Abstract

Background, aim, and scope

Carbon footprint (CF) has become a hot topic as public awareness of climate change is placing demands on manufacturers to declare the climate impact of their products. Calculating the CF of food products is complex and associated with unavoidable uncertainty due to the inherent variability of natural processes. This study quantifies the uncertainty of a common food product and discusses the results in relation to different types of CF systems for food product labelling.

Materials and methods

A detailed LCI with global warming potential as the only impact category was performed on King Edward table potatoes grown in the Östergötland region of Sweden. Parameters were described using one probability distribution for spatial and temporal variation and one separate distribution describing measuring/data uncertainty, allowing the effect of parameter resolution on CF uncertainty to be studied. Monte Carlo simulation was used to quantify the overall uncertainty. The influence of individual parameters on the CF was analysed and differences in CF for food products from different production systems, with and without climate impact reduction rules, were simulated.

Results

The potato CF fell in the range 0.10–0.16 kg CO2e per kilogram of potatoes with 95% certainty for an arbitrary year and field. Emissions of N2O from soil dominated the CF uncertainty. Locking the temporal variation to a specific year lowered the uncertainty range by 19%. Parameter collection on a spatial scale of one field did not reduce the uncertainty. The most sensitive parameters were the yield, the soil humus content and the emissions factors for N2O emissions from soil. Potatoes grown according to climate rules lowered the CF by 9% with a probability of 53% for an arbitrary year and field.

Discussion

The importance of yield, which proved to be the most influential parameter, is a common characteristic of agricultural products in general, since the accumulated emissions from a cultivated area are divided across the yield from that area. Maximising the yield reduces the CF but could have negative impacts on other environmental aspects. The purpose of the CF labelling scheme, together with uncertainty analysis, needs to be considered when determining how the CF should be calculated, as an average or for a specific year, farm, field, region, etc.

Conclusions

The CF of a potato crop calculated for an arbitrary year and field varied between approximately -17% and +30% of the average value with 95% certainty, showing that uncertainty analysis in the design, calculation and evaluation of food product CF labelling schemes is important to ensure fair comparisons.

Recommendations and perspectives

Similar studies comparing different production systems for the same type of product and products from different categories, on large and small scale depending on the purpose of the CF system, are needed in order to determine how the CF of food products can be compared and the precision with which data have to be collected in order to allow fair and effective comparison of the CF of food products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

Consumption of food products contributes approximately 25% of the total greenhouse gas (GHG) emissions caused by the average Swede (SEPA 2008a). With growing public awareness about climate change, there is an increasing willingness on the part of individuals to lower their GHG emissions due to food consumption (Toivonen 2007; L.E.K. 2008; SEPA 2008b). Determining the climate impact caused by a food product is very difficult for consumers as aspects such as product type, production system, packaging, origin, transport, etc. need to be weighed together (Jungbluth et al. 2000).

Carbon footprint (CF) and carbon declaration are terms that have evolved to describe the amount of GHG emissions that a particular product or service will cause during its lifetime, typically expressed in CO2 equivalents (CO2e) and including emissions of CO2, CH4, and N2O. A CF can be seen as a subset of a life cycle assessment (LCA) in which only the global warming potential impact category is studied (SETAC 2008; Weidema et al. 2008; Finkbeiner 2009). In order to facilitate active choices by individuals, the CF can be communicated to consumers in different ways: through a carbon or climate label on the product package or at the point of sale, in marketing or via a website. Although calculating and, in particular, communicating the CF is difficult and the potential of such systems is being questioned, several climate labelling systems are being discussed and some are already in limited use (Berry et al. 2008; Olofdotter and Juul 2008; Schmidt 2009).

The British supermarket Tesco became a forerunner in the area of food product CF by introducing a carbon label with the CF of some of its food products back in 2007 (Olofdotter and Juul 2008). In an attempt to provide a consistent method for calculating the CF of products and services, the British Standards Institute developed the PAS 2050 Specification for assessment of the life cycle GHG of goods and services (BSI 2008). It builds on the existing LCA methods standardised in ISO 14040 and ISO 14044 (ISO 2006a, b) and adds further principles specific to GHG assessment. In Sweden, KRAV and Seal Quality Systems LtdFootnote 1 are jointly driving the Climate Labelling for Food (CLfF) project (CLfF 2009). The CLfF project has approached the task from a slightly different angle, and instead of calculating a numerical CF the system builds on a set of rules that the producer has to obey in order to be allowed to label the products. LCA methodology, together with expert opinion, is used when developing the climate rules. During autumn 2008, ISO also initiated the development of an international standard on CF for products (ISO 14067), which will build on the existing ISO standards for LCA.

