Abstract

Poly(vinylchloride) (PVC) is an insulator and acts as a host in polymer electrolyte systems where addition of inorganic salt lithium trifluoromethanesulfonate (LiCF3SO3) and dibutyl phthalate (DBP) converts the system to become conductor. The conductivity of polymer electrolytes is explained on the basis of ionic mobility. Thirty-five weight percent DBP plasticized polymer electrolyte has the highest conductivity value (3.30 × 10−9 S cm−1) at 303 K. Temperature dependence of the conductivity of polymer films obeys the Arrhenius rule. X-ray diffraction (XRD) proves that addition of DBP will increase the amorphous nature of the system and lead to enhancement in ionic conductivity. Complexation between high molecular weight PVC, LiCF3SO3, and DBP is confirmed by the shifting of peaks, decreasing of peaks intensity, and broadening of peaks in XRD. Thermogravimetric analysis reveals that addition of DBP to PVC–LiCF3SO3 system reduces the stability of the film. Subsequently, thermal stability decreases with the increase in DBP content in the polymer electrolytes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid polymer electrolytes triumph over liquid electrolytes in battery industry due to its capability to eliminate the problem of leakage in highly toxic liquid electrolyte. Utility of solid polymer electrolytes in power sources are due to its wide operating temperature range, high ionic conductivity, high energy density, solvent-free condition, leak proof, wide electrochemical stability windows, easy processability, and light weight [1].

The compositions of polymer electrolytes play an important role in characterization of the polymer electrolytes. In order to enhance the ionic conductivity at ambient condition, one of the approaches is to incorporate a plasticizer to make the matrix more liquid like [2]. The addition of plasticizer toward polymer electrolytes had been studied commonly [3–7]. Plasticized polymer electrolytes have been proved to be promising for the use as electrolytes of the lithium batteries owing to their high ionic conductivity. In the study by M. M. E. Jacob, three types of ester class plasticizers, namely dioctyl phthalate, dibutyl phthalate (DBP), and dimethyl phthalate, were employed to examine their effect on the ionic conductivity of polyethylene oxide (PEO)–LiClO4 polymer complex. It was found that the conductivity of 10−5 S cm−1 can be achieved for all electrolyte systems added with either of the plasticizers at room temperature, which is several orders of magnitude higher than conventional PEO polymer electrolyte without plasticizer [8]. The conductivity is further related to glass transition temperature, T g, and the interlinking of the polymer chain, which makes the material more crystalline as confirmed by X-ray diffraction analysis (XRD) [9]. Moreover, the thermal stability of polymer electrolytes is studied by using thermal gravimetric analysis (TGA) to investigate the operating temperature range of polymer electrolytes [10].

A poly(vinylchloride) (PVC)-hosted polymer electrolyte was developed in the present work. Usage of PVC is due to its chlorine atom with lone pair electrons which are solvated by LiCF3SO3. The dipole–dipole interaction between hydrogen and chlorine atoms, which can stiffen the polymer backbone and perhaps make the PVC–Li salt complexation difficult, can be weakened by the addition of plasticizer [11]. Thus, it should be possible to turn PVC into a good ion-conducting polymer. Structural, thermal, and electrochemical studies are also performed on PVC–LiCF3SO3–DBP system.

Experimental

Sample preparation

High molecular weight PVC and LiCF3SO3, both of high purity, were obtained from Fluka, tetrahydrofuran (THF) AR. grade was obtained from J.T. Baker and DBP of 99% purity were obtained from Aldrich. LiCF3SO3 was dried at 100 °C for 1 h due to its hygroscopic characteristic. The polymer electrolytes were prepared by solution cast technique with THF as solvent. The solution obtained thus was cast on a Petri dish and allowed to evaporate slowly inside a dessicator. This procedure yields mechanically stable and free-standing films. The thickness of the films was between 0.07 and 0.09 mm.

Characterization techniques

Impedance study

The thickness of the films was measured using micrometer screw gauge before impedance spectroscopy was carried out. Conductivity measurement was performed by impedance spectroscopy using HIOKI Model 3532-50 bridge interfaced to a computer for data acquisition over frequency range of 50 Hz to 1 MHz. The films were sandwiched between two stainless disk electrodes with an area of 4.91 cm2. The conductivity–temperature study was conducted in the temperature range of 25 °C to 100 °C.

