that can provide information about cation distribution as well as about the magnetic behavior of ferrite materials. XMCD is the difference between x-ray absorption spectra measured in a magnetic field in presence of left and right circularly polarized light. This method is a well-known and powerful technique to find the atomistic origin of the magnetic moment. Sometimes, these measurements are also performed at cryogenic temperatures. This method is a surface-sensitive element-specific core electron spectroscopy, and is widely used for magnetic studies in material science and inorganic chemistry. Various magnetic systems, such as bulk materials, thin films, multilayers, and nanostructures, can be examined by this technique. It is also used to investigate the phenomena of exchange bias and magnetic anisotropy. XMCD plays a major role in understanding the spin and orbital magnetic moments of 3d transition metal, and of lanthanide and actinide systems. XMCD measurement is a two-step process (Fig. 5).157 At the first step, the angular momentums (ħ and − ħ) of opposite helicity are transferred to the excited photoelectrons by left and right circularly polarized light. Thus, the electrons with opposite spins are mostly excited due to two opposite helicities. The angular momentum of the photon becomes coupled with electron spin through spin–orbit coupling. In the second step, the electrons with spin-up and spin-down create an imbalance in the valence bands in the presence of the magnetic field. These spin-polarized electrons are differently absorbed in valence shells depending on their spin direction. If the valence shell has a net orbital moment, then the magnetization originates from the spin–orbit coupling.

(a) Schematic of the principle of the XMCD process in a two-step method: (b) XAS and XMCD spectra of the Fe L2,3 edge; reprinted from Ref. 157 with permission from Elsevier.

XMCD studies on Ferrite Nanoparticles

Various spinel ferrites have been characterized using XMCD to study the cation distribution and element-specific magnetic moments and hysteresis loops. XAS and XMCD spectra of the Fe L2,3 edge collected at 300 K in a magnetic field of 6 T are shown in Fig. 6 for CoFe2O4 nanoparticles. In the XMCD spectra, three peaks are observed in the Fe L3 edge. The first negative peak corresponds to the Fe2+ at octahedral (Oh) sites, the positive peak represents the Fe3+ at the tetrahedral (Td) sites, and the second negative peak corresponds to Fe3+ at octahedral (Oh) sites. The Fe cation distribution at tetrahedral and octahedral sites is found by fitting the experimental spectra using a linear combination of the multiplet ligand field (LFM) calculated spectra for each site. For this simulation, all the parameters are taken from the reported values.158 Fig. 6c shows the LFM-calculated XMCD spectra for Fe2+ Oh, Fe3+ Td, and Fe3+ Oh cations. The linear combination of these three spectra fits the experimental curves. The Fe cation distribution for these samples is shown in Table XI. The positive peaks with respect to the negative peak arise due to the antiferromagnetic interaction between the Fe ions at the octahedral and tetrahedral sites.159 The two positive peaks indicate the ferromagnetic interaction between Fe2+ and Fe3+ at the octahedral sites.

(a) XAS and (b) XMCD spectra of the Fe L2,3 edge for CoFe2O4 nanoparticles. (c) LFM calculated XMCD spectra and (d) Experimental and simulated spectra; reproduced from Ref. 11 with permission from the Copyright Clearance Center.11

XMCD studies on the Fe L3 edge of ZnxFe3−xO4 nanoparticles demonstrate the amount of ferrous (Fe2+) and ferric (Fe3+) ions oxidation states and their coordination environment.160 The results show that Zn0.16 nanoparticles are more magnetic than Zn0 with Zn0.92 , exhibiting lower magnetic moments. Zn2+ substituting Fe3+ from tetrahedral sites results in an increase in oxidation states from Fe2+ to Fe3+ at octahedral sites to maintain the charge neutrality of the material. The ratio of Fe3+ ions at tetrahedral and octahedral sites has been estimated to be 0.33 in ZnFe2O4 nanoparticles.161 In the case of Co-Zn ferrites, Co2+ ions prefer to occupy the octahedral sites with a magnetic moment of 3.64 μB.162 The spin and orbital magnetic moments of Fe and Co atoms have been estimated in CoxFe3−xO4 nanoparticles using XMCD at the temperature of 2 K.12 The orbital moments of Fe and Co atoms were around 0.05 and 0.15 μB respectively. However, the spin magnetic moment is always dominant over the orbital moment for both Fe and Co atoms. The element and site-specific hysteresis loops confirm the improvement of the magnetic order and crystallinity in these materials. The environment of Co2+ has been found to be effective in influencing the magnetic anisotropies of CoFe2O4 nanoparticles.163

The orbital magnetic moment of Fe and Cr ions in Li0.5FeCr1.5O4 spinel ferrite was found to be dominant due to the strong spin–orbit coupling and partially filled t2g orbitals.164 The antiferromagnetically-coupled Fe and Cr ions in Li0.5FeCr1.5O4 occupy the tetrahedral and octahedral sites, respectively. XMCD measurements were carried out on NiFe2−xRxO4 ® = Gd, Dy) nanoparticles to understand the cationic ordering and the element-specific magnetic moment.165 The spin and orbital moments of the Ni-L, Fe–L, Gd-M, and Dy-M absorption edge with the net magnetic moment of pure and doped NiFe2O4 have been calculated using the sum rules. Both the spin and orbital magnetic moments were reduced in Gd- and Dy-doped NiFe2O4 compared to pristine NiFe2O4. A summary of XMCD measurements on nanoparticles with experimental parameters is listed in Table XII.

