Abstract

The efficient management and treatment of pharmaceutical industry wastewater (PIWW) have become a serious environmental issue due to its high toxicity. To overcome this problem, the present study deals with the phycoremediation of PIWW using Chlorella vulgaris microalga isolated from the Ganga River at Haridwar, India. For this, response surface methodology (RSM) and artificial neural network (ANN) tools were used to identify the best reduction of total phosphorus (TP) and total Kjeldahl’s nitrogen (TKN) based pollutants along with the lipid production efficiency of C. vulgaris. Three different concentrations of pharmaceutical wastewater (0, 50, and 100%), operating temperatures (20, 25, and 30 °C), and light intensity (2000, 3000, and 4000 lx) were used to design the phycoremediation experiments having 6:18 h of dark/light period and reactor functional volume of 15L. Findings revealed that C. vulgaris was good enough to remove maximum TP (90.35%), TKN (83.55%) along 20.88% of lipid yield at 25.62 °C temperature, 60.73% PIWW concentration, and 4000 lx of light intensity, respectively. Based on the model performance and validation results, ANN showed more accuracy as compared to the RSM tool. Therefore, the findings of this study showed that C. vulgaris is capable of treating PIWW efficiently along with significant production of lipid content which can further be used in various applications including biofuel production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, the management of industrial wastewater has become one of the prime issues of planet Earth (Jayaswal and Sahu 2018; Shrestha et al. 2017). It has been estimated that nearly 80% of global wastewater is disposed of untreated which later creates environmental pollution (Cong and Yu 2018). Parallelly with the growth of the industrial sector, the requirement for freshwater has also increased vis versa. However, modern man has to deal with various diseases driven by lifestyle and sedentary life (Aziz et al. 2019; Egger et al. 2017). To deal with these diseases, certain drugs are required, and here comes the role of the pharmaceutical industry. The pharmaceutical sector produces a variety of medicines like antibiotics, herbal medicines, sedatives, hormone-based, and pills of human and veterinary importance. To meet the increasing demands of the population, recently, the number of pharmaceutical industries has increased, drastically (Patil 2016).

In order to manufacture certain drugs, the pharmaceutical industry utilizes a wide variety of raw materials including natural, synthetic, and biological. In this, active pharmaceutical ingredients (APIs) also called bulk drugs are the key ingredients used in medicine manufacturing. APIs are water-persistent, biochemically active chemical compounds (Carvalho et al. 2018; Pudasaini et al. 2017). Besides this, water is also used in various industrial processes such as manufacturing, cleaning, and washing. The pharmaceutical industry wastewater (PIWW) has a complex composition, therefore difficult to treat. Generally, it contains high chemical oxygen demand (COD), salt content, residual drugs, and organic compounds (Shah and Shah 2020; Dong et al. 2022). Therefore, the pharmaceutical industries produce highly toxic wastewater which is hard to manage using conventional treatment technologies (Dar et al. 2017; Dixit and Parmar 2013). However, the level of pollution and volume of wastewater generated depends on the type and size of the industry. In low-wage countries, most of the industrial wastewater is discharged without adequate treatment (Cong and Yu 2018) which results in environmental pollution, disrupting the normal functioning of aquatic flora and fauna by increasing the nutrient loads of waterbodies thereby causing eutrophication. PIWW may induce mutagenic effects upon entering the food chain via different routes (Sboichakov and Reshetnikova 2020). Therefore, the proper and safe management of industrial wastewater is the need of the hour (Martínez-Pachón et al. 2021; Maity et al. 2021).

Several methods are available for the treatment of PIWW such as membrane separation and adsorption; however, these methods are cost-intensive and are likely to cause secondary contaminations (Liang et al. 2019; Xu et al. 2017). While on the other hand, phycoremediation technology involves the use of algae to remove pollutants from wastewater (Fayyad et al. 2020). Phycoremediation technology is cost-efficient, more proficient in the treatment of wastewater including the removal of anti-inflammatory drugs, antibiotics, etc. (Hom-Diaz et al. 2017) rather than the physical and chemical methods (Sharma et al. 2020; Zeng et al. 2019). Out of several algal species utilized for phycoremediation purposes, Chlorella vulgaris is a green-colored unicellular eukaryotic microalga having a thick cell wall. It is one of the widely studied members of the Chlorophyceae family. It has a fast growth rate and the capability to grow in most nutrient-stressed mediums including contaminated water bodies (Zhu et al. 2020). In order to provide resistance to stressed environments, the thick cell wall of C. vulgaris mediates certain chemical and mechanical processes for its efficient survival (Rana et al. 2017; Sydney et al. 2019). C. vulgaris is reported to have a proficient ability to remove biological oxygen demand (BOD), chemical oxygen demand (COD), and phosphorous and nitrogen-based pollutants from wastewaters within short periods (Liu et al. 2008; Azizi et al. 2020). Previously, various successful studies have been done on the bioremediation efficiency of C. vulgaris using different types of wastewater such as domestic (Miao et al. 2016), municipal (Znad et al. 2018), synthetic (Lee et al. 2020), and petrochemical and textile (Subashini and Rajiv 2018) wastewaters. Algal biomass is a rich source of lipids, proteins, pigments, and vitamins which can be utilized in various applications such as making nutrition supplements, food products, and pharmaceuticals. Along with phycoremediation application, algae are also known for their lipid production efficiency (Mao et al. 2020). Recently, algal lipids are in great demand for the production of biofuels having good fatty acid profiles (Hess et al. 2018; López et al. 2019).

The Ganga River is a sacred water body for Hindus that flows from the Himalayas to the Bay of Bengal within the Indian subcontinent. Its freshwater has a great diversity of flora and fauna including Chlorella sp. The biological diversity present in the river water helps to maintain its water quality through nutrient sequestration (Zhang et al. 2019). From the previously available literature, it is evident that C. vulgaris has the ability to grow in different types of wastewater such as municipal wastewater (Ferro et al. 2019) and slaughterhouse wastewater (Katırcıoğlu Sınmaz et al. 2023) including PIWW by utilizing the available nutrients (Santos et al. 2017; Bansal et al. 2018; Chandel et al. 2022). Therefore, C. vulgaris can be used for the phycoremediation of PIWW along with the potential application of lipid production. Apart from the wastewater type, various environmental conditions (light intensity, temperature) also affect the growth of algal species. Therefore, their optimization using different statistical tools and mathematical models is crucial in order to maximize the wastewater treatment efficiency of C. vulgaris (Liyanaarachchi et al. 2021). The current study explores the nutrient sequestration and lipid production scope of locally isolated C. vulgaris for PIWW which adds novelty to this study. Through a combination of experimental analysis, optimization techniques, and predictive modeling, this study aims to enhance the efficiency of wastewater treatment processes while simultaneously generating valuable lipid resources from microalgae. For this, response surface methodology (RSM) and artificial neural network (ANN) are statistical approaches extensively used to maximize the outputs by optimizing the operational variables (Zhang and Huang 2015; Sabour and Amiri 2017).

