Abstract

In the present work, we have tried to study and develop the processing of amorphous BaTiO3 nanothin films, which have amorphous structure and nanometric thickness. It was seen that they exhibit enhanced optical responses. An improved method was used to prepare amorphous BaTiO3 nanothin films, which, compared to other approaches, is simple, cost-effective, and environmentally friendly. It was found that amorphous BaTiO3 films exhibit better optical transmittance in contrast to the similar nanocrystalline, polycrystalline, or thick films. This finding is due to the absence of grain boundaries, which have an important role in light scattering processes. AFM and SEM results indicate that the surface of the nanothin film is uniform, smooth, and amorphous. Moreover, the surface of the nanothin film exhibits a dense structure with no crack and voids. RMS roughness of the prepared nanothin film was quite small and equal to 0.7 nm. This value is very less than other reported RMS roughness values which were in the range of 5 to 11 nm. XRD results indicate that all of the prepared thin films in this work are amorphous, independent of number of dip-coated layers and preparation conditions. The work also aims to study and develop the processing of the amorphous BaTiO3 nanothin films deeply. The results showed that annealing temperature has a more pronounced effect on transmittance, thickness, and shift in the absorption edge of the thin films than annealing time. It was found that the viscosity of the sol has remarkable influence on the transmission spectrum and shift in the absorption edge of the films. The transparency of the films decreases with an increase in the viscosity and concentration of the sol. It was found that size of particle within the sol and rate of the sol–gel reactions have important roles on the transmittance of the films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Barium titanate (BaTiO3; BTO) is the most common perovskite ferroelectric material, which has been studied extensively because of its wide band gap and outstanding dielectric and ferroelectric properties.[1–3] Highly transparent, amorphous BTO nanothin films are of interest for a number of applications, including electro-optic switches, optical modulators, optical mixers, dielectric mirrors, solar power systems, and antireflective coatings. Recently, in an article entitled “Hybrid solar cells: Perovskites under the Sun” which has been published in the Nature Materials,[4] it has been shown that the thin films of the perovskite materials have potential applications in highly efficient and cheap solar cells. In order to apply BTO thin films to solar cells, the optical properties of BTO films under the illumination of ultraviolet–visible light should be studied.

Recently, researchers have been interested in studying the amorphous films. Moreover, nanocrystalline films are a topic of recent interest due to their optimized properties and performance. In the present work, we have tried to study and develop the processing of the amorphous nanothin films, which have amorphous structure and nanometric thickness. The properties of thin films are generally influenced by the preparation conditions such as deposition method, post-deposition annealing temperature, types of substrates, etc.[5,6] Moreover, surface morphology is one of the most important characteristics of thin films for optical device applications because a rough surface increases the light scattering and deteriorates the optical quality. Good control and understanding of the process in all stages are critically required to obtain a thin film with desired optical and morphological properties.[6] This fact has remained untouched in the literature for the amorphous BTO nanothin films.

Although many structural and electrical data of crystalline BTO sol–gel-derived thin films have been published,[5–10] so far, there are only few data available for the optical properties of the amorphous BTO nanothin films. In the literature, there are sufficient information regarding the optical properties of the crystalline (nanocrystalline and polycrystalline) BTO thin films,[11,12] but there are little information addressing those of the amorphous BTO nanothin films. Therefore, the topic needs to be further researched by a deep systematic study. Moreover, there is not an elaborated and wide-ranging study about processing of the amorphous BTO nanothin films in the literature and the studies on the processing of the amorphous BTO nanothin films are not systematic. In other words, although several authors have studied the structural, dielectric, and optical properties of the sol–gel-derived, crystalline BTO films as a function of various parameters,[11–15] the relationships between the processing conditions and optical properties of the amorphous BTO nanothin films are still not well established. For instance, the influences of the processing conditions on the transmission spectrum, thickness, and optical absorption edge of the amorphous BTO nanothin films are not clear now. The critical process variables are necessary to obtain optical-quality amorphous BTO nanothin films by sol–gel process. In this work, an improved method of preparation has been reported for obtaining high-quality amorphous BTO nanothin films, which can prepare very thin and smooth films with enhanced optical responses in contrast to the literature. Moreover, we have performed a series of experiments aimed at characterizing the influences of the processing conditions on the transmittance, thickness, and optical absorption edge of the amorphous BTO nanothin films. The research also aims to elucidate the critical processing parameters required to obtain high-quality BTO nanothin films. Through this study, it has been tried to disclose the role of the processing on the optical response of the amorphous BTO nanothin films by use of the related evidences aided by in-depth discussions.