It remains to be seen how the systems for food CF will be designed, how the standards will be applied, and whether it is possible to develop a CF system that will have a significant impact on consumption patterns. However, based on the immense momentum for CF data, it is likely that CF values will be used by companies for strengthening their corporate brand and for product differentiation (Carbon Trust 2008). As this CF will be connected to economic values, the focus on accuracy, precision, and reliability in the numbers presented will be sharpened.

Determining the CF of a food product is complex for several reasons. One of the challenges is the variability in natural processes. Variability is an inherent property of a system and, unlike uncertainty, it cannot be reduced by more accurate modelling of the system or collection of the data. While some variations arise from differences in cultivation practices, others are less easily explained—one example being the difference in yield from similar fields. In addition to variations in the natural crop cultivation processes, there are variations in the subsequent processing and distribution processes. In addition to the spatial and temporal variation in natural processes, different types of uncertainty in models and data contribute to the uncertainty of the overall LCA result, as has been described by Björklund (2002) and Heijungs and Huijbregts (2004) among others. Uncertainty due to choices and mistakes and epistemological uncertainties and model uncertainties can be decreased to some extent by the use of standards and by critical review (Huijbregts 1998; Björklund 2002). Minimising inaccuracy in data requires careful data collection, which is often costly and time consuming and in some cases not even practically possible.

Uncertainty and sensitivity analysis can be used to determine the contribution to the end result uncertainty from uncertainties in the input data and model parameters (Heijungs and Huijbregts 2004). The results from such studies can be of help when determining whether a CF system provides an acceptable level of precision. Uncertainty analysis also identifies focal points for improving the models and contributes to greater understanding of the processes behind the CF. The results of an uncertainty analysis also help to determine the probability of a predicted reduction potential.

Uncertainty assessments of LCA data can be performed in different ways: by using empirical data to calculate the uncertainty distribution, by using expert judgement to make qualified estimates, or by describing the data using quality indicators (Weidema and Wesnaes 1996). In the ecoinvent database, all data are described using seven quality indicators, one being the reliability indicator which describes whether the data are based on verified or unverified measurements and on qualified or unqualified assumptions. The seven indicators are put together to form one numerical uncertainty measurement (Frischknecht et al. 2004).

The main aim of the present study was to quantify the uncertainty in the CF of a common food product resulting from natural variations and model and parameter uncertainty, in accordance with how data collection could be performed in a ‘real-life’ CF labelling system. A secondary aim was to investigate the particular parameters (including their temporal and spatial resolution) and processes influencing the uncertainty in the end result. Table potatoes were chosen as the study object since they are one of the most common staple food products on the Swedish market. They are a product that is sold with little refinement and that is easily traced from the farm to the supermarket shelf. This makes a potato case study suitable for illustrating how uncertainty analysis of food products can be carried out and relevant for a general discussion of uncertainties in the CF of agricultural products.

Understanding the natural variation and uncertainties associated with food production and how they affect the CF is important. Most essentially, product comparison, the ultimate goal of CF analysis aimed at influencing consumer behavior, can only be carried out with confidence if the range of uncertainty is known. As an example of CF comparison for products from different production systems, this study includes a quantification of the probability that an arbitrary bag of table potatoes available for purchase in a supermarket and produced according to CLfF rules has led to a reduction in GHG emissions during production compared with a bag produced without specific climate actions being taken.

2 Materials and methods

2.1 System boundaries, functional unit, and allocations

The study comprised a detailed investigation of the parameter variability and uncertainty in the CF of 1 kg of table potatoes available for purchase in a 2-kg ‘kraft’ paper bag at a Swedish supermarket. Since it is common Swedish practice for the information presented to the user on the potato packaging to include the potato variety and the producer, these parameters were fixed. The common variety King Edward was chosen and production was assumed to occur on a fictitious but specific farm in Östergötland, a region of Sweden that produces 10% of Swedish annual production of table potatoes (SCB 2008).

The CF constitutes a ‘cradle to retail’ inventory including emissions arising from soil preparation up until the potatoes are available for purchase on the shelf, including the production and transport of all inputs and the waste handling of any potatoes rejected before packaging and transport to the supermarket. Although often omitted from LCA studies, emissions from the production, maintenance, and waste handling of agricultural machinery and buildings were included here since capital goods have been shown to contribute considerably (approximately 10%) to the climate impact of agricultural products (Frischknecht et al. 2007).

