Abstract

The nonisothermal decomposition process of the powder sample of palladium acetylacetonate [Pd(acac)2] was investigated by thermogravimetric (TG) and X-ray diffraction (XRD) techniques. The experimental TG and differential thermogravimetric (DTG) curves were obtained at different heating rates (β = 2 °C min−1, 5 °C min−1, 10 °C min−1, 20 °C min−1, and 30 °C min−1) under a pure nitrogen (N2) atmosphere. The kinetic triplet (A, E a , and model function f(α)) was determined using different kinetic methods. It was found that the apparent activation energy was not really changed and was almost independent with respect to the level of conversion (α). This result suggests that the nonisothermal decomposition process of palladium acetylacetonate follows a single-step reaction. Practically constant E a values approximating 140.1 ± 1.5 kJ mol−1 were found. It was concluded that the reaction model R3, for the integral composite method I, is the model with the best regression and with kinetic parameters that are both unique and very similar to those obtained by the Friedman isoconversional method. In addition, it was found that the results obtained from both the Master-plot and Málek methods confirm the results obtained from the multiple-rate isotemperature method, specifically, that the R3 (contracting volume) reaction mechanism can best describe the investigated decomposition process. By applying the Miura procedure, a distributed reactivity model (DRM) for the investigated decomposition process was established. From the α = α(E a ) dependence, the experimental distribution curve of E a was estimated. Using the nonlinear (NL) least-squares analysis, it was found that the Gaussian distribution model (with distribution parameters: E 0 = 138.4 kJ mol−1 and σ = 0.71 kJ mol−1) represents the best reactivity model for describing the investigated process. Also, it was concluded that the E a values calculated by the Friedman isoconversional method and the estimated distribution curve (f(E a )), are correct, even in the case in which the investigated decomposition process occurs through a single-step reaction mechanism.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recent advances in solid-state electronics[1] and catalysis[2–4] have often been achieved through the use of organometallic complexes as precursors of high-purity metal phases with the desired composition and topology. In this respect, acetylacetonate complexes have a significant role,[5–8] because they are easily synthesized and purified; their volatility may also be finely tuned for chemical vapor deposition (CVD) applications by the controlled introduction of fluorine atoms. Moreover, the supported metal phase is simply obtained by the controlled thermal removal of acetylacetonate ligands. However, the final properties of the metal phase, particularly for catalytic purposes, are generally dependent on the nature of the chemical interactions between the organometallic complex and the oxide support.[5–9]

Thermochemical methods play a primary role in the characterization of the kinetics of the decomposition processes of the supported organometallics, to yield the desired metal phase. Many different approaches have been proposed, ranging from conventional differential thermogravimetric (DTG) studies[6,8] to more specialized flow techniques for catalyst characterization.[10–12] A large amount of information about a catalytic system can be obtained by using thermogravimetric (TG) techniques (working with an appropriate temperature program).[13] From the thermal data, it is possible to achieve information regarding the composition and structure of the different phases of a given sample. Mass changes as a function of the temperature registered through the TG analysis technique are caused by the formation and rupture of chemical bonds at high temperatures, either by processes that cause volatile compounds or by reaction products that modify the sample mass.

The decomposition of organometallic compounds that are in the solid state and that are components of various viscous compositions, such as pastes and polymers, can be regarded as separate techniques. Organometallic compounds of the platinum group can decompose to a metal or an oxide under the influence of: heat, electric discharge, and electron beam and laser radiation; these techniques are employed for the vapor phase decomposition.[14] The decomposition of organometallic compounds in solution is frequently performed thermally, photochemically, electrochemically, or via chemical reduction and hydrolysis.[14–16] Any organometallic platinum group compound is potentially suitable for the formation of films from solution via thermal decomposition. The determining factor is the availability of the compound and its possible commercial production.

Palladium is one of the less expensive platinum group metals; the chemistry of its organometallic compounds is well developed.[17,18] Palladium, ruthenium, rhodium, iridium, and platinum acetylacetonates have been used as CVD precursors, to prepare asymmetric membranes by coating a tubular γ-Al2O3.

Our principal objective is the kinetic analysis of the nonisothermal decomposition of palladium acetylacetonate [Pd(acac)2] (where acac denotes C2H7O2), that is, the determination of the full kinetic triplet: pre-exponential factor (A), apparent activation energy (E), and analytical form of reaction model function (f(α)). Palladium acetylacetonate has been used to prepare either Pd/MgO catalysts by the dry-mix method[19] or Pd catalytic monoliths by CVD.[20]

In modern literature, there is no information about the nonisothermal decomposition of palladium acetylacetonate from the point of view of solid-state kinetics.

Cominos and Gavriilidis[21] have investigated the sublimation and deposition of [Pd(acac)2] through TG and X-ray diffraction (XRD) analysis. They concluded that the temperature range for sublimation, avoiding the thermal decomposition, lies in the range 100 °C to 160 °C and that sublimation is required to take place in the presence of an inert gas such as helium. They also found that the investigated complex is highly unstable in the presence of hydrogen. In addition, the same authors have established that the deposition of the complex on monolithic substrates required the presence of adsorption sites and that the change in the apparent deposition activation energy was found to take place within the range 100 °C to 150 °C.

Poston and Reisman[22] have investigated the relative stabilities of palladium acetylacetonate and palladium hexafluoroacetylacetonate using differential thermal analysis (DTA) and weight loss analysis. In general, the acetylacetonates decompose in solid state at relatively low temperatures (100 °C to 200 °C); several of them exhibit appreciable vapor pressures at temperatures below which their decomposition rate is significant. At the heating rates employed, ≤2 °C min−1, palladium acetylacetonate tends to decompose upon heating in either an inert or oxidizing atmosphere before significant quantities volatilize. Heating palladium acetylacetonate in argon at ≤2 °C min−1 shows the onset of an endotherm at approximately 196 °C, at the conclusion of which a product containing 75 pct palladium was found, with the remainder comprised of carbon, hydrogen, and oxygen.[22] These authors found that, in an oxidizing atmosphere at the same heating rate, [Pd(acac)2] decomposes exothermically at 180 °C, yielding essentially pure palladium. Continued heating in oxygen to 800 °C results in pure PdO. At 900 °C, the PdO decomposes, yieling pure palladium. From the kinetic point of view, the authors do not give any information about the mechanistic conclusions of the investigated process or about the values of the Arrhenius parameters (A and E).

