Abstract

A compression model for sand–silt mixtures is needed in geotechnical engineering, for example in the analysis and prediction of deformation of levees and embankments due to internal erosion. In this paper, we introduce a novel concept of dividing the voids of a granular material into two hypothetical fractions: active and inactive voids. The active voids are kinematically available to the compression process. The inactive voids are kinematically unavailable to the compression process. The volume of active voids is dependent on the initial density and effective stress level. The volume of inactive voids is dependent on the amount of fines in the mixture. The current paper considers 1-D and isotropic compression behavior of sand–silt mixtures at stress levels lower than 2 MPa, so no substantial particle breakage is expected to occur. To successfully predict the void ratio for a sand–silt mixture during compression loading, we need (1) a mathematical expression for the evolution of the active void ratio during compression and (2) a relationship between the inactive void ratio and fines content of the mixture. For sand–silt mixtures with any amount of fines, the proposed model requires five material parameters, which are determined from two compression tests, and four minimum void ratio tests on sand–silt mixtures with different fines content. The performance of the proposed model is verified for six different types of sand–silt mixture with various fines contents, by comparing the predicted void ratios with the measured data from the experiments. The comparisons show a good agreement between the predictions and the measured data and prove the suitability of the proposed model for the prediction of compressibility of sand–silt mixtures with any amount of fines.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sand–silt mixtures are abundant in the nature as well as in the man-made structures such as levees and embankments. Understanding the mechanical behavior of these materials is essential to the engineers to predict their deformation behavior and strength characteristics under different loading scenarios.

It has been shown by many researchers that the fines content has very important effects on different aspects of the mechanical behavior of sand–silt mixtures [1, 8, 9, 13, 14, 16,17,18,19, 21,22,23, 26,27,28,29,30, 32, 35, 37,38,39, 41,42,43]. Several experimental works have shown the effect of fines content on the compression behavior of sand–silt mixtures [3, 11, 12, 15, 20, 34, 44, 46].

A compression model for sand–silt mixture that accounts for the effect of fines content is needed in the practice of geotechnical engineering. For example, in studying the mechanics of internal erosion, as was shown by Chang and Meidani [4] and Hicher [14], it is essential to have a compression model for sand–silt mixtures that explicitly considers the amount of fines, to be able to simulate the effects of loss of fines on the overall deformation behavior and strength characteristics of the eroded soil.

To date, there is no compression model for sand–silt mixtures that explicitly considers the fines content as a variable in its formulation. The conventional compression models for granular materials consider factors such as initial void ratio, applied effective stress, and particles mineralogy [10, 24, 25, 31, 36]. The material constants in these conventional models need to be calibrated for each mixture with particular fines content.

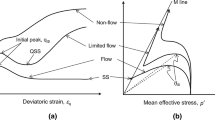

In this paper, we develop a mathematical model to predict the compressibility of sand–silt mixtures by explicitly considering its fine content as an input variable. To do so, we introduce a novel concept of dividing the voids in a granular packing into two hypothetical fractions, named active and inactive voids. This postulate leads us to look at the compression test data from a non-traditional perspective; instead of treating compressibility as a function of stress level, we study the relationship between compressibility and density state. Based on the experimental evidence from compression tests on various sand–silt mixtures, we identify a linear relationship between the material compressibility and its density state. It is shown that this linear relationship is valid up to stress levels at which the effect of particle breakage is not prominent; however, there are limited particle crushing effects that are implicitly embedded in this linear relationship.

This linear relationship is expressed in the form of a differential equation. After integration, a mathematical model for the compressibility of sand–silt mixtures is derived. The two hypothetical fractions, i.e., active and inactive void ratios, are identified in the derived mathematical relationship. We show that active void ratio diminishes with an exponential rate with respect to the stress level. It is also shown that the inactive void ratio can be expressed as an explicit function of fines content. Finally, the proposed model is verified by comparing the predicted void ratios with the measured data for six different types of sand–silt mixtures with various amounts of fines and different mineralogy.

2 Active and inactive voids in granular materials

For convenience in the modeling process, we divide the voids in a granular packing into two hypothetical fractions: (1) active voids and (2) inactive voids. The traditional phase diagram for a granular material is shown in Fig. 1a. The active and inactive voids are separated in another phase diagram shown in Fig. 1b.

The compression of solid particles is negligible for the stress levels considered in this study. Therefore, we can divide the volumes of active and inactive voids by the total volume of solids \(V_{\text{s}}\) and define active void ratio \(e_{\text{active}}\) and inactive void ratio \(e_{\text{inactive}}\), respectively (Fig. 1). The total void ratio (\(e\)) of a soil at any stress level is the sum of \(e_{\text{active}}\) and \(e_{\text{inactive}}\).

