Abstract

The separation of rare earth elements (REEs) using solvent extraction adding complexing agents appears to be an alternative to saponification of the extractant. We evaluated the effect of lactic acid concentration on didymium (praseodymium and neodymium) and lanthanum extraction with 2-ethylhexyl phosphonic acid mono-2-ethyl hexyl ester [HEH(EHP)] as extractant. First, we investigated in batch experiments the separation of lanthanum (La) and didymium (Pr and Nd) using McCabe–Thiele diagrams to estimate the number of extraction stages when the feed solution was or was not conditioned with lactic acid. Additionally, we conducted continuous liquid–liquid extraction experiments and evaluated the influence of lactic acid concentration on the REE extraction and separation. The tests showed that the extraction percentage of REEs and the separation factor Pr/La increased when the lactic acid concentration increased, but the didymium purity decreased. Lanthanum, praseodymium, and neodymium extraction rate were 23.0, 89.7, and 99.2 pct, respectively, with 1:1 aqueous/organic volume flow rate and feed solution doped with 0.52 mol L−1 lactic acid. The highest didymium purity reached was 92.0 pct with 0.26 mol L−1 lactic acid concentration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rare earth is a term used to designate the lanthanides (series of chemical elements from lanthanum through lutetium), scandium and yttrium. There are a variety of rare earth minerals known, but the main minerals that are mined are monazite, bastnaesite, and xenotime. In Brazil, monazite is the most abundant mineral and consists mainly of light rare earth elements (LREEs). This group of LREEs comprises lanthanum, cerium, praseodymium, and neodymium. Separating this ensemble into individual elements is challenging because of the similarity of their chemical properties. Cerium (Ce) can be recovered by oxidation and selective precipitation with potassium permanganate and sodium carbonate while solvent extraction can be used to separate lanthanum (La) from both praseodymium (Pr) and neodymium (Nd).[1,2]

The rare earths have high demand in Brazil for use as constituents in several strategic materials, such as catalysts and magnets. The motivation of this study is to establish parameters for the development of more efficient processes for the separation of lanthanum and didymium (Pr and Nd). This is an issue that has been considered a priority in Brazil since 2010, when there was a large rise in export prices of Chinese rare earths.

Organophosphorus acid extractants, such as 2-ethylhexyl phosphonic acid mono-2-ethyl hexyl ester (HEH(EHP)) and di-2-ethylhexyl phosphoric acid (D2EHPA), are used to separate rare earth elements.[3] The hydrogen ions liberated during the solvent extraction is not beneficial for metal extraction. Bases such as NaOH and NH4OH are used to saponify the extract to overcome this problem and improve the extraction. Even though the saponification of the extractant improves the separation of REEs, this practice produces wastewater containing ammonia and/or sodium, both of which need be removed before discharge in the environment.[4,5]

The addition of complexing agents in the aqueous phase has been studied as a more sustainable alternative to improve the solvent extraction technique and facilitate the separation of REEs. Lactic, citric, and acetic acids are weak carboxylic acids that, when present in the aqueous feed solution, enhance the extraction of REEs.[6,7] Ying et al.[6] observed higher separation factors between light rare earth elements when lactic acid was present in the feed solution than when it was not, with the other conditions the same. Additionally, it was possible to recover the lactic acid from raffinate with tributyl phosphate (TBP) as extracting reagent. Recycled lactic acid can be used again in the extraction circuit, avoiding water contamination with organic matter. The conjugated base of hydroxy carboxylic acids acts as a pH buffer of the aqueous solution, avoiding drastic reduction of pH, and favoring extraction and separation of the REEs.[7]

Scal et al.[8] reported the effect of lactic acid addition as well as the feed solution pH variation along with the effect of aqueous/organic volume flow ratio on didymium separation from lanthanum by continuous liquid–liquid extraction experiments employing the extractant [HEH(EHP)]. When the lactic acid concentration and pH in the feed solution increased, the LREE extraction also increased. Their experiments also revealed that LREE extraction diminished when the A/O ratio increased. Yin et al.[9] studied the use of lactic acid and citric acid on the separation of adjacent rare earths such as cerium and praseodymium. The distribution coefficient of Ce and Pr and the Pr/Ce separation factor increased with the equilibrium pH and citric acid/lactic acid concentration ratio, with a maximum value of 5.78. The effect of acetic acid on separation of light rare earths was also studied by Chang et al.[7] The results showed that the separation factor of the LREEs and the extraction capacity increased with rising acetic acid concentration. When the feed pH value was 2.0, the REE/acetic acid concentration ratio was 1:1 and rare earth concentration was 0.35 mol L−1, while in the DEHPA–HCl–acetic acid system, the highest separation factors reached were βCe/La = 4.09, βPr/Ce = 1.96, and βNd/Pr = 1.53.