Structural analysis

XRD analysis was performed with a Control Software MXP3 diffractometer using Cu Kα radiation of wavelength λ = 1.5418 Å with 2θ angles between 5° and 45° with scanning rate at 5° min−1. The coherent length (Å) was calculated from the Scherrer equation, i.e.,

where λ is the X-ray wavelength, θ b is the glancing angle, and Δ2θ b is the full width at half maximum.

Thermal study

The films were subjected to Mettler Toledo TGA. The samples were heated from room temperature up to 350 °C at a rate of 10 °C min−1 under a nitrogen atmosphere.

Results and discussion

Ionic conductivity (impedance spectroscopy)

Practically, ionic conductivity of polymer complexes was calculated using the equation [12–14]:

where R is bulk resistance, t is the thickness of sample, and A is the cross-sectional area of the sample. The bulk resistance is determined from the intercept at the Z r axis of the impedance plot obtained from impedance spectroscopy. The inversely proportional relationship between the bulk resistance and the conductivity can be seen for high molecular weight PVC/LiCF3SO3/DBP (60:40) in Fig. 1 and Table 1.

Figure 2 shows the ionic conductivity of polymer electrolytes as a function of DBP content at room temperature. The variation in conductivity with DBP content in PVC–LiCF3SO3–DBP systems can be explained in terms of the number of free mobile ions. Net ionic conductivity is in accordance with the relation [6]:

where σ is ionic conductivity, n is the number of free mobile ions, q is the magnitude of ionic charge, and μ is the ionic mobility. Thirty-five weight percent DBP system gives the highest conductivity (3.30 × 10−9 S cm−1) due to the high concentration of mobile ions in that system. However, occurrence of ion pairing causes the decrease of conductivity in the 40 wt.% DBP polymer electrolyte. This phenomenon is due to the formation of aggregates to form a viscous solution which reduces the mobility of Li+ charge carriers. Although ion aggregates may be charged, their mobility is still limited by their size which is much larger when compared to free ions. DBP serves to plasticize this polymer electrolyte not only with the purposes to induce flexibility and segmental motion but also reduce the local viscosity and thereby facilitate the mobility and conductivity. Contribution from plasticizer toward the enhancement of conductivity is twofold: A higher percentage of plasticizer would (a) open up the narrow rivulets of plasticizer-rich phase for greater ionic transport and (b) provide large free volume of relatively superior conducting phase [15]. This is consistent with the value in Fig. 2 where the presence of more effective intramolecular coordination in plasticized system facilitates Li+ coordination than in mere polymer salt system leading to greater LiCF3SO3 dissociation. As DBP content in polymer electrolyte system increases, the more effective dissociation of salt will thus creates the facile conductive pathways for Li+. This is especially true when stronger coordination bonds form between the phthalate ester group with Li+ due to the presence of conjugated double bonds in phthalate plasticizer that strengthen the ion-ester group (DBP) coordination.

Figure 3 shows the conductivity of different DBP content systems at increasing temperature. It was found that these polymer electrolytes have almost the same trend where the highest ionic conductivity can be obtained in 35 wt.% DBP system and the ionic conductivities at 40 wt.% DBP drop slightly due to the phenomenon of ion pairing. Besides, as temperature is rises from 333 K to 353 K, the respective ionic and segmental mobility within the polymer matrix increased and thus conductivity of plasticized polymer electrolytes increased gradually with temperature increment.

The temperature dependence of conductivity of polymer electrolyte can be ascertained by Arrhenius rule as well:

where E a is the activation energy and k is the Boltzmann constant. Figure 4 depicts the Arrhenius plots of logarithmic conductivity versus inverse temperature for 20 and 40 wt.% DBP complex. The regression value for 20 and 40 wt.% DBP complex is 0.9879 and 0.9896, respectively. Regression values of these plots ∼1 indicate that the conductivity–temperature data obey the Arrhenius rule. Since the conductivity–temperature data follows the Arrhenius relationship, the possibility of cation transport in these complexes are claimed to be quite similar with ionic crystals, where ions jump into neighboring vacant sites and hence increase the ionic conductivity to a higher value [16]. The activation energy (E a), which is a combination of defect energy formation and the energy of defect migration, can be calculated from the plots. The activation energy for the lithium ion transport is significantly low for the present polymer electrolytes. The activation energy for 20 and 40 wt.% DBP complexes are 2,323.63 and 2,295.47 J mol−1, respectively. While at high DBP concentration, the formation of PVC–LiCF3SO3–DBP will create a new path for the transport of Li+ ion so that 40 wt.% DBP complex has higher conductivity and lower activation energy compared to 20 wt.% DBP complex. For devices operating over a wide temperature range, it is desirable to have a uniform conductivity. Thus, 40 wt.% DBP with the low values of activation energies is desirable [17–19].