As aforementioned, considering the problems associated with the management of PIWW, the present study has been designed to assess the phycoremediation efficiency of isolated Chlorella vulgaris alga under different levels of wastewater loads, temperature, and light intensities. The findings are supported using two different types of optimizations and prediction modeling, i.e., response surface methodology (RSM) and artificial neural network (ANN) tools.

Materials and methods

Organism used

Being a freshwater resource, Chlorella vulgaris naturally occurs in the Ganga River which helps in nutrient sequestration and works as a feedstock for several macro-and microbenthic organisms (Beuckels et al. 2015). For the present experiment, C. vulgaris (NIES:227) microalgae were isolated from the disposal point of Jagjeetpur Sewage Treatment Plant (STP) situated near the Ganga River at Haridwar, India (29° 53′ 58.6″ N and 78° 08′ 28.9″ E). The morphological identification of C. vulgaris (NIES:227) was done by using a digital microscope (Optika, B-383PLi, IN) following Bellinger and Sigee (2015) identification keys and that of genetic identification by 28s rRNA (Fig. S4). For the sequencing, ABI PRISM® BigDyeTM Terminator Cycle Sequencing Kits with AmpliTaq® DNA polymerase (FS enzyme) (Applied Biosystems) was used and it was further purified by ABI 3730xl sequencer (Applied Biosystems) (Talavera and Castresana 2007). The screened algal culture was replicated and maintained on a sterile BG-11 medium under controlled environmental conditions. The purity validation of the BG-11 medium was done by sterilizing it at 25 °C for 3 days to ensure no microbial growth was observed. Standard laboratory sterilization protocols were followed to maintain the purity of the C. vulgaris culture on the BG-11 medium. The composition of BG-11 medium includes 40 mL solution of each of NaNO3 (150 g/L), K2HPO4 (4.0 g/L), MgSO4·7H2O (7.5 g/L), CaCl2·2H2O (3.6 g/L), citric acid (0.60 g/L), ammonium ferric citrate green (0.60 g/L), EDTA (0.1 g/L), Na2CO3 (2 g/L), and 1 mL of each micronutrients solution [2.85 g/L H3BO3, 1.81 g/L MnCl2·4H2O, 0.22 g/L ZnSO4·7H2O, 0.39 g/L Na2MoO4·2H2O, 0.08 g/L CuSO4.5H2O, and 0.05 g/L Co(NO3)2·6H2O] in a 2L Erlenmeyer flask to make 1000 mL of stock solution.

Collection of pharmaceutical industry wastewaters

In the present study, pharmaceutical industry wastewater (PIWW) was collected from Unicure India Pvt. Ltd situated at Bhagwanpur, Haridwar, India (29° 57′ 14.2″ N and 77° 48′ 00.1″ E). The wastewater samples were collected in 20 L capacity non-reactive polyvinyl chloride (PVC) containers. The samples were transported to the laboratory and stored at 4 °C until further utilization in the phycoremediation experiments.

Experimental design and conditions

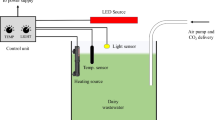

The phycoremediation experiments were carried out in the Agro-ecology and Pollution Research laboratory of the Department of Zoology and Environmental Science, Gurukul Kangri (Deemed to be University), Haridwar, India (29° 55′ 11.9″ N and 78° 07′ 09.7″ E). In this regard, Design-Expert software (Stat-Ease, USA) was used for obtaining the suggested design matrix (16 experimental trials). Glass aquariums (25 × 30 × 28 cm; length × height × width) of 20 L capacity were used as photo-bio-reactor having. For the optimization experiments, a total of three control variables, i.e., pharmaceutical wastewater concentration (A: 0, 50, and 100%), reactor temperature (B: 20, 25, and 30 °C), and light intensity (C: 2000, 3000, and 4000 lx) were used to optimize the total phosphorous (Y1: TP; %), total Kjeldahl’s nitrogen (Y2: TKN; %), and lipid production (Y3: %) efficiency of isolated C. vulgaris, respectively (Table 1). Purposely, wastewater concentration was adjusted using the addition of borewell water (BWW) (29° 55′ 11.8″ N 78° 07′ 10.0″ E) to achieve high (+1) and medium (0) levels. BWW is typically groundwater extracted from a borehole, and its quality is often uncontaminated. The DO of BWW was 2.47 mg/L. Using BWW for dilution is considered best practice in bioremediation experiments as previously outlined by several researchers (Singh et al. 2021; Kumari et al. 2022). The glass reactors were filled with a 15 L working volume of pharmaceutical wastewater followed by the addition of 150 mL stock algal culture (cell density 0.375 g/L). The experimental layout of the glass bioreactor used for C. vulgaris cultivation is given in Fig. 1. The light source was fitted at the top surface of the reactor and algae was manually stirred daily 5 times so all cells get light exposure and do not get settled at the bottom. The glass reactors were equipped with a 150W aquarium heater and light-emitting diode (LED-white) bulb (2W G4, VRCT, IN) for controlling the temperature and light intensity (calibrated using digital LUX meter; LX-1010B, MEXTECH, IN), respectively. C. vulgaris was provided with 6 h dark and 18 h light period till the 16th day with 3% CO2 with a rate of 0.5 L/min. Previous studies showed that C. vulgaris is best grown in 6/18 h dark to light period under laboratory conditions (Kumari et al. 2022; Sharma et al. 2022). Likewise, Sánchez-Bayo et al. (2020) showed that photoperiod having a higher number of light/dark hours, i.e., 18:6, 12:12 resulted in maximum biomass accumulation in A. maxima, C. vulgaris, and N. gaditana as compared to 6:18 which is in line with the present study.