Paasonen et al.[23] have investigated the thermal decomposition of palladium acetylacetonate intercalated into a fluorocarbon matrix using mass spectrometry (MS). It is demonstrated that thermal decomposition occurs within a narrower temperature range at a higher rate and comes to its completion at a lower temperature (∼200 °C) than for the case of individual [Pd(acac)2]. Lashdaf et al.[24] have investigated the thermal properties of volatile β-diketonato complexes of ruthenium, palladium, and platinum. The thermal characterization of the complexes mentioned were studied with TG, DTA, DSC, and MS methods, but the kinetic aspects of the considered decomposition processes were not presented.[24]

In this article, the complete kinetic investigation of palladium acetylacetonate decomposition under nonisothermal conditions was realized using the isotemperature method of multiple heating rates[25] and the Bosewell, Augis–Bennett,[26,27] Master-plots,[28] differential isoconversional (model-free),[29] and differential and integral composite I methods,[30–32] and the Málek kinetic procedure.[33–35] In this article, the distributed reactivity model (DRM) for the investigated decomposition process was also established. For determining the DRM for the considered process, the Miura procedure[36,37] was used.

2 Experimental

2.1 Materials and Methods

Palladium acetylacetonate was synthesized by precipitation from a solution of PdCl2 and acetylacetone in ethanol. The precipitate was washed with ethanol and dried under a vacuum approximating 10 mbar at room temperature. The Pd(acac)2 was synthesized using the procedure published by Okeya et al.,[38] beginning with PdCl2 and acetylacetone. The purity of Pd(acac)2 was determined by TG analysis in the hydrogen atmosphere, at the point at which the main decomposition occurs at a temperature of only 100 °C and a Pd residue, which was found to amount to 34.5 pct, corresponding to a purity of 98.8 pct (this is close to the 99 pct purity of the commercial product by Aldrich, Catalog No. 20.901-5).

Thermal decomposition was studied by thermogravimetry, using a TA (TA Instruments Ltd., Crawley, West Sussex, UK) SDT 2960 thermobalance. The average mass of samples was approximately 4 mg. The purging gas was nitrogen (99.9995 vol pct) at a flowing rate of 90 mL min−1. The flow of pure filtered nitrogen carrier gas was supplied from a high-pressure cylinder. The furnace temperature rose linearly at the heating rates 2 °C min−1, 5 °C min−1, 10 °C min−1, 15 °C min−1, and 30 °C min−1, in the range of temperatures from ambient up to 350 °C.

The microphotograph of the samples upon decomposition was taken by a JEOLFootnote 1 JSM-6460 scanning electron microscope (SEM). The X-ray powder diffraction patterns were collected using a PhilipsFootnote 2 PW-1050 automatic diffractometer with a Cu Kα1,2 line of 1.5418 nm.

3 Kinetic Analysis

According to nonisothermal kinetic theory, the thermal decomposition kinetic equation of solid-state material is

where α is the extent of conversion (for a gravimetric measurement, α is defined by α = (m 0 − m t )/(m 0 − m f ), where m 0 is the initial mass, m t is the mass at time t (or temperature T), and m f is the final mass); β is the heating rate; E a is the apparent activation energy; A is the pre-exponential factor; R is the gas constant; and f(α) is the differential expression of the kinetics model function.

Equation [2][39] is the integral form of Eq. [1]:

where g(α) is the integral expression of the kinetics model function and p(x) is the temperature integral for x = E a /RT, which does not have an analytical solution. To overcome this difficulty, the temperature integral has been solved using series, expansions, and approximation and numerical solution methods.[40] The basic analytical expressions for the f(α) and g(α) model functions used in this work for the kinetic analysis of the decomposition process of [Pd(acac)2] are presented in Table I.

If T 0 is low, it may be reasonably assumed that T 0 → 0, so that at the lower limit of the integral on the right side of Eq. [2], T 0 can be approximated as zero.

The differential isoconversional method suggested by Friedman[29] is based on Eq. [1] in the logarithmic form:

The apparent activation energy (E a ) is determined from the slope of the plot of ln [β i (dα/dT)α,i ] vs 1/T α , at a constant α value. The subscript i is the ordinal number of an experiment performed at a given heating rate. This method is rather accurate, because it does not include any mathematical approximations.

The isoconversional methods, which allow for model-independent estimates of the apparent activation energy at progressive degrees of conversion by conducting multiple experiments at different constant heating rates, are highly recommended for obtaining a reliable kinetic description of the investigated process.[41]

In order to determine the apparent activation energy, the Bosewell method[26] uses the following equation:

where T p is the DTG peak temperature at a given heating rate β. The slope of the graph ln (β/T p ) vs 1/T p gives the apparent activation energy (E a ). However, Eq. [4] does not provide any information about the pre-exponential factor (A), and a single E a value is obtained.

According to the method suggested by Augis and Bennett:[27]

where T 0 is the onset temperature. The values of E a and A can be obtained from the plot of ln [β/(T p − T 0)] vs 1/T p .

The composite methods presuppose one single set of activation parameters for all conversions and heating rates. In this way, all the experimental data can be superimposed in one single master curve.

The composite integral method I[30,31] is based on the Coats–Redfern equation,[42] which is rewritten as follows:

For each form of g(α), the curve ln (βg(α)/T 2) vs 1/T was plotted for the experimental data obtained at different heating rates. We then chose the kinetic model that gives the best correlation coefficient for which the data fall in a single master straight line. A single set of activation parameters, E a and A, can be obtained from the slope and intercept of the straight line.

The composite differential method I[32] is based on the following equation:

where dα/dt is the rate of the considered process at a given heating rate β. The data for different heating rates must be grouped together in a single relation from which a single set of activation parameters, E a and A, is obtained.

Equation [8] is derived from the logarithmic form of Eq. [2]:[25]

If the considered mechanism conforms to a certain g(α) when plotting ln g(α) vs ln β using a linear regression of the least-squares method, the slope K and the linear correlation coefficient r should both be equal to −1.00000. The pre-exponential factor (A) can be estimated from the intercept of the plot of ln g(α) vs ln β. In addition, Eq. [8] can also be applied under isothermal experimental conditions, with the supposition that p(x) → 1.

3.1 Determination of Most Probable Mechanism Function

The conversions α corresponding to multiple rates at the same temperature are inserted into the left side of Eq. [8] and combined with the 19 types of mechanism functions presented in Table I; the slope K and linear correlation coefficient r are obtained from the plot of ln g(α) vs ln β. The probable model function is that for which the value of the slope (K) is near −1.00000 and r is better. If several g(α) answer for this requirement, the conversions (α) that correspond to multiple rates at several of the same temperatures were applied to calculate the probable using by the same method. The most probable mechanism (model function) is that for which the value of K is closest to −1.00000, among the results of K and r.