The smaller pKa value of the lactic acid (3.86) in comparison with the pKa value of the acetic acid (4.76) justified the use of the former in this study. The lower the pKa is, the higher the conjugated base concentration is, at a certain solution pH. The presence of conjugated base is necessary to form a buffer solution which must have an acid/base conjugate pair.

Most of the studies published on separation of REEs in the presence of complexing agents involve preliminary bench tests and do not include experiments in continuous regime. In the present study, we first investigated the extraction of REEs in batch tests and through the construction of a McCabe–Thiele diagram we defined the operation line and estimated the number of stages required in continuous liquid–liquid extraction of light rare earth elements. Additionally, continuous counter-current extraction experiments with HEH(EHP) as the extracting reagent were performed. The aim was to evaluate the influence of the lactic acid concentration variation on light rare earth element separation by continuous solvent extraction.

Experimental

Reagents

The extractant used to separate lanthanum from didymium was 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester (HEH(EHP)), provided by Aodachem (China). The diluent used was commercial kerosene (isoparaffin), provided by Ypiranga (Brazil).

The aqueous feed solution used in the extraction tests was a synthetic solution of La, Pr, and Nd with similar characteristics to a Brazilian monazite leachate (20.3 g L−1 of La2O3, 4.7 g L−1 of Pr6O11, 16.3 g L−1 of Nd2O3),[10] and the oxides (99.9 pct purity) were provided by Pacific Industrial Development Corporation. The total molar concentration of rare earth elements in the feed solution was 0.249 mol L−1. All other chemicals had analytical grade.

Batch Test (McCabe–Thiele Diagram)

HEH(EHP) at 0.6 mol L−1 was used in all extraction experiments. The pH of the aqueous phase was 3.5 and the lactic acid concentration was 0.52 mol L−1.[11]

The extractant and the feed solution were placed in contact during 15 minutes (initial experiments showed that equilibrium was achieved within 5 minutes). After mixing the phases, they were separated in a separatory funnel and the concentrations of rare earth metals in the aqueous phase were determined. The extraction experiments were performed at room temperature and in triplicate. The standard deviations of all variables were calculated.

The aqueous and organic volume ratio (A/O) varied from 1/12 to 4/1.

Continuous Counter-Current Extraction

After the definition of the number of extraction stages and the operation line, we conducted continuous extraction experiments in ten counter-current stages using mixer-settler extractors. The volumes of the mixing and settling chambers were 242 and 372 mL, respectively. We did not perform a scrubbing stage of the organic load. The concentration of lactic acid varied between 0 and 0.52 mol L−1. The organic and aqueous phases were the same used in batch experiments. All the experiments were conducted at room temperature and with feed solution at pH of 3.5. The aqueous and organic volumetric flow rates were both 30 mL min−1. The residence time in each stage at A/O 1:1 was 10.2 minutes.

We collected aqueous samples from each extraction cell for analysis. The pH level and REE concentration in the aqueous phase were measured. The samples were collected at three different intervals and standard deviations of all variables were calculated.

Chemical Analysis

We determined the Pr and Nd concentrations in aqueous phase by UV-Vis spectrophotometry (HACH DR 6000 spectrophotometer) (Limit of Quantification for Pr = 0.16 g L−1 and Nd = 0.15 g L−1) . The total REE concentration by complexometric titration with EDTA and xylenol orange as indicator. The La concentration was calculated by the difference between the total concentration of REEs and Pr + Nd concentrations.