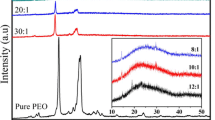

Structural analysis (X-ray diffraction analysis)

Figure 5 shows the typical diffraction pattern for PVC, PVC–LiCF3SO3, and PVC–LiCF3SO3–DBP systems. XRD reveals structural change with addition of inorganic salt (LiCF3SO3) and plasticizer (DBP) to PVC [20–22]. Figure 5 a illustrates the X-ray diffractogram of PVC with peaks at 2θ angles at 9.3° and 18.1°. With the addition of LiCF3SO3 and 20 wt.% of DBP to the system, the amorphous character of the sample is further increased and this can be implied by shifting of peaks, decreasing of peaks intensity, and broadening of peaks in PVC–LiCF3SO3 system and PVC–LiCF3SO3–DBP system. These broad peaks are called amorphous humps and are typical characteristics of amorphous material. The peaks have been shifted to 9.44° and 17.8° for PVC–LiCF3SO3 system in Fig. 5 b, 9.58° and 17.44° for PVC–LiCF3SO3–DBP system in Fig. 5 c. Fully amorphous nature produces greater ionic diffusivity in agreement with the high ionic conductivity that can be obtained in amorphous polymers having fully flexible backbones [23]. This is parallel with the ionic conductivity result where PVC–LiCF3SO3–DBP amorphous system with the broadest amorphous hump has the higher conductivity than the polymer electrolyte system without DBP (PVC–LiCF3SO3 system). The X-ray diffractogram also ascertain that complexation takes place between the salt and the heteroatom of polymer. Appearances of shifted peaks confirm complexation in the polymer electrolyte.

From these diffractograms, the coherent or Scherrer length was calculated using the peak at 2θ ≈9°. The coherent length for pure PVC, PVC–LiCF3SO3, and PVC–LiCF3SO3–DBP was 0.42, 0.35, and 0.30 Å, respectively. It is noteworthy that the length decreases with the increase in the amorphous nature of the sample. This finding proves that the plasticized electrolytes are more amorphous in nature.

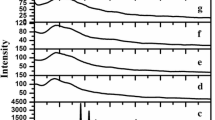

Thermogravimetric analysis

Thermal characterizations of polymeric materials cover many aspects of material science. In this research, thermal studies of the polymer electrolytes will provide us the information with regard to their thermal stability, crystallinity, and other thermal parameters. Thermal stability depends upon the extent to which homogeneity and a plastic mixture can be found within the polymeric solution before it gets plasticized into a thin film [24]. Weight loss obtained from the TGA graphs ascertained thermal stability of the polymer electrolyte systems.

Figure 6 shows the thermogravimetric curve for PVC and PVC–LiCF3SO3 system. The weight loss of PVC (Fig. 6a) below 100 °C is due to the removal of moisture and transition of the sample. Volatilization of monomers and oligomers adsorbed in the matrix can also be responsible for this initial mass loss [25]. The weight loss of 8.54% corresponds to the first decomposition of PVC at 138 °C. Above 237 °C, second decomposition of PVC causes film stability to decrease significantly evidenced by the weight of the film reducing drastically (weight loss = 60.14%). In PVC–LiCF3SO3 system as shown in Fig. 6b, the weight loss 3.81% below 100 °C is contributed by the hygroscopic nature of LiCF3SO3. The weight loss of first decomposition is 6.83% showing that the thermal stability of the PVC–LiCF3SO3 system is higher than pure PVC system. The weight loss above 250 °C is analogous to the second decomposition.

