Abstract

The phase equilibria of Fe-Ni-X-O (X = Mg, Al) systems, including their lower-order systems, at temperatures between 1200 °C and 1600 °C in air in the subsolidus region, have been experimentally studied. In the present study, the ‘Fe2O3’-MgO, ‘Fe2O3’-Al2O3, and NiO-Al2O3 binary phase diagrams, as well as the ternary phase diagrams in the Fe-Ni-Mg-O and Fe-Ni-Al-O systems projected onto the Fe-Mg-Ni and Fe-Al-Ni planes, have been constructed. Differences have been found between the present measurements, the previously published data, and the FactSage predictions, especially in the lower-order systems. It is suggested that the improved experimental techniques used in the present study, which involve carefully planned equilibration procedures followed by electron probe X-ray microanalyses (EPMA), provide more accurate and precise measurements of the phase boundaries and phase compositions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the Caron process,[1] nickel is extracted from nickel laterite through a combination of pyrometallurgy and hydrometallurgy processes. The nickel laterite, a mixture of limonitic (oxides/hydroxides) and saprolitic (silicates/hydrosilicates) ores, is processed through reduction roasting prior to leaching in an ammoniacal solution. The reduction roasting is carried out at an average reactor temperature of 750 °C. The nickel laterite, however, can be exposed to a temperature in excess of 1200 °C in the area close to the burner. The pregnant liquor resulting from the leaching process is then purified and precipitated to form an intermediate product, basic nickel carbonate (BNC). The BNC is further reduced, to produce nickel metal product.[2]

Detailed thermodynamic information on the phase equilibria in the Fe-Ni-X-O and Fe-Ni-X-Si-O (X = Mg, Al, Cr) systems, including information on the nickel distribution between the phases present, is vital for the control of the reduction roasting process and to achieve maximum nickel extraction. It has been shown previously[3,4] that the optimum conditions, from the thermodynamic point of view (e.g., temperature and effective oxygen partial pressure), are different for the processing of limonitic and saprolitic laterite ores.

Previous experimental studies[5] on the phase equilibria of the Fe-Ni-O system in air and at various oxygen partial pressures have provided the basis for the present study. In the present article, the phase equilibria of the Fe-Ni-X-O (X = Mg, Al) system in air between the temperatures 1200 °C and 1600 °C in the subsolidus regions are investigated using improved experimental techniques, which include equilibration and quenching followed by electron probe X-ray microanalysis (EPMA) examination.

A number of studies have been undertaken on the phase equilibria of the Fe-Ni-O[5–23] system. The most recent study on this system was carried out at temperatures between 800 °C and 1600 °C, in air and at oxygen partial pressures (pO2) between 10–11.8 and 1 atm, using the equilibration and quenching techniques and followed by EPMA.[5] The solubility of iron in bunsenite (Ni,Fe)O at 1200 °C is reported to be 16.1 Fe mole pct in air and increases up to a maximum of 66.2 Fe mole pct with a decreasing oxygen partial pressure down to pO2 = 10−8.3 atm. The solubility of iron in bunsenite is also reported to increase with increasing temperature. The solubility of iron at 1200 °C in a Ni,Fe alloy is reported to increase with decreasing pO2, while the solubility of nickel in wustite (Fe,Ni)O decreases with decreasing pO2.

Several studies on the phase equilibria of the Fe-Mg-O system have been carried out.[24–30] The most recent study of the subsolidus phase equilibria in the Fe-Mg-O system was carried out by Hansson et al.[30] at 1200 °C to 1600 °C; the focus of the study was to define the extent of the spinel (Fe,Mg)3O4+y and periclase (Mg,Fe)O solid solutions. Hansson et al. used the equilibration-quenching techniques and EPMA in this study; they reported that the concentration of iron in the spinel in equilibrium with periclase increases with increasing temperature. The abnormal inflection in the spinel composition at the spinel/periclase boundary at approximately 1400 °C reported by Wilshee and White[29] was not observed in their study.