Experimental

Thin Film Preparation

As shown in Figure 1, the preparation method of the amorphous nanothin film is based on liquid precursors, direct deposition of precursor solution onto substrates by means of dip-coating technique, followed by pyrolysis. Barium titanate precursor solution was prepared using CH3COOH, Ba(CH3COO)2, Ti(CH3CH3CHO)4, CH3CH(OH)CH3, and deionized water as precursors. The preparation method is an improved acetate-alkoxide sol–gel route, and its volatile by-products are not harmful and toxic. Therefore, the preparation method is green and environmentally friendly. The preparation of the precursor solution (sol) was as follows: first, barium acetate was completely dissolved in acetic acid, and then, alcohol was added to the solution. In the next step, the addition of alkoxide initiates the hydrolysis process. Then, deionized water was introduced to the mixture. Finally, a highly transparent and colorless sol was prepared. Quick preparation is key characteristic of the present method because the BTO precursor solution is prepared in 90 minutes, which is fast and economical. In contrast to the other established method,[7,11,12] the preparation costs decreased because a much lower amount of 2-propanol and acetic acid was used and no modifier was used. The stability of the precursor solution is a key requirement for thin film fabrication. The precursor solution is stable for 100 days at ambient condition. This characteristic is another advantage of our established method over other works.[7,11,12] Therefore, it can be stated that the overall procedure used in this work is very simple, cost-effective, and environmentally friendly. Viscosity of the sol was measured to follow the chemical evolution of the polymeric species in sols. A viscometer (VISCOELITE; Fingilab S.A.) was used to measure the viscosity of the sol at ambient conditions. The concentration of the precursors was adjusted by adding proper amount of the deionized water.

BTO nanothin films have been deposited onto soda-lime glass substrates with varying processing parameters such as sol preparation method, dip-coating operating parameters, and post-annealing conditions. Nanothin films were prepared by dipping the substrate in the sol and withdrawal by the rate of 1 cm/min and 90-deg vertical lifting in ambient atmosphere and temperature. The coated substrates were dried at 373 K (100 °C) for 1 hour in air for the evaporation of moisture and organic impurities using an electric oven. The BTO nanothin films were annealed at 773 K (500 °C) for 1 hour in furnace with increasing temperature rate of 5 K/min (5 °C/min). Films produced in this way were amorphous and transparent without any crack and void.

Thin Film Characterization

Optical spectroscopy of BTO nanothin films was performed using a Hitachi 3410 UV–visible-NIR spectrophotometer. The differential scanning calorimetric measurements (DSC) and the thermal gravimetric analysis (TGA) were performed using a thermal analysis system (Rhomiric Scientific; STA 1500), in air, at a heating rate of 5 K/min (5 °C/min), in a platinum crucible, with α-Al2O3 powder as a reference. XRD study was performed to get the structure and final phase formation in the thin films. XRD patterns of the samples were recorded for 2θ, in the range of 20 to 80 deg with a Philips PW3710 diffractometer using monochromatized Cu Kα radiation (k = 1.541 Å). A surface profiler (VEECO; DEKTAK) was used to determine film thicknesses. The DEKTAK 150 is a surface profilometer that takes surface measurements using contact profilometry techniques and can provide down to 2-Å step height measurements. The microstructure and surface morphology of the prepared nanothin films were characterized using atomic force microscopy (Thermo Microscopes; Auto probe CP Research) and scanning electron microscopy (Philips; Vega Tescan XL31). The microstructure of the sol particles was characterized using TEM (Philips CM200).