Using the reference point α = 0.5, the following integral master equation is easily derived from Eq. [2]:

where g(0.5) and p(x 0.5) represent the integral model function and the temperature integral at α = 0.5, respectively. Equation [9] is valid for the constant value of the heating rate (β).

The function p(x) can be expressed using the fourth rational approximation by Senum and Yang:[43]

Plotting g(α)/g(0.5) vs α corresponds to the theoretical master plots of various g(α) functions. Both the conversion-temperature (α-T) profile and the value of E a for the process should be known in advance, in order to draw the experimental master plots of p(x)/p(x 0.5) vs α from the experimental data obtained at a given heating rate. To draw the experimental master plots obtained under different βs, an approximate formula of p(x) given by Eq. [10] was used. Thus, Eq. [9] indicates that, for a given α, the experimental values of p(x)/p(x 0.5) and the theoretically calculated values of g(α)/g(0.5) are equivalent when an appropriate model function is used.

Once the apparent activation energy has been determined, it is possible to find the kinetic model that corresponds more closely to the description of the experimental data issued from the TG experiments. For this purpose, it is possible to define two especial functions proposed by Málek,[33–35] which can easily be obtained through the transformation of experimental data. For dynamic conditions, these functions are defined as

The value of α at the maximum of the z(α) function, α * z , is characteristic of the kinetic model,[33] the shape of the y(α) function is formally identical to the differential form of the kinetic model function f(α),[33,34] and its maximum value is labeled as α * y .

4 Determination of drm for decomposition process of [Pd(acac)2]

For determining the DRM for the investigated nonisothermal decomposition process of [Pd(acac)2], the Miura procedure[36,37] is used.

In accordance with this procedure, the cumulative mass loss can be expressed by the following equation:

where f(E a ) is a distribution curve of the apparent activation energy and A is the pre-exponential (frequency) factor corresponding to the E a value. The distribution curve f(E a ) is normalized to satisfy

The pre-exponential (frequency) factor (A) is generally assumed to be a constant for all reactions, to avoid the complexity of the analysis. However, the assumption of a constant A value may not be valid when f(E a ) spreads over a wide range of E a values, because it is well known that A and f(E a ) are interrelated.[44] Specific mathematical forms of f(E a ) appearing in the literature are the Gaussian,[45–47] Weibull,[48] and Gamma distributions.[49–52] The distribution can also be a finite, discrete distribution of arbitrary form, in which case the integral in Eq. [13] would be replaced with a summation.[53,54] Knowing f(E a ) and A, we can calculate the change in α for any heating profile.

The procedure for determining both f(E a ) and A(E a ) in at least three sets of experimental data can be summarized as follows.[36,37]

-

(a)

Measure α-vs-T relationships at a mimimum of three different heating rates.

-

(b)

Calculate the values of dα/dT at selected α values from the α-vs-T relationships obtained at the different heating rates.

-

(c)

Make the Friedman plots (ln [β(dα/dT)] vs 1/T) at the same values of α, using the relationship in Eq. [3].

-

(d)

Determine the apparent activation energies from the Friedman plots at different levels of α, then plot α against the apparent activation energy (E a ).

-

(e)

Differentiate the α-vs-E a relationship by E a to give f(E a ), because the following relation holds approximately

$$ \alpha = 1 - {\int\limits_{E_{a} }^\infty {f{\left( {E_{a} } \right)}} }dE_{a} = {\int\limits_0^{E_{a} } {f{\left( {E_{a} } \right)}} }dE_{a} $$(15) -

(f)

Calculate A corresponding to each E a value at all heating rates β i (i = 1, 2, 3, ...), using the following equation:[37]

$$ \frac{{0.545\beta _{i} E_{a} }} {{A{\text{R}}T^{2} }} = \exp {\left( { - \frac{{E_{a} }} {{{\text{R}}T}}} \right)} $$(16)and then employ the average value of A as a true A value.

Equation [16] was obtained when approximating Eq. [13] by Eq. [15]. No a priori assumptions were required for the functional forms of f(E a ) and A(E a ). In other words, we could estimate A and E a at any level of α by using the procedure discussed here.

5 Results and discussion

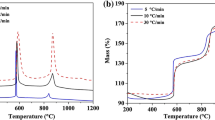

The TG and DTG curves of the decomposition process of palladium acetylacetonate samples obtained at different heating rates (β = 2 °C min−1, 5 °C min−1, 10 °C min−1, 20 °C min−1, and 30 °C min−1) are shown in Figures 1 and 2.

The effect of the heating rate on the TG and DTG behaviors of [Pd(acac)2] samples in a nitrogen atmosphere is presented in Figures 1 and 2.

Lowering the heating rate brings the reaction system closer to the equilibrium conditions and minimizes the effects of the heat transfer and thermal lag. As a result, the reaction starts and ends at lower temperatures and decomposition occurs over a narrower temperature range.

Figure 3 shows the relationships of α vs T at different heating rates (2 °C min−1, 5 °C min−1, 10 °C min−1, 20 °C min−1, and 30 °C min−1).

Figure 3 shows the temperature range in which the decomposition process occurs at the considered values of the heating rates (135 °C ≤ T ≤ 300 °C). It can be pointed out that the decomposition process does not start until approximately 135 °C. The mass loss during the thermal decomposition is the same at all heating rates, which is somewhat more than 65.5 pct expected on the basis of the real Pd content in the synthesized sample. This difference may be a consequence of the sublimation loss already considered in the literature.[55,56] Namely, Zharkova et al.[55] stated that, in vacuum, [Pd(acac)2] starts to sublime at 135 °C, while Guang et al.[56] found by TG-DTA and gas chromatography-MS techniques that, in an inert atmosphere of argone, [Pd(acac)2] sublimes at approximately 200 °C and decomposes simultaneously, forming mainly 2,4-pentadione and 1-propen-2-ol acetate. The exact estimation of the mass loss due to evaporation along the temperature axis is a difficult task and depends on many parameters. However, bearing in mind that, because both decomposition and sublimation are rate processes that follow similar exponential temperature dependencies, an approximate correction of the experimental TG curves may be obtained by multiplying the measured data by the correction factor (1 − Δα), where Δ is the difference between the measured and the theoretically expected final mass loss, and α has the usual meaning. We estimated that, after such a correction, the α-T curves differ from the original ones by less than 1 pct; thus, this correction was unnecessary.