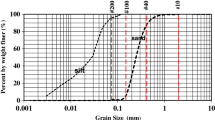

We define active voids such as this hypothetical fraction of total voids is kinematically diminishable during compression due to particles rearrangement, i.e., particle sliding and rotation (Fig. 2). On the other hand, inactive voids are kinematically unavailable to be diminished by particles rearrangement. The volume of inactive voids is dependent on the particle size distribution (PSD) and particles shapes. These two factors dictate the densest kinematic limit of a granular packing as described in details by Meidani et al. [25]. PSD and particle shape can be changed by particles breakage, particles bonding, or particles loss. Varying the fines content in a sand–silt mixture changes the PSD of the soil (Fig. 2).

A desirable compression model for sand–silt mixtures with a given fines content (\(f_{c}\)) can be written in the following general form as:

where \(e\) is the total void ratio of the mixture, \(p^{{\prime }}\) is the effective stress, \(e_{0}\) is the initial void ratio of the mixture. \(f_{c}\) is the fines content in the mixture. \(f_{c}\) is defined as the dry mass of fines in the mixture divided by the total dry mass of the mixture. e active and e inactive are the active and inactive void ratio components, respectively. They build up the total void ratio e. Equation (1) shows the simple postulate that we want to examine its applicability in this study.

In the next section, we derive a mathematical relationship for the compression of sand–silt mixtures. We show that active voids diminish with an exponential rate with respect to the effective stress and initial density of the mixture. We also show that the inactive void ratio is a function of fines content, which will be related to the minimum void ratio of the mixture. The inactive void ratio will be shown to be independent of the stress magnitude up to certain levels. We will show that the effects of particle crushing in the range of validity of the proposed model are implicitly embedded into the function that defines the evolution of active void ratio.

3 Derivation of the compression model

Meidani et al. [25] showed an approximate linear relationship can be identified between \(\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) and \(e\), based on the compression test data from 20 different types of granular soils. The result of compression test on a typical quartz sand is shown in Fig. 3. Determined from compression test data, we can observe that the approximate linear relationship is valid up to certain stress level, for example 40 MPa for most quartz sands and 10 MPa for most calcium-based sands [25]. It is clear that some particle breakage occurs in quartz sand prior to 40 MPa due to compression. Hence, the effects of particle breakage on the change of void ratio are implicitly included in the linear relationship between \(\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) and \(e\) [25].

\(\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) plotted versus void ratio \(e\). Data from compression tests on Cambria sand (after [25])

We apply the similar concept to the compression of sand–silt mixtures. We select compression tests data on specimens made of Hukksond sand and Chengbei silt with various fines contents, ranging from 0 to 94% (Table 1), to check the validity of this concept in sand–silt mixtures. After normalizing all applied stresses to the reference atmospheric pressure and defining the normalized effective pressure as \(p_{*}^{{\prime }} = \frac{{p^{{\prime }} }}{{p_{\text{atm}} }}\), where \(p_{\text{atm}}\) = 0.101325 MPa, the values of \(\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) versus \(e\) are plotted in Fig. 4 for all fines contents.

\(\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) plotted versus void ratio for mixtures of Hukksond sand and Chengbei silt with various fines contents. The solid lines are the best-fit linear approximation to the tests data with a given fines content. The slopes of three lines for the 30, 70, and 94% fines content specimens are shown as \(\alpha_{30\% }\), \(\alpha_{70\% }\), and \(\alpha_{94\% }\). The x-intercept of the trend line for the mixtures with 94% fines content is shown as \(e_{{r_{94\% } }}\)

Linear correlations can be identified among the data points with a given fines content. For instance, the tests results from the mixtures with 70% fines content are shown with solid squares in Fig. 4. A line is fitted to these data points. The same procedure is done for all other fines contents. The trend lines have different slopes and different intercepts. In a general form, these lines can be expressed by the following relationship:

where \(f_{c}\) designates the fines content of the specimen. \(\alpha_{{f_{c} }}\) and \(\beta_{{f_{c} }}\) are the slopes and y-intercepts of the lines, respectively.