Results and Discussion

Preparation of Highly Transparent, Smooth, and Amorphous BTO Nanothin Films

In the present investigation, we have developed a sol–gel process for preparation of amorphous BTO thin films with enhanced transparency. The method also can prepare ultrathin BTO films in the range of 10 to 30 nm, which could not be prepared by other established methods.[7,12,14] Transmission spectra of the uncoated glass substrate and coated substrate [which was annealed at 773 K (500 °C) for 1 hour] were recorded and presented in Figure 2. The fired film thickness was 30 nm. According to Figure 2, it can be seen that deposited film is highly transparent in the wavelength range from 400 to 800 nm with average transmission of 87 pct, which is much higher than the previous reported value in similar researches in which the average values in the range of 70 to 75 pct were reported.[7,16–18] This figure demonstrates the enhanced optical transparency of the prepared thin film when compared with other similar works[12,16,17] and indicates improvement made by our established method. It will be confirmed that the annealed nanothin film is amorphous. According to the recorded transmission spectrum presented in Figure 2, it can be said that the optical propagation losses of the prepared nanothin film are much lower than those of crystalline (normal polycrystalline and nanocrystalline) BTO thin films.[12,16,17] This fact is due to the decrease in optical scattering losses because of absence of grain boundaries. Grain boundaries play an important role in the scattering of the photons.[19,20] In order to characterize the role of the grain boundaries and crystallization of the thin film on the film transparency, a thin film is prepared by the same method and same sol and is annealed at 1073 K (800 °C) for 1 hour. It is found that pure and stoichiometric single-phase BTO thin film is prepared after 1-hour calcination of as-dried thin film at 1073 K (800 °C). Figure 2 also compares the transmission spectra of the amorphous and crystalline thin films. A significant decrease in the transparency of the thin film is seen when the amorphous thin films crystallize. Moreover, it is seen that the surface roughness of the thin films increases from 0.7 to 5.6 nm with the increase in the annealing temperature from 773 K to 1073 K (500 °C to 800 °C). This sharp increase is due to the existence of grain boundaries on the surface of the crystalline BTO thin film, which, accordingly, leads to a significant decrease in the transparency of the thin film (see Figure 2). This observation clearly confirms that the amorphous nanothin films exhibit better transmittance and, accordingly, they are better candidates for optical applications. Moreover, there is no fluctuation in the transmission spectrum of the prepared amorphous nanothin film, and this appealing phenomenon has not been observed in similar researches.[12,16,17] In other words, the transmission spectrum of the prepared amorphous nanothin film does not exhibit successive maxima and minima, which have appeared in the spectra of the thin films prepared by Dube et al.[16] and Pencheva et al.[17] Figure 2 also indicates a high absorption in the ultraviolet region. The transmission of the amorphous nanothin film decreases sharply when the wavelength was reduced to around 376 nm, which is due to the fundamental absorption of light and occurrence of inter-band transitions as it has been mentioned earlier.[7,21] Absorption of the light photon occurs by the promotion or excitation of an electron from the nearly filled valence band, across the band gap into an empty state within the conduction band. It seems to us that the homogeneous and high-level transparency of the thin film prepared through the method developed in this work can be used for several applications and can improve the energy efficiency of the solar power systems.

The high transparency quality of the prepared nanothin film maybe due to the small surface roughness and good homogeneity of the film surface. Figure 3(a) shows the AFM image of the prepared nanothin film. It is obvious from AFM three-dimensional image that the surface of the nanothin film is uniform, smooth, and amorphous and also exhibits a dense structure. The root mean square (RMS) roughness of the amorphous nanothin film was determined from the AFM image. In this statistic evaluation, the studied surface was equal to 0.4 μm × 0.4 μm in area. The RMS roughness of the surface of the amorphous nanothin film was quite small and equal to 0.7 nm, which indicates that the amorphous nanothin film is very smooth. This value is very less than other reported RMS roughness values which were in the range of 5 to 11 nm.[7,10] This characteristic is another advantage of our established method, which makes our method desirable for obtaining high-quality optical thin films. The low value of RMS roughness, meanwhile, indicates that the thickness of the prepared thin film is uniform over the substrate area. Roughness of the surface of the thin film has a pronounced impact on the optical losses. Therefore, it can be stated that small surface roughness and good uniformity of the prepared nanothin film result in a decrease in the optical losses through scattering, which in turn lead to high transparency quality in the prepared nanothin films. The incident light on a transparent material is divided into two sections. The first fraction transmits through the material, and the other is the losses that are incurred by absorption and reflection.[19] The surface roughness has opposing impacts on the transmittance; a rougher surface increases forward scattering but also absorbs more. In a thin film, absorption and reflection of the light depend on the surface area and surface quality of nanothin film. Generally, an increase in the surface roughness reduces the quality of the surface and increases the real surface area for a constant projected area. This is the reason behind this fact that a rougher surface increases forward scattering but also absorbs more. The height distribution histogram of the prepared nanothin film (Figure 3(b)) exhibits a narrow height distribution, which is an indication of smoothness of the surface of the nanothin film. The other statistical parameter of significance for surface morphology is profile across the surface, which relates to smoothness of the surface topography and also represents a measure of the randomness of surface heights. According to the Figure 3(c), the range of height variation between peaks and valleys is 1.4 nm, which clearly indicates the surface of the nanothin films is uniform and very smooth.

SEM micrograph of the surface of the prepared nanothin film has been shown in Figure 4(a). The image also shows the edge of the deposited nanothin film. The quality and smoothness of the surface of the prepared nanothin film are evident in the SEM photograph. SEM image clearly indicates that the prepared nanothin film is amorphous because crystallites and grain boundaries have not formed on the surface of the prepared nanothin film. The morphology (given by SEM and AFM) was given in a very small scale. Therefore, it may be not convincing to judge the film is crack-free only through these SEM and AFM micrographs. Figure 4(b) shows the optical micrograph of the surface of the annealed thin film, which was prepared according to our established method. As it is seen, there are no crack and void on the surface of this thin film. According to the SEM and AFM images, it can be stated that the absence of grain boundaries reduces the RMS roughness of the nanothin film. This fact in turn reduces the optical losses and, accordingly, results in high transparency quality of the amorphous nanothin film. Moreover, surface quality, small surface roughness, and good homogeneity of the film are evident in the SEM micrograph. Smooth surface morphology and good film integrity, which are evident in the SEM micrograph, are other reasons behind the high transparency quality and homogeneous transparency of the amorphous nanothin films. In brief, it can be stated that enhanced optical response of the prepared nanothin is due to the newly developed method of preparation, which can prepare high-quality, smooth, and uniform BTO nanothin films.