Parameter Equations

We calculated the accumulated extraction (pct E M) of the REEs from Eq. [1], as well as the metal concentrations in the loaded organic phase (Eq. [2]). The total REE concentration in the organic phase is the sum of individual metal concentrations (Eq. [3]). The distribution ratio of each element (D) is the ratio of the concentration of metal in the organic phase and aqueous phase at equilibrium (Eq. [4]). The separation factor (β) indicates the degree of separation of two elements and was calculated from the distribution coefficient of two different metals (Eq. [5]). Finally, the didymium purity in the loaded organic phase and mass flow rate of each element were determined by Eqs. [6] and [7], respectively.

In these equations, [M]feed represents the REE concentration in the feed solution, [M]raffinate is the REE concentration in the output aqueous solution, [M]loaded(o) is the REE concentration in the loaded organic solution, [M] N(a) is the aqueous phase REE concentration in the Nth—cell, and [M]total(o) is total REE concentration in the organic phase. Also, A/O is the aqueous and organic phase’s volumetric flow ratio and \( \mathop {m_{i} }\limits^{.} \) is the REE mass flow rate.

Results and Discussion

Batch Experiments (McCabe–Thiele Diagram)

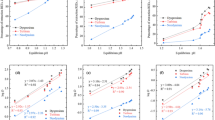

The McCabe–Thiele diagrams for the counter-current extraction of Pr and Nd from an aqueous solution of LREEs at pH 3.5 without adding lactic acid are shown in Figures 1 and 2. In the ten counter-current stages, raffinate was obtained containing 20.1 g L−1 La, 3.67 Pr g L−1, and 11.41 g L−1 Nd using an A/O ratio of 1:1 (Figure 3). The corresponding La, Pr, and Nd percentages of extraction were 1, 22, and 30 pct, respectively.

The McCabe–Thiele diagrams for the counter-current extraction of Pr and Nd from aqueous LREE solution containing lactic acid 0.52 mol L−1 are shown in Figures 4 and 5. The graphs show that ten counter-current stages are required to obtain raffinate containing 16.0 g L−1 La, 0.4 g L−1 Pr, and 0.7 g L−1 Nd using an A/O ratio of 1:1 (Figure 6). The corresponding La, Pr, and Nd percentages of extraction were 22, 92, and 96 pct, respectively. The presence of lactic acid greatly increased the extraction compared to the case without this acid.

Continuous Counter-Current Extraction Circuit

We investigated the influence of lactic acid concentration on the extraction and separation of didymium/lanthanum when the A/O ratio was 1:1. The preference for REE extractions was Nd > Pr > La and the accumulative extraction of the lanthanides increased when the lactic acid concentration rose. For example, the accumulative Nd extraction increased from 29.5 to 99.2 pct when the lactic acid concentration increased from 0 to 0.52 mol L−1 (Figure 7).

Lactic acid (HLa) is a weak acid that ionizes partially in water, and its pKa value is 3.86. At the pH of the feed solution (pH 3.5), lactic acid is 33 pct ionized and in the form of lactate ions (La−) (Eq. [8]). The organophosphorus acid extractant (H2A2) exchanged hydrogen ions with REE ions present in the aqueous phase (Eq. [9]). In the aqueous solution, the lactate ions combined with hydrogen ions released by the organic extractant (Eq. [10]). Thus, the lactate ions prevented acidity increase of the aqueous solution, improving the extraction and separation.

Increasing concentration of lactic acid augmented the values of β Pr/La, β Nd/Pr, REE concentration in the loaded organic, and mass flow rate (Table I). Nevertheless, the didymium purity declined. The increase in the extraction with rising lactic acid concentration is associated with higher equilibrium pH values of the aqueous solution. Lanthanum, praseodymium, and neodymium extraction rates were 23.0, 89.7, and 99.2 pct, respectively, with 1:1 aqueous/organic volume flow rate and 0.52 mol L−1 lactic acid. The highest didymium purity reached was 92.0 pct with 0.26 mol L−1 lactic acid concentration.

After the extraction step, a scrubbing of the loaded organic must be carried out with the purpose of removing the La element from the organic loaded. The loaded organic phase can be scrubbed again aiming the Pr and Nd separation using Nd acid solution as a scrubbing solution. The Nd contained in the scrubbing solution is exchanged with the Pr present in the loaded organic phase, resulting in an organic phase containing only Nd and a raffinate solution containing only Pr.