The values of the peak temperature (T p ) and the extent of conversion at the maximum reaction rate (α p ) at the different heating rates are presented in Table II.

Increasing the rate leads to an increase in the peak temperature value (T p ) from 215 °C to 255 °C. On the other hand, the values of α p vary in the range 0.69 ≤ α p ≤ 0.73. The values of α p at 2 °C min−1 and 5 °C min−1 are equal (α p = 0.73), while the value of α p at 10 °C min−1, 20 °C min−1, and 30 °C min−1 is somewhat lower (Table II). It can be pointed out that Lee and Dollimore[57] established the kinetic procedure for choosing a reaction model function from the value of the extent of conversion at the maximum reaction rate (α p ).

This approach has not gained wide use. Therefore, Vyazovkin and Wight[58] have recommended using the isoconversional methods instead of methods similar to those mentioned here.

The nonisothermal decomposition process of [Pd(acac)2] was analyzed by the differential (Friedman) isoconversional method.

Typical Friedman plots, constructed to evaluate the slopes d(ln β(dα/dT))/d(1/T), are presented in Figure 4.

If the conversion mechanisms are the same at all conversion levels, all the isoconversion lines would have the same slopes. From Figure 4, we can observe that the presented isoconversional lines at all considered conversion levels (inset in Figure 4) have nearly the same slopes.

The dependence of the apparent activation energy (E a ) on the extent of conversion (α) (E a − α plot) for the nonisothermal decomposition process of [Pd(acac)2] obtained by the Friedman method is presented in Figure 5. Figure 5 also shows the dependence of the apparent isoconversional intercepts (Eq. [3]) on the extent of conversion (α) (ln [Af(α)] − α plot) for the investigated decomposition process.

It was observed from Figure 5 that the apparent activation energy was not really changed and was almost independent with respect to the level of a conversion. This suggests that the nonisothermal decomposition process of [Pd(acac)2] follows a single-step reaction. Practically constant E a values approximating 140.1 ± 1.5 kJ mol−1 were found (changes lie within the associated uncertainties). It should be noticed that this result was obtained without any knowledge of the reaction model function, f(α).

Figure 6 shows the comparison between the directly calculated values of the apparent activation energy (diamond symbol ♦) using the Friedman equation (Eq. [3]) and the simulated trend values of E a (dotted line) with the extent of conversion (α).

The simulated trend of E a on α can be described by the predicted equation in the form of a simple third-degree polynomial regression function:

The significant difference (ΔE a ) between the actual and predicted values of E a can be observed only at the beginning of the investigated process, i.e., in the range 0.05 ≤ α ≤ 0.10. For α = 0.05 and 0.10, these differences are ΔE a,1 = 3.4 kJ mol−1 and ΔE a,2 = 4.2 kJ mol−1, while for the remainder α, i.e., for α > 0.10, this difference does not exceed 2.0 kJ mol−1. Accordingly, the numerically evaluated Eq. [17] describes very well the dependence of the effective activation energy values (E a ) on the extent of conversion (α) for the decomposition process of palladium acetylacetonate under nonisothermal conditions.

The values of E a calculated using the Bosewell and Augis–Bennett peak temperature methods for the investigated decomposition process are presented in Table II (fourth and sixrth columns). It can be observed that the value of E a calculated by the Bosewell method (142.2 kJ mol−1) is somewhat higher than the value of E a calculated by the Augis–Bennett method (138.3 kJ mol−1). It can also be seen that the value of E a calculated from the Friedman isoconversional method (140.1 kJ mol−1) represents the intermediate value between the values of E a evaluated from the Bosewell and Augis–Bennett methods (Table II).

We chose the corresponding conversions at the experimental temperature T = 220 °C, for example, to put into 19 types of model functions (Table I); the slope K, the linear correlation coefficient r, and the intercept B of the linear regression of ln g(α) vs ln β are obtained (as shown in Table III).

The parameters in Table III show that the slopes of the number 5, 6, and 7 models are closer to −1.00000 than the others and have a better linear correlation coefficient r; although this type of reaction mechanism is the most probable one, it requires additional research.

For further investigation, we chose several temperatures that correspond to conversions in the range 0.05 ≤ α ≤ 0.95, in order to calculate the slope K, the linear correlation coefficient r, and the intercept B of model functions 5, 6, and 7. The obtained results are listed in Table IV; they show that the slope of model 7 is the closest to −1.00000 and that the linear correlation coefficient r is much better. From the results obtained, we can determine that the reaction mechanism function 7 is the most probable one for the decomposition process of [Pd(acac)2], with the integral form g(α) = [1 − (1 − α)1/3] and the differential form f(α) = 3(1 − α)2/3, which belongs to the mechanism of the phase-boundary reaction Rn with the accommodation parameter n = 3.

In order to confirm the established values of E a and A (see the results discussed earlier) and the evaluated reaction mechanism (model R3, Table IV), we have applied the integral/differential I composite methods and also the Master-plot and Málek methods.

To confirm these results, we used the composite integral method and the differential method I. Figures 7(a) and (b) show our results for the R3 model. Once again, it can be seen that, in both cases, the Rn model with n = 3 best fits the decomposition process, because all the different heating rate data are in only one master curve.

(a) Composite integral and (b) composite differential methods I of nonisothermal TG data (2 °C min−1, 5 °C min−1, 10 °C min−1, 20 °C min−1, and 30 °C min−1) based on Eqs. [6] and [7], for investigated decomposition process of [Pd(acac)2]. Empty square symbols correspond to integral data; empty circle symbols correspond to differential data

From Table V, we can see that the differential version of the composite method (Eq. [7]) produces results similar to those produced using the integral method, but with less accuracy. Furthermore, model R3 for the integral composite method I is the model with the best regression and with parameters that are both unique and very similar to those obtained by the Friedman isoconversional method (Figure 5).

Furthermore, the variations in the y(α) and z(α) functions with the extent of conversion are indicated in Figures 8 and 9; these are calculated using Eqs. [11] and [12], respectively. We normalized the values of both the y(α) and z(α) functions within (0,1) interval under nonisothermal conditions for the decomposition process of palladium acetylacetonate.

The shapes of the y(α) and z(α) plots are practically unchanged with respect to the heating rate. For the calculations of these functions, the apparent activation energy value of E a = 140.1 kJ mol−1 evaluated from the isoconversional (model-free) method was used.

The conversions, in which the y(α) and z(α) functions exhibit the maximum values (α * y and α * z , respectively) for the different heating rates (β), are listed in Table VI.