Mathematical models for optimization and prediction studies

Nowadays, mathematical models are being widely used to optimize the bioremediation of industrial effluents. In this, response surface methodology (RSM) and artificial neural network (ANN) are some of the most feasible tools that can be used to maximize the pollution reduction efficiency of bioremediation systems (Seragadam et al. 2021). In the present study, the experimental trials were randomly organized according to the face-centered (k = 1) central composite design (CCD) of response surface methodology (RSM). The prediction and optimization of the developed RSM model were done by using the following quadratic model (Eq. 1):

where Y is the optimizable response variables in terms of TP/TKN removal and lipid production, β0, βa, βb, and βc are the estimated quadratic regression coefficients, while A, B, and C correspond to wastewater concentration, reactor temperature, and light intensity, respectively.

On the other hand, a feed-forward and back-propagation (FFBP) method of ANN was used to construct the prediction model based on the variables given in Table 1. The ANN model was composed of three different layers including the input layer (3 neurons), hidden layer (10 neurons), and output (1 neuron) as given in Fig. 2. The dataset was divided into three different groups viz., 70, 15, 15% referring to training, testing, and validation groups, respectively. The maximum number of epochs tested during the model training was 100. For this, the logistic activation function was used to train the model. The output layer corresponds to the response variable, i.e., TP/TKN removal and lipid production (Fig. S1, Fig. S2, and Fig. S3). For this, the “nntool” module of MATLAB Version 2020b (MathWorks, USA) was used.

Moreover, the prediction feasibility of both RSM and ANN models was estimated using the minimum difference between a measure and predicted response values and coefficient of determination (R2) tools (Eq. 2).

The validation of the models was carried out using mean square error (MSE) and root mean square error (RMSE) tools as per the following formula (Eqs. 3–4):

where \(\hat{y\ }\) and \(\overline{y}\) are predicted and mean values of the y response variable while N is the number of observations, respectively (Kim et al. 2019).

Wastewater analytical methods

In this study, the water and wastewater samples were analyzed for selected physicochemical and nutrient parameters such as pH, electrical conductance (EC: dS/m), total dissolved solids (TDS: mg/L), total Kjeldahl’s nitrogen (TKN: mg/L), total phosphorus (TP: mg/L), magnesium (Mg: mg/L), sodium (Na: mg/L), calcium (Ca: mg/L), and potassium (K: mg/L) following standard methods (Latimer, 2019; APHA 2017) (Table 2). Purposely, a microprocessor-based digital multi-meter (1615, ESICO, IN) was used for pH, EC, and TDS estimation. The spectrophotometric (Agilent Cary 60, USA) method was used for TP (470 nm) and COD (600 nm) analysis whereas the contents of K and Na were analyzed using the flame photometric method (1382, ESICO, IN). Moreover, TKN was determined by using Kjeldahl’s acid-digestion and distillation method. Despite this, the titrimetric method was used for the determination of Ca and Mg contents. Laboratory-grade reagents procured from Sigma-Aldrich (IN) were used in all chemical analyses of this experiment.

Determination of pollution removal efficiency and lipid content

The efficiency of selected C. vulgaris in the removal of TP and TKN pollutants from pharmaceutical wastewater was enumerated based on the pollutant removal efficiency index (Re: %). The form of the formula (Eq. (5) is given below (Faiz et al. 2017):

where C0 and Ct were the initial and residual (after t time) concentrations of TP and TKN of pharmaceutical wastewater.

On the other hand, the cultivated algal biomass was harvested through the anhydrous Al2(SO4)3 flocculation method (150 mg/L; 100 rpm; 5 min). Further, the harvested algal biomass was used for lipid extraction using the Soxhlet method. For this, n-hexane was used as an extraction solvent under a total of 10 cycles at 70 °C for 1 h. The quantification of the extracted lipids was done by calculating the weight of lipids left after the evaporation of the extraction solvent used, i.e., n-hexane. Finally, the lipid content was estimated using the gravimetric method as previously described by Karpagam and Jawahar (2015).

Software and statistics

For the present study, different software packages such as Design Expert (12, State Ease, USA), Microsoft Excel (2019, Microsoft Corp, USA), MATLAB (MathWorks Inc., USA), and OriginPro (2021b, Origin Corp., MX) were used for experimental designing, statistical, modeling, and graphical works. All experiments were performed in a triplicated random design and the level of statistical significance was adjusted to the prob. (P) < 0.05.

Results and discussion

Characteristics of borewell water and pharmaceutical industry wastewater

Table 2 provides the physicochemical and nutrient parameters of PIWW and BWW used for phycoremediation experiments. Results indicated that BWW contains a lesser pollution load than that PIWW used in this study. In general, values of various physicochemical and nutrient parameters of BWW viz., EC (0.33 ± 0.03 dS/m), pH (7.62 ± 0.01), BOD (2.56 ± 0.24 mg/L), COD (5.76 ± 0.59 mg/L), TDS (114.35 ± 7.62 mg/L), TKN (4.12 ± 0.03 mg/L), TP (2.57 ± 0.19 mg/L), Mg (5.14 ± 0.02 mg/L), Na (5.16 ± 0.24 mg/L), Ca (4.28 ± 0.26 mg/L), and K (2.58 ± 0.03 mg/L) were significantly lower (P < 0.05) as compared to PIWW which had EC (0.6 ± 0.02 dS/m), pH (6.8 ± 0.4), BOD (9435.2 ± 549 mg/L), COD (15,423.6 ± 1121 mg/L), TDS (940.34 ± 124 mg/L), TKN (825 ± 52 mg/L), TP (215 ± 13 mg/L), Mg (23.6 ± 0.11 mg/L), Na (184.08 ± 3.12 mg/L), Ca (69.5 ± 1.05 mg/L), and K (159.04 ± 1.23 mg/L) contents much higher, respectively. The sources of various pollutants in pharmaceutical wastewater might be the residual chemicals during drug production. While the nutrients might be the result of the processing and manufacturing of herbal medicines using plant-based raw materials.

The above findings suggest that the discharge of improperly treated PIWW in water bodies may lead to several environmental issues in the study province including arable land pollution and pollutant accumulation in aquatic bodies. Therefore, there is an urgent necessity to implement efficient PIWW treatment technologies before discharging them in the open environment. Studies from the past few years showed that being rich in several nutrients, PIWW can be utilized in algal cultivation. Out of them, Pal (2018) studied the physicochemical and nutrient parameters of PIWW which contained several organic and inorganic nutrients. Hence, the physicochemical and nutrient profile of PIWW used in this study showed that it can be used as a nutrient medium for algal growth.

