Abstract

Purpose

About 82% of the seafood consumed in Aruba is imported. Among canned fish products, tuna is consumed mostly. The purpose of this research was to compare the environmental impact of different types of canned tuna, and to identify environmental hotspots within the supply chains. Three comparisons were made: between three different supply chains (brands) of canned tuna, between six different accompanying liquids (oils, brine, and tomato sauce), and between small and large cans.

Methods

Life cycle assessment (LCA) was used to calculate the environmental impact of “1 kg edible tuna at the distribution center in Aruba, including packaging,” from the fishing stage until the distribution center in Aruba. An Agribalyse tuna model was selected as the basis of the models and was adjusted in SimaPro. Adjusted processes were tuna species consumption mix, electricity mix during canning, size of cans, packaging, sea, and truck transport, accompanying liquids, and storage. Added processes were transport in country of origin, and use of frozen loins (for one supply chain).

Results and discussion

Generally speaking, the observed differences in environmental impact in the three different comparisons were quite small. After normalization, seven environmental impact indicators were selected as most relevant. Environmental hotspots were usually related to diesel combustion on the fishing vessel, or to steel production in the canning stage. Although packaging was modelled with attention to detail, and sea transport was modelled with attention to detail for the used vessels and vessel characteristics, these were not one of the environmental hotspots.

Conclusions and recommendations

Although differences in environmental impact were quite small, most outstanding were that canned tuna that had the longest and partly frozen sea transport supply chain had the highest environmental impact. Preference should be given to local canning activities instead of shipping frozen tuna over long distances before canning. Furthermore, large cans always had a lower environmental impact compared to small cans. From a hospitality or consumer point of view, it can be recommended to select larger can sizes where practically possible. The choice of tuna canned in tomato sauce, oil, or brine would necessitate an analysis including the subsequent steps, for example, tuna canned in tomato sauce may be part of a meal as such, while tuna canned in brine may be prepared, after opening the can, with another warm or cold sauce, which would lead to additional separate impacts for these sauces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Global seafood production is increasing year after year. Aquaculture production in particular is on the rise. Within the period 1990–2018, the global aquaculture production increased by 527% (FAO 2020a). The global seafood production is expected to continue to grow due to the increasing world population and increasing demand for animal protein especially in emerging countries where income is growing (Farmery et al. 2014; FAO 2020b). In wild-capture fisheries, the production and combustion of fossil fuel used on the vessels appear to be the main sources of greenhouse gases (GHGs) (Vázquez-Rowe et al. 2012). Seventy-five to ninety-five percent of the total carbon footprint of wild-captured species can be traced back to the fishing stage with fuel use as main driver. The second most important driver of GHGs during the fishing stage is the use of refrigerants on the fishing boats (Ziegler et al. 2016). Capture fisheries also affect the stock size of target and non-target species, cause physical changes in the seabed, release chemicals and waste in the ocean, and cause eutrophication (Pelletier et al. 2007; Vázquez-Rowe et al. 2012; Farmery et al. 2014; O’Neill and Ivanović 2016).

One of the biggest gaps in seafood LCA is the gap in geographic coverage. As also highlighted in the research of Vázquez-Rowe et al. (2012) and by Prof. Peter Tyedmers during his invited lecture on seafood sustainability at LCAFood 2022 (Lima, Perú), seafood LCAs are strongly biased towards industrialized countries. Moreover, the lack of transparency in seafood LCA literature results in a big data hurdle for those who want to perform a seafood LCA. Most of the authors do not reveal which life cycle inventory (LCI) data they used and which assumptions they made, making it difficult for others to further build on their findings. Also, the LCI databases which are available such as ecoinvent and Agri-footprint contain restricted data concerning seafood production (Bohnes and Laurent 2021). These challenges impede the widespread adoption of seafood LCA, making it difficult to assess the environmental impact of these products (Bohnes et al. 2019).

In Aruba, an island in the Dutch Caribbean situated north to Venezuela, the average seafood consumption per capita was 53 kg per year (in 2015–2017). In the same period, the global average seafood consumption per capita was 20 kg, showing that the seafood consumption in Aruba is high (National Marine Fisheries Service 2021). The Aruban seafood production, however, is rather low compared with the demand. Approximately 82% of the seafood consumed in Aruba is imported (own calculations based on Pauly et al. 2015; personal communication Central Bureau of Statistics (CBS) Aruba, dataset food imports 2019, September 9, 2020). Typical about Aruba’s fish imports is that most registered fish imports are by sea (~ 94%) rather than by air (own calculations based on personal communication Central Bureau of Statistics (CBS) Aruba, dataset food imports 2019, September 9, 2020). Fish imported by sea arrives mostly frozen or in cans. Compared to other canned fish products, people spent most (69%) of their budget on canned tuna (Central Bureau of Statistics Aruba 2019).

