Abstract

Purpose

Cheese is one of the world’s most widely consumed dairy products and its popularity is ever growing. However, as concerns for the environmental impact of industries increase, products like cheese, which have a significant environmental impact, may lose their popularity. A commonly used technique to assess the environmental impact of a product is life cycle assessment (LCA). In this paper, a state-of-the-art review of LCA studies on the environmental impact of cheese production is presented.

Methods

Sixteen LCA studies, which explored the impact from the production of a variety of cheese types (fresh, mature and semi-hard) were examined and discussed. The four stages of the LCA were examined and the range of results of selected environmental impact categories (global warming potential, acidification potential and eutrophication potential) were detailed and discussed.

Results and discussion

For each of these environmental impact categories, raw milk production was consistently found to be the most significant contributor to the total impact, which was followed by processing. It was found that allocation between cheese and its by-products was crucial in determining the impact of cheese production and standardisation or guidelines may be needed. Very little information relating to wastewater treatment system and processes were reported and this leads to inaccurate environmental impact modelling relating to these aspects of the manufacture of cheese. Very few studies included the design of packaging in terms of reducing food waste, which may significantly contribute to the overall environmental impact.

Conclusions

As raw milk production was found to have the greatest contribution to environmental impact, mitigation strategies at farm-level, particularly in relation to enteric fermentation and manure management, need to be implemented. Additionally, based on the literature, there is a suggestion that fresh cheese has less of an environmental impact than semi-hard cheeses, particularly when examining direct energy consumption. However, there needs to be more case studies investigated to justify this statement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The European Union (EU) is the largest producer of cheese in the world with 9.5 million tonnes in 2015, followed by the USA with 5.4 million tonnes (Eurostat 2017). A breakdown of the main cheese producers in the EU is shown in Fig. 1. In April 2015, the milk quota system in the EU was abolished, which instigated an increase in milk production as well as production of dairy products. Cheese is the main dairy product in Europe, utilising 36% of milk produced in 2015 (Eurostat 2017). In 2016, total cheese production from 28 member countries in Europe increased by 1.8% compared with 2015, which was in turn an increase of 1.6% on 2014 (CLAL 2017). This is likely to continue given the continuous increase of milk production and the projected global demand for dairy products in developing countries (FAO 2016), which may be sourced from EU countries. In the meantime, however, it is important to understand the environmental effect of the growing cheese production industry so as to make sure that the growth does not cause deterioration of the environment.

Summary of cheese production in the EU during 2014, 2015 and 2016, in ‘000 tonnes. (data obtained from CLAL (2017))

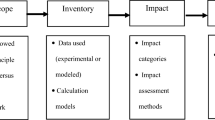

Life cycle assessment (LCA) is a holistic analysis technique that is used to assess the environmental impact of products or services (ISO 2006a). LCA was first used in the 1960s (Hunt and Franklin 1996), but developed quickly since the 1990s after standardisation (i.e. the International Standards Organization (ISO) 14000 series (ISO 2006a, b)). The four LCA phases standardised by ISO are as follows:

-

Goal and scope definition

-

Life cycle inventory (LCI) analysis

-

Life cycle impact assessment (LCIA)

-

Interpretation of results

The first LCA studies relating to dairy products were compiled in the early 2000s on cheese (Berlin 2002) and fluid milk production (Eide 2002; Hospido et al. 2003). To date, various LCA case studies have been performed on cheese production. For example, González-García et al. (2013a) analysed the environmental impact of the traditional Galician cheese in Spain using plant specific data. Sheane et al. (2011) analysed the greenhouse gas emissions of the Scottish dairy supply chain using regional data and Aguirre-Villegas et al. (2012) investigated the methodological issue of allocation in LCA of cheese and whey production in Wisconsin. Milani et al. (2011) reviewed the environmental impact of dairy processing and products. Though, their review mainly reported the details from LCA studies relating to raw milk production. Additionally, other reviews of LCA studies relating to the dairy sector primarily focuses on raw milk production on farms (e.g. Baldini et al. (2017), Crosson et al. (2011), Fantin et al. (2012) and Yan et al. (2011)).

In this paper, a state-of-the-art review of LCA-based studies relating to the manufacture of cheese was performed. The main objective of the review was to establish the current knowledge gaps and weaknesses and the potential for future work in this area. The LCI was assessed based on data quality and the LCIA results for global warming potential (GWP), acidification potential (AP) and eutrophication potential (EP) have been summarised and discussed.

2 Methods

In order to complete this state-of-the-art review, 16 published LCA studies have been selected. These studies explored the impacts from the production of a variety of cheese types, including fresh, mature and semi-hard cheeses in the USA, Canada and a number of EU countries. A summary of these reviewed studies is presented in Table 1. In order to discuss the main findings from the review in a structured manner, the Results section is broken down into the four phases for LCA. Recently, the FIL-IDF released a LCA methodology (FIL-IDF 2015) for analysing the carbon footprint of the dairy sector, which provides a standardised method for performing these types of LCAs.