Phycoremediation and lipid production efficiency of isolated C. vulgaris

In this study, the isolated C. vulgaris was efficient enough for the phycoremediation of PIWW in terms of TP/TKN removal and lipid production. Table 3 depicts the results of PIWW phycoremediation experiments conducted using the CCD method of RSM. In this, varied ranges of TP/TKN removal and lipid yield were seen amongst different experimental trials while considering the control. More specifically, run number 1 showed the highest reduction of TP and TKN which was observed as 91.11 and 82.41%, respectively, along with 1.230 g/L of dry microalgal biomass using 50% wastewater concentration. Other than this, the maximum lipid yield was 20.6% extracted using the Soxhlet extraction method (Fig 4).

Generally, TP and TKN are the major nutrients that are extremely necessary for the growth and reproduction of living organisms including algal cells. TP plays an important role in the formation of genetic material while TKN is required for amino acid, lipid, and protein synthesis. Algae evolved to utilize these nutrients from water bodies and grow simultaneously. However, they can survive up to a certain level of TP and TKN nutrients. That might be the reason why a slight growth inhibition was observed using absolute PIWW treatment which contained high TP and TKN loads. Thus, the optimum nutrient uptake helps in the algal biomass and lipid production (Escapa et al. 2017; Chen et al. 2020).

There are very limited studies on the phycoremediation of PIWW using algal species. However, no study focused on TP and TKN removal by C. vulgaris using the RSM-CCD method. A report by Xiong et al. (2017) investigated multiple exposures of C. vulgaris to levofloxacin-contaminated PIWW. Their findings showed that the biodegradation of levofloxacin improved significantly after acclimation. Besides this, Nayak and Ghosh (2019) also studied the phycoremediation efficacy of Scendesmus abundans using PIWW under 21 days of hydraulic retention time. They observed that the contents of nitrate and phosphate were significantly removed by 97.12 and 93.71% along with 0.97 ± 0.01 g/L of biomass production, respectively. The cultivated algal biomass had a good fatty acid profile which can be further used for secondary purposes such as bioenergy production.

Effects of different control variables on C. vulgaris performance

Effect of pharmaceutical industry wastewater concentration

The PIWW concentrations as a control variable significantly (P < 0.0001) affected all three response variables viz., TP/TKN removal and lipid yield, respectively. The results of the CCD matrix given in Table 3 showed that a medium level (0) of PIWW concentration, i.e., 50% gave the maximum pollutant removal along with the highest production of lipid yield. However, the growth of isolated C. vulgaris was slightly retarded using a high dose (+1) of PIWW (100%). The absolute PIWW contained a high load of TP and TKN nutrients which might not be feasible for efficient algal growth experiments. Since the alga was isolated from the confluence points between freshwater and polluted water environments, it might have been adopted to grow under a nutrient-stressed environment up to an optimum level. On the other hand, the lowest growth in control, i.e., 0% PIWW may be due to the lesser availability of nutrients in borewell water.

Recently, Madadi et al. (2021) analyzed C. vulgaris growth potential in their experiments on the phycoremediation of petrochemical wastewater. The most feasible concentration was 50% resulting in the highest concentration of lipid production. However, the removal of nutrients showed varied trends such as 25% dilution for P removal and 50% removal for remaining parameters including BOD. This report showed that the P tolerance of Chlorella sp. was much higher as compared to other pollutants. Our results are also in line with their findings as TP removal in 50% PIWW dilution was 91.11% as compared to TKN’s 82.41%. Another study by Singh et al. (2017) investigated the nutrient removal efficiencies of C. vulgaris cultivated under different dilutions of urban wastewater such as 10, 20, and 30%. They observed that maximum nutrient removal was achieved using 30% dilution, i.e., 87.9% (from 59.31 to 9.61 mg/L) and 98.4% (7.14 to 0.15 mg/L) for N and P, respectively. This report also supported our results as PIWW concentration was one of the most deterministic factors which affected the removal of pollutants along with lipid production.

Effect of reactor temperature

Temperature is one of the major factors that strongly affect the rate of biochemical changes happening within the algal cells (Duan et al. 2018; Liang et al. 2021). In the present study, we observed that out of the three applied temperatures viz., 20, 25, and 30 °C, the highest algal growth was found at 25 °C. The growth of isolated C. vulgaris exponentially increased from 20 to 25 °C while it again reduced up to 30 °C. The reactor performance was robust at 25 °C in terms of TP and TKN removal along with the highest production of lipid content within algal cells. The interactive effect of temperature on growth performance and pollutant reduction of selected C. vulgaris is given in Fig. 3. Temperature as a climatic parameter affects the diversity and composition of aquatic microorganisms. The phytoplankton is one of the most dominating microbial communities of the Ganga River. C. vulgaris is also one of the commonly found microorganisms which act as food for upper trophic levels. It is found that C. vulgaris can grow most efficiently within a temperature range of 23–26 °C. Therefore, its in situ cultivation should also be done under conditions that mimic its natural temperature environments.

In the previous reports, the effect of temperature on the growth performance of Chlorella sp. is widely investigated. However, its response under PIWW treatment using different temperature ranges has not been done to date. In a study, Asadi et al. (2019) assessed the effect of temperature on two algal species viz., C. vulgaris and C. sorokiniana pa.91 during phycoremediation of dairy wastewater. It was observed that the best performance of C. vulgaris and C. sorokiniana pa.91 was observed within a temperature range of 25–28 °C, respectively. During their experiment, Bamba et al. (2015) studied the effect of temperature ranges (25 to 35 °C) and CO2 delivery rate (2%) on biomass production, pH, and nitrate removal by C. vulgaris. They found that at 25 and 30 °C temperature ranges, the maximum biomass production of 950 ± 12 and 1000 ± 15 mg/L and nitrate consumption of 42.5 and 44.2% were achieved after 12 days, respectively.