XMCD Studies on Ferrite Thin Films

XMCD studies were carried out on ferrite thin films to understand the element-specific magnetic moments with their spin and orbital components. Spinel ferrite ZnFe2O4 thin films show a ferrimagnetic nature, with the Curie temperature above room temperature, having different cation distribution and oxygen vacancies.13 Surface magnetic properties and element-specific hysteresis loop were studied in ZnFe2O4 thin films (Fig. 7).166 The results show that the Fe3+ at octahedral and tetrahedral sites are antiferromagnetically coupled. The magnetic moment of Fe3+ at octahedral sites is aligned along the applied magnetic field.

XMCD studies on inverse spinel NiFe2O4 thin films were carried out to show the cation distribution.102 Measurements on Fe L2,3 edge have revealed the spin magnetic moment of 0.1 μB per atom and the ratio of orbital and spin magnetic moment of 0.12. The cation distribution in Fe2+ Oh, and Ni2+ Td played an important role in determining the magnetic anisotropy and damping in Zn/Al-doped NiFe2O4.103 The XMCD studies at Fe and Mn L2,3 edges of MnFe2O4 (111) thin films confirm the normal spinal structure where tetrahedral sites are occupied by Mn atoms.167 MgFe2O4 thin films showed one positive and one negative peak in the Fe L2,3 edge XMCD signal.168 The positive and negative peaks corresponded to the Fe3+ ions at the A and B sites, respectively. The role of iron content in magnetic damping of Mg(Al, Fe)2O4 spinel ferrite thin films was reported by Wisser et al.118 In this report, the XMCD result confirms the magnetic moment originating predominantly from Fe3+ cations distributed at the cathedral and tetrahedral sites with a ratio of 60:40. However, Fe2+ cations showed a minimal contribution to the magnetic moment. XMCD studies on MgAl0.5Fe1.5O4 spinel ferrite using total electron yield mode shows peaks at 709.2 eV and 710.0 eV.169 These peaks indicate the Fe3+ is coordinated tetrahedrally and octahedrally, respectively, with a saturation magnetization of 1.5 μB per formula unit. However, Fe3+ Oh and Fe3+ Td align parallel and antiparallel to the magnetic field, respectively. To find the Fe cation distribution in Ni0.65Zn0.35Al0.8Fe1.2O4 thin films, XMCD spectra on Fe L2,3 edge were collected.170 The weight ratio of the three components associated with Fe2+ Oh, Fe3+ Td, and Fe3+ Oh cations was 10:46:44. The XMCD spectra of the Ni L2,3 and Fe L2,3 edges confirmed that the moments of the Ni2+ Oh, and Fe2+/3+ Oh ions were parallel to the applied magnetic field. Using the sum rule, the spin and orbital magnetic moments have been calculated for Co and Fe ions in Co-rich cobalt ferrites.171 The XMCD results reveal the partial inverse spinal structures in CoxFe3−xO4 (x = 1.1, 1.4) due to the presence of Co3+ cations in a low spin state at octahedral B sites. A summary of XMCD measurements on thin films is listed in Table XIII.

Mössbauer Spectroscopy

This technique is widely used to find the cation distribution in ferrites, relying on the radioactive57 Fe present in the materials.57The Fe nucleus, which emits γ-rays, faces a recoil with an equal and opposite momentum. This is described by the equation,

, where Eγ-ray = energy of the γ-ray, Ent = energy of the nuclear transition, and ER = energy of the recoil. The process when the nucleus absorbs the energy of the γ-ray without recoiling forms the basis of Mössbauer spectroscopy. The Mössbauer effect occurs because of recoil-free absorption. The transmission spectra show isomer shift when the nuclear energy levels of the source and absorber atoms are different. In the case of nuclear quadrupole moment, the transmission spectrum is split into doublets. In the presence of a magnetic field, a sextet pattern appears due to the Zeeman effect. The sextet appears due to 6 nuclear transitions which are allowed by the magnetic dipole selection rule Δm = 0 ± 1. The ratio of the relative intensities of these peaks is 3:2:1:1:2:3 for a sample with isotopic magnetic field distribution. Thus, three parameters obtained from these measurements are isomer shift, quadrupole splitting, and hyperfine splitting (Fig. 8).