It is clear from the data in Table V and from Figures 8 and 9 that the values of α * y and α * z are nearly independent of the heating rate. The maxima of the z(α) plots fall into the narrow range 0.69 ≤ α * z ≤ 0.73. The y(α) functions show a convex behavior for α > 0.02, at all heating rates. However, for the range 0.00 ≤ α ≤ 0.02, the y(α) deviates from the convex behavior; this is characteristic of the phase-boundary group of reaction models.[33] It should be stressed that the shape of the y(α) function is strongly influenced by the E a value. The results obtained from the isoconversional method in the range 0.05 ≤ α ≤ 0.95 and the shapes of the y(α) functions indicate that there is a high probability of the presence of a single-step reaction.[59] This fact was confirmed by the positions of the maxima of the z(α) functions, which are found in the range of α from 0.69 to 0.73. The values of parameter α * z presented in Table VI for the investigated decomposition process of [Pd(acac)2] corresponds to the intermediate case between the contracting volume and the contracting area model functions (R3 and R2).

In order to determine unambiguously the most likely mechanism for the decomposition process of [Pd(acac)2], the theoretical master plots of g(α)/g(0.5) vs α (for the R2 and R3 models) and the experimental master plots of p(x)/p(x 0.5) vs α are obtained, as shown in Figure 10. For construction of the experimental master plots, the value of the apparent activation energy (E a ) obtained by the isoconversional (Friedman) method is used.

Master plots of theoretical g(α)/g(0.5) against α for R2 and R3 model functions (phase-boundary models) and experimental master plots p(x)/p(x 0.5) against α at different heating rates: (■) 2 °C min−1; (•) 5 °C min−1; (□) 10 °C min−1; (○) 20 °C min−1, and (▴) 30 °C min−1, for decomposition process of palladium acetylacetonate, [Pd(acac)2]

The superposition of the experiment master plotted at different heating rates indicated that the kinetics of the nonisothermal decomposition process of palladium acetylacetonate could be described by a single model function. It can be easily seen from Figure 10 that the investigated decomposition process is most probably described by the R3 reaction model:

The phase-boundary model R3 also represents the two-thirds-order kinetic model (F2/3) with an apparent reaction order n = 2/3, which reflects the influence of the degree of concentration on the reaction. The higher the n, the deeper the influence of the concentration. In our case, n is less than unity and, because of that, this influence is less expressive.

As mentioned in Section I, the extent of conversion (α) is related to f(E a ) by Eq. [15]. Therefore, f(E a ) is given by differentiating Eq. [15] by the E a as

This equation shows that f(E a ) can be obtained by differentiating the α-vs-E a relationship, which may be deduced from Figure 5. The graphically estimated distribution curve f(E a ) for the investigated decomposition process of [Pd(acac)2] is presented in Figure 11.

From Figure 11, it can be observed that the estimated curve (Eq. [19]) for the investigated process represents a sharp and somewhat “right-tailed” asymmetrical distribution curve. The obtained distribution curve does not show a broad peak and the apparent activation energy does not spread in the large E a interval. The peak position is placed in a single point, at E a,p = 138.4 kJ mol−1. These results indicate that f(E a ) can be presented by a single Gaussian distribution. By applying the nonlinear (NL) least-squares analysis (using the Levenberg–Marquardt algorithm) the Gaussian reactivity model is established for the considered system, and can be presented in form of Eq. [20]:

where E 0 and σ represent the mean apparent activation energy and the standard deviation, respectively. Using the NL least-squares analysis, the following values of the Gaussian distribution parameters are obtained: E 0 = 138.4 kJ mol−1 and σ = 0.71 kJ mol−1. It can be pointed out that the obtained value of E 0 is very similar to the value of E a calculated by the isoconversional (Friedman) method (140.1 kJ mol−1).

Figure 12 shows the comparison between the estimated distribution and calculated distribution curves, assuming the Gaussian reactivity model (Eq. [20]).

It can be seen from Figure 12 that there is good agreement between the estimated distribution curve and the calculated distribution curve with the Gaussian function (Eq. [20]). The only deviations between these two distribution curves can be observed at the beginning and the end of the left and right tails of the considered distributions.

After this analysis, the A values were estimated using Eq. [16] at the five heating rates, and the average values of A are plotted against α in Figure 13 as distribution bars.

From Figure 13, we can see that obtained average values of A calculated by the Miura method follow the same trend as the values of E a obtained by the isoconversional (Friedman) method on the extent of conversion (α) (Figure 5). In the same figure, the simulated trend values of A (dashed-dotted line) with the extent of conversion (α) are presented. It can be seen that the predicted behavior of the pre-exponential values (A) follows the same trend as the predicted behavior of the E a values on α, expressed through Eq. [17] and shown in Figure 6.

The simulated trend of A on α can be described by the predicted equation in the form of a third-degree polynomial regression function as

Equation [21] is very similar to Eq. [17]; sole difference between these equations lies in the different values of the numerical coefficients. It can be pointed out that the A value varies from an order of 1012 to an order of 1014 min−1 (Figure 13); this result shows that A cannot be strictly assumed to be a constant for the investigated decomposition process. However, we may see from Figure 13 that a large number of A values were grouped about the order of 1013, which corresponds to a very narrow range of E a (E a = 137.0–139.7 kJ mol−1). This result is in agreement with the order of A calculated by the integral and differential composite methods I (Table V).

Figure 14 show the comparison between the experimental α-T curves and the conversion curves obtained by the model-free prediction (using Eq. [3] and the R3/F2/3 reaction model in differential form) at all considered heating rates (β), for the nonisothermal decomposition process of palladium acetylacetonate.

The deviations in the predicted results from the experimental data can be calculated by the following expression:

where α i,calc is the predicted data, α i,exp is the experimental data, and N is the number of data items.

The deviations (S) of the predicted results from the experimental ones are shown in Table VII.

From Figure 14 and Table VII, we can see that the model-free prediction yields the best agreement at the heating rate of β = 10 °C min−1; at other heating rate values, the obtained predictions give satisfactory results (Table VII).

These results confirm that the evaluated values of the Arrhenius parameters; the established mechanism (phase-boundary-controlled reaction with contracting volume or the two-thirds-order kinetics (R3, F2/3)) describes the real process of the thermal decomposition of [Pd(acac)2] under nonisothermal experimental conditions, which is characterized with a Gaussian reactivity model.