Effect of reactor light intensity

Light intensity is an important growth parameter and has a direct impact on the growth performance of alga. It is one of the major requirements since green algae require light to undergo photosynthesis (Badar et al. 2018). This study investigated the optimization of three different light intensities viz., 2000, 3000, and 4000 lx using RSM in order to identify the best growth conditions for C. vulgaris. From the results, it was evidenced that algal growth was positively correlated to light intensity up to saturation point, i.e., increases from 2000 to 4000 lx. The artificial LED light was sufficient to grow C. vulgaris without any restricted growth. The factor-response interaction study showed that light intensity had an exponential effect on lipid production and TP/TKN removal. However, light intensity as a control variable showed a moderately significant effect (P < 0.1586) compared to PIWW concentration (P < 0.0001) and reactor temperature (P < 0.3325) (Table 4). The 3D-surface plots given in Fig. 3 also revealed that the light intensity showed an inclining trend of lipid production and TP/TKN removal from 2000 to 4000 lx, respectively.

Numerous studies support the effect of light intensity on algal growth. In a study by Metsoviti et al. (2020), an increase in light intensity from white to red LED lamps (130 to 520 μmol photons/m2/s) has resulted in a faster growth rate of C. vulgaris, along with an increase in lipid content from 7.9 to 22.2%, respectively. Similarly, Chang et al. (2016) in their experiment optimized the light intensity to achieve maximum biomass production and a specific growth rate. They concluded that C. vulgaris showed maximized biomass production and growth rate at a light intensity of 120 μmol/m2/s.

Comparative assessment of RSM and ANN prediction models

Optimization modeling using RSM and ANN is one of the most commonly used tools to maximize the desired processes using different control variables (Sabour and Amiri 2017; Song et al. 2023). In our study, the phycoremediation efficiency of isolated C. vulgaris was tested using three different reactor control factors as the independent variable (A: PIWW concentration, B: reactor temperature, and C: light intensity). The effect of these parameters was investigated in order to maximize the TP/TKN removal and lipid production of C. vulgaris. For this, a quadratic model was constructed for the prediction and optimization of the desired response. On the other hand, the ANN architect having three different layers was also used for predicting the same response variables.

The findings of this study revealed that both the RSM and ANN models were efficient in predicting the TP/TKN removal and lipid production of C. vulgaris. In this, the comparative analysis results shown in Table 5 showed that ANN models had relatively higher values of coefficient of determination (R2 > 0.9894), lesser MSE (<1.976), and RMSE (<1.406) as compared to RSM models which had a coefficient of determination (R2 > 0.9870), lesser MSE (<5.330), and RMSE (<2.309), respectively. The RSM models had a highly significant P value, i.e., <0.0001 for all three responses. The following quadratic equations can be used for the maximization of TP/TKN removal and lipid production of C. vulgaris grown in PIWW:

Y (TP removal) = 83.89 + (15.46 A) + (1.19 B) + (3.16 C) – (1.40 AB) – (0.20 AC) + (0.73 BC) – (35.18 A2) – (6.46 B2) – (1.55 C2)

Y (TKN removal) = 76.37 + (13.90 A) + (1.75 B) + (1.92 C) – (0.87 AB) + (0.19 AC) + (0.53 BC) – (33.25 A2) – (6.66 B2) + (3.61 C2)

Y (Lipid production) = 19.09 + (3.48 A) + (0.43 B) + (0.48 C) – (0.21 AB) + (0.04 AC) + (0.13 BC) – (8.31 A2) – (1.66 B2) + (0.90 C2)

On the other hand, the development of ANN models showed that for TP/TKN and lipid production models, the architect worked efficiently for all three phases, i.e., training, testing, and validation. Overall, the R2 values were above 0.9800 for all the development steps. However, the errors were minimal while using 6, 6, and 5 epochs at gradient levels of 0.4896, 47.0075, and <0.0001, respectively for TP/TKN and lipid production models (Supplementary information 1). The minimum difference between the experimental and predicted response values was also encountered for ANN models. The comparative assessment of experimental vs. predicted model values in terms of TP/TKN removal and lipid production of C. vulgaris is given in Fig. 4. The optimization studies revealed that maximum reduction of TP (90.35%) and TKN (83.55) along with maximum enrichment of lipid contents in C. vulgaris (20.88%) can be achieved by adjusting the PIWW concentration at 60.73%, reactor temperature of 25.62 °C, and light intensity of 4000 lx, respectively (Table 6).

Previous studies have shown that the efficiency of artificial neural network models is much higher as compared to RSM models (Kumar et al. 2021). The same justification was observed from the results of this study. In a recent study, Liyanaarachchi et al. (2021) constructed RSM and ANN-based models for the optimization of algal biomass, total lipid, unsaturated lipid, and oleic acid production along with time and pH. After 16 days, the optimum oleic acid concentration of 745.21 mg/L was noticed at pH 7.46. On the other hand, 2663.34, 1266.33, and 1072.58 mg/L of algal biomass, total lipid, and unsaturated lipids production were observed, respectively. Since the above studies also support the findings of our study, therefore, both the RSM and ANN models can be effectively used in the optimization of PIWW phycoremediation experiments using isolated C. vulgaris.

Conclusion

This study concluded that the isolated C. vulgaris was capable of eliminating the TP (91.11%) and TKN (82.41%) pollutants of PIWW wastewater along with significant enrichment of lipid contents (20.60%). Based on the reactor optimization studies, the optimum values of PIWW concentration, temperature, and light intensity were 60.73%, 25.62 °C, and 4000 lx, respectively. RSM and ANN modeling showed that both models can be used for designing and optimizing phycoremediation experiments. However, ANN models were identified as more robust in terms of high accuracy and fewer error parameters as compared to RSM models. Overall, the study suggests that phycoremediation might be a suitable option for the biological treatment of PIWW. Moreover, the harvested algal biomass showed a good amount of lipid content; therefore, it can also be utilized for biofuel production. Further studies, on specific removal of BOD and COD loads of PIWW, should also be addressed. Also, studies on the occurrence of different pharmaceutical compounds such as antibiotics and their effects on algal growth are highly recommended.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

APHA (2017) Standard methods for the examination of water and wastewater standard methods for the examination of water and wastewater. American Public Health Association (APHA), Washington, DC

Asadi P, Rad HA, Qaderi F (2019) Comparison of Chlorella vulgaris and Chlorella sorokiniana pa. 91 in post treatment of dairy wastewater treatment plant effluents. Environ Sci Pollut Res 26(28):29473–29489. https://doi.org/10.1007/s11356-019-06051-8

Aziz A, Basheer F, Sengar A, Khan SU, Farooqi IH (2019) Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci Total Environ 686:681–708. https://doi.org/10.1016/j.scitotenv.2019.05.295