Potatoes are grown in a 4- to 6-year crop rotation, so the field used for potato cultivation and hence the clay and humus content and the distance between field and farm were assumed to vary between years. Cultivation on sandy soil with moderate humus content dominates and mineral fertilisers were assumed to be used. Seed potatoes were assumed to be bought and reproduced on the farm once before being used in potato production and the harvested potatoes stored on the farm in a cold storage facility and delivered by tractor and trailer to the packaging plant. After washing, sorting, and packaging, the majority of the potatoes were assumed to be distributed for sale to Stockholm, the largest city in Sweden (Röös 2009).

All GHG emissions were allocated to the marketable potatoes uniformly, disregarding the fact that potatoes are sold at different prices for different qualities. All potatoes not marketable as table potatoes were assumed to be spread on the field according to common practice. During reproduction of seed potatoes, fractions with suitable sizes were assumed to be used as seed and the rest sold as table potatoes minus the unmarketable fraction, which was removed. An equal burden was allocated to the seed potatoes and the fraction sold as table potatoes.

2.2 Data collection

The parameter data in this study were collected in accordance with how data would realistically be collected from the existing Swedish potato production chain for use in a CF system, without the introduction of extended accounting regulations or measuring equipment. This gives an estimate of the precision of the table potato CF if introduced into the current Swedish production system and calculated using existing and practically applicable models. The reference year was 2007 but the data are approximately applicable for several preceding and subsequent years. For a detailed description of how the distributions for all parameters were estimated, see Röös (2009).

The parameters were split into two types: (1) activity data and (2) emission factors. Activity data (AD) were directly measurable parameters describing, for example, the amounts of inputs spent, such as the amount of fuels, fertilisers, and chemicals, and descriptive parameters such as the soil humus content and the transport distance. The emission factors (EF) included: (1) EF for emissions caused by the production and transport of inputs (EF-inputs) and (2) EF for soil emissions (EF-soil) and EF for transport of potatoes (EF-transport). AD, except for capital goods, were collected as primary data, while secondary data were used to calculate the EF. This corresponds to how data would realistically be collected in a practical CF calculation. AD such as yield, fertiliser use, tillage operations performed, energy spent, etc. are already being recorded on farms, as this is required in legislation and from certification programmes (LRF 2009; Seal Quality Systems Ltd. 2009a, b; SMAK 2009) to which the majority of the producers in Östergötland belong. As long as the inputs themselves are not climate-labelled, it is realistic to assume that EF values need to be collected from the available literature.

The variations and uncertainties were assessed separately using probability distributions for all parameters individually. The distributions for variation outline the variability between years and fields for AD and between different ways of production for EF-inputs. The uncertainty distributions for AD describe the precision that can realistically be assumed when collecting the data from the potato production chain. Due to the large uncertainties in the models for calculating the soil emissions, it was not possible to divide the uncertainties in EF-soil into variations and uncertainties and hence both variations and uncertainties are grouped under uncertainties for these. Variations in EF-transport take into consideration the size of trailer used and the degree of loading.

The AD for table potato production are summarised in Table 1. In order to estimate the uncertainty as accurate as possible for the specific situation of potato cultivation in Östergötland, the AD were collected directly from cultivation advisors, producers, and the packaging plant, while some data were collected from the detailed Swedish table potato LCA conducted by Mattsson et al. (2001), except for capital goods data, which were taken from ecoinvent (Nemecek and Kägi 2007). The AD describe fictitious but realistic production of King Edward potatoes in the Östergötland region.

The EF for inputs are summarised in Table 2. Sales statistics, in combination with information from fertiliser manufacturers regarding the N2O reduction equipment being used in production plants in 2007, were used to determine the distribution of the GHG emissions caused by the production of fertilisers used on the Swedish market. Manufacturing plants equipped with N2O reduction equipment were assumed to emit 4 kg CO2e/kg N according to BAT 2007 (EC 2007), while plants without such were assumed to emit 6.8 kg CO2e/kg N, corresponding to the European average (Jenssen and Kongshaug 2003). The probability distribution for seed potato production was calculated by performing a Monte Carlo simulation (Rubinstein and Kroese 2007) with the AD values adjusted for seed production (20% reduction in yield, 80% of the amounts of N fertiliser, one anti-viral treatment, no transport or packaging). Samples or an average from that simulation was used as input for the rest of the calculations. The Nordic countries, except Iceland, are connected on a common electricity market (Nordel 2005) so the Nordic electricity mix was used to calculate the emissions from electricity consumption. The variation was assumed to be normally distributed and the mean value and the standard deviation calculated from the yearly averages for the years 2005–2008 (Swedenergy 2009). The contribution from production and transport of fuel and chemicals is minor and hence the variation was assumed to be negligible and only uncertainty was included. EF for packaging material (‘kraft’ paper) and capital goods was taken from the ecoinvent database v2.0 (ecoinvent Centre 2007). Distributions for transport-related emissions were estimated using data from NTM Calc (2009) and are summarised in Table 3. As is often the case, the literature data used to determine the EF-inputs did not include any uncertainty assessment. Therefore, the methodology based on quality indicators, also used in the ecoinvent database, was used to assess the uncertainty (Weidema and Wesnaes 1996; Frischknecht et al. 2004).