3 Results

3.1 Goal and scope

3.1.1 Functional unit

The functional unit (FU) advised by FIL-IDF (2015) is 1 kg of product, with x% fat and y% protein depending on the product, packaged at the dairy factory. Of the 16 studies reviewed, 14 studies used 1 kg of packaged cheese product as the FU (Table 1). The others used slightly different mass units (grams and tonnes). Only five studies specified the characteristics of cheese including dry solids, fat and protein content (Aguirre-Villegas et al. 2012; Kim et al. 2013; Palmieri et al. 2017; van Middelaar et al. 2011; Vergé et al. 2013). Given the large variety of cheese products and characteristics (for example, protein content can vary from 15 to 25%), it is necessary to include specifications (e.g. moisture content, fat and protein content) into the description of FU.

3.1.2 System boundaries

A schematic of the various stages in the life cycle of cheese production, along with two commonly used boundaries, is shown in Fig. 2. Packaging is given a separate life cycle stage, even though it takes place within the processing factory, as some studies have omitted packaging of the final product. Also, it is important to note that dairy processing includes the dairy wastewater treatment system. The letters A to H are used to indicate the different life cycle stages that make up the system boundaries of the 16 studies listed in Table 1. The most commonly used system boundary (8 out of 16 studies) is the cradle-to-processing factory gate, which includes feed production, raw milk production, raw milk transportation, dairy processing and packaging, and is illustrated in Fig. 2 (A–E). However, five of the studies reviewed include life cycle stages downstream of the processing factory gate. The contribution of each life cycle stage to the total impact is discussed further in Section 3.3.

Boundaries and stages of the life cycle of dairy products. The letters A to H indicate the stages for different system boundaries used in Table 1. Two system boundaries, cradle-to-grave (indicated by the stages enclosed by a solid black line) and cradle-to-processing factory gate (indicated by the stages enclosed by a dashed grey line), have been included

3.1.3 Allocation between products

As recommended by ISO 14044 (ISO 2006b), input and emissions associated with a specific product should be allocated to that product as much as possible by sub dividing the system. However, this is very difficult in the case of cheese production, where substantial unit processes are shared between cheese and the by-products, liquid whey and whey cream (Fig. 3).

Common and unique processes needed in the multifunctional system for the production of cheese, dry whey and whey cream. (boxes representing common processes are shaded; adapted from Aguirre-Villegas et al. (2012))

ISO 14044 (ISO 2006b) recommended that if sub dividing the system is not possible, the next option in the hierarchy should be system expansion, which means to include the avoided production of liquid whey and associated whey cream from other systems. Since liquid whey is only produced from either cheese or casein production (both as by-products), and the two types of whey have different characteristics and, therefore, cannot substitute each other, system expansion is not appropriate in this case. The next option is to allocate in such a way that reflects the underlying physical relationships between co-products. FIL-IDF (2015) advised that this should be carried out on a dry solids basis (mass allocation using dry weight). When input and emissions statistics are only known on a whole factory basis, FIL-IDF (2010) had, previously, advised the use of a physico-chemical allocation matrix, which has been developed by Feitz et al. (2007) specifically for the dairy industry. However, in the updated FIL-IDF report (2015), engineering estimates for allocation of resources and emissions and, where necessary, energy allocation on a dry solids basis is advised. Therefore, according to the FIL-IDF, this is the most appropriate allocation method to employ where the required information is not available.

Depending on the processing technology on site, the liquid whey may be directly discharged to effluent treatment plant (González-García et al. 2013a), land spread as waste (the SSINGLE-O scenario in Aguirre-Villegas et al. 2012), or processed into whey powder (Kim et al. 2013) and whey cream (Aguirre-Villegas et al. (2012)). The resulting allocation factor to cheese varied from 50 to 100% of on-site impacts (Table 2). In addition, cheese production can also take place in multi-product dairy processing where other products such as butter and yoghurt are produced (Flysjö et al. 2014) and further allocation in overheads is needed. It was, therefore, not surprising that Aguirre-Villegas et al. (2012) found that the allocation method has a significant effect on the results, where the global warming potential associated with processing cheese varied from 0.46 to 1.3 kg CO2 eq./kg, and energy intensity varied from 7.1 to 19.5 MJ/kg.

3.2 Life cycle inventory

FIL-IDF (2015) outlined all significant process steps taken in the manufacturing of a dairy product and the emissions that should be included in the LCI. The document (FIL-IDF 2015) outlines the nesessary process, inputs and emissions that should be included in each system boundary for both the raw milk production and processing.