Equation (2) can also be written in the following form:

In this equation, \(e_{{r_{{f_{c} }} }}\) is equal to \(\frac{{\beta_{{f_{c} }} }}{{\alpha_{{f_{c} }} }}\), which is the x-intercept of the trend line for specimens with fines content \(f_{c}\), as shown in Fig. 4. As the void ratio decreases under compression, \(\left( {\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}} \right)_{{f_{c} }}\) decreases linearly. When the void ratio reaches \(e_{{r_{{f_{c} }} }}\), \(\left( {\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}} \right)_{{f_{c} }}\) becomes zero, which means that the void ratio will not decrease anymore. According to our postulate, this is when all kinematically available voids are diminished due to particles rearrangement. The remaining voids, \(e = e_{{r_{{f_{c} }} }}\), are no longer compressible, as they are kinematically unavailable to the compression process. We name \(e_{{r_{{f_{c} }} }}\), representative inactive void ratio. The reason we do not simply call this variable inactive void ratio is that the approximate linear correlation between \(\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) and \(e\) is only valid up to certain stress levels (Fig. 3). So, the x-intercept (\(e_{{r_{{f_{c} }} }}\)) only represents the compression behavior up to certain stress levels.

Taken from Fig. 4, we plot the slopes of the fitted lines \(\alpha_{{f_{c} }}\) versus the initial void ratios of various specimens made of Hukksond sand and Chengbei silt (Fig. 5). A correlation can be found between \(\alpha_{{f_{c} }}\) and \(e_{0}\), which is expressed as:

where \(\hat{a}_{{f_{c} }}\) is a material parameter and \(e_{0}\) is the initial void ratio of each specimen. As shown in Fig. 5, the parameter \(\hat{a}_{{f_{c} }}\) is approximately 0.4 for all fines contents in this mixture. Therefore, we drop the subscript \(f_{c}\) from \(\hat{a}_{{f_{c} }}\) and rewrite Eq. 4 as:

where \(\hat{a}\) is a material parameter. In the case of Hukksond sand and Chengbei silt mixtures, this parameter is 0.4. Even though the proposed linear relationship in Eq. 5 is approximate, we show later that it causes a very small error in void ratio predictions.

Linear correlation between the slopes of trend lines (shown in Fig. 4) and the initial void ratios of specimens for the mixtures of Hukksond sand and Chengbei silt with various fines contents

Replacing Eq. 5 into Eq. 3 gives:

or, if \(e_{0}\) is moved to the left side of Eq. 6, we have:

which means that if the values of \(\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) are divided by the initial void ratio of each specimen and plotted versus the void ratio, the result will be a group of parallel lines that has a slope equal to \(\hat{a}\) and different x-intercepts equal to \(e_{{r_{{f_{c} }} }}\). The intercepts vary with the fines content of the specimen, as shown in Fig. 6. The general relationship for these parallel lines is Eq. 7.

\(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) plotted versus void ratio \(e\) for mixtures of Hukksond sand and Chengbei silt with various fines contents. The slopes of three lines from 30, 70, and 94% fines content specimens are shown as \(\hat{a}\). The x-intercept of the trend line for the mixtures with 94% fines content is shown as \(e_{{r_{94\% } }}\)

In order to derive the mathematical relationship for the compression model, we reorganize Eq. 7 as:

Recall that \({\text{d}}p_{*}^{'} = \frac{{{\text{d}}p^{\prime}}}{{p_{\text{atm}} }}\).

This relationship can be integrated over the variables \(e\) and \(p^{{\prime }}\) for a constant \(e_{{r_{{f_{c} }} }}\) as follows:

where the upper integral limit, \(e\), is the void ratio at the target stress \(p^{{\prime }}\). For a given fines content, \(e_{{r_{{f_{c} }} }}\) is constant (Fig. 6).

Integration of Eq. 9 leads to the following form, which expresses the void ratio as a function of applied stress \(p^{{\prime }}\), initial void ratio \(e_{0}\), and representative inactive void ratio \(e_{{r_{{f_{c} }} }}\):

Through analogy of the terms between Eqs. 10 and 1, we can identify the active and inactive void ratios as follows:

The graphical representation of Eq. (9) for a given fines content is shown in Fig. 7.

Graphical representation of Eq. 10, showing the evolution of void ratio during compression

Figure 8 shows the evolution of volume of voids during compression in three phase diagrams for a mixture with a given fines content. Since the volume of the representative inactive voids does not change during loading (Eq. 12), and the volume of solids remains constant, all the volume change is attributed to the change in active voids (Eq. 11).