Direct and indirect N2O emissions from soils were calculated using the IPCC methodology (IPCC 2006). For the EF for N2O emissions, the factors employed by the Swedish Environmental Protection Agency (SEPA) in the national inventory were used (SEPA 2009) except for the EF for leaching, for which the EF from IPCC (2006) was used. The EFs used by SEPA are based on the EF provided by IPCC, with some modifications (Kasimir-Klemedtsson 2001). For the EF unaltered by SEPA, the uncertainty range (lognormal distribution) provided by IPCC was used, while for the adjusted values a new uncertainty range was estimated by assuming a corresponding lognormal uncertainty and using the uncertainty range provided in Kasimir-Klemedtsson (2001) The CO2 emissions or sequestration due to changes in the soil carbon pool was calculated using the ICBM model (Andrén et al. 2004). The governing parameters in the ICBM model, the humification factor (h) and a factor summarising the effect of temperature, water content, and tillage intensity (r e), were assumed to vary normally (Olof Andrén, professor of Soil Biology/Agriculture, Dept. of Soil & Environment, SLU, Uppsala, Sweden—personal communication).

On the spatial scale chosen, cultivation on a specific farm, it is realistic to assume that most parameters are independent, for example, soil clay and humus content and yield. On the national level, however, or if the potato variety had not been specified, independency in the AD would not have been a realistic assumption since yields vary considerably between potato varieties and different geographical locations in Sweden (SCB 2008). Examples of parameters that are correlated are the fuel consumption during tillage operations and the soil clay content, as heavier soils require more fuel, and the amount of machinery used depending on the type of field operations performed. These correlations are included in the study. For a detailed description of the parameters that were assumed to be correlated and independent, see Röös (2009).

2.3 Analytical methods

The potato CF was calculated as a deterministic mean using the mean values of all parameters and as a range of values between the 2.5 and 97.5 percentiles using Monte Carlo simulation for a base scenario that represented an arbitrary year between 2005 and 2009 and production in an arbitrary field on a farm in the Östergötland region (scenario a1). The MC simulation was repeated for an additional seven scenarios (Table 5) with 50,000 iterations each.

Scenarios a2, b1, and b2 were added in order to study how temporal and spatial resolution in data collection affected the uncertainty in the CF. In scenarios c1, d1, c2, and d2, the climate rules from the Swedish CLfF project were applied. The rules require fertilisers to have a maximum emission factor of 4 kg CO2e/kg N and electricity to be obtained from sustainable sources (CLfF 2009). Scenarios a1–d1 represent the CF for an arbitrary year between 2005 and 2009. Scenarios a2–d2 represent the results for a specific year during the same period, with the variations for all AD except the transport AD set to zero, since the yield, amount of fertilisers, etc. are known for that year with a precision described by the uncertainty distribution (Table 1). For scenarios b1, b2, d1, and d2, collection of data was assumed to be bound to a specific field in order to study how variations between fields affected the end result.

In order to assess the contribution to the uncertainty from the different processes involved in the potato production chain, the relative uncertainty from an individual process was calculated by dividing the range between the 2.5 and 97.5 percentiles for that process by the total mean CF value. The uncertainty contribution from individual parameters was examined using a traditional sensitivity analysis of a ± 20% change in the parameter values. This was compared with an uncertainty importance analysis on an individual parameter basis using a change of ± 2 standard deviations for normal and log-normally distributed parameters and highest and lowest value for discretely distributed parameters, including both variation and uncertainty.

Table potatoes grown according to the CLfF rules were compared against the base scenario in order to calculate the probability that the CF for CLfF-grown potatoes from an arbitrary year and an arbitrary field was lower than that from the base scenario. By calculating the differences between individual samples from the CLfF MC simulation (scenario c1) and the base scenario MC simulation (scenario a1), a probability distribution of the difference between arbitrary bags of potatoes from the two production systems was obtained. This distribution was used to determine the probability that the CF of a bag of potatoes cultivated according to the CLfF system caused lower emissions (in grams) at different levels than those from the base scenario.