In 2018, skipjack tuna (Katsuwonus pelamis) was the third most captured species worldwide following anchoveta and Alaska pollock (FAO 2020a). Sixty-four percent of the world’s tuna products originate from the Pacific Ocean, and the dominant fishing technique is purse seining. Skipjack, albacore (Thunnus alalunga), and yellowfin (Thunnus albacares) tuna are mainly used for the canning industry, while bluefin (Thunnus thynnus) and bigeye tuna (Thunnus obesus) are the main species used for sashimi and sushi. The world’s top exporter of canned and processed tuna is Thailand with Bangkok being the heart of the global tuna processing industry. The largest importers of processed and canned tuna are the USA and the European Union (FAO 2021).

The objective of this research is to assess the environmental impact and environmental hotspots of different brands and types of canned tuna imports into Aruba, with a focus on three comparisons. First, the environmental impact of three different brands of canned tuna, originating from Thailand or Peru. Second, the environmental impact of six different accompanying liquids, i.e., oils or sauces. Third, the environmental impact of a small (0.142 kg) and a large (1.88 kg) can size. The larger cans are sold in supermarkets but also used in the hospitality industry. To our knowledge, comparisons between the environmental impact of tuna can sizes and between different accompanying liquids have not been made before. Moreover, we will provide extensive details on our methods, such as the use of LCIs and databases.

2 Methods

The ISO 14040 and the ISO 14044 standards were used in this study (European Commission et al. 2010).

2.1 Data collection

First, we identified the target products, as described in Sect. 2.2. After describing the goals and scope in Sect. 2.3, we collected detailed data on the supply chains (see Sect. 2.4) of the different brands of canned tuna by interpreting information on the packaging, through various online sources, and by materials provided by stakeholders in Aruba.

2.2 Identification of target products

To make a realistic selection of the types of canned tuna sold in Aruba, seven differently sized supermarkets were visited in May 2021 and pictures were taken of the shelfs and individual products (Fig. 1). It was assumed that the number of facings represented the popularity of a specific type of canned tuna. The most abundant brands were Sa-Pac, Brunswick, Santa Rita, Chicken of the Sea, and Bumble Bee. Canned tuna brands with different supply chain characteristics were chosen to study in this paper. Santa Rita and Sa-Pac tuna were caught and canned in Peru and Thailand, respectively. Tuna from the three other brands was caught and pre-processed into frozen loins in Thailand and shipped to the cannery in the USA. As most information was available on the Chicken of the Sea supply chain, the brands Brunswick and Bumble Bee were not selected for this study. Most of the tuna sold in Aruba is canned in vegetable, sunflower, or soybean oil. Other liquids such as brine, olive oil, and tomato sauce are sold as well in lower amounts.

2.3 Goal and scope definition

The goal of this study is to assess the environmental impact of canned tuna imported in Aruba, and to compare the environmental impact of different tuna supply chains, different accompanying liquids, and different can sizes. By performing an attributional LCA, environmental hotspots in the seafood supply chains could be identified.

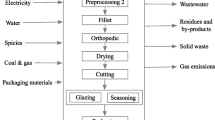

The functional unit is 1 kg edible tuna at the distribution center in Aruba, including packaging. This study performs a cradle-to-gate LCA for in which the gate refers to the gate of the distribution center in Aruba. All transport steps between the different supply chain stages were considered, as well as the transport of the packaging material. Figure 2 shows the system boundaries as well as a representation of how the Agribalyse tuna process was adjusted in this study. The colored boxes and texts indicate which processes were adjusted (beige), except necessary scaling, or added (turquoise). Now, details of the supply chains and the depicted adjustments will be discussed.

System boundaries of canned tuna imports into Aruba, and graphical representation of the canned tuna models based on the Agribalyse process “Tuna, flaked in oil, canned, drained, processed in FR | Ambient (average) | Already packed Aluminium | at distribution/FR.” The white boxes and texts indicate the processes were only changed by scaling to our processes. Some processes were adjusted by adding primary data and/or improving geographic representation (beige). Finally, some new life cycle stages were added (turquoise)

2.4 Process description and Life Cycle Inventory

The Agribalyse tuna process was used as the basis for this research: “Tuna, flaked, in oil, canned, drained, processed in FR | Ambient (average) | Already packed—Aluminium | at distribution/FR.” It was modified to the Aruban case study by adapting the geographical range, the packaging material, and the transport routes and modes. The background processes in Agribalyse® originate from the database ecoinvent. To adjust the tuna model, background processes of the databases ecoinvent and Agri-footprint were used. Seafood datasets from Agribalyse use the system model “Allocation, cut-off.” The reason Agribalyse uses this system model as default for seafood datasets is a lack of data on the multifunctionality of seafood products (Asselin-Balençon et al. 2020). Therefore, this system model was also selected when datasets from the database ecoinvent were used.

2.4.1 Fishing stage

The tuna system started with the fishing activity, related to fishing and fish on vessels. This included the construction, maintenance, and end-of-life treatment of the vessels and the fishing gear. The Agribalyse model on the fishing stage was adjusted by altering the caught species. Chicken of the Sea tuna includes the species skipjack, yellowfin, and albacore tuna (Chicken of the Sea 2020). Sa-Pac and Santa Rita did not disclose information on the tuna species in their products. As not sufficient information was available for all brands, we assumed a similar tuna mix of 90% skipjack tuna and 10% yellowfin tuna.