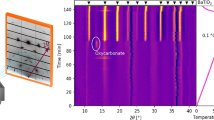

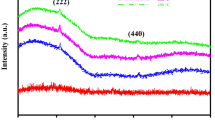

The crystallinity of the prepared nanothin films was examined by X-ray diffraction. XRD pattern of the prepared nanothin film annealed at 773 K (500 °C) for 1 hour has been shown in Figure 5. The film thickness was 30 nm. According to the XRD pattern, it can be said that the prepared nanothin film is amorphous. Since the maximum annealing temperature, which was used in the present work, was 773 K (500 °C), it can be said that all of the prepared thin films in this work are amorphous, independent of number of dip-coated layers and preparation conditions. The observations indicate that annealing at higher temperatures is required to develop crystallinity. DTA results (see Figure 6) indicate that the crucial point in the synthesis is 884 K (611 °C) and this temperature is required for BTO to crystallize. At this temperature, the gel films begin to crystallize into BTO and intermediate phases. XRD pattern also demonstrates that the substrate is amorphous. This statement is obvious, because no peak has appeared in the XRD pattern after the post-deposition annealing at 773 K (500 °C). The XRD pattern also can be used to confirm that no reaction has occurred between the substrate and amorphous-pyrolyzed BTO film.

Due to the following facts, annealing at higher temperatures [>773 K (500 °C)] was not used in the present work: (i) the soda-lime glass substrates tend to deform at temperatures higher than 773 K (500 °C), and (ii) the amorphous nanothin films begin to crystallize at higher temperatures, and due to the progress of the crystallization process, the transmittance of the film decreases gradually. In other words, the optical properties of the amorphous nanothin films are much better than nanocrystalline or polycrystalline films.[19,20]

Characterization of Dependences of Transmittance, Thickness, and Absorption Edge of the Nanothin Films with Respect to the Processing Conditions

The thickness of the prepared thin film has a significant effect on its optical properties and optical constants.[22–26] In sol–gel dip-coating process, preparation conditions, sol properties, dipping conditions, and annealing schedule change the thickness of the thin films. On the other hand, the thickness, transmission spectrum, and optical absorption edge of the thin films can be influenced by factors like concentration and viscosity of the sol, number of dipping cycles, and withdrawal speed of the substrate.[27] Unfortunately, there is not an elaborated and wide-ranging study about the role of the processing on the optical responses of the amorphous BTO nanothin films in the literature. Therefore, we have tried to do it. All of the optical properties, constants, and parameters such as absorption and reflection spectra, band gap, extinction coefficient, refractive index, and absorption coefficient can be determined following the methods of Manifacier et al.[22] and Swanepoel.[23] However, the thickness and transmission spectrum of the nanothin films are needed to determine optical properties and parameters by use of these methods. Therefore, dependences of film transmittance/thickness on the processing conditions are important and need to be investigated. Consequently, in all experiments, the transmission spectra were recorded and thicknesses of the films were determined. All the dependences are deeply disclosed in the next sections.

Effect of post-annealing temperature

It is well known that the structural properties of thin films can be obviously improved by post-annealing process.[24] Moreover, post-deposition annealing always is performed on the as-coated substrates to stabilize or crystallize the gel film. In order to fabricate high-quality transparent BTO nanothin film, it is important to study the temperature-dependent optical properties of this material. Figure 7 shows the effect of the post-annealing temperature on the transmittance of the films. The prepared nanothin films were annealed at different temperatures in the range of 373 K to 773 K (100 °C to 500 °C) for 1 hour. In Figure 7 for comparison, the transmission curve of an uncoated substrate was also included. The average transmittance of all thin films was found to be above 87 pct or more in the visible light range (400 to 700 nm), and meanwhile, no fluctuation was found in the spectra. Moreover, with the increase of the annealing temperature, the transmission spectra show more absorption and the absorption edges of the films shift to longer wavelengths as shown in Figure 8(a). The intensity of the transmitted light can be expressed by the following equation[19]:

The partial enlarged figures of Fig. 7 ranging from (a) 313 to 323 nm and (b) 300 to 400 nm

where I 0 and I are the intensities of the incurred and transmitted light, respectively, d is the thickness of the film, and α is absorption coefficient of the film which increases with the increase of the film density and film thickness. However, the effect of the density is more dominant than the thickness. During the annealing process, the volatile materials in the gel film gradually evaporate. This fact increases the density of the annealed thin films in contrast to the as-coated films, which, according to the Eq. [1], is accompanied by reduction in the intensity of the transmitted light. This fact is the reason behind the reduction of the transmittance with annealing temperature increasing.[25,26] Another fact reducing the transmittance is progress of the nanothin films in the direction of crystallization with the increase of the annealing temperature. However, according to the Figures 4, 5, 6, all of the annealed thin films are amorphous but among them, the nanothin film annealed at 773 K (500 °C) has the deepest tendency to be crystallized. This fact is the real reason behind the greater decrease in the transmittance of the nanothin film annealed at 773 K (500 °C) (see Figures 7 and 8(b)) and its shift in the absorption edge toward visible light region (see Figure 8(a)) in contrast to the films annealed at lower temperatures. At the highest annealing temperature, an increase near the absorption edge is observed which indicates the related thin film provides a better UV protection.

Figure 9 shows the effect of the annealing temperature on the thickness of the films. This figure indicates that the thickness of all of the prepared thin films is nanometric. Based on the principles of the sol–gel dip-coating process,[15,27] it is expected that the film thickness shall decrease with the increase of the annealing temperature. Nanothin films showed a continued thickness reduction with annealing temperature due to the shrinkage of the film. The thin films fabricated by sol–gel dip-coating method may shrink due to different chemical and physical changes taking place during the film formation process.[16] They are (i) surface tensional forces exerted by the solid–liquid interface during solvent evaporation which occurs at room temperature, (ii) removal of organics and subsequent collapse of pores during the pyrolysis of organic compounds, (iii) bond formation between the metal atoms through oxygen atom due to the condensation of hydroxyl groups, and (iv) structural relaxation which is assisted by ionic movements at elevated temperature. The last one was not seen in the present work, because the prepared thin films were amorphous and were processed at low temperature. Therefore, reduction of thickness of the thin films is due to the vaporization of residual or non-structural water and volatile organic solvents and pyrolysis of the Ba–Ti organic precursors. Thermogravimetry curve has been recorded at temperature range of 323 K to 823 K (50 °C to 550 °C) and has been presented in Figure 6. The TGA results advocate the results of Figure 9. It is seen that the trends and shapes of the curve of Figure 9 and TGA curve (see Figure 6) are similar indicating these results approve each other. Moreover, the total reduction in thickness of the thin films and the total weight loss (see Figures 6, 9) are 36 and 34 pct, respectively. This fact demonstrates the accuracy of the results of the DEKTAK profiler.

Effect of post-annealing time

The effect of the post-annealing time on the transmittance of the nanothin films was shown in Figure 10. Nanothin films were annealed at 773 K (500 °C) for different times ranging from 0.5 to 4 hours. Figure 10 indicates that with the increase of the annealing time, the transmission spectra show more absorption. Sharp absorption edges shift to the longer wavelength as the increases of the annealing time as shown in the inset of Figure 10. The results also indicate that the thickness of the films has no significant change with the annealing time increasing. It can be said that the post-annealing temperature has a more pronounced effect on the thickness of the prepared nanothin film compared with the post-annealing time. In analysis of the results (Figure 10), it can be said that the amount of the thermal energy of atoms resulted from the annealing process increases with the annealing time.[25] This fact increases the density and stability of the film, which accordingly reduces the transmittance of the nanothin films. The absorption edge of the nanothin films annealed for 1 and 4 hours did not exhibit significant difference (see the inset of Figure 10). This means that they both have similar UV protections, which is better than that for nanothin film annealed for 0.5 hour. This fact also indicates that after annealing at 773 K (500 °C) for l h, the shift in the absorption edge needs higher temperatures. In other words, post-annealing temperature has a more pronounced effect on the absorption edge of the prepared nanothin film compared with the post-annealing time.

Finally, it seems to us that the nanothin film that was annealed at 773 K (500 °C) for 1 hour is optimal option to be used for optical applications. This fact is due to its high transparency quality, higher density, thinner thickness, higher cohesion strength, and better adhesion to the substrate. These characteristics make the prepared nanothin film more stable than other films. It is known that increase of the annealing temperature increases the adhesion between nanothin film and substrate. Thus, nanothin films, which were annealed at 773 K (500 °C) for 1 and 4 hours, are more stable than that of annealed for 0.5 hour. Moreover, they exhibit better UV protection. By simultaneous consideration of transparency and stability of thin films and economical limitations, it can be concluded that the optimal annealing time is 1 hour. Consequently, an annealing process at 773 K (500 °C) for 1 hour was found to be optimum and was used for the rest of the study.