The effect of variation of model parameters \(e_{{r_{{f_{c} }} }}\) and \(\hat{a}\) on the calculated compression lines is shown in Fig. 9. It can be seen that decreasing parameter \(e_{{r_{{f_{c} }} }}\) increases the slope of compression lines and slightly shifts them to the left, while increasing \(\hat{a}\) does not have a significant effect on the slope of compression lines, but shifts the calculated compression lines to the left, depicting a reduction in the yield stress of the material.

Effect of variation of model parameters a \(e_{{r_{{f_{c} }} }}\) and b \(\hat{a}\) on the calculated compression lines from Eq. 10

In order to determine the model parameters \(\hat{a}\) and \(e_{{r_{{f_{c} }} }}\) for the selected sand–silt mixtures (Table 1), we construct \(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{'} }}\) versus \(e\) graphs similar to Fig. 6 for each type of mixture. Five of the mixtures are made from quartz sand and quartz silt with various fines contents [11, 12, 20, 44, 46]. The \(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{'} }}\) versus \(e\) graphs showed that for each type of mixture, all trend lines correlated with the compression tests data performed on specimens with various fines contents have the same slope (\(\hat{a}\)). The determined \(\hat{a}\) values for these five types of mixtures are reported in Table 1. The sixth type of mixture, tested by Cabalar [3], is made of quartz sand and mica fines. When \(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) versus \(e\) graph for Cabalar’s data was constructed, the trend lines did not seem to be parallel to each other, in contrast to the other five types of mixtures. We attribute this to the high crushability of mica particles compared with the quartz particles. The determined slopes of trend lines (i.e., \(\hat{a}\)) for these mixtures are shown in Fig. 10 for various fines contents.

For the six types of mixtures, the determined \(e_{{r_{{f_{c} }} }}\) values from \(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) versus \(e\) graphs are plotted in Fig. 11. For all mixtures and at each fines content, \(e_{0}\) is also presented in Fig. 11. The distance between \(e_{0}\) and \(e_{{r_{{f_{c} }} }}\) represents the range of active void ratio (i.e., compressible voids) for each mixture.

Representative inactive void ratios (\(e_{{r_{{f_{c} }} }}\)) versus fines content for six different types of sand–silt mixtures. The values of \(e_{{r_{{f_{c} }} }}\) are determined from the compression tests data by constructing \(\frac{{{\text{d}}e}}{{{\text{d}}p^{{\prime }} }}\) vs. \(e\) graphs similar to Fig. 6

3.1 Predicting \(e_{{r_{{f_{c} }} }}\) as a function of fines content

The schematic trend of \(e_{{r_{{f_{c} }} }}\) versus fines content, which is observed in Fig. 11 for six different types of sand–silt mixtures, is drawn in Fig. 12. It can be seen that \(e_{{r_{{f_{c} }} }}\) (i.e., kinematically unavailable void ratio) is influenced by the amount of fines in the mixture. The next step is to find a mathematical relationship between \(e_{{r_{{f_{c} }} }}\) and the fines content, so that we can eliminate the need for compression tests at all fines contents and predict \(e_{{r_{{f_{c} }} }}\) from fewer experiments.

As the fines content is increased from 0%, \(e_{{r_{{f_{c} }} }}\) decreases to a minimum value and then continues to increase after a reversal point. This trend is similar to that observed in the studies for the variation of minimum void ratio of sand–silt mixtures with various amounts of fines. For the minimum void ratio, the specific fines content corresponding to the reversal point is called threshold fines content (TFC) by Thevanayagam et al. [40], transitional fines content by Yang et al. [45], or limiting fines content by Polito and Martin [33]. This reversal point occurs at transient fine contents ranging from approximately 20–35% for most sand–silt mixtures [5].

Intuitively, the theory of mixtures [2] is the first choice for estimating \(e_{{r_{{f_{c} }} }}\) of a mixture from the properties of clean sand and clean silt specimens. We examine the validity of upper-bound and lower-bound solutions for predicting the \(e_{{r_{{f_{c} }} }}\) from \(e_{{r_{\text{sand}} }}\) and \(e_{{r_{\text{silt}} }}\) at various fines contents.

Voigt’s upper-bound solution for the representative inactive void ratio (\(e_{{r_{{f_{c} }} }}\)) of a mixture can be expressed as:

where \(e_{{r_{\text{sand}} }}\) and \(e_{{r_{\text{silt}} }}\) are the properties of clean sand and clean silt, determined from \(\frac{1}{{e_{0} }}\frac{{{\text{d}}e}}{{{\text{d}}p_{*}^{{\prime }} }}\) versus \(e\) graphs.