LCIs of wild capture and aquaculture in the context of the Sustainable Recycling Industry program where the ecoinvent association is in charge of developing national LCA data in several regions and countries are available in the report of Avadí et al. (2019). Herein, a fuel use efficiency (FUE, i.e., the volume of diesel that is needed to capture and land 1 ton of fish) of 831.6 L/t in Ecuador is indicated as being similar to FUE values reported for other purse seining tuna fisheries reported in Parker and Tyedmers (2014). Hence, the fishing stage Agribalyse model was not adapted to the specific fishing areas in this study. Instead, the LCI was based on a float of four worldwide average fishing vessels for tuna using purse seine fishing.

2.4.2 Truck transport

For all products, truck transport occurred between the fishing port and the processing facility, between the processing facility and the export port, and from the port of Barcadera in Aruba to the distribution center in Aruba. For Chicken of the Sea, truck transport also occurred between the port and the cannery in the USA. The transport between the fishing harbor and the processing facility occurred without packaging in a refrigerated truck (Noal Farm 2018). This was modelled with the ecoinvent process “Transport, freight, lorry with reefer, freezing {GLO}| market for | Cut-off, S.” The transport step from the cannery to the export port was modelled with the ecoinvent process “Transport, freight, lorry 16–32 metric ton, EUROX {GLO}| market for | Cut-off, S.” EURO norms used for modelling truck transport are depicted in Table 1.

Chicken of the Sea canned tuna was caught in the FAO Area 71 in the Western Central Pacific Ocean. The caught tuna was processed into frozen loins in Thailand in a Thai Union facility, this was assumed to be the Thai Union Manufacturing Plant 2, which was located 10 km from the fishing port and 45 km from the Port of Bangkok. After pre-processing, the frozen loins were shipped in a reefer (i.e., a refrigerated container) to the cannery in Lyons in the USA to be further processed into canned tuna. This port was chosen as it was located closest to the Port of Savannah (Chicken of the Sea 2020). The distance from the port of Savannah to the cannery was 135 km.

Santa Rita canned tuna was caught in Peru and canned in the canning factory “Inversiones y Comercio Internacional SRL” in Lima. The port of Callao was assumed to be both the fishing and export port; this port was located 20 km from the canning factory. The transport to the cannery was frozen transport, while the transport away from the cannery was ambient. The canned tuna was exported by ship via Cartagena in Colombia.

Sa-Pac canned tuna was caught and canned in Thailand. The canning and processing facility was Unicord Public Company Limited. A fishing port along the Tha Chin River located 10 km from the processing facility was chosen as representative fishing port. The processing facility was located 45 km from the Port of Bangkok. From there, the tuna was shipped directly from Thailand to Aruba, without passing by any distribution center.

2.4.3 Packaging

The primary packaging was adjusted by using the weights of small tuna cans collected in Aruba, and the weight of a large tuna can from a restaurant in Aruba. The amount of oil and tinplate used in this process was adapted to the amount of oil and tinplate used in the tuna cans that are most commonly sold in supermarkets or used by restaurants in Aruba, i.e., tuna cans with a net weight of 142 and 1880 g, for small and large cans respectively. Their drained weights were 113 and 1498 g, respectively. For small and large cans, 0.022 and 0.01 m2 of tin-plated steel were used per kilogram drained tuna, respectively.

Agribalyse used the conversion ratio 1 kg drained tuna/1.33 kg canned tuna. This conversion ratio, however, was adapted to the conversion ratio of canned tuna products in this study, 1 kg drained tuna/1.61 kg canned tuna. The conversion ratios used for modelling are depicted in Table 2.

Secondary packaging was included by adding cardboard boxes, EUR-pallets, and the plastic around the boxes on the pallets. The weight and amount of cardboard boxes and pallets used were determined by interpolation of the data from the study of Hospido et al. (2006) (Table 3). In this study, the secondary packaging material is described for 660 kg drained tuna canned in small cans with an individual drained weight of 62 g. Although the can size this research focuses on is larger, the assumption was made that the weight of the secondary packaging material was similar to the cans with a drained weight of 62 g. EUR-pallets weighed 25 kg and are not re-used in Aruba but collected to use for other purposes (personal communication wholesaler Aruba, Feb 20, 2022). The plastic wrap weighed 0.64 kg and was obtained from an importer in Aruba.

Transport of the packaging materials was modelled using default distances specified by the Product Environmental Footprint Category Rules Guidance (PEFCR) of the European Commissions (European Commission 2017). It was assumed that the EURO norm of vehicles in each country complied with the obligated Euro norm for that country (see Table 1). Although none of the focus species is packed in Europe, the PEFCR values were used since no such detailed default transport distances are available for other regions of the world. To model the transport distances, the PEFCR differentiates two transport scenarios: the packaging supplier of the European packaging facility is located outside Europe or within Europe. It was assumed that the factory of the packaging material was not located on a different continent than the packaging facility. Therefore, the distances of the scenario of a packaging supplier within Europe were assumed. Distances and LCIs used, as specified by the PEFCR document, are depicted in Table 4.