The scrubbing of lactic acid is not necessary because the lactic acid does not affect the didymium oxide purity (the final product). After the didymium chloride solution is obtained, the didymium oxalate is produced by the reaction between sodium oxalate and didymium chloride. Finally, the didymium oxide is obtained by calcination of didymium oxalate. In calcination process all the organic compounds are transformed in volatile compounds, i.e., carbon dioxide and water.

The equilibrium pH values of aqueous solution in the extraction cells were higher when the lactic acid concentration was greater. This behavior can be attributed to the buffer effect of the lactic acid, which keeps the acidity from rising (Figure 8). When the lactic acid concentration increased, the buffer capacity also did.

Conclusion

Based on the extraction isotherm, we defined an effective counter-current simulation study to determine the number of theoretical stages for lanthanum–didymium separation using HEH(EHP) as extractant and lactic acid as buffer. The results of this study indicate that lactic acid added in the aqueous feed at pH 3.5 greatly increases the extraction of LREEs (La, Pr, and Nd). When the A/O ratio was 1:1, extractions of 92 pct Pr and 96 pct Nd were achieved in ten theoretical stages of extraction.

The continuous liquid–liquid extraction experiments revealed that increasing the lactic acid concentration in the feed solution improved the overall extraction of LREEs and the separation factors between Pr and La and between Nd and Pr, but the didymium purity in the loaded organic phase first increased when the lactic acid concentration was between 0 and 0.26 mol L−1 and diminished when the lactic acid concentration exceeded 0.26 mol L−1. The presence of lactic acid caused a less pronounced reduction of pH of the aqueous phase, enhancing the extraction and separation of light rare earth elements. These experiments demonstrated that the use of lactic acid can be a viable alternative to the practice of saponification used in REE separation through solvent extraction techniques.

References

C.K. Gupta and N. Krishnamurthy: Extractive Metallurgy of Rare Earth. CRC Press., Boca Raton, Florida, 2005, pp. 172-75.

Carlos A. Morais and Virginia S.T Ciminelli. Hydrometallurgy, 2004, vol. 73, pp. 237-244.

G.M. Ritcey: Solvent Extraction. Principles and Applications to Process Metallurgy. G. M. Ritcey & Associates Incorporated, Ottawa, Canada, 2006, pp.

W. Wang, H.L. Yang, H.M. Cui, D.L Zhang, Y. Liu and J. Chen, Ind. Eng. Chem. Res., 2011, vol. 50, pp. 7534–7541.

S.H. Yin, S.W. Li, F. Xie, J.H. Peng and L.B. Zhang, RSC Adv, 2015, vol. 5, pp. 64550–64556.

S.H Yin, W. Wu, X. Bian, Y. Luo and F. Zhang, Ind. Eng. Chem. Res., 2013, vol. 52, pp. 8558–8564.

H. Chang, M. Li, Z. Liu, Y. Hu and F. Zhang, J. Rare Earths, 2010, vol. 28, pp. 116.

M.L.W. Scal, L.A. Seruff, Y.M. Vera, Technol. Metal. Mater. Miner., São Paulo, 2016, vol. 13, pp. 373-380.

S.H. Yin, S.W. Li, W.Y. Wu, X. Bian, J.H. Peng and L.B. Zhang, RSC Adv., 2014, vol. 4, pp. 59997-600001.

A.B. da Luz and F.F. Lins: Rochas & Minerais Industriais. Usos e Especificações, CETEM/MCT, Rio de Janeiro, RJ, 2005, pp. 629-654.

M.L.W. Scal, L.A. Seruff, and Y.M. Vera. 2015. Comparação entre a saponificação do extratante e a adição de ácido lático usados na separação de didímio de lantânio a partir da técnica de extração por solvente. XXVI Encontro Nacional de Tratamento de Minérios e Metalurgia Extrativa.

Acknowledgments

We acknowledge the Brazilian National Council for Scientific and Technological Development (CNPq).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 2, 2017.

Rights and permissions

About this article

Cite this article

de Carvalho Gomes, R., Seruff, L.A., Scal, M.L.W. et al. The Influence of Lactic Acid Concentration on the Separation of Light Rare Earth Elements by Continuous Liquid–Liquid Extraction with 2-Ethylhexyl Phosphonic Acid Mono-2-ethylhexyl Ester. Metall Mater Trans B 49, 460–465 (2018). https://doi.org/10.1007/s11663-017-1124-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1124-4