The lower-bound solution for \(e_{{r_{{f_{c} }} }}\) of a mixture can be calculated from Ruess theory and is given by:

Figure 13 shows typical measured values of \(e_{{r_{{f_{c} }} }}\) for sand–silt mixtures with various fines contents (circle symbols). Equations 13 and 14 are used to calculate the upper-bound (solid line) and lower-bound (dashed line) solutions of \(e_{{r_{fc} }}\) for mixtures with \(e_{{r_{\text{sand}} }} = 0.5\) and \(e_{{r_{\text{silt}} }} = 0.9\). As shown in Fig. 13, the upper and lower bounds of the mixture theory cannot cover the range of measured \(e_{{r_{fc} }}\) values. The typical measured \(e_{{r_{fc} }}\) values are significantly lower than the Reuss lower bound (Fig. 13), although the Voigt’s upper bound is not violated in this figure.

Previously, Chang and Meidani [5] showed that the theory of mixtures is not applicable to the variation of minimum void ratio of sand–silt mixtures, because this theory does not account for the mixing mechanism of particles; for instance, it cannot consider the filling of fines into the voids of the coarse-grains skeleton, or in the other case, the embedment of coarse particles into the fine-grains skeleton. Chang and Meidani [5] proposed a model for the variation of minimum void ratio of sand–silt mixtures and showed that the same model can also predict the critical state void ratio of such mixture. Chang et al. [5, 7, 33] extended the previous model and proposed a new relationship that could predict the minimum and maximum void ratios of such mixtures with a unique set of parameters.

According to Chang et al. [6], minimum void ratio of sand–silt mixtures can be calculated from the following equations:

where

The subscripts c and f on the left side of Eqs. 16 and 17 refer to the coarse-grain and fine-grain dominant structures, respectively (Fig. 14). The minimum void ratios of clean sand (\(e_{{\min_{\text{sand}} }}\)) and clean silt (\(e_{{\min_{\text{silt}} }}\)) are known a priori. Equations 16 and 17 represent the lines on the left and right sides of Fig. 14. Out of the two values of minimum void ratio calculated from Eqs. 15 and 16, the larger one is the easier outcome during mixing, because it consumes less energy. Based on Eq. 15, the solid line is the true solution for the minimum void ratio of a mixture.

The range of coefficients \(\alpha\) and \(\beta\) is between 0 and 1. These two coefficients are used to include the effects of inclusion and embedment of coarse and fine particles into the dominant grain structure. The special case of \(\alpha = \beta = 0\) corresponds to the Voigt solution (upper bound). The special case of \(\alpha = 1\) corresponds to a case where the change in voids volume is equal to the volume of fines particles added to or removed from the mixture. The special case of \(\beta = 1\) represents a case where the volume of voids remains the same after removing or adding coarse particles into the mixture. The coefficients \(\alpha\) and \(\beta\) are determined by back fitting Eqs. 15 and 16 to the minimum void ratio data obtained from experiments.

In what comes next, we examine the validity of Eq. 15 for prediction of \(e_{{r_{fc} }}\) for sand–silt mixtures with various fines contents.

Even though the two density state measures \(e_{{r_{fc} }}\) and \(e_{{\min_{fc} }}\) are determined from two different loading processes and different degrees of particle crushing occur in each process, they both bear the same meaning toward the inactive void ratio concept. The loading process to reach the minimum void ratio state includes vibration of the specimen under small vertical load. The loading process to reach \(e_{{r_{fc} }}\) is compression (isotropic or 1-D) where all active voids are diminished by particle rearrangement. Therefore, the values of \(e_{{r_{fc} }}\) and \(e_{{\min_{fc} }}\) are not expected to be the same as shown in Fig. 15, where experimentally measured values of \(e_{{r_{fc} }}\) and \(e_{{\min_{fc} }}\) for the six types of sand–silt mixtures are plotted versus fines content.

Predicted \(e_{{r_{{f_{c} }} }}\) (solid lines), and predicted e min (dot-dash lines) for all fines contents based on the same sets of \(\alpha\) and \(\beta\) coefficients for six different types of sand–silt mixtures. \(e_{{r_{{f_{c} }} }}\), e min values and specimen initial void ratios are shown with square, circle, and diamond symbols, respectively

Despite their difference, the effect of varying fines content in a mixture seems to be similar on the variation of \(e_{{r_{fc} }}\) and \(e_{{\min_{fc} }}\) as shown in Fig. 15. We employ the forms of Eqs. 16 and 17 to predict \(e_{{r_{fc} }}\) for sand–silt mixtures by replacing \(e_{\hbox{min} }\) with \(e_{r}\):

where \(e_{{r_{c} }}\) and \(e_{{r_{f} }}\) are the reference inactive void ratios for coarse-grain and fine-grain dominant mixtures, respectively. Similar to the case of minimum void ratio, out of the two calculated values from Eqs. 18 and 19, the higher one is the true solution:

The coefficients \(\alpha\) and \(\beta\) used in Eqs. 18 and 19 are the same as those used for calculating \(e_{\hbox{min} }\) of the same type of mixture.