The PEFCR document also specifies which ecoinvent transport processes should be used. The European geographic range {RER} was substituted for the correct geographic range of the lorry, train, and ship transport. Additionally, the Euro norm of the lorry transport specified by the PEFCR (EURO6) was substituted for the obligated Euro norm in the country/geographic range of the packaging facility (Table 1).

2.4.4 Accompanying liquids

The Agribalyse model assumed canning in vegetable oil, which was a mixture of 6.62% cottonseed oil, 47.05% palm oil, and 46.33% soybean oil. To model the different accompanying liquids, the LCIs depicted in Table 5 were selected. For small and large cans, 257 g and 382 g of accompanying liquid were used per kilogram drained tuna, respectively.

2.4.5 Overseas transport

To model the shipping routes, durations, and distances, we used the schedule on cma-cgm.com, which is one of the largest shipping companies (AXSMarine 2022). The possible routes were the same for Chicken of the Sea and Santa Rita canned tuna, and two different routes were possible for Sa-Pac canned tuna. For Sa-Pac tuna, an average route was based on two possible routes. Details on transshipments, ports, ship size, sailing distances, and transit days are provided in Table 6. Ship size was determined via marinetraffic.com, expressed as deadweight tonnage (DWT).

The DWT of a ship indicates the load capacity. It is the total weight of cargo, fresh water, ballast water, fuel, passengers, provisions, and crew. The summer DWT differs from the winter DWT since the density of water declines in summer due to thermal expansion. Consequently, a sea ship floats deeper in the water during summer and can carry less cargo (Maritime Impact 2020).

LCIs from Agri-footprint were used as these allowed to select different characteristics, such as DWT, load factor (LF), distance (short, middle, long), “default,” or “empty return.” It was assumed that all ships had an LF of 100%, except for the ship with the last transshipment to Aruba, which was assumed to have a LF of 80%, since Aruba is not situated at a main maritime transport route. All ships arriving in transhipment ports were assumed “default.” The ships of the last transshipment were assumed to have an “empty return,” due to Aruba’s limited exports. This is modelled as the return trip of the same distance with a 0% LF. “Default” considers that sea ships may travel to a next port to pick up new load instead of returning to the original port of loading. To account for the refrigeration during transport, the LCI “Operation, reefer, freezing {GLO}| market for | Cut-off, S”, expressed in kg*day, was selected.

2.4.6 Storage

Ambient storage was modelled according to the PEF guidance document (Asselin-Balençon et al. 2020), similar to Agribalyse’s methodology. For Chicken of the Sea canned tuna, it was assumed that no frozen storage occurred at the pre-processing plant in Thailand. It was assumed that products remained stored for 1 year.

2.5 Life cycle impact assessment (LCIA)

The three mandatory steps of an LCIA — selection, classification, and characterization — were performed by the LCIA method ILCD 2011 Midpoint + in SimaPro. Table 7 depicts an overview of all impact categories, their abbreviations, and unit.

External normalization of the environmental impacts was performed to interpret the results better. This optional step in LCIA compares the calculated impact scores to the scores of a reference system, identifying the relative significance of a certain impact score (Laurent and Hauschild 2015). ILCD uses the normalization factors recommended by the Joint Research Centre which reflect the total impact of an average European person for the different impact categories for the reference year 2010 (Benini et al. 2014; Rosenbaum et al. 2018). Although the lifestyle of Europeans is different from the lifestyle of Arubans, the adoption of the average European impacts is justified by the fact that these impacts are the most up-to-date and reliable impacts.

The impact categories that were identified as relevant contribute together to more than 80% of the total normalized impact of one scenario. This threshold was based on the PEFCR guidance document (European Commission 2017). Following the PEFCR guidance document, the three toxicity-related impact categories — HTCE, HTNCE, and FRTOX — were excluded from the normalization step (European Commission 2017). This is because the normalization factors in the model behind these impact categories (USEtox model) are not sufficiently robust (Fazio et al. 2018a, b). The impact category IRE was excluded as well since this impact category is not yet fully developed.

A contribution analysis was performed for the impact categories that were identified as most contributing to the total normalized impact. An additional weighting step was not performed since the ILCD method assigns equal weights to all impact categories (European Commission 2016).

3 Results and discussion

The objective of this research was to assess the environmental impact and environmental hotspots of different brands and types of canned tuna imports into Aruba, with a focus on three comparisons. First, the environmental impact of three different brands of canned tuna (Sect. 3.2), originating from Thailand or Peru. Second, the environmental impact of six different accompanying liquids, i.e., oils or sauces (Sect. 3.3). Third, the environmental impact of a small (0.142 kg) and a large (1.88 kg) can size (Sect. 3.4). A normalization step was carried out first to identify the most relevant impact categories (Sect. 3.1).