In the case of ferrites, the double sextet is observed to have Fe at both the tetrahedral and octahedral sites. For example, the general formula of nickel-zinc ferrite is (Zn21−λFe3+λ)[Ni2+λFe3+2−λ]{O2−}4 , where the round and square brackets denote the tetrahedral and octahedral sites, respectively. The degree of inversion, λ, is calculated from the Mössbauer spectral intensities

for bulk and nanosized Ni0.58Zn0.42Fe2O4,8 where \(\frac{{f}_{A}}{{f}_{B}}\) = 1 at 5 K and \(\frac{{f}_{A}}{{f}_{B}}\) = 0.94 at room temperature.173 The degree of inversion is found to be 0.58 at both low temperature and room temperature. The structure will be normal spinel for λ = 0 and inverse spinel for λ = 1. High-energy milling-synthesized MgFe2O4 nanoparticles exhibit superparamagnetism at low temperatures.28 The degree of inversion decreases from λ = 0.904(1) to λ = 0.856(3) and λ = 0.756(1) for MgFe2O4 with increasing milling time of 15 and 30 min, respectively. This result confirms the importance of synthesis parameters on the cation inversion of ferrites. The degree of inversion of bulk and nanosized particles of CuFe2O4, MnFe2O4, and NiFe2O4 show the dependency on particle size distribution. As the particle size decreases, the degree of inversion decreases in CuFe2O4 and NiFe2O4 , whereas it increases for MnFe2O4.15 Mössbauer's studies on NiFe2−xCrxO4 ferrite suggest that Cr3+ and Ni2+ have a strong preference for octahedral sites and Cr3+ prefers to substitute Fe3+.16 So the cation distribution studies on NiFe2−xCrxO4 confirm the conversion of inverse spinel to a normal spinel structure by increasing the Cr content in NiFe2O4. Similar structural changes have been observed in the case of CoFe2−xCexO4 ferrites with increasing the content of Ce.17 Mössbauer spectroscopy confirms the occupancy of Ni2+ at the octahedral sites in solid-state-synthesized NixMg1−xFe2O4 ferrite.174 This reduces the availability of octahedral sites for both Mg2+ and Fe3+. So a higher percentage of Mg2+ is found at tetrahedral sites for Ni-rich spinel systems. Hence, Mössbauer spectroscopy plays an important role in finding out the cation occupancies at tetrahedral and octahedral sites in a spinel system. However, this method is based on sensing 57Fe which is only 2% of Fe in a system. Thus, the signals that come from the measurements are in most cases low, which is the major drawback of this technique.

X-ray Absorption Spectroscopy (XAS)

The x-ray absorption near-edge structure (XANES) and extended x-ray absorption fine structure (EXAFS) are powerful techniques for studying cation distribution in ferrites.18,175,176 XANES provides information about the oxidation states and site symmetry of the elements, whereas EXAFS gives information about the coordination number and bond length of the surrounding shells. These techniques are element-selective, and their ability to find the local structure surrounding the selective elements makes them an ideal tool for studying disorder systems. In the case of ferrites, the local structure of both Fe3+ and M2+ edges can be studied using these techniques. On the other hand, this technique does not provide information regarding the magnetic behavior of the elements.

In the EXAFS signal, the peak observed around 2 Å corresponds to the metal–oxygen bond distance (Fig. 9).9 On the other hand, the peaks observed between 2.5 and 4 Å correspond to the metal–metal distance, which is crucial for determining the degree of inversion for a spinel ferrite. The distances between two metals having octahedral and tetrahedral sites are approximately 3 and 3.5 Å, respectively. For a normal spinel, M2+ ions occupy the tetrahedral site, while, for an inverse spinel, M2+ ions occupy the octahedral site. In the case of the M K-edge EXAFS signal, the normal spinel shows a strong peak at 3.5 Å, whereas an inverse spinel shows a strong peak at 3 Å. The peak intensity at 3.5 Å decreases and the peak intensity at 3 Å increases going from a normal spinel to an inverse spinel structure. In the case of Fe K-edge EXAFS signals, the region between 2.5 and 4 Å will be affected similarly to the M K-edge. Although the changes in peak intensities are minimum going from normal spinel to inverse spinel because of the presence of Fe3+ at both tetrahedral and octahedral sites. The occupancy of M2+ ions at octahedral sites is specified by \({x}_{B}\) (M2+), known as the inversion parameter. Thus, the occupancy of M2+ ions at the tetrahedral site is \({x}_{A}=1-{x}_{B}\). Fitting the outer shells of the EXAFS signals with a metal–metal interaction gives information regarding the coordination number and bond distance. The degree of inversion is determined by fitting the EXAFS signals originating due to the tetrahedral and octahedral sites occupied by Fe3+ and M2+. In MnFe2O4, the degree of inversion is found to be 0.2, meaning that 20% of Mn2+ occupies the octahedral sites.19 The degree of inversion in MnFe2O4 varies with different synthesis methods.177 It also depends on the particle size distribution, which demonstrates the importance of various synthesis procedures.20 CoFe2O4 is a partially inverted spinel ferrite with a degree of inversion from 0.68 to 0.8.18 NiFe2O4 is known as an inverted spinel ferrite, whereas NiFe2O4 nanoparticles prepared by high-energy ball-milling show a mixed spinel structure.178

Conclusions

We have demonstrated the role of cation occupancies to define the structure of ferrite materials and their magnetic properties. Since the cation occupancies are predominantly dependent on the synthesis methods, various such methods have been described for preparing ferrite nanoparticles and thin films. The changes of the different physical properties in ferrites with cation occupancies and synthesis methods are also described. A summary between these techniques and the cation distribution in ferrite nanoparticles and thin films is presented. To further study the cation occupancies and magnetic properties of these ferrites, the basic principles and applications of the XMCD technique are illustrated. Other techniques, such as Mössbauer spectroscopy and x-ray absorption spectroscopy, are discussed in order to find the cation distribution in ferrites. The advantages and disadvantages of these techniques are reported, and a comparison is made in determining the cation occupancies.