The LCI is usually compiled from data obtained from industry. Of the 16 studies reviewed, 7 used data from one dairy processing plant and 4 studies used data from seven or more dairy processing plants. The remainder obtained data from either a dairy company with production sites across several countries, or industry level data from a region or from previously published literature. The main elements of the LCI are detailed in the following sub-sections, which include raw milk production and transportation, energy usage, water consumption, wastewater treatment, packaging of products and chemical consumption.

3.2.1 Raw milk production and transportation

The volume of raw milk required for the production of cheese was included in 12 studies and ranges from 1.5 to 11 L of raw milk per kilogram of cheese produced. However, the majority of these studies reported volumes of raw milk between 5.7 and 10.1 L per kilogram cheese, which is evident from Table 3. The volume of raw milk required to produce cheese is mainly dependant on the allocation method used, which is discussed in Section 3.1.3, and the type of cheese and, to a lesser degree of significance, the efficiency of usage of raw milk within the processing plant. For example, cheddar cheese, which has approximately 64% milk solids (Feitz et al. 2007), requires more raw milk than mozzarella cheese, which has approximately 51% milk solids (Kim et al. 2013).

Raw milk transportation varies widely as it is dependent on the distance of the dairy farms (raw milk suppliers) from the dairy processing factories, which is evident from the five studies reviewed that specify the average raw milk transportation distances that ranges from 65 to 200 km (Table 3). However, Ulrich et al. (2013) found that the average round trip distance was 850 km from analysing approximately 30,000 milk collection routes in the USA.

To reduce the transportation costs of raw milk to dairy processing, it has been suggested that concentration and separation of raw milk can be performed on the farm (Garcia and Medina 1988). A recent study (Colombi 2016) also investigated the real-time milk classification technology for optimised milk use and cheese production. More research is needed to quantify potential benefits of these activities from the life cycle point of view.

3.2.2 Energy consumption

Large variations in energy consumption of cheese production have been reported. For example, fresh cheese (mozzarella) was found to consume less energy than semi-hard cheeses, and most of the on-site energy was in the form of thermal energy with notable exceptions from one study (Fig. 4). This was also highly dependent on the allocation procedure used, as suggested by Aguirre-Villegas et al. (2012). During the multifunctional cheese production where cheddar cheese, dry whey and whey cream are produced, the largest energy consumption was found to be milk pasteurisation (30%), followed by whey evaporation (17%) and whey drying (16%), while the actual cheese-making process (cheese-making vats and cheddaring) only consumed 2.5% (refer to Table 5 of Aguirre-Villegas et al. (2012)). Using the data reported in Aguirre-Villegas et al. (2012), Briam et al. (2015) derived energy intensities for cheese and whey and compared a number of allocation methods.

The energy consumption for cheese production at the dairy processing factory is given in Table 2. For the majority of cases, the LCIA method employed was cumulative energy demand (CED), and cheese processing tends to be the most significant contributor to the overall energy consumption (i.e. between 43 and 89%). However, from the data presented in Table 2, energy consumption associated with packaging and storage may also be significant. For example, these studies estimated packaging to be between 12 and 24% of the total energy consumption, while the study of van Middelaar et al. (2011) estimated storage as 32% of the total energy consumption. Aguirre-Villegas et al. (2012) reported that energy intensity (EI) varied from 7.1 to 19.5 MJ per kilogram cheese, depending on the allocation method employed.

Previously, the International Dairy Federation (FIL-IDF) produced a report relating to energy usage in the dairy industry (FIL-IDF 2005) and estimated that the largest energy use for cheese production was in feed production (52%) followed by retail/consumer (16%), milk processing (12%), dairy farm (11%), distribution (8%) and raw milk transportation (1%). Ramírez et al. (2006) presented a breakdown of direct energy consumption during cheese, fluid milk, butter and milk powder production in Dutch dairies in the year 2000 and Finnegan et al. (2017b) reported direct electrical and thermal energy consumption based on a survey of dairy processing plants in the Republic of Ireland.