Data and model parameter uncertainty was included in this study. Uncertainty on a higher conceptual level such as uncertainty due to choices, epistemological uncertainty, uncertainty due to mistakes, or uncertainty introduced by estimating the uncertainty (Björklund 2002) was not included.

3 Results

3.1 Mean value and contributing processes

Using the mean values for all parameters to calculate the CF from producing 1 kg of potatoes in a 2-kg paper bag resulted in a value of 0.12 kg CO2e. The processes that contributed most to the result are shown individually in Fig. 1. The error bars show the uncertainty as a 2.5–97.5 percentile range in each individual process due to variations and uncertainty in the input parameters. Soil emissions showed a relative uncertainty contribution of 27% and 15% of the total CF for N2O and CO2 emissions, respectively. The production of fertilisers, the packaging process, and the distribution of the potatoes to the supermarket contributed to the uncertainty by similar magnitudes (13%, 11%, and 14%), while the remaining processes showed a relative uncertainty that was 6% or less. Applying the CLfF rules lowered the deterministic mean by 9%, to 0.11 kg CO2e per kilogram of potatoes.

3.2 Sensitivity and uncertainty importance analysis

The parameters that affected the CF by 5% or more at one of the boundaries are shown in Table 4. The sensitivity analysis showed that the most sensitive parameters were potato yield and quality and the amount of N fertiliser used. The uncertainty importance analysis revealed that the soil humus content, the fuel spent during tillage operations, the amount of electricity spent during the packaging process, the distribution distance, and two of the EF for soil emissions were also important for the end result. The results clearly show how a traditional sensitivity analysis can fail to recognise the sensitivity in the parameters with large variability, especially if these are not normally or uniformly distributed. Examples of such in this study included the log-normally distributed EF for N2O emissions and the energy spent during packaging.

3.3 Uncertainty analysis

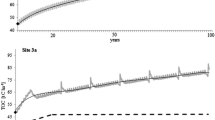

The outcome of the MC simulation of the base scenario (a1) in which variations and uncertainties for all parameters were included was that 95% of the results fell within a range of 0.10–0.16 kg CO2e per kilogram of table potatoes (Fig. 2).

The Monte Carlo simulation results for all scenarios are summarised in Table 5. The 95% uncertainty range for the CF decreased by 19% for a specific year when variations between years in AD such as yield, fertiliser amounts, and energy spent (scenario a1 compared with a2) were not included. The uncertainty range was only very slightly affected by calculating the CF for a specific field for which only uncertainty in AD was included and not variations in clay and humus content and the distance between the field and the farm. The CLfF rules reduced boundaries and marginally reduced the uncertainty range.

3.4 Comparison between scenarios

The distribution of the differences between individual samples from the base scenario a1 and scenario c1 simulations showed that, with a probability of 72%, the CF of potatoes produced according to the CLfF rules (c1) was lower for an arbitrary year and field. The probability that the CF was 9% lower (the deterministic average reduction) was 53% (Table 6).

4 Discussion

Yield proved to be the most influential parameter. This is a common characteristic of agricultural products in general since the accumulated emissions from a cultivated area are divided across the yield from that area. Hence, maximising yields reduces the CF. Carbon labelling systems with a numerical representation of the CF include this relationship but need to consider the resolution at which yield data (and other data) are collected and how to account for the variations between different years. How this is done depends on the purpose of the CF labelling system. If the aim is to stimulate individual producers to reduce emissions, data have to be collected for each producer individually. The most accurate CF result would be obtained from collecting the data on a per-year, per-field, and per-variety basis (scenario b2) and calculating a CF for a specific year. However, such a procedure would hardly be understandable or fair since the crop yield, and as a consequence the CF, from the same farm and under equal cropping systems could vary substantially due to varying weather conditions, pesticide attacks, etc. A correctly designed CF system should not punish a producer for uncontrollable factors but should promote high yield due to good farming practice, which would lead to higher average yields. Therefore, the use of yield data as a temporal average is more reasonable and would take into consideration the influence of yield on the CF but would not punish a certain product and/or producer in a certain year of misfortunate and uncontrollable conditions. Omitting to take this into consideration when designing a CF system could lead to other products that cause higher overall emissions being favored during a specific year, leading to an undesired effect of the CF labelling system. A system in which the CF for a specific product from the same producer, using the same production technology, varies considerably between years would also be very confusing for the consumer.

