Abstract

Solidification microstructures and solidification modes in different austenitic Fe-Mn-Si-Cr-Ni shape memory alloys were investigated. Based on these results, a new set of Creq and Nieq equations (Creq = Cr + 1.5Si; Nieq = Ni + 0.164Mn + 22C) were developed. The above results show that Mn is still an austenite former in austenitic Fe-Mn-Si-Cr-Ni alloys containing above 12 wt pct Mn and 4 wt pct Si, but its effect is weaker than that in austenitic stainless steels with lower Mn content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Shape memory alloys (SMAs) have attracted attention owing to their shape memory effect (SME) and superelasticity. Fe-Mn-Si-based SMAs exhibit lower cost, better workability, and weldability as compared with Ni-Ti-based and Cu-based SMAs. Thus, there have been many studies on Fe-Mn-Si-based SMAs since Sato and his co-workers discovered the SME behavior in Fe-Mn-Si single crystals.[1–14] Unfortunately, the recovery strain is only 2 to 3 pct in polycrystalline Fe-Mn-Si-based SMAs prepared by conventional processing techniques.[3–14] To improve the recovery strain, the processed Fe-Mn-Si-based SMAs have to be subjected to training,[4–6] thermo-mechanical treatment,[9–11] or ausforming.[8] However, the training is not only too complicated to be performed for components with complicated shapes, but also increases the production cost. The thermo-mechanical treatment and ausforming are essentially a training step. As a result, the processed Fe-Mn-Si-based SMAs have not been used commercially so far. Current research focuses mainly on developing training-free Fe-Mn-Si-based SMAs.

Very recently, Wen et al.[12] developed a novel training-free cast Fe-18Mn-5.5Si-9.5Cr-4Ni alloy which solidifies primarily as delta ferrite. Its recovery strain reaches 6.4 pct, which is higher than that of the trained Fe-14Mn-5Si-8Cr-4Ni alloy.[13] Manufacture of parts with this alloy system is simple and less costly compared to Fe-Mn-Si-based alloy systems which require the training. Moreover, it is easy to cast components with complicated shapes. Therefore, this alloy system provides a novel way for producing a training-free Fe-Mn-Si-based alloy with the high recovery strain. In addition, it can be expected that an even higher recovery strain can be developed in cast Fe-Mn-Si-Cr-Ni SMAs through optimization of alloy compositions, casting parameters, and heat treatment techniques.

Fe-Mn-Si-Cr-Ni SMAs are a special kind of austenitic stainless steels. There exist four types of solidification mode in austenitic stainless steels, i.e., austenitic (A), austenitic-ferritic (AF), ferritic-austenitic (FA), and ferritic (F) modes. The four solidification modes are determined according to solidification sequence, as follows:[15,16]

Different solidification modes produce distinctive as-cast microstructures, inevitably leading to different SME behaviors. Obviously, it is of importance to investigate the effect of solidification modes on solidification microstructures and their resulting SME. However, our previous work showed that four sets of Creq and Nieq equations (Delong et al.[17] Hull,[18] Hammar and Svensson[19,20] as well as WRC-1992[21] equations) and Thermo-Calc software® are invalid to predict the solidification modes of cast Fe-(13–27)Mn-5.5Si-8.5Cr-5Ni SMAs.[22] Therefore, a new set of Creq and Nieq equations has to be developed to predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs. In the present paper, we investigated solidification microstructures of cast Fe-(13–27)Mn-(4.5–6.5)Si-(7–9)Cr-(4–6)Ni SMAs and determined their solidification modes according to their microstructural features. Based on their solidification modes, a new set of Creq and Nieq equations was successfully developed.