3.2.3 Water consumption

The dairy sector is one of the largest consumers of water globally and it takes approximately 5000 L of water to produce 1 kg of cheese (Mekonnen and Hoekstra 2012). Within the dairy processing factories, the main reason for this is large volumes required for cleaning and washing up to keep the facility to the required food production standards. Water is obtained from a number of sources including groundwater, surface water (rivers and lakes), public supply and recycled water. Rad and Lewis (2014) reviewed water utilisation, energy utilisation and wastewater management in the dairy industry and presented a summary of water consumption, which ranged from 0.48 to 58 L of water per kilogram milk processed based on data from 11 studies worldwide. This range is greater than the range 1.2–33.6 L water per kilogram product that is reported in the nine LCA studies for the manufacture of cheese products (Table 4). In most instances, these values are measured data for water consumption from processing plants, which has been allocated to the cheese product under study. Table 4 provides benchmark values for water consumption. In 2006, the European Commission published a reference document, as part of the Integrated Pollution Prevention and Control (IPPC) Directive, for best available techniques in the food, drink and milk industries (EC 2006). Within the document, a range for water consumption within European dairies is given as 1–60 L water per kilogram milk processed for cheese and whey production and within Nordic dairies as 1.2–3.8 L water per litre milk processed for cheese and whey production. No explanation is given in EC (2006) for the significant difference in the reported values for European dairies and Nordic dairies. The published water consumption (Table 4) is within the range of the European dairies, but higher than the Nordic dairies (EC 2006). The report is currently being revised with updated consumption rates and details for strategies to reduce water consumption within dairy factories.

3.2.4 Wastewater treatment

Large volumes of wastewater are generated at dairy processing factories worldwide. This is mainly as a result of cleaning and disinfection processes within the factory. In order to comply with environmental regulations, mainly large-scale dairy processing factories have an on-site wastewater treatment plant. From the summary presented in Rad and Lewis (2014), the volume of wastewater generated from cheese produced ranges from 0.6 to 50 L of wastewater per litre of milk processed. EC (2006) reported that 0.7–60 L of dairy wastewater are generated for every kilogram of milk processed in Europe, which is aligned with Rad and Lewis (2014). Data from the reviewed studies that reported volumes for wastewater generated are given in Table 4. If these values are converted to “per L of milk processed”, the reported values are well within the ranges above. In one of the studies (Palmieri et al. 2017), where data on wastewater treatment was not available, data from the Ecoinvent database (Weidema et al. 2013) referring to the wastewater treatment plant for whey disposal was used. In many of the LCA studies reviewed, very little information relating to the types of wastewater treatment system and processes was provided. This information is vital as, not only the volume, but also the composition of dairy wastewater is highly variable. For example, for cheese production, the chemical oxygen demand (COD) has been reported in one study as < 3000 mg/L, while it is given as 365,000 mg/L in another (Rad and Lewis 2014). Therefore, it would be more accurate to use site-specific data when estimating the impacts from the wastewater treatment system.

3.2.5 Packaging, chemicals and cleaning-in-place

Packaging can have a significant effect on the environmental impact of the dairy processing plant. However, this is dependent on the type and quantity of packaging used and disposal scenarios. Meneses et al. (2012) investigated the effect of packaging selection and its disposal on the LCA of fluid milk for global warming potential and acidification potential and found that larger aseptic carton packages always have lower environmental impact than smaller ones for the same amount of liquid, and recycling has a lower environmental impact than disposal in landfills or incineration plants, for all materials and sizes compared. Limited data has been reported on the packaging used for cheese production and very few studies included the waste management of consumer packaging (Table 5). Flysjö et al. (2014) found that packaging contribution to the carbon footprint of cheese was minimum when the system boundary was set from farm to wholesale or retailer. When studying the carbon footprint of butter with the system boundary from farm to consumer including waste management, Flysjö (2012) pointed out that size and type of packaging were less important than the ingredients (fat and veg oil), but it is crucial to have the correct size and type of packaging to avoid product losses at the consumer. It is likely that packaging on its own (production, transportation, waste management) may not be a significant contributor to the environmental impact of cheese products, but the design of packaging in terms of reducing food waste may be more important.

Limited data has been reported on the chemicals used for cheese production (Table 6). Sodium hydroxide and nitric acid was the most commonly reported chemicals, but the concentration is not always reported, resulting in apparently large variations in the literature.

The effect of cleaning-in-place (CIP) on dairy production has been found to be important. Eide (2002) compared four CIP methods for dairies using LCA and found that milk residues flushed out in the rinsing phase were the main contributors to eutrophication, but the phosphorus and nitrogen in the detergents also influenced the results. No study has been conducted on CIP contribution to cheese production. It may be necessary to conduct such studies given the large variety of cheese products and associated processing pathways.

3.3 Life cycle impact assessment

All 16 studies (Table 1) evaluated the GWP associated with cheese production, while 9 of them explored the EP, 8 investigated the AP and 5 investigated CED. The results from these analyses will be compared at each stage of the product’s life cycle.

3.3.1 Global warming potential

A summary of the reported values of GWP associated with the production of cheese products is presented in Table 7 and summarised graphically in Fig. 5, where a comparison for studies that evaluate semi-hard cheese is presented in Fig. 5a and fresh and soft cheese in Fig. 5b. GWP has been calculated using the IPCC guidelines. However, as these guidelines are revised regularly, the same GWP factors were not used in all cases but, in most cases, the most update version was used. For example, González-García et al. (2013a) and Finnegan et al. (2017a) use the 2001 and 2007 IPPC GWP guidelines, respectively. In the 2007 IPPC GWP guidelines, the GWP factors for 100-year time horizon are given as 25 for methane (CH4) and 298 for nitrous oxide (N2O). However, in the most recent IPCC report (Stocker et al. 2013), the 2013 IPCC GWP factors for 100-year time horizon are given as 28 for CH4 and 265 for N2O.