Effect of dipping (layer) number

Figure 11 shows the transmission spectra of the BTO nanothin films with different layer numbers annealed at 773 K (500 °C) for 1 hour. After each dipping process, the formed layer was dried at 373 K (100 °C). Although the average optical transmittance of the films with one layer is above 87 pct when wavelength is between 400 and 1200 nm, BTO films with more layer numbers exhibit lower transparency. In order to make physical thickness measurements of the thin films and also to characterize the dependence of the film thickness on the number of dipping cycles (at withdrawal speed of 1 cm/min), the DEKTAK profilometer was used. The film thickness is found to be 30, 57, 112, and 271 nm at number of dipping application of 1, 2, 4, and 10, respectively. It is seen that the film thickness is proportional to the number of layers. Nevertheless, this behavior is not linear due to the partial dissolution of the dried layer during the successive dips. During the submersion period of each dipping, partial dissolution of the dried layer occurs due to the interactions between dried layer and sol. This fact results in deviation from linear behavior in plot of film thickness vs layer numbers. It is evident from Figure 11 that the optical transmittance of the BTO films decreases with layer number increasing. This fact is due to the thickness increment. The decrease in the transparency of the thin films with increasing the layer number may be due to roughness of the surface, which increases by number of the dipping cycles. The researchers have shown that the roughness of the surface increases as the thickness of the film increases.[28]

Effect of withdrawal rate

In the current work, a range of withdrawal speeds (1 to 30 cm/s) was studied. Figure 12 indicates the dependences of the thin film transmittance and thickness on the withdrawal speed. All BTO thin films are highly transparent with an average transmittance of more than 82 pct in the visible region. The absorption edge seems to be independent of the withdrawal speed. For the analysis of the optical transmittance spectra (presented in Figure 12(a)), we should consider two factors: film thickness and surface morphology, since they play important role on the optical properties of the nanothin films. It was observed that the film thickness (see Figure 12(b)) increases with the withdrawal speed increasing. Moreover, it was demonstrated that the roughness parameter increases as the thickness of the film increases.[28] Therefore, it should be noted that the BTO thicker film, which was deposited with a withdrawal speed of 30 cm/min, exhibits a higher surface roughness. These factors reduce the transmittance of the film at higher withdrawal rate. The dependence of the film thickness on the withdrawal speed is shown in Figure 12(b). Based on the principles of the sol–gel dip-coating process[15,27] and the related theoretical equations,[15] increase in withdrawal speed increases the thickness of the fluid film, which correspondingly results in an increase in the thickness of the film. The film thickness is shown to increase with the withdrawal speed raised to the power 0.62. It has been reported[27] that the thickness of the films increases in proportion to the withdrawal speed raised to the power 1/2 to 2/3.[27] Our result is in good accordance with these results. The withdrawal speed of 1 cm/s was found to be optimum (in terms of stability of the nanothin film, which exhibits no cracks and for its better surface quality and transmittance) and was used for the rest of the study. Withdrawal speeds of >1 cm/s resulted in a much thicker coating with lower transparency. The thicker films also exhibited surface cracks and shrinkage.

Effect of the viscosity of the sol

BTO films were fabricated by different viscosity sols, and then the influence of the viscosity on the thickness and optical properties of BTO films was deeply investigated. There are different methods including evaporating the solvent,[29] use of additive,[9] and progress of the sol–gel reactions[30] for adjusting the viscosity of the sol. In the present work, the last one was employed. In other words, the increase in the viscosity of the sol is attained basically through progress of the condensation reactions. The sol–gel reactions, especially polycondensation reactions, have a pronounced effect on the viscosity of the sol. In this regard, it can be stated that as polycondensation reactions proceed, the length and size of the forming species increase. This fact and successive interactions between these polymeric species increase the viscosity of the sol. The visual inspections indicated that the as-prepared sol is colorless and remains colorless for 100 days. The as-prepared sol has low viscosity (1.35 cP) due to the presence of high volume of the water in its composition. After 100 days, the sol slowly changes its color to bluish and its viscosity increases as well. This fact is due to the progress of the polycondensation reactions. As-prepared sol is colorless due to the presence of ultrafine nanoparticles in the sol (see the related TEM micrograph in Figure 13), which have a lower tendency to absorb the light. As shown in Figure 13, the viscous sol contains the larger particles. The growth of the particles embedded in the sol with time is due to the progress of the sol–gel reactions. Particle size has opposing impacts on the transmittance; a larger particle increases forward scattering but also absorbs more.[31] This fact changes the color of the sol to bluish, which is evident in Figure 13.