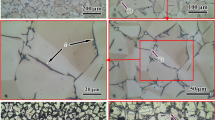

Cast Fe-Mn-Si-Cr-Ni SMAs were prepared by the method described in Reference[22]. Chemical compositions of the cast Fe-Mn-Si-Cr-Ni SMAs are listed in Table I. Solidification modes were determined using optical metallography. F mode was determined by ordinary optical micrographs etched using 1 g C2H2O4 + 15 mL H2O2 + 1 mL HF + 15 mL distilled water (referred as Etchant 1). FA, AF, and A modes were determined by a color metallographic technique developed by Rajasekhar et al.[16] The etchant is 0.5 g K2S2O5 + 20.0 g NH4HF2 + 100 mL distilled water (referred as Etchant 2). The skeletal structure presenting in dendritic centers represents the FA mode, while the mixture of cellular and dendritic structure represents the AF mode. The dendritic structure represents the A mode. For cast 13Mn-27Mn alloys listed in Table I, we have determined their solidification modes in our previous work.[22] In the present paper, we investigated solidification microstructures of other cast Fe-Mn-Si-Cr-Ni alloys listed in Table I, as illustrated in Figure 1. In the ordinary optical micrographs, the microstructures of 6.5Si, 4Ni, and 5Ni alloys are the typical Widmanstätten morphology, whereas the microstructures of 4.5Si and 6Ni alloys are the dendritic morphology. F mode results in the Widmanstätten microstructure.[15,16] Therefore, the solidification mode of 6.5Si, 4Ni, and 5Ni alloys is the F mode. However, we cannot determine the solidification mode of 4.5Si and 6Ni alloys only according to their dendritic morphology. In order to determine their solidification modes, we used the color metallographic technique. The results showed that in the color micrographs, the skeletal structure (indicated by white arrows) presents in the dendritic centers of 4.5Si and 6Ni alloys, indicating that their solidification mode is the FA mode. In the research completed so far, only F and FA modes of cast Fe-Mn-Si-Cr-Ni SMAs were attained through adjusting the chemical compositions, as seen in Table I.

For the purpose of developing a new set of Creq and Nieq equations to predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs, the first step was to analyze why four sets of Creq and Nieq equations (Table II) are invalid to predict their solidification modes. The WRC-1992 equation does not consider the influence of Mn and Si on the solidification behavior. Therefore, it cannot predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs. In the case of the Hull equation, Mn suppressed the formation of austenite when it was above about 12.79 wt pct. However, our previous work showed that Mn still promotes the formation of austenite when it is above 12 wt pct.[22] The Delong et al. equation[17] is derived from welding studies, and the equation attributed to Hammar and Svensson[19] was derived from studies of small samples by thermal analysis. Generally, the cooling rate of our cast Fe-Mn-Si-Cr-Ni SMAs is between 0.6 and 60 K/min,[23] and is much lower than that of weld metals which typically cool at a rate of 4000 K/min,[24] and is a magnitude similar to that of thermal analysis experiments conducted by to Hammar and Svensson, which was typically 20 K/min.[19] However, the Hammar and Svensson equation does not correctly predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs.[22] Note that the Mn and Si concentrations are above 12 and 4 wt pct, respectively, in the cast Fe-Mn-Si-Cr-Ni alloys while are below 2 and 0.8 wt pct, respectively, in the thermal analysis samples investigated by Hammar and Svensson. Furthermore, the Cr and Ni concentrations in the thermal analysis samples are much higher than that in the cast Fe-Mn-Si-Cr-Ni alloys. Accordingly, the coefficient of Mn or Si in the Hammar and Svensson equation is unsuitable for predicting the solidification modes of cast Fe-Mn-Si-Cr-Ni alloys because the Cr, Ni, Mn, and Si concentrations in the cast Fe-Mn-Si-Cr-Ni alloys is much different from that in the thermal analysis samples. Based on the above analysis, a new set of Creq and Nieq equations would be developed through revising the coefficient of Mn or Si in the Hammar and Svensson equation.

Our previous study showed that the solidification mode of 23Mn alloy is a mixture of F and FA modes (Table I).[22] Therefore, the Creq/Nieq value of 23Mn alloy is approximately the critical value, over which the solidification mode changes from F to FA mode. In the case of Hammar and Svensson equation, this critical Creq/Nieq value is 1.95.[20] Thus, when we only corrected the coefficient of Mn element in Hammar and Svensson equation, a revised coefficient for Mn was calculated to be a value of 0.164, from the following Eq. [1].

The first new set of Creq and Nieq equations was developed as follows:

Similarly, when we only corrected the coefficient of Si element in Hammar and Svensson equation, a revised coefficient for Si was calculated to be a value of 2.66, from the following Eq. [2].