For six different types of mixtures selected for this study, the coefficients \(\alpha\) and \(\beta\) are determined for five types of mixtures from the minimum void ratio data. The sixth dataset from Konishi et al. [20] did not report the values of minimum void ratio, so these two coefficients are determined from \(e_{{r_{fc} }}\) values for this type of mixture. These values are shown in Table 1.

4 Calibration of the model parameters and instructions on using the proposed model

The proposed model can predict the compression lines of sand–silt mixtures with any fines content, using two main parameters, i.e., \(\hat{a}\) and \(e_{{r_{fc} }}\) (Eq. 10). Parameter \(\hat{a}\) is directly determined from a compression test on one mixture with an arbitrary fines content. Parameter \(e_{{r_{fc} }}\) is dependent on the fines content of the mixture and is predicted by an augmented model expressed by Eq. 20. In order to calculate \(e_{{r_{fc} }}\) from Eq. 20, four parameters are required: \(e_{{r_{\text{sand}} }}\), \(e_{{r_{\text{silt}} }}\), \(\alpha\), and \(\beta\). These four parameters are determined from compression tests on two specimens with different fines contents and maximum density (i.e. minimum void ratio) tests on four mixtures with different fines contents. Briefly, the model uses five parameters to predict the compression lines for sand–silt mixture with any amount of fines and with any initial void ratio. The total number of required experiments for calibration of the model parameters are: compression tests on two specimens and minimum void ratio tests on four mixtures.

The process of calibrating the model parameters is shown in Figs. 16 and 17 in detailed steps.

5 Performance of the proposed model

Based on the augmented model proposed for \(e_{{r_{{f_{c} }} }}\) (Eq. 20), and plugging the predicted values of \(e_{{r_{{f_{c} }} }}\) in the proposed model (Eq. 10), we predict compression lines for the selected sand–silt mixtures in the stress ranges shown in Table 1. The predicted compression lines are shown in Fig. 18 together with the measured void ratios from the experiments.

To check the performance of the proposed model, the predicted void ratios are plotted versus the measured void ratios in Fig. 19 for the selected six types of mixtures. The coefficient of determination R 2 is equal to 0.97, which proves the suitability of the proposed model to predict the compression lines for different types of sand–silt mixtures with any amount of fines.

6 Conclusions

We introduced a postulate to divide the voids in a granular material into active and inactive fractions. Based on this postulation, we proposed a mathematical expression to predict the void ratio during 1-D and isotropic compression for sand–silt mixtures with various fines contents. This model has two main parameters \(\hat{a}\) and \(e_{{r_{fc} }}\). We also proposed a method to predict the model parameter \(e_{{r_{fc} }}\) as a function of fines content, which is based on four coefficients. Two of the coefficients (i.e., \(\alpha\) and \(\beta\)) can be determined from the minimum void ratio tests on four different sand–silt mixtures. The other two coefficients \(e_{{r_{\text{sand}} }}\) and \(e_{{r_{\text{silt}} }}\) are determined from compression tests on two specimens of sand–silt mixture with two different fines contents, one of which has fines content less than and the other has fines content higher than transitional fines content.

The performance of the proposed model is verified by comparing the measured and predicted compression lines for six types of sand–silt mixtures with various fines contents. The comparison shows a coefficient of determination R 2 = 0.97, thus proving the suitability of the proposed model for predicting compressibility of sand–silt mixtures with any amount of fines.