It can be pointed out that Eqs. [15] and [16] implicitly assume that the E a values differ for different α values. The f(E a ) distribution curve used in the model calculations (Eq. [20] and Figure 12) satisfy this assumption, but nearly the same E a value was obtained for the considered range of α when we applied the calculation method discussed earlier. In that case, a single-step reaction covers the considered α range; the A value can be estimated directly from the Friedman equation (Eq. [3]), asuming the reaction model is known (determined using the analytical form of f(α) model function).

The extreme, when absolutely the same E a value is obtained for all considered α values, is not observed in the present case. In addition, if we look at Figure 5 carefully, it is observed that the obtained E a values do not lie along a straight line. This observation can be better seen in Figure 6.

In addition, it was shown that the Friedman method can be applied to reactions that can be described by a narrow distribution of the apparent activation energies (where σ ≤ 4 pct of the E 0 value).[45] From the results given here, we can conclude that the Friedman method represents the appropriate kinetic method for the isoconversional (model-free) analysis of the investigated decomposition process. In fact, from the results obtained by applying the Friedman method, we have established the narrow distribution curve of the apparent activation energies, f(E a ), which corresponds to the Gaussian distribution of reactivity with σ < 4 pct of the E 0 value (σ = 0.5 pct of E 0; the values of σ and E 0). Accordingly, these results confirm the statement that the isoconversional Friedman method can be applied for the reactions that can be described with a narrow distribution of the apparent activation energies.

From the established results discussed here, we can conclude that the E a values calculated by the Friedman model-free method and the estimated distribution curve f(E a ) are correct in the case in which the investigated decomposition process occurs through a single-step reaction mechanism.

For the nonisothermal decomposition process of palladium acetylacetonate in a nitrogen atmosphere, the following kinetic triplet (E a , A, and function f(α)) is obtained: E a = 138.7 kJ mol−1, A = 3.02 × 1013 min−1, and the geometrical contraction model (contracting volume) is f(α) = 3(1−α)2/3.

The R group of models assumes that nucleation occurs rapidly on the surface of the crystal. The rate of decomposition is controlled by the resulting reaction interface progress toward the center of the crystal. For any crystal particle, the following relation is applicable:

where r is the radius at time t, r 0 is the radius at time t 0, and k is the reaction rate constant. It should be emphasized that the particle size is incorporated into the rate constant (k) for the R group of models and for other models in which the geometry of the solid crystal is part of the mathematical derivation (e.g., diffusion models). Therefore, a sample of the varying particle sizes will have variable reaction rate constants; this will cause the α-T curves to shift greatly.[60,61] This would produce a curved isoconversional plot, assuming an isoconversional (model-free) method is used for the kinetic analysis. In our case, the corresponding isoconversional plots at considered levels of α do not show any curvature behavior (Figure 4). From this point of view, the particle-size effects do not have any influence on the shape of the α-T plots for the investigated decomposition process.

The contracting geometry models are based on an initial rapid (instantaneous) dense nucleation across all, or across some specific, crystal faces. The close spacing of the nuclei results in the rapid (low-α) generation of a coherent reaction zone that advances inward at a constant rate in the absence of diffusion effects. This topic has been discussed for a variety of crystal shapes by Delmon.[62] In Eq. [18], n = 3 represents the number of dimensions in which the interface advances.

On the basis of the shape of the established TG curves, one can conclude that the decomposition of [Pd(acac)2] is a single-step process that can be presented simply by the following formula:

An accompanying destruction of the ligand, if it does occur, does not play a significant role in the kinetics of the overall investigated process. According to the SEM microphotographs (Figure 15), the thermal decomposition commences at the outer crystal surface, yielding the ragged Pd film, which surrounds the remainder of the Pd(acac)2 crystal.

The film thickens by sampling the Pd atoms deliberated during the decomposition of the remainder of the Pd(acac)2, primarily at the places of close contact. It is possible that the film grows partly via Pd(acac)2 evaporation decomposition;[63–65] however, this way may not predominate, because the mass loss caused by the sample evaporation has not been registered by the TG curves. It can be pointed out that the vapor nucleation in the system occurs at very high supersaturations (more than 106); it may be assumed that the beginnings of the new phase always exist in the system. The crystalline phase of the particles is determined only by the processes that occur on the surface of the growing particles.

The XRD pattern of the decomposition product (Figure 16) essentially corresponds to the metallic Pd, with a somewhat enlarged elementary cell. The width of the diffraction lines indicates the low degree of crystallinity. Accordingly, the mean crystal diameter calculated by means of the Scherer formula amounts to a value of 18 nm.

The additional small peaks appearing in Figure 16 at approximately 2θ = 34 and 42 deg correspond to reflections from the PdO planes (101) and (110), respectively (JCPDS Card No. 60515).[66,67] Because the Pd sample was held in air before it was subjected to X-ray diffractometry, due to its nanocrystalline nature, surface oxide obviously formed in an amount able to manifest itself in the XRD pattern.

Generally, the decomposition process starts with the initial nucleation, which was characterized by the rapid onset of an acceleratory reaction behavior without the presence of an induction period (up to approximately α = 0.10, in Figure 3). Furthermore, the considered process was characterized by the growth of Pd particles in three dimensions and spherical particle shapes (the center areas in Figure 3). Finally, in processes involving the advance of an interface, product formation will cease when the migrating interfaces have swept throughout the reactant volume; termination of the reaction may be relatively abrupt (this behavior can be seen in Figure 3 for the values of α > 0.95, at all β values).

The investigated decomposition process of [Pd(acac)2] can be well described by a single Gaussian reactivity model with the following distribution parameters: E 0 = 138.4 kJ mol−1 and σ = 0.71 kJ mol−1. It was established that the value of the mean apparent activation energy (E 0) is in good agreement with the value of E a calculated by the Friedman isoconversional method (140.1 kJ mol−1), which corresponds approximately to the middle of the conversion values (for α ≈ 0.40 to 0.50). The value of E 0 corresponds to the mean apparent activation energy for the Pd spherical particle growth in the crystalline phase, for the investigated nonisothermal decomposition process.