Providing consumer guidance that maximises the reduction in overall GHG emissions from food consumption is another potential goal for a CF system. In such a case, the system needs to allow comparisons between different types of products and a CF for potatoes on a regional or national level could be justified. Building on the work initiated in this study, the uncertainty in such a CF for potatoes and other comparable products could be calculated and used in order to determine whether it is possible to have one CF value for all Swedish potatoes with the necessary precision to allow comparison with similar products. However, further methodological complexities are then introduced. Studies are needed on whether a fair comparison is possible without including the use phase in the CF, i.e., the energy requirement for home storage and preparation. The issue of what products can be considered comparable is another area in need of research. Comparable products need to be interchangeable from a functional point of view and must have similar nutrient content, which may require a functional unit based on energy or protein content or similar instead of mass (Schau and Fet 2008).

Focusing on maximising yield could have serious impacts on other environmental aspects. Crop protection chemicals have little influence on the CF, while excluding pesticides would reduce yield substantially for several crops, giving a great negative influence on the CF. This is especially true for potatoes, a crop that is heavily sprayed with fungicides in particular. Quantifying how different CF systems would affect eco-toxicity, biodiversity, soil quality, and other factors is an area for further investigation.

The amount of N fertiliser is an important parameter since it determines the processes with the largest and the second largest contribution to the CF; the emissions of N2O from soil and the production of mineral fertilisers. However, the importance of N fertiliser amount might be overestimated since N2O emissions depend on several other parameters (Kasimir-Klemedtsson 2001) that are not accounted for in the method used to calculate the N2O emissions. The outcome from the N2O method only varies with the amount of N applied, giving this parameter too great importance on a per-year basis. However, in the long run, the amount of N applied is an important parameter since it contributes to accumulation of N in the soil that will affect N2O emissions in years to come.

The soil processes involved in the cultivation of agricultural products are often non-linear and difficult to predict and estimate due to their dependency on environmental and climatological factors with large variability in time and space. The large-scale methods for calculating soil emissions used in this study give rise to large uncertainties. More accurate estimates of the soil emissions would be possible using more advanced models, but in a CF system the models need to be practically applicable for CF calculation. For example, by using detailed data such as daily mean air temperature, precipitation, and several soil properties, the ICBM model can be used to more precisely calculate the emissions or sequestration of CO2 from soils (Andrén et al. 2004). Measurements of soil properties required by the model, which are associated with considerable variability on a temporal and spatial level, are not realistic during normal crop production today. Future research will have to evaluate whether it is possible to develop methods for assessing soil emissions that take into account controllable factors such as soil type, tillage methods and intensity, crop species, etc. and climate conditions in order to compare products from different product categories as well as products cultivated in different geographical locations and under different cultivation systems.

Calculating the CF using data from a specific field did not decrease the uncertainty in the CF in this study. However, since the soil humus content is a parameter that can have a considerable impact on GHG emissions (Table 4), this could justify calculation of the CF on a per-field basis. Potato cultivation on soils with low humus content could be favored in practice. This would be especially relevant for regions rich in high-humus soils.

The comparison between the CF for production with and without CLfF rules for an arbitrary year and field showed that only approximately half of the climate-labelled bags of potatoes led to an emissions reduction of 9% (the deterministic mean reduction) compared with the unlabelled bags. This clearly illustrates the large uncertainty associated with food product CF calculations due to natural variations and uncertainties in models. Obvious reduction measures that do not alter the cultivation system and risk influencing the yield, etc., such as the use of low-emissions fertilisers and electricity as suggested by the CLfF project, should of course be promoted in any case. However, when introducing numerical CF labelling schemes or more complex rule-based systems for comparisons between products, uncertainty analysis cannot be neglected.

The results were compared with the process of potato production in the ecoinvent database (ecoinvent Centre 2007). The mean value in ecoinvent was 0.13 kg CO2e per kilogram of table potatoes. Although the ecoinvent process did not include the packaging process, the paper bag, or the distribution, the result was still higher than the result from this study. The higher value is explained by the lower yield (37.7 ton/ha) used in the ecoinvent process, once again showing the great importance of the yield for the resulting CF. Running a Monte Carlo simulation on the ecoinvent process gave an uncertainty range of 0.045 kg, which should be compared with the uncertainty range in the present study for a specific year (a2), 0.047, since variation in yield was not included in the simulation. Thus, good agreement was found between the two uncertainty ranges even though the underlying methodology for assessing the uncertainty information differed.