Muan[31,32] carried out a study to investigate the occurrence of the \( {\text{Fe}}_2{\text{O}}_3{\cdot}{\text{Al}}_2{\text{O}}_3 \) phase in the ‘Fe2O3’-Al2O3 system in air and at a 1-atm O2 pressure, using high-temperature equilibration and quenching techniques. The phase identification in the equilibrated samples was carried out using optical microscopy and the X-ray diffraction (XRD) method (measurements of the d-spacings of the crystalline phases). The \( {\text{Fe}}_2{\text{O}}_3{\cdot}{\text{Al}}_2{\text{O}}_3 \) was reported to exist in stable equilibrium at subsolidus temperatures between 1318 °C and 1410 °C. It is indicated in the article that, in the subsolidus region (e.g., below 1340 °C), an equilibrium condition was difficult to be achieved in a reasonable time. At temperatures above 1340 °C, equilibrium was achieved in 1 to 3 days. The most recent work on the ‘Fe2O3’-Al2O3 system was carried out by Hansson et al.[33] as part of the study on the phase equilibria of the Al-Fe-Zn-O system in air. Hansson et al. also used the equilibration and quenching techniques; however the phase identification and phase boundaries were determined by direct measurement of phase compositions using EPMA. Hansson et al. reported a significantly higher solubility of Al2O3 in hematite (Fe,Al)2O3 at 1250 °C compared to the results from Muan and Gee.[31] The maximum solubility of Al2O3 in the \( {\text{Al}}_2{\text{O}}_3{\cdot}{\text{Fe}}_2{\text{O}}_3 \) phase was also reported to be 0.03 mole fraction Al2O3, larger than reported by Muan and Gee.

Phillips et al.[34] conducted a study on the phase equilibria of the NiO-Al2O3-SiO2 system that also includes some work on the NiO-Al2O3 phase equilibria. High-temperature equilibration and quenching techniques were used in the study. The phase identification was carried out using petrographic microscopy and XRD analysis. In the subsolidus region, the following phases were reported to present: NiO solid solution, \( {\text{NiO}}{\cdot}{\text{Al}}_2{\text{O}}_3 \) spinel, and corundum Al2O3. At 1650 °C, the \( {\text{NiO}}{\cdot}{\text{Al}}_2{\text{O}}_3 \) spinel phase was observed in a composition range of approximately 38 to 50 mole pct Al2O3. Due to problems with NiO loss at high temperature and the limitations of the XRD technique for phase identification, accurate phase boundaries could not be obtained by Phillips et al.[34] The NiO solid solution field in the NiO-Al2O3 binary phase diagram constructed in the work by Phillips et al. was based on previously reported data.[35]

No experimental work has been found in the literature on the phase equilibria of the Fe-Ni-Mg-O and Fe-Ni-Al-O systems.

Experimental design

Experimental Techniques

The phase equilibria of the Fe-Ni-O-Mg and Fe-Ni-O-Al systems were investigated using the equilibration and quenching techniques, followed by measurements of phase compositions using the EPMA technique. These improved techniques, which have a number of advantages, including enhanced accuracy and reliability,[36] were developed and have been used extensively by the authors for studying the phase equilibria of oxides. The use of EPMA following equilibration makes it possible to determine whether all phases have reached steady-state composition and equilibrium has been achieved. The techniques are described briefly in the following paragraphs.

Sample preparation

The following oxide and metal powders, obtained from Sigma-Aldrich (Sydney, NSW, Australia), were used as starting materials in the present study: Fe2O3 (99.98 wt pct purity), NiO (99.99 wt pct purity), MgO (99.99 wt pct purity), Al2O3 (99.99 wt pct purity), Fe (99.99 wt pct purity), and Ni (99.8 wt pct purity). The samples were prepared by thoroughly mixing the powders of oxide or combinations of oxide and metal in an agate mortar. The compositions were selected such that two or three condensed phases would be present in the samples after equilibration. The mixtures were then pelletized in a steel die at approximately 40 MPa, to form disks 6 to 10 mm in diameter and 2 mm in thickness. The pellets were fractured to 2 mm in size and the fragments were used for the experiments.