Consequently, addition of DBP to PVC–LiCF3SO3 system deteriorates the stability of the film. This can be proven by the increase in weight loss due to first decomposition from 6.83% weight loss in PVC–LiCF3SO3 to 11.66% weight loss in PVC–LiCF3SO3–15 wt.% DBP system (Fig. 7a) above 100 °C. Figure 7b, c demonstrates that thermal stability of plasticized polymer electrolytes decrease as DBP content in the thin film increases to 20 (weight loss = 15.84%) and 25 wt.% DBP (weight loss = 23.35%). Obviously, one can claim from these observations that polymer electrolyte of low plasticizer content (PVC–LiCF3SO3–15 wt.% DBP system) has a relatively good thermal stability. The conductivity is found to be a minimum for an addition of 15 wt.%. This is evident from the fact that the highest stability of the same has resulted in the restricted movement of ions, thus accounting for the behavior [11].

Conclusion

High mobility and high concentration of free mobile ions contribute to high conductivity. Plasticized polymer electrolytes system PVC–LiCF3SO3–DBP has more amorphous nature thus higher conductivity compared to PVC–LiCF3SO3 system without plasticizer. Complexation in polymer electrolytes is assured by broadening of peaks, decreasing of peak intensities, and shifting in peaks as obtained in XRD results. Polymers of lower DBP content was found to have relatively good stability.

References

Ramesh S, Yahaya AH, Arof AK (2002) Solid State Ionics 152–153:291–294

Sheldon MH, Glasse MD, Latham RJ, Linford RG (1989) Solid State Ionics 34:135–138

Liang YH, Wang CC, Chen CY (2005) J Power Sources 148:55–65

Nicotera I, Ranieri GA, Terenzi M, Chadwick AV, Webster MI (2002) Solid State Ionics 146:143–150

Cha EH, Lim SA, Lee CW, Macfarlane DR (2006) J Power Sources 163:269–273

Pradhan DK, Samantary BK, Choudhary RNP, Thakur AK (2005) J Power Sources 139:384–393

Rajendran S, Sivakumar M, Subadevi R (2000) Mater Lett 44:242–247

Jacob MME, Michael MS, Prabaharan SRS, Radhakrisna S (1997) Solid State Ionics 98:167–174

Mohamed NS, Zakaria MZ, Ali AMM, Arof AK (1997) J Power Sources 66:169–172

Ramesh S, Arof AK (2001) J Power Sources 99:41–47

Uma T, Mahalingam T, Stimming U (2005) Mater Chem Phys 90:239–244

Macfarlane DR, Sun J, Meakin P, Fasoulopoulos P, Hay J, Forsth M (1995) Electrochim Acta 40:2131–2136

Gorecki W, Andreani R, Berthier C, Armand M, Mali M, Roos J, Brinkmann D (1986) Solid State Ionics 18–19:295–299

Hudson MJ, Sequira CAC (1995) J Electrochem Soc 142:4013–4017

Rhoo HJ, Kim HT, Park JK, Hwang TS (1997) Electrochim Acta 42:1571–1579

Souquet JL, Levy M, Duclot M (1994) Solid State Ionics 70/71:337–345

Cowie JMG, Spence GH (1998) Solid State Ionics 109:139–144

Lobitz P, Fullbier H, Reiche A, Illner JC (1992) Solid State Ionics 58:41–48

Xu W, Zhang XZ, Deng ZH, Zheng YG, Wan GX (1998) Solid State Ionics 111:219–226

Arof AK, Kamaluddin B, Radhakrisna S (1993) J Phys III (France) 3:1201–1209

Acosta JL, Morales E (1996) Solid State Ionics 85:85–90

MacCallum JA, Vincent CA (1987 and 1989) Polymer electrolyte review 1 and 2. Elsevier Appl. Sci, London

Frech R, Chintapalli S (1196) Solid State Ionics 85:61–66

Uma T, Mahalingam T, Stimming U (2004) Mater Chem Phys 85:131–136

Mano V, Felisbersti MI, Matencio T, De Paoli MA (1996) Polymer 37:5165–5170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramesh, S., Yi, L.J. Structural, thermal, and conductivity studies of high molecular weight poly(vinylchloride)-lithium triflate polymer electrolyte plasticized by dibutyl phthalate. Ionics 15, 725–730 (2009). https://doi.org/10.1007/s11581-009-0323-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-009-0323-7