Azizi S, Bayat B, Tayebati H, Hashemi A, Pajoum Shariati F (2020) Nitrate and phosphate removal from treated wastewater by Chlorella vulgaris under various light regimes within membrane flat plate photobioreactor. Environ Prog Sustain. Energy:e13519. https://doi.org/10.1002/ep.13519

Badar SN, Mohammad M, Emdadi Z (2018) Yaakob Z (2018) Algae and their growth requirements for bioenergy: a review. Biofuels 10(1080/17597269):1472978

Bamba BSB, Lozano P, Adjé F, Ouattara A, Vian MA, Tranchant C, Lozano Y (2015) Effects of temperature and other operational parameters on Chlorella vulgaris mass cultivation in a simple and low-cost column photobioreactor. Appl Biochem Biotechnol 177(2):89–406. https://doi.org/10.1007/s12010-015-1751-7

Bansal A, Shinde O, Sarkar S (2018) Industrial wastewater treatment using phycoremediation technologies and co-production of value-added products. J Bioremediat Biodegrad 9(1):1–10. https://doi.org/10.4172/2155-6199.1000428

Bellinger EG, Sigee DC (2015) Freshwater algae: identification, enumeration and use as bioindicators. John Wiley & Sons. https://doi.org/10.1002/9781118917152

Beuckels A, Smolders E, Muylaert K (2015) Nitrogen availability influences phosphorus removal in microalgae-based wastewater treatment. Water Resour 77:98–106. https://doi.org/10.1016/j.watres.2015.03.018

Carvalho ACB, Lana TN, Perfeito JPS, Silveira D (2018) The Brazilian market of herbal medicinal products and the impacts of the new legislation on traditional medicines. J Ethnopharmacol 212:29–35. https://doi.org/10.1016/j.jep.2017.09.040

Chandel N, Ahuja V, Gurav R, Kumar V, Tyagi VK, Pugazhendhi A, Bhatia SK (2022) Progress in microalgal mediated bioremediation systems for the removal of antibiotics and pharmaceuticals from wastewater. Sci Total Environ 825:153895. https://doi.org/10.1016/j.scitotenv.2022.153895

Chang HX, Huang Y, Fu Q, Liao Q, Zhu X (2016) Kinetic characteristics and modeling of microalgae Chlorella vulgaris growth and CO2 biofixation considering the coupled effects of light intensity and dissolved inorganic carbon. Bioresour Technol 206:231–238. https://doi.org/10.1016/j.biortech.2016.01.087

Chen D, Wang Q, Li Y, Li Y, Zhou H, Fan Y (2020) A general linear free energy relationship for predicting partition coefficients of neutral organic compounds. Chemosphere 247:125869. https://doi.org/10.1016/j.chemosphere.2020.125869

Cong Q, Yu W (2018) Integrated soft sensor with wavelet neural network and adaptive weighted fusion for water quality estimation in wastewater treatment process. Measurement 1-22. https://doi.org/10.1016/j.measurement.2018.01.001

Dar RA, Shahnawaz M, Qazi PH (2017) General overview of medicinal plants: a review. J Phytopharm 6(6):349–351

Dixit D, Parmar N (2013) Treatment of pharmaceutical waste water by electro-coagulation and natural coagulation process: review. VSRD Int J Technol Non Technol Res 4(5):79–88

Dong Y, Yuan H, Ge D, Zhu N (2022) A novel conditioning approach for amelioration of sludge dewaterability using activated carbon strengthening electrochemical oxidation and realized mechanism. Water Res 220:118704. https://doi.org/10.1016/j.watres.2022.118704

Duan Z, Tan X, Parajuli K, Upadhyay S, Zhang D, Shu X, Liu Q (2018) Colony formation in two Microcystis morphotypes: effects of temperature and nutrient availability. Harmful Algae 72:14–24. https://doi.org/10.1016/j.hal.2017.12.006

Egger G, Binns A, Rössner S (2017) Health and the environment: clinical implications for lifestyle medicine. In: Lifestyle Medicine. Academic Press, pp 309–315. https://doi.org/10.1016/b978-0-12-810401-9.00019-x

Escapa C, Coimbra RN, Paniagua S, García AI, Otero M (2017) Comparison of the culture and harvesting of Chlorella vulgaris and Tetradesmus obliquus for the removal of pharmaceuticals from water. J Appl Phycol 29(3):1179–1193. https://doi.org/10.1007/s10811-016-1010-5

Faiz AA, Poonam S, Abhishek G, Faizal B (2017) Microalgal cultivation using aquaculture wastewater: integrated biomass generation and nutrient remediation. Algal Resour 21:169–161

Fayyad RJ, Muslim SN, Ali ANM (2020) Application strategies for using fungi and algae as bioremediators: a review. Plant Arch 20(1):788–792

Ferro L, Colombo M, Posadas E, Funk C, Muñoz R (2019) Elucidating the symbiotic interactions between a locally isolated microalga Chlorella vulgaris and its co-occurring bacterium Rhizobium sp. in synthetic municipal wastewater. J Appl Phycol 31:2299–2310. https://doi.org/10.1007/s10811-019-1741-1

Hess SK, Lepetit B, Kroth PG, Mecking S (2018) Production of chemicals from microalgae lipids–status and perspectives. Eur J Lipid Sci Technol 120:1700152. https://doi.org/10.1002/ejlt.201700152

Hom-Diaz A, Jaén-Gil A, Bello-Laserna I, Rodríguez-Mozaz S, Vicent T, Barceló D, Blánquez P (2017) Performance of a microalgal photobioreactor treating toilet wastewater: pharmaceutically active compound removal and biomass harvesting. Sci Total environ 592:1–11. https://doi.org/10.1016/j.scitotenv.2017.02.224

Jayaswal K, Sahu V, Gurjar BR (2018) Water pollution, human health and remediation. In: Water Remediation. Springer, Singapore, pp 11–27. https://doi.org/10.1007/978-981-10-7551-3_2

Karpagam R, Jawahar K, Ashok kumar B, Varalakshmi P (2015) Characterization and fatty acid profiling in two fresh water microalgae for biodiesel production: lipid enhancement methods and media optimization using response surface methodology. Bioresour Technol 188:177–184. https://doi.org/10.1016/j.biortech.2015.01.053