Phase equilibration

Gas/oxide equilibrations in air atmosphere were carried out in a vertical tube (alumina ceramic with an inner diameter of 32 mm) SiC resistance furnace. A few fragments were placed in a small Pt crucible/basket suspended to a hooked Pt wire placed inside a smaller fixed-alumina tube (inner diameter of 3 mm) in the hot zone of the furnace. The fragments were equilibrated at predetermined temperatures for a certain period of time before the Pt wire was pulled up to unhook the Pt basket, allowing the fragments to fall into the quenching medium located below the furnace. The quenching process occurs in a period of approximately 1 second.

Control of temperature

The temperature inside the furnace was controlled within ±1 °C. The tip of a calibrated working thermocouple was positioned immediately adjacent to the sample, to track the sample’s actual temperature. The working thermocouple was calibrated against a standard thermocouple supplied by the National Measurement Laboratory (CSIRO, Melbourne, Australia). An overall absolute temperature accuracy of ±3 °C is achieved.

Ensuring the achievement of equilibria

The achievement of an equilibrium state in the samples was ensured by: (1) conducting repeat experiments at extended equilibration times, i.e., doubling or tripling the equilibration time and (2) carrying out selected experiments with the equilibrium compositions approached from two opposite directions, i.e., from more oxidized and more reduced mixture compositions. For example, in the case of the spinel and bunsenite (NiO) equilibrium, the starting compositions of a mixture of Fe2O3/NiO powders (with Fe/[Fe + Ni] = 0.5 in moles) and a mixture of FeO/NiO powders (1:1 Fe2O3:Fe/NiO with Fe/[Fe + Ni] = 0.5 in moles) were used.

These methods were applied to selected experiments (the experimental data with the diamond symbol, shown in Tables III through V). The achievement of equilibrium in the rest of the experiments was confirmed using only the first method.

The procedure of the equilibration of the samples, similar to the procedure reported previously,[5] is described as follows.

-

(a)

Mixed powder is pelletized then fractured to fragments 2 mm in size.

-

(b)

The fragments are equilibrated at temperature, at set conditions.

-

(c)

A small piece of the sample is mounted and polished and phase compositions are measured using EPMA.

-

(d)

If EPMA results show differences in phase compositions between samples approaching from different directions, the samples are then recrushed, pelletized, and equilibrated once more at set conditions.

-

(e)

Steps (b) through (d) are repeated until the compositions of phases in samples approaching equilibria from opposite directions coincided.

Analysis Techniques

Following the quenching, the samples were dried and then crushed into smaller pieces, to be mounted in epoxy resin and cured in a vacuum chamber. Cross sections of the samples were then prepared by polishing the surface with SiC paper and diamond paste. The sample microstructures were then initially examined using an optical as well as a scanning electron microscope and energy-dispersive X-ray spectroscopy analysis, using a JEOLFootnote 1 6460LA.

An electron probe X-ray microanalyzer, a superprobe JEOL 8200L equipped with five wavelength-dispersive X-ray detectors, was then used to determine the phase compositions of the equilibrated samples. The microanalyzer was operated at 15-kV accelerating voltage and a probe current of 15 nA. The Fe2O3, MgO, Al2O3 (from the Charles M. Taylor Co., Stanford, CA), and NiO (prepared in-house using NiO, 99.99 wt pct purity) standards were used for the iron, nickel, magnesium, and aluminum calibrations for the EPMA measurements. The Duncumb–Philibert atomic number, absorption, and fluorescence correction procedure supplied with the superprobe JEOL-8200L was applied. The average accuracy of the EPMA measurements was within 1 wt pct.

Phase Equilibria Predictions

Predictions of the phases and their compositions and proportions formed under equilibrium conditions in the samples were carried out using the FactSage[37] (CRCT, Montreal, Canada and GTT, Aachen, Germany) thermodynamic software (Version 5.5). The appropriate optimized thermodynamic solution databases[38] were used in the modeling; these include solution databases for spinel (Fe2+, Ni2+, Mg2+)[Fe3+, Al3+]2O4, monoxide (wustite and bunsenite) (Fe, Mg, Ni) O y , and hematite (corundum) (Fe, Al)2O3.