3.1 Normalization and identification relevant impact categories

By performing an external normalization step (Table 8), the most relevant impact categories could be identified.

Similar values were found for the different comparisons. The environmental impact indicators considered in this study are climate change (CC), particulate matter (PM), ionizing radiation human health (IRHH), photochemical ozone formation (POF), acidification (AC), terrestrial eutrophication (EUTT), and mineral, fossil, and renewable resource depletion (MFRRD). Although climate change was not one of the most contributing impact categories, it was included in this analysis because of its relevance in today’s world.

3.2 Environmental impact of different supply chains

The environmental impact of the three different supply chains, based on tuna in vegetable oil in small cans, is depicted in Fig. 3. The three models show similar results. Being based on the same background data, the differences are resulting from the adaptations in the following life cycle stages: processing, truck transport, and sea transport. The highest environmental impact in all categories was found for Chicken of the Sea canned tuna from Thailand. Similar, and slightly lower results were found for Sa-Pac canned tuna from Thailand and Santa Rita canned tuna from Peru.

It stands out that the diesel combustion on the fishing vessel has the same environmental impact for supply chains from Peru and from Thailand: as indicated above, it is part of the background processes that were not adapted (see also Fig. 2), yet we made the choice to keep it visible in the results so that the processes that were adapted (Processing, Truck transport, and Sea transport) can be appreciated within the larger perspective.

For most impact categories, diesel combustion on the fishing vessel is the most contributing life cycle stage. The contribution of diesel combustion is particularly high for AC, EUTT, and POF, compared to other life cycle stages. AC by diesel combustion is caused by the release into the air of acidifying compounds, such as sulfur dioxide (SO2), nitrogen oxides (NOx), and ammonia (NH3) (EEA 2020). These acidifying compounds cause EUTT after atmospheric deposition (Rosenbaum et al. 2018). POF by diesel combustion is caused by the emission of non-methane volatile organic compounds (NMVOCs) (Sun et al. 2018). Although NMVOCs are also emitted during metal production and combustion of fuels during sea freight (Siddiqui and Dincer 2021), these life cycle stages contribute less to the overall particulate ozone formation.

For some impact categories, the contribution of the tin-coated steel contributed more than in other impact categories, namely, for CC, IRHH, PM, and MFRRD. This was mainly due to steel production and not due to the tin. For CC, this was due to the electricity consumption and heat in the production process of steel, because of coal combustion. For IRHH, this was mostly due to electricity consumption, and for PM this was mostly due to the production of heat. IRHH was caused by the production of radionuclides, which have an ionizing potential, during electricity consumption (Frischknecht et al. 2000). To MFRRD, steel consumption contributed for about two-thirds, and tin consumption for about one-third. This indicates that tin is scarcer than steel, as a tin can mainly consist of steel. Another contributing life cycle stage to MFRRD was the fishing gear, due to the consumption of minerals including lead.

Figure 3 further indicates that generally the differences in environmental impact were mainly related to the sea transport and processing, including the tin for the cans. Chicken of the Sea canned tuna consistently had a higher environmental impact due to a longer overseas transport and, even more important, due to the frozen transport step of frozen loins from Thailand to the American cannery (corresponding to 80% of the total overseas transport time). The fact that the transport mode (refrigerated or frozen) matters more is visible when comparing the transport distances between Chicken of the Sea and Santa Rita, with the latter being only less than 4000 km shorter yet the bright blue being much less visible in Fig. 3. For Chicken of the Sea, the freezing contributed for 38–50% to the environmental impact of sea transport, for most impact categories. For MFRRD and IRHH, freezing contributed even for 75% and 74% to the environmental impact of sea transport, respectively.

As mentioned above, minor differences in the environmental impact of sea transport were observed due to differences in distance sailed. In addition, although different ship sizes were used between transshipments, this did not cause large differences in the environmental impact of sea transport for different supply chains. For all supply chains, most of the sea transport was by relatively large ships. The ship size is measured by its DWT, and mostly a ship with a different size was used between transshipments. For all supply chains, the largest part of the overseas transport (72–85%) was by a relatively large container ship, of 120,000 DWT. While for the other transshipments a relatively small ship was used, of 10,000 or 15,000 DWT.

Some adjustments to the original Agribalyse process did not result in major differences between the supply chains. First, secondary packaging was modelled in detail by adding cardboard boxes, pallets, the plastic film around the boxes on the pallet, and transport of the packaging, and these did not contribute much to any of the environmental impacts. Second, there was no difference in the contribution of truck transport because the distance covered was similar for the different supply chains. Third, although the electricity during processing was adjusted, there was no difference in the environmental impact of processing between canned tuna from Peru or Thailand. The use of heat during processing often contributed more to the environmental impact of this life cycle stage than electricity, and this was not adjusted.