Summary of reported values and average values of global warming potential (GWP), which are derived from the data detailed in Table 7, for a semi-hard cheese and b soft cheese (SC) and fresh cheese (FC)

It is evident from Fig. 5 that, for the 12 studies that include the impact from raw milk production, the most significant contributor to the total GWP (from cradle-to-processing factory gate) is raw milk production, which accounts for approximately 79–95% for all but one study (fresh cheese in Doublet et al. (2013)). The reason for this is Doublet et al. (2013) reported 1.53 L of raw milk per kilogram of fresh cheese, which is much less than that of Kim et al. (2013) of approximately 3.17 L per kilogram fresh cheese (Table 3). The second largest contributor to the total GWP is processing of raw milk into cheese, which accounts for approximately 2–18% for all but one study (fresh cheese in Doublet et al. (2013)). The input/emission that drives the GWP in the processing life cycle stage is energy usage within the processing factory. The accurate modelling and allocation of energy usage is vital in order to accurately estimate the GWP in this life cycle stage. For semi-hard cheese, the study with the highest GWP is González-García et al. (2013b) where no allocation is used, as detailed in Table 2. Again, for semi-hard cheese, the study with the highest total is Santos et al. (2017) and this total is driven by GWP associated with raw milk, which accounts for 83% of the total. Therefore, when examining the GWP associated with the production of cheese, it is essential to include both the impact from raw milk production and processing. It is also important to note that downstream life cycle stages may also have a significant contribution to the GWP, which can be seen in the cradle-to-grave study by Kim et al. (2013). The studies in Fig. 5 are ordered from semi-hard to fresh cheeses. However, since there is only one study examining soft cheese, two studies examining fresh cheese and the remainder examining semi-hard cheese, there is not enough information to accurately say if the type of cheese affects GWP.

3.3.2 Acidification potential

A summary of the reported values of AP of cheese products is presented in Table 8, which are also shown graphically in Fig. 6. All studies were found to use kilogram SO2 eq. to characterise AP using standardised characteristic factors, where factors from either the ReCiPe Midpoint method (used by Santos et al. (2017)) or the CML method (used by Berlin (2002), González-García et al. (2013a) and González-García et al. (2013b)) were employed rather than regional specific AP characteristic factors. However, it is important to understand that AP varies significantly across regions and using standardised characteristic factors may be misleading (Seppälä et al. 2006). Similar to GWP, the most significant contributor to the total AP (from cradle-to-processing factory gate) is raw milk production, which accounts for approximately 88–99% (Fig. 6). Therefore, the variation in AP is driven by the amount of raw milk used but, also, the amount of ammonia (NH3) emissions from manure storage on dairy farms, which was reported as 79% of AP associated with raw milk production by González-García et al. (2013a). In two studies (González-García et al. 2013a, b), the impact from processing was also significant at approximately 10 and 12% of total AP (from cradle-to-processing factory gate), respectively. However, for these two studies, the impact associated with transportation and packaging is included within processing and may be the reason it is significant. The six studies, which are detailed in Table 8, found that the contribution to the overall impact from packaging and any life cycle stages downstream of dairy processing is insignificant. Furthermore, none of the studies explored the impact of AP from raw milk transportation from the farms to the processing factories, as this is assumed to be negligible. It is important to note that all of the studies reported in Table 8 and Fig. 6 examine the production of semi-hard cheeses as AP was not included in any of the studies examining other types of cheese (e.g. fresh cheese).

Summary of reported values and overall average value of acidification potential (AP) from the data detailed in Table 8