Results and discussion

Pseudobinary Phase Diagrams of the ‘Fe2O3’-MgO, ‘Fe2O3’-Al2O3, and NiO-Al2O3 Systems in Air

Experiments have been carried out on the Fe-Mg-O phase equilibrium in air at temperatures between 1200 °C and 1600 °C, to complement the experiments carried out by Hansson et al.[30] The compositions (expressed in metal-mole fractions) measured in the phases at hematite-spinel and spinel-periclase equilibria are reported in Table I. These data were also presented on a pseudobinary ‘Fe2O3’-MgO phase diagram shown in Figure 1, i.e., closed-circle data points. Previous results by Paladino,[27] Phillips et al.,[28] Wilshee and White,[29] and Hansson et al.[30] and predictions using FactSage thermodynamic software[37] are also shown in the figure.

The concentration of iron in the spinel phase in equilibrium with hematite increases with increasing temperature; this is in agreement with previous studies. The spinel composition at the spinel/periclase boundary obtained from the current study is also in agreement with previous work by Paladino[27] and Hansson et al.[30] The FactSage prediction[37,38] underestimates the Fe concentration of this spinel boundary. The abnormal inflection in the spinel composition at the spinel/periclase boundary at approximately 1400 °C reported by Wilshee and White[29] was not observed in the current study; this supports the observation by Hansson et al.[30]

The limiting composition of the periclase in equilibrium with the spinel phase in air contains increasing concentrations of iron with increasing temperature. The results from the current study are in agreement with the periclase boundary determined by Wilshee and White[29] and calculated using FactSage. A sharp increase in the solubility of iron in periclase was observed above 1200 °C.

A detailed study of the morphology of the phases formed in the equilibrated samples is beyond the scope of the present article. However, since the quantification of the compositions of phases at a microscopic level is one of the techniques used in the present study, the typical microstructures observed in the samples are presented in the present article. Figures 2(a) and (b) show examples of the microstructure observed in the samples in the case of the spinel-periclase and spinel-hematite equilibria, respectively, at 1300 °C. Different levels of grayscale represent the different phases present in the sample. The phase grains are dense and have a polygon shape, a typical sintered structure (Figure 2). In general, the microstructures equilibrated at higher temperatures were denser (fewer pores and voids) compared to those equilibrated at lower temperatures. No other significant changes in the microstructures were observed with increasing temperature, in the range of conditions studied.

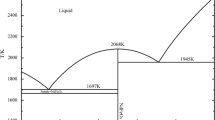

The results of experiments on the Fe-Al-O system in air at temperatures between 1200 °C and 1400 °C carried out in the present study are tabulated in Table II and are also shown in a pseudobinary phase diagram of ‘Fe2O3’-Al2O3 in Figure 3 (closed-circle data points). The results from the Hansson et al.[33] open-triangle data points, from Muan,[31,32] and from the FactSage predictions are also shown in the figure.

It can be seen from Figure 3 that, at a temperature of 1200 °C, only hematite and corundum phases were observed. The solubilities of aluminum in the hematite phase and of iron in the corundum phase increase with increasing temperature. The solubility of aluminum in the hematite phase was found to be much higher than the solubilities reported by Muan[31,32] and predicted by FactSage. The present results, however, show the same trend as the results from Hansson et al.[33] The iron solubility in corundum at 1200 °C was also found to be higher than that reported by Muan, but is in good agreement with the FactSage predictions.

At 1300 °C, hematite, corundum, and Fe2Al2O6 phases were observed. In the previous study by Muan, a Fe2Al2O6 phase was reported to form at 1318 °C. It appears that the actual Fe2Al2O6 phase field in Figure 3 is bigger than that reported by Muan; it extended down to 1300 °C (note that equilibrium at 1300 °C was approached from a low temperature, starting from pure Fe2O3 and Al2O3 powders).