Katırcıoğlu Sınmaz G, Erden B, Şengil IA (2023) Cultivation of Chlorella vulgaris in alkaline condition for biodiesel feedstock after biological treatment of poultry slaughterhouse wastewater. Int J Environ Sci Technol 20(3):3237–3246. https://doi.org/10.1007/s13762-022-04137-4

Kim Z, Shin Y, Yu J, Kim G, Hwang S (2019) Development of NOx removal process for LNG evaporation system: comparative assessment between response surface methodology (RSM) and artificial neural network (ANN). J Ind Eng Chem 74:136–147

Kumar P, Kumar V, Singh J, Kumar P (2021) Electrokinetic assisted anaerobic digestion of spent mushroom substrate supplemented with sugar mill wastewater for enhanced biogas production. Renew Energy 179:418–426. https://doi.org/10.1016/j.renene.2021.07.045

Kumari S, Kumar V, Kothari R, Kumar P (2022) Experimental and optimization studies on phycoremediation of dairy wastewater and biomass production efficiency of Chlorella vulgaris isolated from Ganga River, Haridwar, India. Environ Sci Pollut Res 29(49):74643–74654. https://doi.org/10.1007/s11356-022-21069-1

Latimer, GW (2019) Official methods of analysis of AOAC international, 21st ed.; AOAC International: Gaithersburg, MD, USA

Lee H, Jeong D, Im S, Jang A (2020) Optimization of alginate bead size immobilized with Chlorella vulgaris and Chlamydomonas reinhardtii for nutrient removal. Bioresour Technol 302:122891. https://doi.org/10.1016/j.biortech.2020.122891

Liang R, Van Leuwen JC, Bragg LM, Arlos MJ, Fong LCLC, Schneider OM, Zhou YN (2019) Utilizing UV-LED pulse width modulation on TiO2 advanced oxidation processes to enhance the decomposition efficiency of pharmaceutical micropollutants. Chem Eng J 361:439–449. https://doi.org/10.1016/j.cej.2018.12.0651

Liang Y, Li J, Xue Y, Tan T, Jiang Z, He Y, Pan Y (2021) Benzene decomposition by non-thermal plasma: a detailed mechanism study by synchrotron radiation photoionization mass spectrometry and theoretical calculations. J Hazard Mater 420:126584. https://doi.org/10.1016/j.jhazmat.2021.126584

Liu W, Huang F, Liao Y, Zhang J, Ren G, Zhuang Z, Wang C (2008) Treatment of CrVI-containing Mg(OH)2 nanowaste. Angewandte chemie (International ed.), 47(30):5619-5622. https://doi.org/10.1002/anie.200800172

Liyanaarachchi VC, Nishshanka GKSH, Sakarika M, Nimarshana PHV, Ariyadasa TU, Kornaros M (2021) Artificial neural network (ANN) approach to optimize cultivation conditions of microalga Chlorella vulgaris in view of biodiesel production. Biochem Eng J 172:1–10. https://doi.org/10.1016/j.bej.2021.108072

López G, Yate C, Ramos FA, Cala MP, Restrepo S, Baena S (2019) Production of polyunsaturated fatty acids and lipids from autotrophic, mixotrophic and heterotrophic cultivation of Galdieria sp. strain USBA-GBX-832. Sci Rep 9:1–13. https://doi.org/10.1038/s41598-019-46645-3

Madadi R, Zahed MA, Pourbabaee AA, Tabatabaei M, Naghavi MR (2021) Simultaneous phycoremediation of petrochemical wastewater and lipid production by Chlorella vulgaris. SN Appl Sci 3(4):1–10. https://doi.org/10.1007/s42452-021-04511-w

Maity S, Singha K, Pandit P (2021) Textile wastewater management. In: Green Chemistry for Sustainable Textiles. Woodhead Publishing, pp 417–427

Mao G, Shi K, Zhang C, Li J, Chen S, Wang P (2020) Biodiesel fuel from Chlorella vulgaris and effects of its low-level blends on the performance, emissions, and combustion characteristics of a nonroad diesel engine. J Energy Eng 146:4020016. https://doi.org/10.1061/(asce)ey.1943-7897.0000668

Martínez-Pachón D, Echeverry-Gallego RA, Serna-Galvis EA, Villarreal JM, Botero-Coy AM, Hernández F, Moncayo-Lasso A (2021) Treatment of wastewater effluents from Bogotá–Colombia by the photo-electro-Fenton process: elimination of bacteria and pharmaceutical. Sci Total Environ 772:144890. https://doi.org/10.1016/j.scitotenv.2020.144890

Metsoviti MN, Papapolymerou G, Karapanagiotidis IT, Katsoulas N (2020) Effect of light intensity and quality on growth rate and composition of Chlorella vulgaris. Plants 9(1):31. https://doi.org/10.3390/plants9010031

Miao MS, Yao XD, Shu L, Yan YJ, ZLiN W, Kong Q (2016) Mixotrophic growth and biochemical analysis of Chlorella vulgaris cultivated with synthetic domestic wastewater. Int Biodeterior Biodegradation 113:120–125. https://doi.org/10.1016/j.ibiod.2016.04.005

Nayak JK, Ghosh UK (2019) Post treatment of microalgae treated pharmaceutical wastewater in photosynthetic microbial fuel cell (PMFC) and biodiesel production. Biomass Bioenergy 131:105415. https://doi.org/10.1016/j.biombioe.2019.105415

Pal P (2018) Treatment and disposal of pharmaceutical wastewater: toward the sustainable strategy. Sep Purif 47(3):179–198. https://doi.org/10.1080/15422119.2017.1354888

Patil S (2016) Early access programs: benefits, challenges, and key considerations for successful implementation. Perspect Clin Res 7(1):4. https://doi.org/10.4103/2229-3485.173779

Pudasaini N, Upadhyay PP, Parker CR, Hagen SU, Bond AD, Rantanen J (2017) Downstream processability of crystal habit-modified active pharmaceutical ingredient. Org Process Res Dev 21(4):571–577. https://doi.org/10.1021/acs.oprd.6b00434

Rana RS, Singh P, Kandari V, Singh R, Dobhal R, Gupta S (2017) A review on characterization and bioremediation of pharmaceutical industries’ wastewater: an Indian perspective. Appl Water Sci 7(1):1–12. https://doi.org/10.1007/s13201-014-0225-3