References

Benahmed N, Nguyen TK, Hicher PY, Nicolas M (2015) An experimental investigation into the effects of low plastic fines content on the behaviour of sand/silt mixtures. Eur J Environ Civ Eng 19:109–128. doi:10.1080/19648189.2014.939304

Bowen RM (1976) Theory of mixtures, part I. Contin. Phys. III

Cabalar AF (2010) Applications of the oedometer, triaxial and resonant column tests to the study of micaceous sands. Eng Geol 112:21–28. doi:10.1016/j.enggeo.2010.01.004

Chang CS, Meidani M (2012) Deformation and failure of soils under erosion. NSF C Eng Res Innov Conf. doi:10.13140/RG.2.1.1964.1204

Chang CS, Meidani M (2013) Dominant grains network and behavior of sand–silt mixtures: stress–strain modeling. Int J Numer Anal Methods Geomech 37:2563–2589. doi:10.1002/nag.2152

Chang CS, Wang J-Y, Ge L (2015) Modeling of minimum void ratio for sand–silt mixtures. Eng Geol 196:293–304. doi:10.1016/j.enggeo.2015.07.015

Chang CS, Wang JY, Ge L (2016) Maximum and minimum void ratios for sand–silt mixtures. Eng Geol 211:7–18. doi:10.1016/j.enggeo.2016.06.022

Chen C, Zhang LM, Chang DS (2016) Stress–strain behavior of granular soils subjected to internal erosion. J Geotech Geoenviron Eng 142:6016014. doi:10.1061/(ASCE)GT.1943-5606.0001561

Choo H, Burns SE (2015) Shear wave velocity of granular mixtures of silica particles as a function of finer fraction, size ratios and void ratios. Granul Matter 17:567–578. doi:10.1007/s10035-015-0580-2

Coop MR, Atkinson JH (1993) The mechanics of cemented carbonate sands. Géotechnique 43:53–67. doi:10.1680/geot.1993.43.1.53

Dash HK, Sitharam TG (2011) Undrained monotonic response of sand–silt mixtures: effect of nonplastic fines. Geomech Geoengin 6:47–58. doi:10.1080/17486021003706796

Derkaoui M, Missoum H, Bendani K, Belhouari F (2016) Shear behavior of sand–silt mixtures: a laboratory investigation of coastal silty sand soils of Mostaganem. Mar Georesour Geotechnol 34:668–680. doi:10.1080/1064119X.2015.1070388

Georgiannou VN (2006) The undrained response of sands with additions of particles of various shapes and sizes. Géotechnique 56:639–649. doi:10.1680/geot.2006.56.9.639

Hicher PY (2013) Modelling the impact of particle removal on granular material behaviour. Geotechnique 63:118–128. doi:10.1680/geot.11.P.020

Huang Y-T, Huang A-B, Kuo Y-C, Tsai M-D (2004) A laboratory study on the undrained strength of a silty sand from Central Western Taiwan. Soil Dyn Earthq Eng 24:733–743. doi:10.1016/j.soildyn.2004.06.013

Jehring MM, Bareither CA (2016) Tailings composition effects on shear strength behavior of co-mixed mine waste rock and tailings. Acta Geotech 11:1147–1166. doi:10.1007/s11440-015-0429-1

Ke L, Takahashi A (2015) Drained monotonic responses of suffusional cohesionless soils. J Geotech Geoenviron Eng 141:1–8. doi:10.1061/(ASCE)GT.1943-5606.0001327

Ke L, Ouyang M, Horikoshi K, Takahashi A (2016) Soil deformation due to suffusion and its consequences on undrained behavior under various confining pressures. Jpn Geotech Soc Spec Publ 2:368–373. doi:10.3208/jgssp.JPN-083

Khalil T, Saiyouri N, Muresan B, Hicher P-Y (2013) Internal erosion of chemically reinforced granular materials: a mathematical modeling approach. Int J Numer Anal Methods Geomech 37:491–502. doi:10.1002/nag.1108

Konishi Y, Hyodo M, Ito S (2007) Compression and undrained shear characteristics of sand-fines mixtures with various plasticity. JSCE J Geotech Geoenviron Eng 63:1142–1152. doi:10.2208/jscejc.63.1142

Kuerbis R, Negussey D, Vaid YP (1988) Effect of gradation and fines content on the undrained response of sand. In: Hydraul. Fill Struct. Geotech. Spec. Pub. No. 21. ASCE, New York, pp 330–345

Lade PV, Yamamuro JA (1997) Effects of nonplastic fines on static liquefaction of sands. Can Geotech J 34:918–928. doi:10.1139/t97-052

Lashkari A (2016) Prediction of flow liquefaction instability of clean and silty sands. Acta Geotech 11:987–1014. doi:10.1007/s11440-015-0413-9

Manzari MT, Dafalias YF (1997) A critical state two-surface plasticity model for sands. Géotechnique 47:255–272. doi:10.1680/geot.1997.47.2.255

Meidani M, Chang CS, Deng Y (2017) On active and inactive voids and a compression model for granular soils. Eng Geol 222:156–167. doi:10.1016/j.enggeo.2017.03.006