Spinel, Fe2Al2O6, and corundum phases were observed at a temperature of 1400 °C. The compositions of the spinel (26.7 Al metal-mole pct) and corundum (87.3 Al metal-mole pct) phases at 1400 °C obtained in the present studies are in good agreement with the results from previous studies.[33] The composition range in which the Fe2Al2O6 phase is observed, however, was found to be different, compared to the results from Muan. In the present study, the Fe2Al2O6 phase was observed in the composition range between 54.6 and 56.5 Al metal-mole pct.

Table III shows the results of experimental studies on the phase equilibria of the Ni-Al-O system in air at temperatures between 1200 °C and 1400 °C. Spinel, bunsenite, and corundum phases were observed in this temperature range. Figure 4 shows the binary phase diagram of NiO-Al2O3 in air. The open- and closed-circle data points represent the present results from experiments in which equilibrium was approached from different directions; the same results confirm that the equilibrium state had been attained. The dashed and dashed-dotted curves in Figure 4 are phase boundaries reported by Phillips et al.[34] and predicted by FactSage, respectively.

In the temperature range studied, the solubility of the aluminum in the bunsenite phase does not change significantly with increasing temperature. The aluminum solubility in the bunsenite phase was found to be slightly higher than that reported by Phillips et al.[34]

The solubility of aluminum in the spinel phase was observed to increase with increasing temperature and was in a good agreement with the FactSage predictions at 1200 °C and 1300 °C. Above 1400 °C, however, FactSage overestimates the aluminum solubility in the spinel phase. Phillips et al.[34] reported a higher aluminum solubility in spinel in this temperature range, e.g., for a composition of spinel 75 Al metal-mole pct at 1400 °C. In the present study, at 1400 °C, the composition of spinel in the spinel + corundum phase field is found to be 71.8 Al metal-mole pct, as shown in Figure 4.

From Figures 1, 3, and 4, it can be seen that there are discrepancies between the results obtained in the present study and in previous studies.[27–29,31,32,34] The earlier studies were carried out using high-temperature equilibration and quenching techniques followed by XRD, for phase identification and for the determination of phase boundaries. There are several advantages of the EPMA over the XRD technique; these include the following.

-

(a)

Increased accuracy: EPMA, including the measurement of phase composition, is carried out after the equilibration experiment, avoiding uncertainty due to the unavoidable loss of components or materials during the sample preparation and equilibration process, i.e., loss through vapor phase reactions or reactions with materials from the suspender.

-

(b)

Microanalysis capability: The quantitative analysis of the composition of the phases can be carried out accurately in a small area 1 to 2 μm in lateral size, which can be used for evaluating local equilibrium.

-

(c)

Imaging capability: The secondary and backscattered electron imaging provide additional information for evaluating the phases present and their morphology and for evaluating other microstructural characteristics.

-

(d)

Analysis of noncrystalline phases: EPMA can be used to determine the composition of amorphous or glassy phases.

Unlike the EPMA technique, the XRD technique is insensitive to small variations in the concentrations of metal cations for determining the phase boundaries, when there are atoms of similar size in a specific crystallographic position.

Particular equilibration procedures, including extended equilibration times and equilibration from different directions (i.e., from reducing and oxidizing states) and the use of small fragments of materials also ensure the achievement of equilibrium in the present study.

These results for the low-order systems described here are important for characterization of higher-order systems and highlight the differences between the results from the present and previous studies.

Ternary Phase Diagram of the Fe-Ni-Mg-O System in Air

The Fe-Ni-Mg-O phase equilibria in air at temperatures between 1200 °C and 1600 °C were investigated. In this system, iron can be present in both the ferric and ferrous forms. In the current study, determination of the concentrations of ferric and ferrous irons was not carried out. The phase equilibria data in this system were projected onto the Fe-Mg-Ni plane using the metal atom ratio (schematic in Figure 5).

The compositions of the equilibrium phases determined by EPMA are presented in Table IV and are also plotted in Figures 6(a) through (e).