3.3 Environmental impact of different accompanying liquids

Due to the small differences in environmental impact between the different supply chains, as described above, an average supply chain was constructed to compare canned tuna with different accompanying liquids and in different can sizes. For both scenarios, one-third was assumed to be Chicken of the Sea, one-third Sa-Pac, and one-third Santa Rita canned tuna. For the small cans, the following six accompanying liquids were modelled: sunflower oil, soybean oil, olive oil, tomato sauce, vegetable oil, and brine. Results are shown in Fig. 4.

Environmental impact of tuna canned in small cans in tomato sauce, in different oils, and in brine. Environmental impact of tuna canned in large cans in vegetable oil. The black and gray life cycle stages are related to fishing. The red and yellow life cycle stages are related to processing. The blue life cycle stages are related to distribution

For most accompanying liquids, there was only a small difference in environmental impact, as the life cycle stages that contributed most had an identical value: diesel combustion during fishing, and the tin can. However, in some impact categories, there were larger differences. First, tuna canned in soybean oil had the highest impact for CC, due to land use change in soybean cultivation. The soybean oil process which was used, “Soybean oil, at plant/FR U,” was a mix of 60.3% Argentina, 20.4% USA, and 19.2% Brazil. Land use change took place in Argentina and Brazil due to the transformation of primary forest into arable land (Nemecek et al. 2016). Second, tuna canned in tomato sauce had the highest impact in the category IRHH. This was due to electricity consumption for cooking of the tomatoes, produced by nuclear power plants in France. Canned tuna in tomato sauce imported into Aruba may have a lower IRHH impact because Peru and Thailand do not rely on energy from nuclear power plants, but mainly on oil and gas; Peru’s energy is also for a large part produced by hydropower (bp 2022). Yet, there is no information on where the tomato sauce was produced and hence the original process remained unchanged. Third, tuna canned in sunflower oil and olive oil had the highest impact for AC and EUTT, due to the farming process and not due to pressing of the sunflowers and olives.

3.4 Environmental impact of different can sizes

A comparison was made between small (142 g) and large (1.88 kg) canned tuna in vegetable oil (see Fig. 4). Large cans always have a lower environmental impact than small cans. This difference between small and large cans is larger in impact categories where the impact from “diesel combustion” is overall less dominating, namely CC, IRHH, PM, and MFRRD. For large cans, more vegetable oil and less tin are required, per kilogram edible tuna, resulting in an overall lower environmental impact. Avadí et al. (2014) also found that an increase in the amount of edible product per amount of packaging reduces the impact of canned products, per kilogram product. One of their results showed that the ReCiPe single score of canned anchoveta was 12% lower for a two times larger can size.

Avadí et al. (2015) performed an LCA on three different processed tuna products from Ecuador. The products that were assessed were canned tuna, pouched tuna, and vacuum-bagged tuna loins. The latter is a semi-finished product which is exported to canneries abroad. Overall, the main contributors to the products’ environmental impact were the fuel use on the fishing vessels and the consumption of packaging material (tin cans in particular). Compared to the other two processed products, the canned tuna product showed the highest impact for all the impact categories assessed in this research (climate change, marine eutrophication, particulate matter formation, metal depletion, cumulative energy demand, marine ecotoxicity, and photochemical oxidant formation).

4 Conclusions

The objective of this research was to assess and compare the environmental impact and environmental hotspots of different types of canned tuna imported into Aruba. Moreover, the goal was to provide extensive details on the used methods.

Although the observed differences in environmental impact were quite small for most environmental impact indicators, some trends were observed. First, canned tuna from the Chicken of the Sea supply chain always had the highest environmental impact especially due to a long and for a large part frozen sea transport from Thailand to the USA. Preference should be given to local canning activities, close to the landing port. Second, for most accompanying liquids, there was only a small difference in environmental impact, as the life cycle stages that contributed most had an identical value: diesel combustion during fishing, and the tin can. Whether it is better to choose for brine in comparison with other accompanying liquids would necessitate an analysis including the subsequent steps, for example, tuna canned in tomato sauce may be part of a meal as such, while tuna canned in brine may be prepared, after opening the can, with another warm or cold sauce, which would lead to additional separate impacts for these sauces. Third, tuna canned in larger cans always had a lower environmental impact compared to tuna canned in smaller cans.

Although the 16 ILCD impact categories were included in this LCA, certain fishery-specific biologic impacts were not assessed since this was outside the scope of this study. These impacts include for example the potential decrease in stock sizes of target and non-target species and the impact of discharged fishing gear on sea life.