References

T. Kiyomura, Y. Maruo, and M. Gomi, Electrical properties of MgO insulating layers in spin-dependent tunneling junctions using Fe3O4. J. Appl. Phys. 88, 4768–4771 (2000).

X. Sui and M.H. Kryder, Magnetic easy axis randomly in-plane oriented barium hexaferrite thin film media. Appl. Phys. Lett. 63, 1582–1584 (1993).

B.Y. Wong, X. Sui, D.E. Laughlin, and M.H. Kryder, Microstructural investigations of barium ferrite longitudinal thin-film media. J. Appl. Phys. 75, 5966–5968 (1994).

A. Lak, S. Disch, and P. Bender, Embracing defects and disorder in magnetic nanoparticles. Adv. Sci. 8, 2002682 (2021).

X. Zeng, Z. Hou, J. Ju, L. Gao, J. Zhang, and Y. Peng, The cation distributions of Zn-doped normal spinel MgFe2O4 ferrite and its magnetic properties. Materials 15, 2422 (2022).

J. Stöhr, H.A. Padmore, S. Anders, T. Stammler, and M.R. Scheinfein, Principles of x-ray magnetic dichroism spectromicroscopy. Surf. Rev. Lett. 05, 1297–1308 (1998).

T. Abbas, Y. Khan, M. Ahmad, and S. Anwar, X-ray diffraction study of the cation distribution in the Mn-Zn-ferrites. Solid State Commun. 82, 701–703 (1992).

S. Thakur, S.C. Katyal, A. Gupta, V.R. Reddy, S.K. Sharma, M. Knobel, and M. Singh, Nickel−Zinc ferrite from reverse micelle process: structural and magnetic properties, Mössbauer spectroscopy characterization. J. Phys. Chem. C 113, 20785–20794 (2009).

D. Carta, M.F. Casula, A. Falqui, D. Loche, G. Mountjoy, C. Sangregorio, and A. Corrias, A structural and magnetic investigation of the inversion degree in ferrite nanocrystals MFe2O4 (M = Mn Co, Ni). J. Phys. Chem. C 113, 8606–8615 (2009).

H. Suzuki, N. Tokitoh, R. Okazaki, S. Nagase, and M. Goto, Synthesis, structure, and reactivity of the first kinetically stabilized silanethione. J. Am. Chem. Soc. 120, 11096–11105 (1998).

E. Bartolomé, P. Cayado, E. Solano, S. Ricart, J. Gázquez, B. Mundet, M. Coll, T. Puig, X. Obradors, M. Valvidares, J. Herrero-Martín, P. Gargiani, and E. Pellegrin, Magnetic stability against calcining of microwave-synthesized CoFe2O4 nanoparticles. New J. Chem. 40, 6890–6898 (2016).

C. Moya, A. Fraile Rodríguez, M. Escoda-Torroella, M. García del Muro, S.R.V. Avula, C. Piamonteze, X. Batlle, and A. Labarta, Crucial role of the Co cations on the destabilization of the ferrimagnetic alignment in Co-ferrite nanoparticles with tunable structural defects. J. Phys. Chem. C 125, 691–701 (2021).

C.E. Rodríguez Torres, G.A. Pasquevich, P.M. Zélis, F. Golmar, S.P. Heluani, S.K. Nayak, W.A. Adeagbo, W. Hergert, M. Hoffmann, A. Ernst, P. Esquinazi, and S.J. Stewart, Oxygen-vacancy-induced local ferromagnetism as a driving mechanism in enhancing the magnetic response of ferrites. Phys. Rev. B 89, 104411 (2014).

J.P. Chen, C.M. Sorensen, K.J. Klabunde, G.C. Hadjipanayis, E. Devlin, and A. Kostikas, Size-dependent magnetic properties of MnFe2O4 fine particles synthesized by coprecipitation. Phys. Rev. B 54, 9288–9296 (1996).

M. Siddique, and N.M. Butt, Effect of particle size on degree of inversion in ferrites investigated by Mössbauer spectroscopy. Physica B 405, 4211–4215 (2010).

S.M. Patange, S.E. Shirsath, S.S. Jadhav, and K.M. Jadhav, Cation distribution study of nanocrystalline NiFe2−xCrxO4 ferrite by XRD, magnetization and Mössbauer spectroscopy. Phys. Status Solidi (A) 209, 347–352 (2012).

A. Hashhash, I. Bobrikov, M. Yehia, M. Kaiser, and E. Uyanga, Neutron diffraction and Mössbauer spectroscopy studies for Ce doped CoFe2O4 nanoparticles. J. Magn. Magn. Mater. 503, 166624 (2020).