Figure 14(a) shows the optical transmission spectra of the annealed thin films prepared with different viscosities. The figure implied that the viscosity of the sols has remarkable influence on the transmission spectrum of the films. The transparency of the films reduces (especially toward near-infrared wavelengths) with sol viscosity increasing. The figure indicated that when the sols’ viscosity was over 8 cps, the film’s transmission decreased remarkably. The thickness of dip-coating layer depends on the viscosity of the sols. The increase of the viscosity of the solution leads to the formation of a thicker film, which is evident in Figure 14(b). This fact is due to the increase of the thickness of the fluid film deposited on the substrate with viscosity increment. Increase in the thickness of the film results in reduction of the transmittance of the thin films. Moreover, it has been demonstrated that the film roughness increases with the increase of the viscosity of the sol.[29] This may be due to the increase in the size of the particles within the sol, which accordingly reduces the transparency of the thin film. A shift in absorption edge to a higher wavelength is observed with sol viscosity increasing. The effect of the viscosity of the sol on the shift of the absorption edge is greater than other processing parameter studied in the present work. This fact is due to the change of the nature of the as-prepared sol with time, which accordingly increases its viscosity. This fact also is due to the size of the species within the sol (see Figure 13).

Effect of the concentration of the sol

In sol–gel dip-coating method, the thickness/transmittance of the thin film can be varied by changing the sol concentration. Since there are few studies on the influence of sol concentration on the optical properties of BTO thin films, we have tried to investigate it. The concentration of the precursors can be adjusted by adding proper amount of the deionized water. The concentration of the Ba and Ti complexes within the as-prepared sol was 0.3 mol/L. Figure 15(a) shows the transmission spectra of the BTO nanothin films with different sol concentrations. It was found that the transmittance decreases with the increase in sol concentration. This decrease is due to the larger roughness in the thicker film resulting from the increase in the sol concentration. All the films show high transmittance in the visible range when the sol concentration is less than 0.3 mol/L. However, when the sol concentration is more than 0.3 mol/L, the transmittance of the films is largely decreased. The transmittance of amorphous BTO nanothin films is mainly affected by the following factors: film thickness and density, surface roughness, and the size of the particles within the sol. In investigating the effect of the sol concentration, the main factor decreasing the transmittance of the BTO thin films deposited by high-concentration sol is roughness of the surface, but the film thickness is also an important factor affecting the transmittance in the visible range. According to the Beer–Lambert law,[19] absorbance of the sol is proportional to the concentration and size of the particles within the sol. An increase in the concentration of the sol increases the number and size of colliding species resulting in more successful collisions and increases the sol–gel reaction rate. Therefore, the rate of the sol–gel reactions is more rapid at higher sol concentration. This fact increases the size of the particles within the sol. On the other hand, particle size has opposing impacts on the transmittance; a larger particle increases forward scattering but also absorbs more.[31] This fact reduces the transmittance of the sol and thin films. The concentration also may affect the transmittance through its relation with viscosity.[15,32] It was seen that the viscosity of the sol increases with an increase in the sol concentration. These facts also affect the thickness of the film. The inset of the Figure 15(a) indicates that the absorption edge decreases with increase in the concentration of the sol.

It is observed that (see Figure 15(b)) the thickness of the thin films increases with an increase in the sol concentration. The amount and size of the particles within the sol increase with an increase in the concentration of the sol.[15,27,33] This fact in turn results in an increase in the thickness of the thin films. The theoretical relationship indicates that at a constant withdrawal rate, the coating thickness depends on the concentration, viscosity, and surface energy.[15,27] Thus, a solution with higher concentration can lead to production of coatings with higher thickness. Moreover, it is obvious that as the concentration of the sol increases, the amount of the coating materials remaining on the surface and which forms the thin film increases. This fact results in the increase in the thickness of the forming layer and accordingly reduces the transmittance of the formed thin film. The greater difference between the transmission spectrum of the sol with concentration of 0.45 mol/L and transmission spectra of other sols (see Figure 15(a)) may be due to its faster sol–gel reaction rate. This fact also results in deviation from linear behavior in the plot of film thickness vs concentration of the sol.

Conclusions

Highly transparent and amorphous BTO nanothin films were successfully prepared via sol–gel dip-coating method. It was seen that the optimal thin film is highly transparent in the wavelength range from 400 to 800 nm with average transmission of 87 pct. In other researches, the average values were in the range of 70 to 75 pct. The relationships between the processing conditions and optical properties of the amorphous BTO nanothin films were deeply disclosed. We have characterized the role of the post-deposition heat treatment, dip-coating operating parameters, and sol properties. It was found that increase of thickness of films, increase in the annealing time and annealing temperature, increase in the layer number and withdrawal rate, and increase in the concentration and viscosity of the sol result in decrease of the transmittance of the prepared nanothin film. The results showed that effect of viscosity of sol on wavelength shift of absorption edge is greater than other processing parameter studied in the work. The results indicated that when the sols’ viscosity was over 8 cps, the film’s transmission decreased remarkably. Finally, it can be said that the enhanced and homogeneous optical transparency of the prepared thin films can significantly improve the energy efficiency of solar power systems.