3.3.3 Eutrophication potential

A summary of the reported values of EP of cheese products is presented in Table 9. A number of different FUs were used when measuring EP, which were dependent on the type of EP being investigated. These included freshwater eutrophication (kg P eq.), marine eutrophication (kg N eq.) and terrestrial eutrophication (kg PO4 3− eq., kg O2 eq.). Again, standardised characteristic EP factors rather than regional specific EP characteristic factors were used, which may lead to inaccuracies in the results (Seppälä et al. 2006). Similar to GWP and AP, raw milk production is the most significant contributor to the total EP (from cradle-to-processing factory gate), which accounted for approximately 59–99%. Similar to the previous section, NH3 emissions from manure storage on the dairy farm and, also, feed production are the main contributors to EP and are a source of variation between studies. Processing was, again, the second highest contributor to the total EP (from cradle-to-processing factory gate) as it accounted for approximately 1–39%. The main source of variation between studies relates the volume of wastewater generated (Table 4) and the treatment strategy employed. However, this was very dependent on the type of EP being explored and the assumptions within the study. For example, in the study performed by Kim et al. (2013) of mozzarella cheese production in the USA, processing accounts for 19% of the total when examining freshwater EP and 39% of the total when examining marine EP. Yet, it is important to note that the combined impact from raw milk production and processing accounts for more than 99% of the total EP (from cradle-to-processing factory gate) in all of the studies reviewed (Table 9). Therefore, when estimating the EP associated with the production of cheese products, it is essential to include both the impact from raw milk production and processing. González-García et al. (2013a) found that the impact of treating dairy wastewater at a nearby municipal wastewater treatment plant on the overall EP is 9%, where Galician cheese (semi-hard cheese) is the main product. This illustrates that EP is highly dependent on the wastewater treatment strategies being employed, and the emissions to water regulation limits, if they are in place. However, these details tend to be omitted from the LCA reports.

4 Discussion

Based on the studies reviewed, there are a number of weaknesses, or limitations, in the way that LCA studies on the production of cheese are conducted, which include the following:

-

In a number of the studies detailed in Table 1, there is a lack of detailed information and data when presenting the LCI and LCIA data. This lack of detailed information and data makes it difficult to replicate the results of these LCA studies. Therefore, when performing LCA of cheese products, presenting increased information, relating to background processes and a breakdown in resource consumption, would improve the repeatability of studies and the comparability within each life cycle stage.

-

When examining dairy processing factories, the accuracy in the modelling of resource consumption and its breakdown between processes needs to be improved. This should include the development of accurate specific inventories for processes, which are generated from measured data or existing verified models. If there is greater detail at process level, more meaningful strategies for lowering environmental impact associated with each life cycle stage, based on LCA, can be derived.

-

The allocation method used, which is discussed in Section 3.1.3, has a major effect on the results of the LCA, which has been reported in a number of publications relating to cheese manufacture (Aguirre-Villegas et al. 2012; Briam et al. 2015; Flysjö et al. 2014). Allocation methods may be improved with more accurate modelling of resource consumption and standardised allocation methods should be established. An example is water consumption at the dairy processing factory. Detailed modelling of water consumption and CIP systems at the factory would give a greater insight into the volume of water used within processes and what dairy product this water should be allocated to. Additionally, this modelling could help inform the allocation of other streams, mainly cleaning chemical usage and wastewater generation, as these could be assumed to be proportional to water consumption.

-

Another factor that affects the environmental performance of an industry is the cost and availability of materials and inputs. For example, if electricity is relatively inexpensive then factories will use technologies that rely on electricity rather than other energy sources. This may be cost effective, but could have a negative impact on the environment unless it is obtained from renewable energy sources. On the other hand, if an input, such as water, is scarce, then measures will be in place to conserve water, regardless of the extra associated costs.

Additionally, there are gaps in the knowledge and potential for future work, which would improve the quality of LCA studies on the production of cheese, including the following:

-

A critical gap in the research is the accurate estimation of the impact associated with the treatment of dairy wastewater. The method used to treat the wastewater (e.g. anaerobic digestion, activated sludge, sequencing batch reactor or a combination of these), the environmental policies and regulations which govern the emissions to water from the factories and the disposal of bio-solids generated during the treatment of wastewater are all factors that will affect the environmental impact of the system, but are often omitted from the published literature.

The analysis of the life cycle stages downstream of the processing factory gate is often omitted. Possible reasons for this may include limited availability of reliable data for these life cycle stages or, when they have been assessed, were found to be insignificant when compared to raw milk production and processing (see Figs. 5 and 6). However, more research into these stages is required in order to accurately determine their impact. For example, in the case of packaging, it is likely that the design of packaging in terms of reducing food waste may be important.

5 Conclusions

A review of 16 LCA studies, which explored the impact from the production of a variety of cheese types, including fresh, mature and semi-hard cheeses in the USA, Canada and a number of EU countries, has been presented. The results presented summaries of the LCI and LCIA of the existing literature and will serve as a benchmark for future LCA studies. Additionally, a discussion on the existing weaknesses and gaps in the knowledge, along with recommendations for potential future research topics, has been presented.