The second new set of Creq and Nieq equations was developed as follows:

For new two sets of Creq and Nieq equations, A, AF, FA, and F modes correspond to the following range of Creq/Nieq value, which is same as the Hammar and Svensson equation:[20] A: Creq/Nieq < 1.35; AF: 1.35 < Creq/Nieq < 1.50; FA: 1.50 < Creq/Nieq < 1.95; F: Creq/Nieq > 1.95.

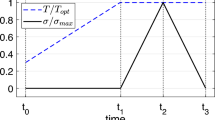

Based on new two sets of Creq and Nieq equations, Table III lists the predicted solidification modes of cast Fe-(13–27)Mn-(4.5–6.5)Si-(7–9)Cr-(4–6)Ni SMAs. The results showed that both are valid to predict the F and FA modes of cast Fe-Mn-Si-Cr-Ni SMAs. To further examine whether the two sets of Creq and Nieq equations can predict the A and AF modes of cast Fe-Mn-Si-Cr-Ni SMAs, we designed two cast Fe-Mn-Si-Cr-Ni SMAs. The solidification modes of Alloys #1 and #2 are A and AF, respectively, according to the first new set of Creq and Nieq equations while they are AF and FA, respectively, according to the second new set of Creq and Nieq equations (Table IV). Figure 2 shows ordinary and color optical micrographs of Alloys #1 and #2. In the ordinary optical micrographs, the microstructures of Alloys #1 and #2 are the dendritic morphology. Moreover, the dendritic structure of Alloy #1 is coarser than that of Alloy #2. In the color micrographs, the microstructure of Alloy #1 is also the dendritic morphology, but the microstructure of Alloy #2 is a mixture of cellular and dendritic morphology (indicated by white arrows). Accordingly, the solidification mode of Alloy #1 is the A mode, and that of Alloy #2 the AF mode. Table V gives the actual chemical compositions as well as the predicted and actual solidification modes of the two cast Fe-Mn-Si-Cr-Ni SMAs. This result shows that the first new set of Creq and Nieq equations (Creq = Cr + 1.5Si; Nieq = Ni + 0.164Mn + 22C) is able to predict the A and AF modes of the two cast Fe-Mn-Si-Cr-Ni SMAs, while the second new set of Creq and Nieq equations (Creq = Cr + 2.66Si; Nieq = Ni + 0.31Mn + 22C) does not correctly predict the solidification modes.

In Creq and Nieq equations, the coefficients associated with each element represent their ability to promote the formation of austenite or ferrite. The larger the coefficients of elements, the stronger their effect. The coefficient for Mn is 0.31 in the Hammar and Svensson equation,[20] but it reduces to 0.164 in our new set of Creq and Nieq equations. Note that the Hammar and Svensson equation was derived from the thermal analysis samples whose Mn concentrations were below 2 wt pct, while our new set of Creq and Nieq equations was derived from the cast Fe-Mn-Si-Cr-Ni alloys whose Mn concentrations were 12 to 27 wt pct. Accordingly, the effect of Mn promoting the formation of austenite is much stronger when its concentration is below 2 wt pct than when its concentration is 12 to 27 wt pct. This result indicates that the effect of Mn is nonlinear, and thus the coefficient of Mn in Nieq equation is not a constant. This is the reason why Hammar and Svensson equation does not correctly predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs.

In summary, the solidification microstructures in different Fe-Mn-Si-Cr-Ni SMAs had been studied. According to their distinctive solidification microstructures, their solidification modes were determined. Based on these results, we developed a new set of Creq and Nieq equations (Creq = Cr + 1.5Si; Nieq = Ni + 0.164Mn + 22C). This set of Creq and Nieq equations can predict the solidification modes of cast Fe-Mn-Si-Cr-Ni SMAs. The above results show that Mn is still an austenite former. However, its effect is nonlinear and is weaker in Fe-Mn-Si-Cr-Ni SMAs containing above 12 wt pct Mn and 4 wt pct Si than in austenitic stainless steels with lower Mn concentration. The new set of Creq and Nieq equations will lay the foundation for designing cast Fe-Mn-Si-Cr-Ni alloys with different solidification modes, investigating the effects of solidification modes on the as-cast microstructure and SME.