The tie-lines and phase boundaries from the current study and the phase boundaries predicted by FactSage are also shown in Figure 6. Several trends can be identified from Figure 6. Monoxide, spinel, and hematite were observed at 1200 °C and 1300 °C, and the composition range of the spinel + hematite phase field decreases with increasing temperature (Figures 6(a) and (b)). Between 1400 °C and 1600 °C (Figures 6(c) and (d)), only spinel and monoxide phases were observed in the system. The composition range of the monoxide phase field, in general, expands with increasing temperature between 1200 °C and 1600 °C; that is, the solubility of iron in the monoxide increases with increasing temperature.

Slight discrepancies were observed on the spinel phase boundaries and in the (spinel + monoxide) and (spinel + hematite) phase assemblages between the present results and the FactSage predictions. In contrast, the monoxide-limiting compositions in equilibrium with spinel were found to be significantly different from the FactSage predictions. The FactSage calculations underestimate the maximum solubility of iron in the Ni-rich monoxide phase and overestimate the iron solubility in the Mg-rich monoxide (a Mg/Ni ratio of between 0 and 1).

Typical microstructures observed in the samples in the case of the spinel-hematite equilibrium at 1200 °C and the spinel-monoxide equilibrium at 1400 °C are shown in Figures 7(a) and (b), respectively. Dense polygon-shaped phases and grains were observed in these samples. No significant changes in the microstructure between 1200 °C and 1600 °C were observed.

Ternary Phase Diagram of Fe-Ni-Al-O System in Air

The results of the phase equilibria study of the Fe-Ni-Al-O system in air at temperatures between 1200 °C and 1400 °C are given in Table V. The results are also shown in phase diagrams; similar to the case of the Fe-Ni-Al-O system, the phase equilibria data are projected onto the Fe-Al-Ni plane, as shown in Figures 8(a) through (c). The solid and dashed-dotted curves are phase boundaries obtained from the present study and the FactSage calculations, respectively. The dashed lines are the tie-lines obtained from the present study.

It can be seen from Figure 8 that, in the temperature range studied, the composition range of the monoxide phase field expands with increasing temperature; both the aluminum and the iron solubilities in monoxide increase with increasing temperature. The composition range of the spinel phase field was also observed to expand with increasing temperature. In contrast, the composition range of the spinel + hematite phase field decreases with increasing temperature.

Spinel, corundum, monoxide, and hematite phases were observed at 1200 °C. Spinel, corundum, and hematite can coexist, forming a three-phase equilibrium, as shown in Figure 8(a). At 1300 °C, in addition to the aforementioned phases, Fe2Al2O6 was also observed. Two three-phase equilibria of spinel + corundum + Fe2Al2O6 and spinel + hematite + Fe2Al2O6 assemblages were observed at 1300 °C, as shown in Figure 8(b). Spinel, corundum, monoxide, and Fe2Al2O6 were present at 1400 °C. No three-phase equilibria were observed at 1400 °C.

Some discrepancies between the present results and the FactSage predictions (Figure 8) were observed. The FactSage thermodynamic solution databases were optimized based on the previously available experimental data (e.g., data from lower-order systems). As has been pointed out in Section III–A, these lower-order systems are not fully characterized and the previously available data need to be revised. Therefore, the differences between the results from the present study and the FactSage predictions can be expected.

Figure 9 shows examples of microstructures observed in the Fe-Ni-Al-O system in air at various temperatures. The black areas in these figures are pores. Figures 9(a) through (c) show the microstructures in the samples with spinel-corundum equilibrium. It appears that the corundum phase exhibits a thick platelike morphology, while the spinel exhibits a more equiaxed polygon morphology. There are no significant differences in the microstructure of the samples at 1200 °C, 1300 °C, and 1400 °C. Examples of microstructures in the samples with the spinel-monoxide equilibrium are shown in Figures 9(d) and (f). It can be seen from the figures that both spinel and monoxide phases exhibit polygon morphology. It also appears that there are no significant differences in the microstructure at 1200 °C, 1300 °C, and 1400 °C. Examples of microstructures of the three-phase equilibria spinel-corundum-hematite and spinel-corundum-Fe2Al2O6 are shown in Figures 9(g) and (h), respectively. The spinel, hematite, and Fe2Al2O6 phases in these microstructures exhibit polygonal morphology. The corundum phase, in the case of the spinel + corundum + hematite phase equilibria, exhibits a platelike morphology (Figure 9(g)); however, in the case of the spinel + corundum + Fe2Al2O6, a more rounded morphology is exhibited (Figure 9(h)).