Sabour MR, Amiri A (2017) Comparative study of ANN and RSM for simultaneous optimization of multiple targets in Fenton treatment of landfill leachate. Waste manage 65:54–62. https://doi.org/10.1016/j.wasman.2017.03.048

Sánchez-Bayo A, Morales V, Rodríguez R, Vicente G, Bautista LF (2020) Cultivation of microalgae and cyanobacteria: effect of operating conditions on growth and biomass composition. Molecules 25(12):2834. https://doi.org/10.3390/molecules25122834

Santos CE, de Coimbra RN, Bermejo SP, Pérez AIG, Cabero MO (2017) Comparative assessment of pharmaceutical removal from wastewater by the microalgae Chlorella sorokiniana, Chlorella vulgaris and Scenedesmus obliquus. Biol Wastewater Treat Resour Recover 99. https://doi.org/10.5772/66772

Sboichakov VB, Reshetnikova OV (2020) Microbial degradation of wastewater. Limnol Freshw Biol 4:1021–1022. https://doi.org/10.31951/2658-3518-2020-A-4-1021

Seragadam P, Rai A, Ghanta KC, Srinivas B, Lahiri SK, Dutta S (2021) Bioremediation of hexavalent chromium from wastewater using bacteria-a green technology. Biodegradation 1-18. https://doi.org/10.1007/s10532-021-09947-w

Shah A, Shah M (2020) Characterisation and bioremediation of wastewater: a review exploring bioremediation as a sustainable technique for pharmaceutical wastewater. Groundw Sustain Dev 11:100383. https://doi.org/10.1016/j.gsd.2020.100383

Sharma J, Kumar V, Kumar SS, Malyan SK, Mathimani T, Bishnoi NR, Pugazhendhi A (2020) Microalgal consortia for municipal wastewater treatment–lipid augmentation and fatty acid profiling for biodiesel production. J Photochem Photobiol B Biol 202:111638. https://doi.org/10.1016/j.jphotobiol.2019.111638

Sharma M, Salama ES, Zhang P, Zhang L, Xing X, Yue J, Li X (2022) Microalgae-assisted microbial fuel cells for electricity generation coupled with wastewater treatment: biotechnological perspective. J Water Process Eng 49:102966. https://doi.org/10.1016/j.jwpe.2022.102966

Shrestha P, Shrestha R, Dangol B (2017) Status of wastewater generation and management in urban Nepal. J Environ 1(1):1–6

Singh J, Kumar V, Kumar P, Kumar P, Yadav KK, Cabral-Pinto MM, Chelliapan S (2021) An experimental investigation on phytoremediation performance of water lettuce (Pistia stratiotes L.) for pollutants removal from paper mill effluent. Water Environ Res 93(9):1543–1553. https://doi.org/10.1002/wer.1536

Singh R, Birru R, Sibi G (2017) Nutrient removal efficiencies of Chlorella vulgaris from urban wastewater for reduced eutrophication. J Environ Protect 8(01):1. https://doi.org/10.4236/jep.2017.81001

Song Z, Han D, Yang M, Huang J, Shao X, Li H (2023) Formic acid formation via direct hydration reaction (CO + H2O → HCOOH) on magnesia-silver composite. Appl Surf Sci 607:155067. https://doi.org/10.1016/j.apsusc.2022.155067

Subashini PS, Rajiv P (2018) An investigation of textile wastewater treatment using Chlorella vulgaris. Orient J Chem 34(5):2517. https://doi.org/10.13005/ojc/340538

Sydney EB, Sydney ACN, de Carvalho JC, Soccol CR (2019) Potential carbon fixation of industrially important microalgae. Biofuels from. Algae:67–88. https://doi.org/10.1016/b978-0-444-64192-2.00004-4

Talavera G, Castresana J (2007) Improvement of phylogenies after removing divergent and ambiguously aligned blocks from protein sequence alignments. Syst Biol 56(4):564–577. https://doi.org/10.1080/10635150701472164

Xiong JQ, Kurade MB, Jeon BH (2017) Biodegradation of levofloxacin by an acclimated freshwater alga Chlorella vulgaris. Chem Eng J 313:1251–1257. https://doi.org/10.1016/j.cej.2016.11.017

Xu Y, Liu T, Zhang Y, Ge F, Steel RM, Sun L (2017) Advances in technologies for pharmaceuticals and personal care products removal. J Mat chem A 5(24):12001–12014. https://doi.org/10.1039/c7ta03698a

Zeng H, Wang L, Zhang D, Yan P, Nie J, Sharma VK, Wang C (2019) Highly efficient and selective removal of mercury ions using hyperbranched polyethylenimine functionalized carboxymethyl chitosan composite adsorbent. J Chem Eng 358:253–263. https://doi.org/10.1016/j.cej.2018.10.001

Zhang C, Huang J (2015) Optimization of process parameters for pharmaceutical wastewater treatment. Pol J Environ Stud 24(1):391–395. https://doi.org/10.15244/pjoes/27866

Zhang Q, Liu YP, Luo FL, Dong BC, Yu FH (2019) Does species richness affect the growth and water quality of submerged macrophyte assemblages? Aquat Bot 153:51–57. https://doi.org/10.1016/j.aquabot.2018.11.006

Zhu L, Hu T, Li S, Nugroho YK, Li B, Cao J, Hiltunen E (2020) Effects of operating parameters on algae Chlorella vulgaris biomass harvesting and lipid extraction using metal sulphates as flocculants. Biomass Bioenergy 132:105433. https://doi.org/10.1016/j.biombioe.2019.105433

Znad H, Al Ketife AM, Judd S, AlMomani F, Vuthaluru HB (2018) Bioremediation and nutrient removal from wastewater by Chlorella vulgaris. Ecol Eng 110:1–7

Author information

Authors and Affiliations

Contributions

All authors have contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Sonika Kumari. The first draft of the manuscript was also written by Sonika Kumari. Supervision and writing—review and editing were done by Vinod Kumar and Richa Kothari. Software, validation, final editing, and translation were performed by Pankaj Kumar. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 746 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, S., Kumar, V., Kothari, R. et al. Nutrient sequestration and lipid production potential of Chlorella vulgaris under pharmaceutical wastewater treatment: experimental, optimization, and prediction modeling studies. Environ Sci Pollut Res 31, 7179–7193 (2024). https://doi.org/10.1007/s11356-023-31719-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-31719-7