References

Asselin-Balençon A, Broekema R, Teulon H, Gastaldi G, Houssier J, Moutia A, Rousseau, V, Wermeille A, Colomb V (2020) AGRIBALYSE v3.0: the French agricultural and food LCI database. Methodology for the food products. Ed. ADEME 2020

Avadí A, Fréon P, Quispe I (2014) Environmental assessment of Peruvian anchoveta food products: is less refined better? Int J Life Cycle Ass 19(6):1276–1293. https://doi.org/10.1007/s11367-014-0737-y

Avadí A, Bolaños C, Sandoval I, Ycaza C (2015) Life cycle assessment of Ecuadorian processed tuna. Int J Life Cycle Assess 20(10):1415–1428. https://doi.org/10.1007/s11367-015-0943-2

Avadí A, Vázquez-Rowe I (2019) Life cycle inventories of wild capture and aquaculture. Ecoinvent Assoc, Zürich, Switzerland

AXSMarine (2022) Alphaliner Top 100. https://alphaliner.axsmarine.com/PublicTop100/

Benini L, Mancini L, Sala S, Manfredi S, Schau E.M, Pant R (2014) Normalisation method and data for Environmental Footprints. EUR 26842. Luxembourg (Luxembourg): Publications Office of the European Union; 2014. JRC91531

Bohnes FA, Hauschild MZ, Schlundt J, Laurent A (2019) Life cycle assessments of aquaculture systems: a critical review of reported findings with recommendations for policy and system development. Rev Aquacult 11(4):1061–1079. https://doi.org/10.1111/raq.12280

Bohnes FA, Laurent A (2021) Environmental impacts of existing and future aquaculture production: comparison of technologies and feed options in Singapore. Aquaculture 532:736001. https://doi.org/10.1016/j.aquaculture.2020.736001

bp (2022) bp statistical review of world energy. (71st edition). https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2022-full-report.pdf

Central Bureau of Statistics Aruba (2019) Income and Expenditure Survey 2016. https://cbs.aw/wp/index.php/2019/04/04/income-expenditure-survey-2016/

Chicken of the Sea (2020) Trace your seafood, can code: 02/17/24 14B. https://chickenofthesea.com/trace/results?code=02/17/24%2014B. Accessed 15 Mar 2022

EEA (2020) 31. Acidification. Europe’s environment - the Dobris assessment. https://www.eea.europa.eu/publications/92-826-5409-5/page031new.html

EMLEG (2018) Vietnam – heavy duty vehicles. http://www.emleg.com/legislation/view/vietnam-heavy-duty-vehicles. Accessed 24 Mar 2022

European Commission (2016) Environmental Footprint Pilot Guidance document, - guidance for the implementation of the EU Product Environmental Footprint (PEF) during the Environmental Footprint (EF) pilot phase, version 5.2, February 2016

European Commission (2017) PEFCR Guidance document, - guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3, December 2017

European Commission, Joint Research Centre, & Institute for Environment and Sustainability (2010) International reference life cycle data system (ILCD) handbook - general guide for life cycle assessment - detailed guidance. https://doi.org/10.2788/38479

FAO (2020a) The State of World Fisheries and Aquaculture 2020a. Sustainability in action. Rome, Italy 244p

FAO (2020b) Global fish production from 2002 to 2019 (in million metric tons) [Graph]. In Statista. Available on: https://www.statista.com/statistics/264577/total-world-fish-production-since-2002. Accessed 13 Apr 2021

FAO (2021) GLOBEFISH Highlights 3rd issue 2021, with Jan.–Mar. 2021 Statistics – International Markets on Fisheries and Aquaculture Products. Quarterly update. Globefish Highlights No. 3–2021. Rome. https://doi.org/10.4060/cb7153en

Farmery A, Gardner C, Green BS, Jennings S (2014) Managing fisheries for environmental performance: the effects of marine resource decision-making on the footprint of seafood. J Clean Prod 64:368–376. https://doi.org/10.1016/j.jclepro.2013.10.016

Fazio S, Castellani V, Sala S, Schau EM, Secchi M, Zampori L (2018a) Supporting information to the characterisation factors of recommended EF Life Cycle Impact Assessment methods, EUR 28888 EN, European Commission, Ispra, ISBN 978–92–79–76742–5. https://doi.org/10.2760/671368, JRC109369

Fazio S, Castellani V, Sala S, Schau E, Secchi M, Zampori L, Diaconu E (2018b) JRC Technical reports. Supporting information to the characterisation factors of recommended EF Life Cycle Impact Assessment method. New models and differences with ILCD Contents. In European Commission. https://doi.org/10.2760/671368

Frischknecht R, Braunschweig A, Hofstetter P, Suter P (2000) Human health damages due to ionising radiation in life cycle impact assessment. Environ Impact Assess Rev 20(2):159–189. https://doi.org/10.1016/S0195-9255(99)00042-6

Hospido A, Vazquez ME, Cuevas A, Feijoo G, Moreira MT (2006) Environmental assessment of canned tuna manufacture with a life-cycle perspective. Resour Conserv Recycl 47(1):56–72. https://doi.org/10.1016/j.resconrec.2005.10.003

Laurent A, Hauschild MZ (2015) Normalisation. In MZ Hauschild, MAJ Huijbregts (Eds.), Life cycle impact assessment (p. 339) Springer Science+Business Media Dordrecht

Maritime Impact (2020) Ticket to trade: increasing deadweight for improved efficiency. Maritime Impact. Retrieved from https://www.dnv.com/expert-story/maritime-impact/Ticket-to-trade-increasing-deadweight-for-improved-efficiency.html#:~:text=The-lower-density-of-water,in-summer-than-in-winter