Examples of microstructure (backscattered electron image) observed in Fe-Ni-Al-O system in air. Spinel-corundum equilibria are shown at (a) 1200 °C, (b) 1300 °C, and (c) 1400 °C; spinel-monoxide equilibria are shown at (d) 1200 °C, (e) 1300 °C, and (f) 1400 °C; (g) spinel + corundum + hematite equilibrium is shown at 1200 °C; and (h) spinel + corundum + Fe2Al2O6 equilibrium is shown at 1300 °C. Legend: S = spinel, C = corundum, H = hematite, and B = bunsenite

Conclusions

The phase equilibria of the Fe-Ni-Mg-O and Fe-Ni-Al-O systems, including their lower-order systems, ‘Fe2O3’-MgO, ‘Fe2O3’-Al2O3, and NiO-Al2O3, at temperatures between 1200 °C and 1600 °C in air at the subsolidus region have been experimentally studied. It was found that there are some differences between the present data and the data published previously. It is suggested that the improved experimental techniques used in the present study provide more accurate and precise measurements of the phase boundaries and compositions.

In the case of ‘Fe2O3’-Al2O3 binary phase diagram, the solubilities of aluminum in hematite and of iron in corundum were found to be much larger than those reported in the previous studies. The Fe2Al2O6 phase was observed to form at temperatures as low as 1300 °C, in contrast to 1318 °C, as was previously reported. In the case of the NiO-Al2O3 binary phase diagram, the present results suggested a lower aluminum solubility in the spinel phase.

In the Fe-Ni-Mg-O system, FactSage calculations underestimate the Fe solubility in the Ni-rich monoxide phase and generally overestimate the Fe solubility in the Mg-rich monoxide (a Mg/Ni ratio of between 0 and 1). In the Fe-Ni-Al-O system, FactSage underestimates the solubilities of Fe and Al in the monoxide phase. Three three-phase equilibria were observed in the system in the temperature range studied, i.e., spinel + corundum + hematite, spinel + corundum + Fe2Al2O6, and spinel + hematite + Fe2Al2O6.

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

M.H. Caron: Trans. AIME, 1950, vol. 188, pp. 67–90; U.S. Patent 1,346,175, 1920

M.A. Rhamdhani, E. Jak, P.C. Hayes: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 218–33

M.A. Rhamdhani, P.C. Hayes, and E. Jak: Miner. Process. Extr. Metall. (Trans. Inst. Min. Metall., Sect. C), 2009

M.A. Rhamdhani, P.C. Hayes, and E. Jak: Miner. Process. Extr. Metall. (Trans. Inst. Min. Metall., Sect. C), 2009

M.A. Rhamdhani, P.C. Hayes, and E. Jak: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 690–701

V. Raghavan: Phase Diagrams of Ternary Iron Alloys, Part 5. Ternary Systems Containing Iron and Oxygen, Indian Institute of Metals, Calcutta, India, 1989, pp. 222–31

R. Luoma: CALPHAD, 1995, vol. 19 (3), pp. 279–95

G.S. Viktorovich, V.A. Gutin, D.I. Lisovskii: Tsvetn. Met. (Moscow), 1966, vol. 39 (12), pp. 54–57

G.S. Viktorovich, D.I. Lisovskii: Tsvetn. Met. (Moscow), 1966, vol. 39 (11), pp. 49–55

G.S. Viktorovich, D.I. Lisovskii, V.A. Gutin: Russ. J. Phys. Chem., 1969, vol. 43 (12), pp. 1709–11

G.S. Viktorovich, R.Y. Dobrovinskii, V.S. Zhagalov, D.I. Lisovskii, A.N. Men, G.I. Chufarov: Russ. J. Phys. Chem., 1970, vol. 44 (1), pp. 116–18

G.S. Viktorovich, V.S. Zhagalov, D.I. Lisovskii: Russ. J. Phys. Chem., 1972, vol. 46 (6), pp. 881–82