6 Summary

The kinetics of the nonisothermal decomposition of palladium acetylacetonate [Pd(acac)2] was accurately determined from a series of thermoanalytical experiments at different constant heating rates. The physical characterization of the decomposition product of the investigated process was analyzed by SEM and XRD experiments. The apparent activation energy (E a ) was calculated by the differential isoconversional (Friedman) method without a previous assumption regarding the model function fulfilled by the reaction. It was found that the apparent activation energy was not really changed and was nearly independent with respect to the level of conversion (α). This result suggests that the nonisothermal decomposition process of palladium acetylacetonate follows a single-step reaction. Practically constant E a values approximating 140.1 ± 1.5 kJ mol−1 were found. It was found that value of E a calculated from the Friedman isoconversional method (140.1 kJ mol−1) represents the intermediate value between the values of E a evaluated from the Bosewell and Augis–Bennett methods (142.2 and 138.3 kJ mol−1, respectively). The multiple-rate isotemperature method is used to define the most probable mechanism, g(α), for the investigated decomposition process. From the obtained results, it was found that the most probable reaction mechanism belongs to the mechanism of the phase-boundary reaction, Rn, with the accommodation parameter n = 3.

In order to confirm the established Arrhenius parameters and reaction mechanism, the integral/differential I composite methods, and the Master-plot and Málek methods, were applied. It was concluded that the differential version of the composite method I produces results similar to those produced using the integral method, but with less accuracy. Also, it was concluded that the reaction model R3, for the integral composite method I, is the model with the best regression and with kinetic parameters that are both unique and very similar to those obtained by the Friedman isoconversional method.

In addition, it was found that the results obtained from both the Master-plot and Málek methods confirm the results obtained from the multiple-rate isotemperature method, in which the R3 (contracting volume) reaction mechanism can best describe the investigated decomposition process.

By applying the Miura procedure, the DRM for the investigated decomposition process was established. From the dependence of α vs E a , the experimental distribution curve of the apparent activation energies, f(E a ), was estimated. From the basic characteristics of the estimated f(E a ), it was concluded that the investigated nonisothermal decomposition process of [Pd(acac)2)] in a nitrogen atmosphere can be represented by a single Gaussian distribution. By applying the NL least-squares analysis, the Gaussian reactivity model is established for the considered system with the following distribution parameters: E 0 = 138.4 kJ mol−1 (the mean apparent activation energy) and σ = 0.71 kJ mol−1 (the standard deviation). It was established that the value of E 0 is similar to the value of E a calculated by the differential (Friedman) isoconversional method. By applying the Miura procedure, the A values were estimated at different heating rates and the average A values are plotted against E a . The order of magnitude for A obtained using this method is in good agreement with the order of magnitude for A calculated by the integral and differential composite methods I (1013).

It was also established that the E a values calculated by the Friedman method and the estimated distribution curve f(E a ) are correct, even in the case in which the investigated decomposition process occurs through a single-step reaction mechanism.

In accordance with the SEM analysis, the thermal decomposition commences at the outer crystal surface, yielding the ragged Pd film that surrounds the remainder of the Pd(acac)2 crystal. The results of the X-ray analysis show that the decomposition product corresponds to the metallic Pd particles with a somewhat enlarged elementary cell. The width of the obtained diffraction lines indicates the low degree of crystallinity. From applying the Scherer formula, the mean crystal diameter was calculated and a value equal to 18 nm is found.

In general, the decomposition process of [Pd(acac)2] starts with an initial nucleation characterized by the rapid onset of an acceleratory reaction behavior without the presence of an induction period. In addition, the considered process was characterized by the growth of Pd particles in three dimensions with spherical shapes.

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

References

H.D. Kaesz, R.S. William, R.F. Hicks, J.I. Zink, Y. Chen, H.J. Muller, Z. Xue, D. Xu, D.K. Shuh, and Y.K. Kim: New J. Chem., 1990, vol. 14, pp. 527–34

R. Ugo, C. Dossi, and R. Psaro: J. Mol. Catal. A, 1996, vol. 107, pp. 13–22

M.A. Aramendía, V. Boráu, I.M. García, C. Jiménez, J.M. Marinas, and F.J. Urbano: Appl. Catal. B, 1999, vol. 20, pp. 101–10

W. Daniell, H. Landes, N.E. Fouad, and H. Knözinger: J. Mol. Catal. A, 2002, vol. 178, pp. 211–18

C. Dossi, R. Psaro, A. Bartsch, A. Fusi, L. Sordelli, R. Ugo, M. Bellatreccia, R. Zanoni, and G. Vlaic: J. Catal., 1994, vol. 145, pp. 377–83

J.A.R. van Veen, G. Jonkers, and W.H. Hesselink: J. Chem. Soc. Faraday Trans I, 1989, vol. 85, pp. 389–413

J.C. Kenvin, M.G. White, and M.B. Mitchell: Langmuir, 1991, vol. 7, pp. 1198–1205

J.R. van Veen, M.S.P.C. DeJong-Versloot, G.M.M. van Kessel, and F.J. Fels: Thermochim. Acta, 1989, vol. 152, pp. 359–70

C. Dossi, R. Psaro, A. Bartsch, E. Brivio, A. Galasco, and P. Losi: Catal. Today, 1993, vol. 17, pp. 527–35

C. Dossi, A. Fusi, and R. Psaro, G.M. Zanderighi: Appl. Catal., 1989, vol. 46, pp. 145–51

C.M. Tsang, S.M. Augustine, J.B. Butt, and W.M.H. Sachtler: Appl. Catal., 1989, vol. 46, pp. 45–56

C. Dossi, A. Fusi, R. Psaro, and D. Roberto: Thermochim. Acta, 1991, vol. 182, pp. 273–80

W. Wendlandt: Thermal Methods of Analysis, 3rd ed., Wiley, New York, NY, 1986, pp. 23–25

G.A. Razuvaev, B.G. Gribov, G.A. Domrachev, and B.A. Solomatin: Metalloorganicheskie Soedineniya v Electronike, Nauka, Moscow, 1972, pp. 16–20

P.H. Nguyen: Eur. Appl., 1989, vol. 266, pp. 877–80

J.-C. Hierso, R. Feurer, and P. Kalck: Coord. Chem. Rev., 1998, vols. 178–180, pp. 1811–34

V.S. Khandkarova: Cobalt , Nickel, Platinum Metals, Nauka, Moscow, 1978, pp. 39–40

P.M. Maitlis: The Organic Chemistry of Palladium, Academic Press, New York, NY, 1971, pp. 17–19

I. Matsuura, Y. Hashimoto, O. Takayasu, K. Nitta, and Y. Yoshida: Appl. Catal., 1991, vol. 74, pp. 273–80

V. Cominos, and A. Gavriilidis: Appl. Catal. A, 2001, vol. 210, pp. 381–90

V. Cominos, and A. Gavriilidis: Eur. Phys. J. AP, 2001, vol. 15, pp. 23–33

S. Poston, and A. Reisman: J. Electron. Mater., 1989, vol. 18, pp. 553–60

V.M. Paasonen, P.P. Semyannikov, and A.S. Nazarov: Chem. Sust. Dev., 2002, vol. 10, pp. 751–56