National Marine Fisheries Service (2021) Fisheries of the United States, 2019. U.S. Department of Commerce, NOAA Current Fishery Statistics No. 2019. Available at: https://www.fisheries.noaa.gov/national/sustainable-fisheries/fisheries-united-states

Nemecek T, Schnetzer J, Reinhard J (2016) Updated and harmonised greenhouse gas emissions for crop inventories. Int J Life Cycle Ass 21(9):1361–1378. https://doi.org/10.1007/s11367-014-0712-7

Noal Farm (2018) Frozen tuna processing line in factory - tuna processing and packing [video]. Youtube. https://www.youtube.com/watch?v=C_7QNaAivMQ. Accessed 25 Mar 2022

O’Neill FG, Ivanović A (2016) The physical impact of towed demersal fishing gears on soft sediments. ICES J Mar Sci 73:i5–i14. https://doi.org/10.1093/icesjms/fsv125

Parker RWR, Tyedmers PH (2014) Fuel consumption of global fishing fleets: current understanding and knowledge gaps. Fish Fish 16:684–696. https://doi.org/10.1111/faf.12087

Pauly D, Ramdeen S, Ulman A (2015) Reconstruction of total marine catches for Aruba, southern Caribbean, 1950–2010. Working Paper #2015 - 10. Fisheries Centre, University of British Columbia

Pelletier NL, Ayer NW, Tyedmers PH, Kruse SA, Flysjo A, Robillard G, Ziegler F, Scholz AJ, Sonesson U (2007) Impact categories for life cycle assessment research of seafood production systems: review and prospectus. Int J Life Cycle Ass 12(6):414–421. https://doi.org/10.1065/lca2006.09.275

Rosenbaum RK, Hauschild MZ, BoulayA-M, Fantke P, Laurent A, Núñez M, Vieira M (2018) Life cycle impact assessment. In M. Z. Hauschild, R. K. Rosenbaum, S. I. Olsen (Eds.), Life cycle assessment, theory and practice (First edit, p. 1197) Springer International

Siddiqui O, Dincer I (2021) A comparative life cycle assessment of clean aviation fuels. Energy 234:121126. https://doi.org/10.1016/j.energy.2021.121126

Sun W, Shao M, Granier C, Liu Y, Ye CS, Zheng JY (2018) Long-term trends of anthropogenic SO2, NOx, CO, and NMVOCs emissions in China. Earth Future 6(8):1112–1133. https://doi.org/10.1029/2018EF000822

TransportPolicy.net (2018a) Thailand: Heavy-duty: Emissions. https://www.transportpolicy.net/standard/thailand-heavy-duty-emissions/. Accessed 24 Mar 2022

TransportPolicy.net (2018b) Peru: Heavy-duty: Emissions. https://www.transportpolicy.net/standard/peru-heavy-duty-emissions/. Accessed 24 Mar 2022

TransportPolicy.net (2018c) US: Heavy-duty: Emissions. https://www.transportpolicy.net/standard/us-heavy-duty-emissions/. Accessed 9 Apr 2022

Vázquez-Rowe I, Hospido A, Moreira MT, Feijoo G (2012) Best practices in life cycle assessment implementation in fisheries. Improving and broadening environmental assessment for seafood production systems. Trends Food Sci Technol 28(2): 116–131. https://doi.org/10.1016/j.tifs.2012.07.003

Velders, G. J. M., Wesseling, J., Geilenkirchen, G. P., & Ligterink, N. E. (2013). The Euro emission standards for cars and trucks in relation to NO2 limit value exceedances in the Netherlands. National Institute for Public Health and the Environment. https://www.rivm.nl/bibliotheek/rapporten/680363001.html

Ziegler F, Hornborg S, Green BS, Eigaard OR, Farmery AK, Hammar L, Hartmann K, Molander S, Parker RWR, Skontorp Hognes E, Vázquez-Rowe I, Smith ADM (2016) Expanding the concept of sustainable seafood using life cycle assessment. Fish Fis 17(4):1073–1093. https://doi.org/10.1111/faf.12159

Acknowledgements

The authors would like to thank the SISSTEM team at the University of Aruba, KU Leuven, and the European Union (FED/2019/406-549). We acknowledge the wholesalers in Aruba, supermarkets in Aruba, fish outlet in Aruba, and a hotel in Aruba, for their support, knowledge, data, and seafood packaging materials provided. We acknowledge students Brittney Koolman and Mizaira Vrolijk from the Faculty of Arts and Science from the University of Aruba for data collection on canned tuna in supermarkets.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

Communicated by Sergiy Smetana.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Alice De Vlieghere and Amber Saïda van Veghel shared first authorship.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

De Vlieghere, A., van Veghel, A.S. & Geeraerd, A. Life cycle assessment of importing canned tuna into Aruba through different supply chains, in varying can sizes and in oils, brine or tomato sauce. Int J Life Cycle Assess 28, 1577–1589 (2023). https://doi.org/10.1007/s11367-023-02207-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02207-4