References

R. Ashiri, Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4414-26.

R. Ashiri, A. Nemati, and M. Sasani Ghamsari, Mater. Res. Bull., 2011, vol. 46, pp. 2291–95.

R. Ashiri, Vib. Spec., 2013, vol. 66, pp. 24-29.

M. Antonietta Loi and J.C. Hummelen: Nat. Mater., 2013, vol. 12, pp. 1087–89.

R. Ashiri, A. Nemati, and M. Sasani Ghamsari: Ceram. Int., 2014, vol. 40, pp. 8613–19.

R. Ashiri, A. Nemati, and M. Sasani Ghamsari: J. Non-Cryst. Sol., 2009, vol. 355, pp. 2480–84.

H.X. Zhang, Mater. Chem. Phys., 2000, vol. 63, pp. 174-77.

F.C.M. Woudenberg, W.F.C. Sager, Thin Solid Films, 2005, vol. 471, pp. 134-39.

H. Kozuka, M. Kajimura, J. Am. Ceram. Soc., 2000, vol. 83, pp. 1056-62.

M.C. Gust, N.D. Evans, J. Am. Ceram. Soc., 1997, vol. 80, pp. 2828-36.

W. Cai, Ch. Fu, J. Gao, Physica, 2011, vol. B406, pp. 3583-87.

O. Harizanov, A. Harizanova, Mater. Sci. Eng., 2004, vol. B106, pp. 191-95.

B. Lee, J. Zhang, Thin Solid Films, 2001, vol. 388, pp. 107-13.

H. Kumazawa, K. Masuda, Thin Solid Films, 1999, vol. 353, pp. 144-48.

C.J. Brinker, G.C. Frye, A.J. Hurd, Thin Solid Films, 1991, vol. 201, pp. 97-108.

R. Thomas, D.C. Dube, Thin Solid Films, 1999, vol. 346, pp. 212-25.

T. Pencheva, M. Nenkov, Vacuum, 2000, vol. 58, pp. 374-86.

M. Burgos, M. Langlet, Thin Solid Films, 1999, vol. 349, pp. 19-23.

W.D. Callister, Fundamentals of Materials Science and Engineering, 5th ed., Wiley, New York, 2004.

S.Y. Ma, X.H. Yang, X.L. Huang, J. Alloys Compd., 2013, vol. 566, pp. 9-15.

Zh. Xu, Y. Tanushi, M. Suzuki, Thin Solid Films, 2006, vol. 515, pp. 2326-31.

J.C. Manifacier and J. Gasiot, J.P. Fillard: Physics, 1976, vol. E9, pp. 1002–04.

R. Swanepoel, Physics, 1983, vol. E16, pp. 1214-22.

E.F. Keskenler, S. Doǧan, Metall. Mater. Trans. A, 2012, vol. 43A, pp. 5088-95.

H.Y. Tian, Thin Solid Films, 2002, vol. 408, pp. 200-05.

G.J. Fang, D. Li, B.-L. Yao, Thin Solid Films, 2002, vol. 418, pp. 156-62.

C.J. Brinker, G.W. Scherer. Sol-Gel Science, Academic Press, New York, 1990.

R.M.S. Martins, V. Musat, Thin Solid Films, 2010, vol. 518, pp. 7002-06.

L. Qian, L. Xifeng, Z. Jianhua, J. Alloys Compd.., 2013, vol. 572, pp. 175-79.

M.R. Golobostanfard, H. Abdizadeh, Ceram. Int., 2012, vol. 38, pp. 5843-51.

O. Harizanov, Sol. Energy Mater. Sol. Cell., 2000, vol. 63, pp. 185-95.

M. Dutta, S. Mridha, D. Basak, Appl. Surf. Sci., 2007, vol. 254, pp. 2743-47.

R. Ashiri: M.Sc. Dissertation, Sharif University of Technology, Tehran, Iran, 2008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 24, 2013.

Rights and permissions

About this article

Cite this article

Ashiri, R. Analysis and Characterization of Relationships Between the Processing and Optical Responses of Amorphous BaTiO3 Nanothin Films Obtained by an Improved Wet Chemical Process. Metall Mater Trans B 45, 1472–1483 (2014). https://doi.org/10.1007/s11663-014-0057-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0057-4