M. Lashdaf, T. Hatanpää, and M. Tiitta: J. Therm. Anal. Calorim., 2001, vol. 64, 1171–82

L. Liqing, and C. Donghua: J. Therm. Anal. Calorim., 2004, vol. 78, pp. 283–93

P.G. Bosewell: J. Therm. Anal. Calorim., 1980, vol. 18, pp. 353–58

J.A. Augis, and J.E. Bennett: J. Therm. Anal. Calorim., 1978, vol. 13, pp. 283–92

F.J. Gotor, J.M. Criado, J. Málek, and M. Koga: J. Phys. Chem. A, 2000, vol. 104, pp. 10777–10782

H. Friedman: J. Polym. Sci. C, 1964, vol. 6, pp. 183–87

P. Budrugeac, and E. Segal: J. Therm. Anal. Calorim., 2005, vol. 82, pp. 677–80

M.A. Gabal: Thermochim. Acta, 2003, vol. 402, pp. 199–208

J.M. Criado, L.A. Pérez-Maqueda, F.J. Gotor, J. Málek, and N. Koga: J. Therm. Anal. Calorim., 2003, vol. 72, pp. 901–06

J. Málek: Thermochim. Acta, 1992, vol. 200, pp. 257–69

J. Málek: Thermochim. Acta, 2000, vol. 355, pp. 239–53

J. Málek: Thermochim. Acta, 1989, vol. 138, pp. 337–46

K. Miura: Energy Fuels, 1995, vol. 9, pp. 302–07

K. Miura, and T. Maki: Energy Fuels, 1998, vol. 12, pp. 864–69

S. Okeya, S. Ooi, K. Matsumoto, Y. Nakamura, and S. Kawaguchi: Bull. Chem. Soc. Jpn., 1981, vol. 54, pp. 1085–95

R.Z. Hu, and Q.Z. Shi: Thermal Analysis Kinetics, Science Press, Beijing, 2001, pp. 20–21

J.H. Flynn: Thermochim. Acta, 1997, vol. 300, pp. 83–92

S. Vyazovkin, and C.A. Wight: Thermochim. Acta, 1999, vols. 340–341, pp. 53–68

A.W. Coats, and J.P. Redfern: Nature, 1964, vol. 201, pp. 68–70

G.I. Senum, and R.T. Yang: J. Therm. Anal. Calorim., 1977, vol. 11, pp. 445–47

D.B. Anthony, and J.B. Howard: AIChE J., 1976, vol. 22, pp. 625–56

R.L. Braun, and A.K. Burnham: Energy Fuels, 1987, vol. 1, pp. 153–61

J.H. Campbell, G. Gallegos, and M. Gregg: Fuel, 1980, vol. 59, pp. 727–32

C.H. Yun, W.J. Kim, and S.C. Yi: J. Ind. Eng. Chem., 2008, vol. 14, pp. 120–30

C.C. Lakshmanan, and N. White: Energy Fuels, 1994, vol. 8, pp. 1158–67

B.P. Boudreau, and B.R. Ruddick: Am. J. Sci., 1991, vol. 291, pp. 507–38

T.C. Ho, and R. Aris: AIChE J., 1987, vol. 33, pp. 1050–51

R. Aris: AIChE J., 1989, vol. 35, pp. 539–48

G. Astarita: AIChE J., 1989, vol. 35, pp. 529–32

P. Ungerer: in Thermal Phenomena in Sedimentary Basins, B. Durand, ed., Technip, Paris, 1986, pp. 235–36

A.K. Burnham, R.L. Braun, H.R. Gregg, and A.M. Samoun: Energy Fuels, 1987, vol. 1, pp. 452–58

G.I. Zharkova, P.A. Stabnikov, S.A. Sysoev, and I.K. Igumenov: J. Struct. Chem., 2005, vol. 46, pp. 320–27

L. Guang, G. Weigui, L. Weipeng, P. Shaoping, Y. Gexin, and H. Ying: Xiyou Jinshu Cailiao Yu Gongcheng (Rare Met. Mater. Eng.), 2006, vol. 35, pp. 150–55

Y.F. Lee, and D. Dollimore: Thermochim. Acta, 1998, vol. 323, pp. 75–81

S. Vyazovkin, and C.A. Wight: Int. Rev. Phys. Chem., 1998, vol. 17, pp. 407–33

J. Opfermann, and H.J. Flammersheim: Thermochim. Acta, 2003, vol. 397, pp. 1–3

N. Koga, and J.M. Criado: J. Am. Ceram. Soc., 1998, vol. 81, pp. 2901–09

N. Koga, and J.M. Criado: J. Therm. Anal. Calorim., 1997, vol. 49, pp. 1477–84

B. Delmon: Introduction a la Cinétique Hétérogéne, Technip, Paris, 1969, pp. 53–55

P.P. Semyannikov, V.M. Grankin, I.K. Igumenov, and A.F. Bykov: J. Phys., 1995, vol. 4, pp. 205–11

A.G. Nasibulin, P.P. Ahonen, O. Richard, E.I. Kauppinen, and I.S. Altman: J. Nanopart. Res., 2001, vol. 3, pp. 385–400

A.G. Nasibulin, I.S. Altman, and E.I. Kauppinen: Chem. Phys. Lett., 2003, vol. 367, pp. 771–77

E. Kenezaki, S. Tanaka, K. Murai, T. Moriga, J. Motonaka, M. Katoh, and I. Nakabayashi: Anal. Sci., 2004, vol. 20, pp. 1069–75

N. Ren, A.-G. Dong, W.-B. Cai, Y.-H. Zhang, W.-L. Yang, S.-J. Huo, Y. Chen, S.-H. Xie, Z. Gao, and Y. Tang: J. Mater. Chem., 2004, vol. 14, pp. 3548–52

Acknowledgments

This study was partially supported by the Ministry of Science and Environmental Protection of Serbia, through Project Nos. 142025 and 142047 (Professor S. Mentus).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 24, 2008.

Rights and permissions

About this article

Cite this article

Janković, B., Mentus, S. A Kinetic Study of the Nonisothermal Decomposition of Palladium Acetylacetonate Investigated by Thermogravimetric and X-Ray Diffraction Analysis Determination of Distributed Reactivity Model . Metall Mater Trans A 40, 609–624 (2009). https://doi.org/10.1007/s11661-008-9754-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9754-4