For each of these environmental impact categories, raw milk production was consistently found to be the most significant contributor to the total impact, which was followed by processing. Therefore, in order to reduce the overall environmental impact of cheese production, mitigation strategies within raw milk production at farm-level, particularly in relation to enteric fermentation and manure management, need to be implemented. Additionally, the allocation method used, which is discussed in Section 3.1.3, has a major effect on the results of the LCA and this has been reported in a number of publications relating to cheese manufacture (Aguirre-Villegas et al. 2012; Briam et al. 2015; Flysjö et al. 2014). Based on the literature, there is a suggestion that fresh cheese has less of an environmental impact than semi-hard cheeses, particularly when examining direct energy consumption. However, since only two studies examined fresh cheese, there needs to be more case studies investigated to justify this statement. Of the publications reviewed in this paper, Kim et al. (2013), which examined the impact of cheddar and mozzarella cheese production in the USA from cradle-to-grave, was the most comprehensive and future studies will need to be a similar scale and thoroughness in order to accurately estimate the true environmental impact of cheese production.

References

Aguirre-Villegas HA, Milani FX, Kraatz S, Reinemann DJ (2012) Life cycle impact assessment and allocation methods development for cheese and whey processing. Trans ASABE 55:15. 10.13031/2013.41363

Baldini C, Gardoni D, Guarino M (2017) A critical review of the recent evolution of life cycle assessment applied to milk production. J Clean Prod 140(Part 2):421–435

Berlin J (2002) Environmental life cycle assessment (LCA) of Swedish semi-hard cheese. Int Dairy J 12:939–953

Briam R, Walker ME, Masanet E (2015) A comparison of product-based energy intensity metrics for cheese and whey processing. J Food Eng 151:25–33

Broekema R, Kramer G (2014) LCA of Dutch semi-skimmed milk and semi-mature cheese. Blonk Consultants, Netherlands

CLAL (2017) Cheese Production, European Union. CLAL. http://www.clal.it/en/?section=produzioni_cheese. Accessed 11 Apr 2017

Colombi G (2016) More cheese from less milk: eco-innovative real-time milk classification technology for optimized milk use (MilkyWay). http://www.milkyway.bio/

Crosson P, Shalloo L, O'Brien D, Lanigan GJ, Foley PA, Boland TM, Kenny DA (2011) A review of whole farm systems models of greenhouse gas emissions from beef and dairy cattle production systems. Anim Feed Sci Technol 166-167:29–45

Djekic I, Miocinovic J, Tomasevic I, Smigic N, Tomic N (2014) Environmental life-cycle assessment of various dairy products. J Clean Prod 68:64–72

Doublet G, Jungbluth N, Stucki M, Schori S (2013) Life cycle assessment of Romanian beef and dairy products. SENSE, ESU-services, Schaffhausen

EC (2006) Reference document on best available techniques in the food. Drink and Milk Industries. European Commission, Brussels

Eide M (2002) Life cycle assessment (LCA) of industrial milk production. Int J Life Cycle Assess 7:115–126

Eurostat (2017) Milk and milk product statistics. European Commission. http://ec.europa.eu/eurostat/statistics-explained/index.php/Milk_and_milk_product_statistics. Accessed 24 Feb 2017

Fantin V, Buttol P, Pergreffi R, Masoni P (2012) Life cycle assessment of Italian high quality milk production. A comparison with an EPD study. J Clean Prod 28:150–159

FAO (2016) OECD-FAO agricultural outlook 2016–2025. OECD Publishing, Paris

Feitz AJ, Lundie S, Dennien G, Morain M, Jones M (2007) Generation of an industry-specific physico-chemical allocation matrix. Int J Life Cycle Assess 12:109–117

FIL-IDF (2005) Energy use in dairy processing vol 401. International Dairy Federation, Brussels

FIL-IDF (2010) A common carbon footprint approach for dairy, a guide to standard life cycle assessment methodology for the dairy sector, vol 445. International Dairy Federation, Brussels

FIL-IDF (2015) A common carbon footprint approach for the dairy sector. The IDF guide to standard life cycle assessment methodology, vol 479. International Dairy Federation, Brussels

Finnegan W, Goggins J, Clifford E, Zhan X (2017a) Global warming potential associated with dairy products in the Republic of Ireland. J Clean Prod 163:262–273

Finnegan W, Goggins J, Clifford E, Zhan X (2017b) Environmental impacts of milk powder and butter manufactured in the Republic of Ireland. Sci Total Environ 579:159–168

Flysjö A (2012) Greenhouse gas emissions in milk and dairy product chains. PhD thesis, Aarhus University

Flysjö A, Thrane M, Hermansen JE (2014) Method to assess the carbon footprint at product level in the dairy industry. Int Dairy J 34:86–92

Garcia A, Medina B (1988) On-farm membrane concentration of milk. Trans Am Soc Agric Eng 31:274

González-García S, Castanheira EG, Dias AC, Arroja L (2013a) Environmental performance of a Portuguese mature cheese-making dairy mill. J Clean Prod 41:65–73