Mohammadi A, Qadimi A (2015) A simple critical state approach to predicting the cyclic and monotonic response of sands with different fines contents using the equivalent intergranular void ratio. Acta Geotech 10:587–606. doi:10.1007/s11440-014-0318-z

Monkul MM, Yamamuro JA, Lade PV (2011) Failure, instability, and the second work increment in loose silty sand. Can Geotech J 48:943–955. doi:10.1139/t11-013

Muir Wood D, Maeda K, Nukudani E (2010) Modelling mechanical consequences of erosion. Géotechnique 60:447–457. doi:10.1680/geot.2010.60.6.447

Murthy TG, Loukidis D, Carraro JAH et al (2007) Undrained monotonic response of clean and silty sands. Géotechnique 57:273–288. doi:10.1680/geot.2007.57.3.273

Ng T, Asce F, Zhou W, Chang X (2016) Effect of particle shape and fine content on the behavior of binary mixture segregation of binary mixtures. J Eng Mech. doi:10.1061/(ASCE)EM.1943-7889.0001070

Pestana JM, Whittle AJ (1995) Compression model for cohesionless soils. Geotechnique 45:611–631. doi:10.1680/geot.1995.45.4.611

Pitman TD, Robertson PK, Sego DC (1994) Influence of fines on the collapse of loose sands. Can Geotech J 31:728–739. doi:10.1139/t94-084

Polito CP, Martin JR (2001) Effects of nonplastic fines on the liquefaction resistance of sands. J Geotech Geoenviron Eng 127:408–415. doi:10.1061/(ASCE)1090-0241(2001)127:5(408)

Rangaswamy K, Boominathan A, Rajagopal K (2010) Influence of initial conditions on liquefaction resistance of silty sands. Geomech Geoengin 5:199–211. doi:10.1080/17486021003706572

Rees SD (2010) Effects of fines on the undrained behavior of Christchurch sandy soils. University of Canterbury, Christchurch, New Zealand

Russell AR, Khalili N (2004) A bounding surface plasticity model for sands exhibiting particle crushing. Can Geotech J 41:1179–1192. doi:10.1139/t04-065

Sadrekarimi A, Olson SM (2011) Yield strength ratios, critical strength ratios, and brittleness of sandy soils from laboratory tests. Can Geotech J 48:493–510. doi:10.1139/T10-078

Scholtes L, Hicher P-Y, Sibille L (2010) Multiscale approaches to describe mechanical responses induced by particle removal in granular materials. C R Mec 338:627–638. doi:10.1016/j.crme.2010.10.003

Stamatopoulos CA (2010) An experimental study of the liquefaction strength of silty sands in terms of the state parameter. Soil Dyn Earthq Eng 30:662–678. doi:10.1016/j.soildyn.2010.02.008

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128:849–859. doi:10.1061/(ASCE)1090-0241(2002)128:10(849)

Wan CF, Fell R (2008) Assessing the potential of internal instability and suffusion in embankment dams and their foundations. J Geotech Geoenviron Eng 134:401–407. doi:10.1061/(ASCE)1090-0241(2008)134:3(401)

Yamamuro JA, Covert KM (2001) Monotonic and cyclic liquefaction of very loose sands with high silt content. J Geotech Geoenviron Eng 127:314–324. doi:10.1061/(ASCE)1090-0241(2001)127:4(314)

Yamamuro JA, Lade PV (1999) Experiments and modelling of silty sands susceptible to static liquefaction. Mech Cohesive Frict Mater 4:545–564. doi:10.1002/(SICI)1099-1484(199911)4:6<545:AID-CFM73>3.0.CO;2-O

Yang SL (2004) Characterization of the properties of sand–silt mixtures. Norwegian University of Science and Technology

Yang S, Lacasse S, Sandven R (2006) Determination of the transitional fines content of mixtures of sand and non-plastic fines. Geotech Test J 29:1–6. doi:10.1520/GTJ14010

Zlatović S, Ishihara K (1995) On the influence of nonplastic fines on residual strength. In: First Int. Conf. Earthq. Geotech. Eng. Tokyo, Japan, pp 239–244

Acknowledgements

This research was supported by National Science Foundation through Grant Number CMMI-1537491.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, C.S., Meidani, M. & Deng, Y. A compression model for sand–silt mixtures based on the concept of active and inactive voids. Acta Geotech. 12, 1301–1317 (2017). https://doi.org/10.1007/s11440-017-0598-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-017-0598-1