D. Carta, G. Mountjoy, G. Navarra, M.F. Casula, D. Loche, S. Marras, and A. Corrias, X-ray absorption investigation of the formation of Cobalt ferrite nanoparticles in an aerogel silica matrix. J. Phys. Chem. C 111, 6308–6317 (2007).

F.W. Harrison, W.P. Osmond, and R.W. Teale, Cation distribution and magnetic moment of manganese ferrite. Phys. Rev. 106, 865–866 (1957).

M.H. Mahmoud, H.H. Hamdeh, A.I. Abdel-Mageed, A.M. Abdallah, and M.K. Fayek, Effect of HEBM on the cation distribution of Mn-ferrite. Physica B 291, 49–53 (2000).

C. Liu, Y. Li, T. Shi, Q. Peng, and F. Gao, Oxygen defects stabilize the crystal structure of MgAl2O4 spinel under irradiation. J. Nucl. Mater. 527, 151830 (2019).

D.S. Mathew, and R.-S. Juang, An overview of the structure and magnetism of spinel ferrite nanoparticles and their synthesis in micro-emulsions. Chem. Eng. J. 129, 51–65 (2007).

T.F. Marinca, I. Chicinaş, O. Isnard, V. Pop, and F. Popa, Synthesis, structural and magnetic characterization of nanocrystalline nickel ferrite—NiFe2O4 obtained by reactive milling. J. Alloy. Compd. 509, 7931–7936 (2011).

T.F. Marinca, I. Chicinaş, and O. Isnard, Synthesis, structural and magnetic characterization of nanocrystalline CuFe2O4 as obtained by a combined method reactive milling, heat treatment and ball milling. Ceram. Int. 38, 1951–1957 (2012).

Y. Todaka, M. Nakamura, S. Hattori, K. Tsuchiya, and M. Umemoto, Synthesis of ferrite nanoparticles by mechanochemical processing using a ball mill. Mater. Trans. 44, 277–284 (2003).

D. Chen, and Y. Zhang, Synthesis of NiFe2O4 nanoparticles by a low temperature microwave-assisted ball milling technique. Sci. China Technol. Sci. 55, 1535–1538 (2012).

M.A. Cobos, P. de la Presa, I. Llorente, A. García-Escorial, A. Hernando, and J.A. Jiménez, Effect of preparation methods on magnetic properties of stoichiometric zinc ferrite. J. Alloy. Compd. 849, 156353 (2020).

V. Šepelák, and K.D. Becker, Comparison of the cation inversion parameter of the nanoscale milled spinel ferrites with that of the quenched bulk materials. Mater. Sci. Eng., A 375–377, 861–864 (2004).

R.S. Yadav, I. Kuřitka, J. Vilcakova, J. Havlica, L. Kalina, P. Urbánek, M. Machovsky, D. Skoda, M. Masař, and M. Holek, Sonochemical synthesis of Gd3+ doped CoFe2O4 spinel ferrite nanoparticles and its physical properties. Ultrason. Sonochem. 40, 773–783 (2018).

R. Singh Yadav, I. Kuřitka, J. Vilcakova, T. Jamatia, M. Machovsky, D. Skoda, P. Urbánek, M. Masař, M. Urbánek, L. Kalina, and J. Havlica, Impact of sonochemical synthesis condition on the structural and physical properties of MnFe2O4 spinel ferrite nanoparticles. Ultrason. Sonochem. 61, 104839 (2020).

P.P. Goswami, H.A. Choudhury, S. Chakma, and V.S. Moholkar, Sonochemical synthesis of cobalt ferrite nanoparticles. Int. J. Chem. Eng. 2013, 934234 (2013).

M. Sivakumar, A. Towata, K. Yasui, T. Tuziuti, T. Kozuka, Y. Iida, M.M. Maiorov, E. Blums, D. Bhattacharya, N. Sivakumar, and M. Ashok, Ultrasonic cavitation induced water in vegetable oil emulsion droplets – a simple and easy technique to synthesize manganese zinc ferrite nanocrystals with improved magnetization. Ultrason. Sonochem. 19, 652–658 (2012).

A.R. Abbasian, S.S. Hosseini, M. Shayesteh, M. Shafiee, and M. Rafigh Esmaeilzaei, Ultrasonic-assisted solvothermal synthesis of self-assembled copper ferrite nanoparticles. Int. J. Nano Dimens. 11, 130–144 (2020).

M.A.S. Amulya, H.P. Nagaswarupa, M.R.A. Kumar, C.R. Ravikumar, and K.B. Kusuma, Enhanced photocatalytic and electrochemical properties of Cu doped NiMnFe2O4 nanoparticles synthesized via probe sonication method. Appl. Surf. Sci. Adv. 2, 100038 (2020).

P.P. Goswami, H.A. Choudhury, S. Chakma, and V.S. Moholkar, Sonochemical synthesis and characterization of Manganese Ferrite nanoparticles. Ind. Eng. Chem. Res. 52, 17848–17855 (2013).

H.A. Choudhury, A. Choudhary, M. Sivakumar, and V.S. Moholkar, Mechanistic investigation of the sonochemical synthesis of zinc ferrite. Ultrason. Sonochem. 20, 294–302 (2013).