González-García S, Hospido A, Moreira MT, Feijoo G, Arroja L (2013b) Environmental life cycle assessment of a Galician cheese: San Simon da Costa. J Clean Prod 52:253–262

Hospido A, Moreira MT, Feijoo G (2003) Simplified life cycle assessment of Galician milk production. Int Dairy J 13:783–796

Hunt RG, Franklin WE (1996) LCA—how it came about. Int J Life Cycle Assess 1:4–7

ISO (2006a) ISO 14040: Environmental management—life cycle assessment—principles and framework. International Organization for Standardization, Geneva

ISO (2006b) ISO 14044: Environmental management—life cycle assessment—requirements and guidelines. International Organization for Standardization, Geneva

Kim D, Thoma G, Nutter D, Milani F, Ulrich R, Norris G (2013) Life cycle assessment of cheese and whey production in the USA. Int J Life Cycle Assess 18:1019–1035

Mekonnen MM, Hoekstra AY (2012) A global assessment of the water footprint of farm animal products. Ecosystems 15:401–415

Meneses M, Pasqualino J, Castells F (2012) Environmental assessment of the milk life cycle: the effect of packaging selection and the variability of milk production data. J Environ Manag 107:76–83

van Middelaar CE, Berentsen PBM, Dolman MA, de Boer IJM (2011) Eco-efficiency in the production chain of Dutch semi-hard cheese. Livest Sci 139:91–99

Milani FX, Nutter D, Thoma G (2011) Invited review: environmental impacts of dairy processing and products: a review. J Dairy Sci 94:4243–4254

Palmieri N, Forleo MB, Salimei E (2017) Environmental impacts of a dairy cheese chain including whey feeding: an Italian case study. J Clean Prod 140(Part 2):881–889

Rad SJ, Lewis MJ (2014) Water utilisation, energy utilisation and waste water management in the dairy industry: a review. Int J Dairy Tech 67:1–20

Ramírez CA, Patel M, Blok K (2006) From fluid milk to milk powder: energy use and energy efficiency in the European dairy industry. Energy 31:1984–2004

Santos HCM, Maranduba HL, de Almeida Neto JA, Rodrigues LB (2017) Life cycle assessment of cheese production process in a small-sized dairy industry in Brazil. Environ Sci Pollut Res 24(4):3460–3482

Seppälä J, Posch M, Johansson M, Hettelingh J-P (2006) Country-dependent characterisation factors for acidification and terrestrial eutrophication based on accumulated exceedance as an impact category indicator. Int J Life Cycle Assess 11:403–416

Sheane R, Lewis K, Hall P, Holmes-Ling P, Kerr A, Stewart K, Webb D (2011) Identifying opportunities to reduce the carbon footprint associated with the Scottish dairy supply chain—main report. Scottish Government, Edinburgh

Stocker TF, Qin D, Plattner G-K, Tignor M, Allen SK, Boschung J, Nauels A, Xia Y, Bex V, Midgley PM (2013) Climate change 2013: the physical science basis. Intergovernmental Panel on Climate Change, Working Group I Contribution to the IPCC Fifth Assessment Report (AR5). Cambridge Univ Press, New York

Ulrich R, Thoma G, Nutter D, Wilson J (2013) Tailpipe greenhouse gas emissions from tank trucks transporting raw milk from farms to processing plants. Int Dairy J 31(Supplement 1):S50–S56

Vergé XPC, Maxime D, Dyer JA, Desjardins RL, Arcand Y, Vanderzaag A (2013) Carbon footprint of Canadian dairy products: calculations and issues. J Dairy Sci 96:6091–6104

Weidema BP, Bauer C, Hischier R, Mutel C, Nemecek T, Reinhard J, Vadenbo CO, Wernet G (2013) Overview and methodology. Data quality guideline for the ecoinvent database version 3. Ecoinvent Report 1(v3). St. Gallen: The ecoinvent Centre, Zurich. http://lca-net.com/p/234. Accessed 6 Nov 2017

Yan M-J, Humphreys J, Holden NM (2011) An evaluation of life cycle assessment of European milk production. J Environ Manag 92:372–379

Funding

The first and last authors would like to acknowledge funding provided by the Department of Agriculture, Food and the Marine for the DairyWater project (Ref.: 13-F-507); for additional details: www.dairywater.ie. The second and third authors would also like to acknowledge funding from Enterprise Ireland (Grant No. TC 2014 0016). The last author would like to acknowledge the support of Science Foundation Ireland through the Career Development Award programme (Grant No. 13/CDA/2200).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Greg Thoma

Rights and permissions

About this article

Cite this article

Finnegan, W., Yan, M., Holden, N.M. et al. A review of environmental life cycle assessment studies examining cheese production. Int J Life Cycle Assess 23, 1773–1787 (2018). https://doi.org/10.1007/s11367-017-1407-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1407-7