5 Conclusions

The CF of table potatoes in this study varied between approximately -17% and +30% of the average value with 95% certainty, showing that uncertainty analysis in the design, calculation, and evaluation of food product CF labelling schemes is important to ensure fair and effective comparison. The method outlined in this study, in which the uncertainties were divided into spatial and temporal variations and data/measuring uncertainty, is able to show how CF uncertainty is affected by the parameter resolution in time and space. The results from our study on potatoes showed that the reduction in uncertainty due to fixing the temporal variation (yield, fertiliser amount, energy consumption, etc.) was only 19%.

The probability of reaching different levels of differentiation in the CF from different food production systems can be calculated using Monte Carlo simulation of the two systems and pair-wise comparison. Including this type of uncertainty analysis adds valuable information about the uncertainties in CF, as illustrated in this study by the example with and without the application of CLfF rules.

6 Recommendations and perspectives

The natural question is: what is an acceptable level of uncertainty? This question is more political or philosophical than scientific in nature. Depending on the purpose of the labelling system, the uncertainty must be low enough to allow comparisons between potatoes from different producers or between potatoes and other comparable products. This study showed that, for an arbitrary year and field, potatoes that were cultivated according to CLfF rules had a lower CF with a probability of 72% and that the average reduction of 9% occurred with a probability of 53%. These numbers could, or could not, be regarded as an acceptable level of probability. Results from similar studies comparing the same product and comparable products would allow a rule of thumb to be devised for the acceptable uncertainty for different purposes.

Notes

KRAV is an incorporated association with 28 members representing farmers, producers, trade, and consumers as well as environmental and animal welfare interests. KRAV develops organic standards and promotes the KRAV label for organic products. Seal Quality Systems Ltd is a wholly owned subsidiary of the Federation of Swedish Farmers (LRF). Seal Quality Systems Ltd owns and develops rules for the Swedish Seal of Quality (Svenskt Sigill) label (conventional farming).

References

Andrén O, Kätterer T, Karlsson T (2004) ICBM regional model for estimations of dynamics of agricultural soil carbon pools. Nutr Cycl Agroecosyst 70:231–239

Berry T, Crossley D, Jewell J (2008) Check-out carbon—the role of carbon labelling in delivering a low-carbon shopping basket. Forum for the Future, London

Björklund A (2002) Survey of approaches to improve reliability in LCA. Int J LCA 7(2):64–72

BSI (2008) PAS 2050 specification for the assessment of the life cycle greenhouse gas emissions of goods and services. BSI British Standards, London

CLfF (2009) The Climate Labelling of Food Product project. www.klimatmarkningen.se (visited 20.04.2009)

Carbon Trust C (2008) Product carbon footprinting: the new business opportunity. The Carbon Trust, London

EC (2007) Reference document on best available techniques for the manufacture of large volume inorganic chemicals—ammonia, acids and fertilisers. Integrated Pollution Prevention and Control, European Commission

Ecoinvent Centre (2007) Ecoinvent data v2.0. ecoinvent reports no.1–25. Swiss Centre for Life Cycle Inventories, Dübendorf

Finkbeiner M (2009) Carbon footprinting—opportunities and threats. Int J LCA 14:91–94

Frischknecht R, Jungbluth N, Althaus H-J, Doka G, Dones R, Heck T, Hellweg S, Hischier R, Nemecek T, Rebitzer T, Spielmann M (2004) The ecoinvent database: overview and methodological framework. Int J LCA 10(1):3–9

Frischknecht R, Althaus H-J, Bauer C, Doka G, Heck T, Jungbluth N, Kellenberger D, Nemecek T (2007) The environmental relevance of capital goods in life cycle assessments of products and services. Int J LCA 13:7–17 (special issue)

Heijungs R, Huijbregts MAJ (2004) A review of approaches to treat uncertainty in LCA. Proceedings of the IEMSS conference, Osnabruck

Huijbregts MAJ (1998) Application of uncertainty and variability in LCA. Part 1: a general framework for the analysis of uncertainty and variability in life cycle assessment. Int J LCA 3(5):273–280

IPCC (2006) IPCC guidelines for national greenhouse gas inventories, volume 4. Agriculture, forestry and other land use. Intergovernmental Panel of Climate Change

ISO (2006a) ISO 14040 International Standard. In: Environmental management—life cycle assessment—principles and framework. International Organisation for Standardization, Geneva, Switzerland

ISO (2006b) ISO 14040 International Standard. In: Environmental management—life cycle assessment—requirements and guidelines. International Organisation for Standardization, Geneva, Switzerland

Jenssen TK, Kongshaug G (2003) Energy consumption and greenhouse gas emissions in fertiliser production. International Fertiliser Society Meeting, London