Y.X. Gan, A.H. Jayatissa, Z. Yu, X. Chen, and M. Li, Hydrothermal synthesis of nanomaterials. J. Nanomater. 2020, 8917013 (2020).

D. Ni, Z. Lin, P. Xiaoling, W. Xinqing, and G. Hongliang, Preparation and characterization of Nickel-Zinc Ferrites by a solvothermal method. Rare Metal Mater. Eng. 44, 2126–2131 (2015).

Z. Li, K. Gao, G. Han, R. Wang, H. Li, X. Zhao, and P. Guo, Solvothermal synthesis of MnFe2O4 colloidal nanocrystal assemblies and their magnetic and electrocatalytic properties. New J. Chem. 39, 361–368 (2015).

Y. Yin, W. Liu, N. Huo, and S. Yang, Synthesis of vesicle-like MgFe2O4/Graphene 3D network anode material with enhanced lithium storage performance. ACS Sustain. Chem. Eng. 5, 563–570 (2017).

Y. Tang, X. Wang, Q. Zhang, Y. Li, and H. Wang, Solvothermal synthesis of Co1−xNixFe2O4 nanoparticles and its application in ammonia vapors detection. Progr. Nat. Sci. Mater. Int. 22, 53–58 (2012).

G. Allaedini, S.M. Tasirin, and P. Aminayi, Magnetic properties of cobalt ferrite synthesized by hydrothermal method. Int. Nano Lett. 5, 183–186 (2015).

S. Yáñez-Vilar, M. Sánchez-Andújar, C. Gómez-Aguirre, J. Mira, M.A. Señarís-Rodríguez, and S. Castro-García, A simple solvothermal synthesis of MFe2O4 (M=Mn, Co and Ni) nanoparticles. J. Solid State Chem. 182, 2685–2690 (2009).

M. Su, C. He, and K. Shih, Facile synthesis of morphology and size-controlled α-Fe2O3 and Fe3O4 nano-and microstructures by hydrothermal/solvothermal process: the roles of reaction medium and urea dose. Ceram. Int. 42, 14793–14804 (2016).

J. Ma, B. Chen, B. Chen, and S. Zhang, Preparation of superparamagnetic ZnFe2O4 submicrospheres via a solvothermal method. Adv. Nano Res. 5, 171–178 (2017).

T. Yao, Y. Qi, Y. Mei, Y. Yang, R. Aleisa, X. Tong, and J. Wu, One-step preparation of reduced graphene oxide aerogel loaded with mesoporous copper ferrite nanocubes: a highly efficient catalyst in microwave-assisted Fenton reaction. J. Hazard. Mater. 378, 120712 (2019).

M.A. Aswad, F.A.H. Mutlak, M.S. Jabir, S.K. Abdulridha, A.F. Ahmed, and U.M. Nayef, Laser assisted hydrothermal synthesis of magnetic ferrite nanoparticles for biomedical applications. J. Phys: Conf. Ser. 1795, 012030 (2021).

B.J. Palla, D. Shah, P.E. Garcia Casillas, and J.A. Matutes-Aquino, Preparation of nanoparticles of barium ferrite from precipitation in micro-emulsions. J. Nanopart. Res. 1, 215–221 (1999).

Z. Gilani, M. Anjum, M.S. Shifa, H. Ul, H. Asghar, J. Rehman, M. Usmani, S. Aslam, A. Khan, and M. Warsi, Morphological and magnetic behavior of neodymium doped LiNi05Fe2O4 nanocrystalline ferrites prepared via micro-emulsion technique. Digest J. Nanomater. Biostruct. 12, 223–228 (2017).

K. Pemartin, C. Solans, J. Alvarez-Quintana, and M. Sanchez-Dominguez, Synthesis of Mn–Zn ferrite nanoparticles by the oil-in-water micro-emulsion reaction method. Colloids Surf., A 451, 161–171 (2014).

R. Ali, M.A. Khan, A. Mahmood, A.H. Chughtai, A. Sultan, M. Shahid, M. Ishaq, and M.F. Warsi, Structural, magnetic and dielectric behavior of Mg1−xCaxNiyFe2−yO4 nano-ferrites synthesized by the micro-emulsion method. Ceram. Int. 40, 3841–3846 (2014).

R. Ali, M. Azhar Khan, A. Manzoor, M. Shahid, and M. Farooq Warsi, Structural and electromagnetic characterization of Co-Mn doped Ni-Sn ferrites fabricated via micro-emulsion route. J. Magn. Magn. Mater. 441, 578–584 (2017).

R. Ali, A. Mahmood, M.A. Khan, A.H. Chughtai, M. Shahid, I. Shakir, and M.F. Warsi, Impacts of Ni–Co substitution on the structural, magnetic and dielectric properties of magnesium nano-ferrites fabricated by micro-emulsion method. J. Alloy. Compd. 584, 363–368 (2014).

M.A. Yousuf, S. Jabeen, M.N. Shahi, M.A. Khan, I. Shakir, and M.F. Warsi, Magnetic and electrical properties of yttrium substituted manganese ferrite nanoparticles prepared via micro-emulsion route. Res. Phys. 16, 102973 (2020).