A.D. Dalvi, R. Sridhar: Can. Metall. Q., 1976, vol. 15 (4), pp. 349–57

G.A. Roeder, W.W. Smeltzer: J. Electrochem. Soc., 1964, vol. 111 (9), pp. 1074–78

H. Davies, W.W. Smeltzer: J. Electrochem. Soc., 1972, vol. 119 (10), pp. 1362–68

A.D. Dalvi, W.W. Smeltzer: J. Electrochem. Soc., 1970, vol. 117 (11), pp. 1431–36

A.D. Dalvi, W.W. Smeltzer: J. Electrochem. Soc., 1974, vol. 121 (3), pp. 386–94

F. Schneider, H. Schmalzried: Z. Phys. Chem. Neue Folge, 1990, vol. 166, pp. 1–18

A.E. Paladino Jr.: J. Am. Ceram. Soc., 1959, vol. 42 (4), pp. 168–75

M.W. Shafer: J. Phys. Chem., 1961, vol. 65, pp. 2055–62

I. Katayama, Y. Watanabe, Z. Kozuka: Trans. JIM, 1979, vol. 20, pp. 593–96

A.D. Pelton, H. Schmalzried, J. Stitcher: J. Phys. Chem. Solids, 1979, vol. 40, pp. 1103–22

P.Y. Eveno, M.P. Paulus: Proc. 8th Int. Symp. Reactivity of Solids, Wiley Interscience Publication, New York, NY, 1976, p. 433

H.S. Roberts, H.E. Merwin: Am. J. Sci., 1931, vol. 21 (122), pp. 145–57

R.G. Richards, J. White: J. Trans. Br. Ceram. Soc., 1954, vol. 53, pp. 422–59

D. Woodhouse, J. White: J. Trans. Br. Ceram. Soc., 1955, vol. 54, pp. 333–66

A.E. Paladino Jr.: J. Am. Ceram. Soc., 1960, vol. 43 (4), pp. 183–91

B. Phillips, S. Somiya, A. Muan: J. Am. Ceram. Soc., 1961, vol. 44 (4), pp. 167–69

J.C. Wilshee, J. White: J. Trans. Br. Ceram. Soc., 1967, vol. 66, pp. 541–55

R. Hansson, P.C. Hayes, E. Jak: Scand. J. Metall., 2004, vol. 33, pp. 355–61

A. Muan, C.L. Gee: J. Am. Ceram. Soc., 1956, vol. 39 (6), pp. 207–14

A. Muan: Am. J. Sci., 1958, vol. 256, pp. 413–22

R. Hansson, P.C. Hayes, E. Jak: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 633–42

B. Phillips, J.J. Hutta, I. Warshaw: J. Am. Ceram. Soc., 1963, vol. 46 (12), pp. 579–83

Y. Iida: J. Jpn. Soc. Powder Met., 1959, vol. 6 (2), pp. 55–58

E. Jak, P.C. Hayes, H.G. Lee: Kor. J. Met. Mater., 1995, vol. 1, pp. 1–8

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melancon, A.D. Pelton, S. Petersen: CALPHAD, 2002, vol. 26, pp. 189–228

S.A. Decterov, I.-H. Jung, E. Jak, Y.-B. Kang, P. Hayes, A.D. Pelton: Proc. VIIth Int. Conf. Molten Slags, Fluxes, and Salts, Capetown, SAIMM, Johannesburg, South Africa, 2004, pp. 839–50

Acknowledgments

The authors thank the Australian Research Council and the BHP Billiton Yabulu refinery at Townsville, Australia, for their financial support for this research (Grant No. ARC LP0562201), which was undertaken under the auspices of the Australian Research Council Linkage program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 2, 2008.

Rights and permissions

About this article

Cite this article

Rhamdhani, M., Hidayat, T., Hayes, P. et al. Subsolidus Phase Equilibria of Fe-Ni-X-O (X = Mg, Al) Systems in Air. Metall Mater Trans B 40, 25–38 (2009). https://doi.org/10.1007/s11663-008-9213-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-008-9213-z