Jungbluth N, Tietje O, Scholz R (2000) Food purchases: impacts from the consumers’ point of view investigated with a modular LCA. Int J LCA 5:134–142

Kasimir-Klemedtsson Å (2001) Metodik för skattning av jordbrukets emissioner av lustgas (Methodology for estimating the emissions of nitrous oxide from agriculture). Report 5170. Swedish Environmental Protection Agency, Stockholm, Sweden

L.E.K (2008) The L.E.K. Consulting Carbon Footprint Report 2007. L.E.K. Consulting llp, London, UK

LRF (2009) Miljöhusesyn 2009 (Environmental inspection 2009). The Federation of Swedish Farmers, Stockholm

Mattsson B, Wallén E, Blom A, Stadig M (2001) Livscykelanalys av matpotatis (Life cycle assessment of table potatoes). Internal report. The Swedish Institute for Food and Biotechnology (SIK), Gothenburg, Sweden

Nemecek T, Kägi T (2007) Life cycle inventories of agricultural production systems. Data v2.0 (2007), ecoinvent report no. 15, ecoinvent centre. Swiss Centre for Life Cycle Inventories, Dübendorf

Nordel (2005) Development and integration of regional electricity markets. Nordel, Oslo

NTM Calc (2009) Calculation tool from The Network for Transport and Environment. <http://www.ntm.a.se> (visited 19.02.09)

Olofdotter M, Juul J (2008) Climate change and the food industry—climate labelling for food products: potential and limitations. Øresund Food Network, Copenhagen

Röös E (2009) Carbon footprint of table potatoes—uncertainties and variations. Report 017. Department of Energy and Technology, SLU, Uppsala

Rubinstein R, Kroese D (2007) Simulation and the Monte Carlo method. Wiley-Interscience, ISBN 0470177942, 9780470177945

SCB (2008) Production of cereals, dried pulses, oilseed crops, potatoes and temporary grasses in 2007, final statistics. Statistics Sweden, Stockholm

Schmidt H-J (2009) Carbon footprinting, labelling and life cycle assessment. Int J LCA special issue “Life cycle performance of aluminium applications”

Schau EM, Fet AM (2008) LCA studies of food products as background for environmental product declarations. Int J LCA 13(3):255–264

Seal Quality Systems Ltd (2009a) IP sigill basregler—standard för kvalitetssäkrad primärproduktion av livsmedel (IP seal—standard for quality assured primary production of food products). Edition 2009:1. Seal Quality System Ltd., Stockholm, Sweden

Seal Quality Systems Ltd (2009b) IP sigill frukt & grönt—standard för kvalitetssäkrad produktion av bär, frukt, potatis, frilands- och växthusgrönsaker (IP seal—standard for quality assured production of berries, fruit, potatoes and vegetables). Edition 2009:1. Seal Quality System Ltd., Stockholm, Sweden

SEPA (2008a) Konsumtionens klimatpåverkan (The climate impact of consumption), report no 5903. Swedish Environmental Protection Agency, Stockholm, Sweden

SEPA (2008b) The general public and climate change 2008, report no 5905. Swedish Environmental Protection Agency, Stockholm

SEPA (2009) The National Inventory Report 2009 Sweden. Swedish Environmental Protection Agency, Stockholm

SETAC Europe LCA Steering Committee (2008) Standardisation efforts to measure greenhouse gases and 'carbon footprinting' for products (editorial). Int J LCA 13(2):87–88

SMAK (2009) Webpage of The Swedish Tablepotato Control Agency Ltd. Älvsjö, Sweden. www.smak.se (visited 01.04.2009)

Swedenergy (2009) Vägledning angående ursprungsmärkning av el (Guidance for origin labelling of electricity). Swedenergy, Stockholm, Sweden

Toivonen A (2007) Konsumenternas syn på klimatmärkta livsmedel—en konsumentundersökning (Consumer views on carbon labelled food products—a consumer review). MAT 21, SLU, Uppsala, Sweden

Weidema B, Wesnaes MS (1996) Data quality management for life cycle inventories—an example of using data quality indicators. J Clean Prod 4(3–4):167–174

Weidema B, Thrane M, Christensen P, Schmidt J, Løkke S (2008) Carbon footprint—a catalyst for life cycle assessment. J Ind Ecol 12(1):3–6

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Matthias Finkbeiner

Rights and permissions

About this article

Cite this article

Röös, E., Sundberg, C. & Hansson, PA. Uncertainties in the carbon footprint of food products: a case study on table potatoes. Int J Life Cycle Assess 15, 478–488 (2010). https://doi.org/10.1007/s11367-010-0171-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-010-0171-8