M.A. Yousuf, M.M. Baig, M. Waseem, S. Haider, I. Shakir, S. Ud-Din Khan, and M.F. Warsi, Low cost micro-emulsion route synthesis of Cr-substituted MnFe2O4 nanoparticles. Ceram. Int. 45, 22316–22323 (2019).

K. Ganure, L. Dhale, V. Tukaram, and K. Lohar, Synthesis and characterization of Lanthanum-doped Ni-Co-Zn spinel ferrites nanoparticles via normal micro-emulsion method. Int. J. Nanotechnol. Appl. 11, 189–195 (2017).

S. Sagadevan, Z.Z. Chowdhury, and R.F. Rafique, Preparation and characterization of Nickel ferrite nanoparticles via co-precipitation method. Mater. Res. 21, e20160533 (2018).

Y. Peng, C. Xia, M. Cui, Z. Yao, and X. Yi, Effect of reaction condition on microstructure and properties of (NiCuZn)Fe2O4 nanoparticles synthesized via co-precipitation with ultrasonic irradiation. Ultrason. Sonochem. 71, 105369 (2021).

K. Islam, M. Haque, A. Kumar, A. Hoq, F. Hyder, and S.M. Hoque, Manganese ferrite nanoparticles (MnFe2O4): Size dependence for hyperthermia and negative/positive contrast enhancement in MRI. Nanomaterials 10, 2297 (2020).

M.S.A. Darwish, H. Kim, H. Lee, C. Ryu, J.Y. Lee, and J. Yoon, Synthesis of magnetic ferrite nanoparticles with high hyperthermia performance via a controlled co-precipitation method. Nanomaterials 9, 1176 (2019).

H. El Moussaoui, T. Mahfoud, S. Habouti, K. El Maalam, M. Ben Ali, M. Hamedoun, O. Mounkachi, R. Masrour, E.K. Hlil, and A. Benyoussef, Synthesis and magnetic properties of tin spinel ferrites doped manganese. J. Magn. Magn. Mater. 405, 181–186 (2016).

R.T. Olsson, G. Salazar-Alvarez, M.S. Hedenqvist, U.W. Gedde, F. Lindberg, and S.J. Savage, Controlled synthesis of near-stoichiometric cobalt ferrite nanoparticles. Chem. Mater. 17, 5109–5118 (2005).

C. Pereira, A.M. Pereira, C. Fernandes, M. Rocha, R. Mendes, M.P. Fernández-García, A. Guedes, P.B. Tavares, J.-M. Grenèche, J.P. Araújo, and C. Freire, Superparamagnetic MFe2O4 (M = Fe Co, Mn) nanoparticles: Tuning the particle size and magnetic properties through a novel one-step coprecipitation route. Chem. Mater. 24, 1496–1504 (2012).

A. Tadjarodi, M. Imani, and M. Salehi, ZnFe2O4 nanoparticles and a clay encapsulated ZnFe2O4 nanocomposite: synthesis strategy, structural characteristics and the adsorption of dye pollutants in water. RSC Adv. 5, 56145–56156 (2015).

S.K. Jesudoss, J.J. Vijaya, L.J. Kennedy, P.I. Rajan, H.A. Al-Lohedan, R.J. Ramalingam, K. Kaviyarasu, and M. Bououdina, Studies on the efficient dual performance of Mn1–xNixFe2O4 spinel nanoparticles in photodegradation and antibacterial activity. J. Photochem. Photobiol. B 165, 121–132 (2016).

M. Venkatesh, G.S. Kumar, S. Viji, S. Karthi, and E.K. Girija, Microwave assisted combustion synthesis and characterization of nickel ferrite nanoplatelets. Modern Electron. Mater. 2, 74–78 (2016).

Kozakova, Z.; Kuřitka, I.; Bazant, P.; Machovsky, M.; Pastorek, M.; Babayan, V.; Ltd, T, Simple and effective preparation of cobalt ferrite nanoparticles by microwave-assisted solvothermal method. In: Nanocon 2012, 4th international conference, Brno, Czech Republic, EU, 01/01; Brno, Czech Republic, EU, 2012; pp 763-766

M. Giridhar, H.S.B. Naik, C.N. Sudhamani, M.C. Prabakara, R. Kenchappa, N. Venugopal, and S. Patil, Microwave-assisted synthesis of water-soluble styrylpyridine dye-capped zinc oxide nanoparticles for antibacterial applications. J. Chin. Chem. Soc. 67, 316–323 (2020).

S.-H. Yu, Q.-L. Wang, Y. Chen, Y. Wang, and J.-H. Wang, Microwave-assisted synthesis of spinel ferrite nanospherolites. Mater. Lett. 278, 128431 (2020).

S. Shirsath, D. Wang, S. Jadhav, M. Mane, and S. Li, Ferrites obtained by sol-gel method, Handbook of Sol-Gel Science and Technology. ed. L. Klein, M. Aparicio, and A. Jitianu (Cham: Springer, 2018), pp. 695–735.

L. Zhang, and Y. Wu, Sol-gel synthesized magnetic MnFe2O4 spinel ferrite nanoparticles as novel catalyst for oxidative degradation of methyl orange. J. Nanomater. 2013, 640940 (2013).