References

A. Sato, E. Chishima, K. Soma, T. Mori: Acta Metall. Mater., 1982, vol. 30, pp. 1177–83.

A. Sato, Y. Yamaji, T. Mori: Acta Metall., 1985, vol. 34, pp. 287–94.

H. Otsuka, H. Yamada, T. Maruyama, T. Mori., H. Tanahashi, S. Matsuda, M. Murakami: ISIJ Int., 1990, vol. 30, pp. 674–79.

Y. Watanabe, Y. Mori, A. Sato: J. Mater. Sci., 1993, vol. 28, pp. 1509–14.

[5] Q. Gu, J.V. Humbeeck, L. Delaey: J. Phys. VI, 1994, vol. 4, pp. 135–44.

S. Kajiwara: Mater. Sci. Eng. A, 1999, vol. 273–275, pp. 67–88.

S. Kajiwara, D. Liu, T. Kikuchi, N. Shinya: Scripta Mater. 2001, vol. 44, pp. 2809–14.

D.F. Wang, D.Z. Liu, Z.Z. Dong, W.X. Liu, J.M. Chen: Mater. Sci. Eng. A, 2001, vol. 315, pp. 174–79.

A. Baruj, T. Kikuchi, S. Kajiwara, N. Shinya: Mater. Sci. Eng. A, 2004, vol. 378, pp. 333–36.

N. Stanford, D.P. Dunne: Mater. Sci. Eng. A, 2006, vol. 422, pp. 352–59.

Y.H. Wen, W. Zhang, N. Li, H.B. Peng, L.R. Xiong: Acta Mater., 2007, vol. 55, pp. 6526–34.

Y.H. Wen, H.B. Peng, P.P. Sun, G. Liu, N. Li: Scripta Mater., 2010, vol. 62, pp. 55–58.

Y.H. Wen, H.B. Peng, C.P. Wang, Q.X. Yu, N. Li: Adv. Eng. Mater., 2011, vol. 13, pp. 48–56.

X.H. Min, T. Sawaguchi, X. Zhang, K. Tsuzakia: Scripta Mater., 2012, vol. 67, pp. 37–40.

J.C. Lippold, D.J. Kotecki: Welding Metallurgy and Weldability of Stainless Steels, 1st ed., Wiley-Interscience, Hoboken, 2005.

K. Rajasekhar, C.S. Harendranath, R. Raman, S.D. Kulkarni: Mater. Charact., 1997, vol. 38, pp. 53–65.

W.T.C. Delong, G.A. Ostrom, E.R. Szumachowski: Weld. J., 1956, vol. 35, pp. 526–32.

F.C. Hull: Weld. J., 1973, vol. 52, pp. 193–203.

Ö. Hammar and U. Svensson: in Solidification and Casting of Metals, Metal Society, Book 192, London, 1979, pp. 401–410.

ASM Handbook, Volume 6: Welding, Brazing and Soldering, 10th ed., ASM International, Materials Park, OH, 1993.

D. Kotecki, T.A. Siewert: Weld. J., 1992, vol. 71, pp. 171–78.

H.B. Peng, Y.H. Wen, Y.Y. Du, Q.X. Yu, Q. Yang: Metall. Mater. Trans. B, 2013. vol. 44B, pp. 1137–43.

M.C. Flemings: Proc. F Weinberg Int. Symp. Solidif. Process., 1990, pp. 173.

N. Suutala: Metall. Trans. A, 1983, vol. 14A, pp. 191–96.

The work was supported by the National Natural Science Foundation of China (Nos. 50871072, 50971095, and 51171123), the Natural Science Foundation for Young Scientists of Sichuan Province in China (No. 2010A01-436), and the Fundamental Research Funds for the Central Universities (No. 2012SCU11068).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 15, 2013.

Rights and permissions

About this article

Cite this article

Peng, H., Wen, Y., Du, Y. et al. A New Set of Creq and Nieq Equations for Predicting Solidification Modes of Cast Austenitic Fe-Mn-Si-Cr-Ni Shape Memory Alloys. Metall Mater Trans B 45, 6–11 (2014). https://doi.org/10.1007/s11663-013-0005-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-0005-8