A. Gatelytė, D. Jasaitis, A. Beganskienė, and A. Kareiva, Sol-gel synthesis and characterization of selected transition metal nano-ferrites. Mater. Sci. (2011). https://doi.org/10.5755/j01.ms.17.3.598.

S.A. Rashdan, and L.J. Hazeem, Synthesis of spinel ferrites nanoparticles and investigating their effect on the growth of microalgae Picochlorum sp. Arab. J. Basic Appl. Sci. 27, 134–141 (2020).

R.S. Yadav, I. Kuřitka, J. Vilcakova, J. Havlica, J. Masilko, L. Kalina, J. Tkacz, V. Enev, and M. Hajdúchová, Structural, magnetic, dielectric, and electrical properties of NiFe2O4 spinel ferrite nanoparticles prepared by honey-mediated sol-gel combustion. J. Phys. Chem. Solids 107, 150–161 (2017).

R.S. Yadav, I. Kuřitka, J. Vilcakova, P. Urbánek, M. Machovsky, M. Masař, and M. Holek, Structural, magnetic, optical, dielectric, electrical and modulus spectroscopic characteristics of ZnFe2O4 spinel ferrite nanoparticles synthesized via honey-mediated sol-gel combustion method. J. Phys. Chem. Solids 110, 87–99 (2017).

K. Jalaiah, and K. Vijaya Babu, Structural, magnetic and electrical properties of nickel doped Mn-Zn spinel ferrite synthesized by sol-gel method. J. Magn. Magn. Mater. 423, 275–280 (2017).

R.S. Yadav, J. Havlica, M. Hnatko, P. Šajgalík, C. Alexander, M. Palou, E. Bartoníčková, M. Boháč, F. Frajkorová, J. Masilko, M. Zmrzlý, L. Kalina, M. Hajdúchová, and V. Enev, Magnetic properties of Co1−xZnxFe2O4 spinel ferrite nanoparticles synthesized by starch-assisted sol–gel autocombustion method and its ball milling. J. Magn. Magn. Mater. 378, 190–199 (2015).

D.H. Bobade, S.M. Rathod, and M.L. Mane, Sol–gel auto-combustion synthesis, structural and enhanced magnetic properties of Ni2+ substituted nanocrystalline Mg–Zn spinel ferrite. Physica B 407, 3700–3704 (2012).

K.M. Muniba, A.D. Chandio, M.S. Akhtar, J.K. Khan, G. Mustafa, N.U. Channa, Z.A. Gilani, and H.M. Asghar, Aluminum substitution in Ni-Co based spinel ferrite nanoparticles by sol–gel auto-combustion method. J. Electron. Mater. 50, 3302–3311 (2021).

S. Jauhar, J. Kaur, A. Goyal, and S. Singhal, Tuning the properties of cobalt ferrite: a road towards diverse applications. RSC Adv. 6, 97694–97719 (2016).

M. Gu, B. Yue, R. Bao, and H. He, Template synthesis of magnetic one-dimensional nanostructured spinel MFe2O4 (M=Ni, Mg, Co). Mater. Res. Bull. 44, 1422–1427 (2009).

M. Sultan, and R. Singh, Magnetic and optical properties of rf-sputtered zinc ferrite thin films. J. Appl. Phys. 105, 07A512 (2009).

Y.-C. Liang, and H.-Y. Hsia, Growth and crystallographic feature-dependent characterization of spinel zinc ferrite thin films by RF sputtering. Nanoscale Res. Lett. 8, 537 (2013).

S. Nakashima, K. Fujita, K. Tanaka, and K. Hirao, High magnetization and the high-temperature superparamagnetic transition with intercluster interaction in disordered zinc ferrite thin film. J. Phys.: Condens. Matter 17, 137–149 (2004).

M. Bohra, S. Prasad, N. Kumar, D.S. Misra, S.C. Sahoo, N. Venkataramani, and R. Krishnan, Large room temperature magnetization in nanocrystalline zinc ferrite thin films. Appl. Phys. Lett. 88, 262506 (2006).

T. Niizeki, T. Kikkawa, K.-I. Uchida, M. Oka, K.Z. Suzuki, H. Yanagihara, E. Kita, and E. Saitoh, Observation of longitudinal spin-Seebeck effect in cobalt-ferrite epitaxial thin films. AIP Adv. 5, 053603 (2015).

H. Yanagihara, Y. Utsumi, T. Niizeki, J. Inoue, and E. Kita, Perpendicular magnetic anisotropy in epitaxially strained cobalt-ferrite (001) thin films. J. Appl. Phys. 115, 17A719 (2014).

T. Niizeki, Y. Utsumi, R. Aoyama, H. Yanagihara, J.-I. Inoue, Y. Yamasaki, H. Nakao, K. Koike, and E. Kita, Extraordinarily large perpendicular magnetic anisotropy in epitaxially strained cobalt-ferrite CoxFe3−xO4 (001) (x = 0.75, 1.0) thin films. Appl. Phys. Lett. 103, 162407 (2013).