Abstract

In recent years, there has been a focus on clean power generation, and it is critical to assess the environmental impact of novel technologies used in pollution control in power generation. The study uses life cycle assessment (LCA) to assess the environmental impacts of coal-fired thermal power plants with different emission control techniques in an Indian scenario. As there are no such studies available in the Indian context, this work might provide a holistic view of the impacts of energy generation. A supercritical coal-fired plant with a capacity of 660 MW is considered in this study. The system boundary included coal extraction, transportation, power plant operation, and transmission losses of electricity with a functional unit of 1 kWh. It was observed that there was an energy penalty due to the power consumed in emission control devices, but the maximum energy penalty was due to the power used in the carbon capture system. The LCA is done from “cradle to gate”, with impact indicators at the mid-point evaluated using the RECIPE (H) 2016 LCIA method. LCA results showed that power plant operation is the most significant contributor to environmental impact. Initially, in cases 1 and 2, climate change (CC) potential was a major impact category, but CC potential was reduced with carbon capture and storage, 0.27 kg CO2 eq. in case 3 with ESP, FGD, SCR, and carbon capture and storage (CCS) and 0.263 kg CO2 eq. in case 4 with ESP and CCS. But there was a considerable increase in the majority of the impact categories in case 4. Freshwater consumption potential increased from 3.98 E−03 m3 in base case 1 to 4.98 E−03 m3 in case 3 due to the amount of water used in chemical production during CCS, as CC potential is a major concern in power generation, However, compared to case 1, the potential for climate change increased in case 2, whilst in case 4, the potential for climate change is lower but has resulted in an increase in the majority of impact categories. Case 3 shows an optimal approach to reducing CO2 emissions compared to other cases. The combination of ESP, FGD, SCR, and CCS is favourable for cleaner energy generation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The economic and social development of a country is crucially dependent on its power generation and consumption. Also, increased net energy availability directly relates to GDP growth (Prakash 2021). There are various sources of power generation, but fossil fuels dominate as a major fuel in power plants globally. Thermal power plants in India must also transition to cleaner energy generation as early as possible. The reports show that the installed power capacity of India is 395 GW, of which 59.7% is fossil fuel-based energy production (Government of India Ministry of Power 2022). Many studies have shown that fossil fuel power plants with emission control technologies still have an adverse impact on the environment, resulting in climate change, acidification, eutrophication, and, ultimately, effects human health, flora and fauna, and resource depletion (Rasheed et al. 2020; Asante-Okyere et al. 2017). As there are not much studies available in the Indian context with emission control technologies, this work might provide a holistic view of the impacts of energy generation and can also guide in the formulation of implementation strategies.

India has submitted its Intended Nationally Determined Contribution (2015) report and committed to achieving the Paris Agreement goals (2015). India’s coal demand is expected to rise 3.9% per year by 2024 (2021). There is a need to implement post-combustion control techniques to achieve INDC’s goals. Flue gas desulphurisation (FGD) is an effective SOx mitigation technique. The SO2 removal efficiency of FGD ranges from 50 to 99.8% (Ganguly et al. 2022). With limestone as its primary raw material, wet-type FGD technology is used globally due to its cheaper capital and operating costs (Pachouri and Saxena 2020). ESPs are utilised to regulate particulate matter (PM) emissions from thermal power plants. A report from The Energy and Research Institute (TERI) stated that the country’s progress in implementing ESPs is proceeding as planned. Selective catalytic reactor (SCR) and SNCR control NOx emissions. NTPC is testing Indian coal viability using SCR pilot plants. As per the Ministry of Power (MoP) regulations of 2017, in addition to SCR/SNCR systems, power plants require pre-combustion modifications such as in-situ boiler upgrades, low NOx burners, and over-fired air by 2022. Carbon capture and storage (CCS) reduces CO2 emissions. Coal power plants emit CO2, causing GWP. There are no emission norms for CO2 emissions. At COP26, the government of India also promised net zero emissions by 2070. Hence, there is an immediate need to implement these mitigation technologies.

Life cycle assessment (LCA) has been employed by various researchers to measure the impact of power generation on environment. Most of these LCA studies focussed on fuel extraction, transportation, and power plant operations such as Agrawal et al. (2013, 2014), Liang et al. (2013), Mingjia et al. (2020), and Restrepo et al. (2015). Also, the emission control technologies and their implementation can effectively reduce emissions but may lead to an energy penalty and increase in other impact categories. A study by Jung et al. (2022) compared a system of PM removal, DeSOx and DeNOx, with and without a CO2 capture module, for the Taean coal power station in South Korea. Results showed that GWP was reduced by 78% with CO2 capture. Petrescu et al. (2017) examined the environmental impact of supercritical power plants with SCR, ESP, FGD, and CCS using amine-based, aqueous ammonia, and calcium looping technologies compared to plants without CCS. CCS-equipped plant designs produce 70–140 kg/MWh of CO2. Amines operate well for GWP but not for all environmental categories. Aqueous amine solution-based CCS is costly due to energy requirement in solvent regeneration but structural modifications can reduce this cost as shown in the study by Sultan et al. (2021). Asante-Okyere et al. (2017) performed a comparison of LCA on a supercritical coal-based power plant with and without CCS. The CCS was found to reduce CO2 equivalent by 71% but led to increases in terrestrial acidification, human toxicity, fossil depletion, metal depletion, and water depletion. In a study by Yujia et al. CO2 emission factors for pulverised coal power plants with only CCS were found to be 182.7 kg/MWh for aquifer storage (2014). Tang et al. (2014) carried out an LCA to assess CCS deployment for pulverised coal power plants in Japan. The results at the midpoint level revealed that human toxicity, acidification, and eutrophication all increased significantly, whilst CCS deployment decreased global warming. Also, a study by Dunmade et al. for the South African case showed the impacts of thermal power plants, and suggested using mitigation technologies to reduce impact on environment (2019).

Similar outcomes were shown in various review studies. As such, a review study by Wang et al. showed that CCS can substantially reduce (~90%) primary CO2 emissions from power plants. Thus, CCS reduces climate change but also leads to an energy penalty and worsens other environmental impacts (2022). A review study by Gilardi et al. (2021) observed that CCS raises certain impacts whilst reducing GHG emissions from power plants. Also, when used in mineral carbonation and enhanced oil recovery applications, carbon capture and utilisation (CCU) is more eco-friendly than carbon capture and storage (CCS) (2021). Another review study by Cho and Strezov observed that pre-combustion CCS reduced GWP by 74.5%, post-combustion by 68.3%, and oxy-fuel by 77.8%. But most CCS studies showed an increase in AP, EP, and human toxicity potential (HTP) effects. A LCA with a geographic information system is recommended to assess impacts locally (2020). Brown coal, hard coal, and diesel fuel had the highest environmental consequences in Australian national power generation. Greenhouse gases and acidic gases including SO2, NOx, and PM are the main thermal power generation pollutants. Long-term solutions would require Australia to reduce its reliance on fossil fuels. A study by Odeh and Cockerill on UK coal-fired facilities using CCS (Odeh et al. 2008) would reduce emissions to the point where emissions from upstream processes would dominate. Thus, coal mine location, content, and mining technique will determine impacts. However, very few studies have included emission mitigation technologies with coal mining and transmission losses within the LCA system boundary.

LCA studies in Indian scenario mainly focussed on GWP of power plant operation such as a study by Agrawal et al. (2013, 2014) assessed GWP of natural gas as 584 gCO2/kWh and imported coal-based powered thermal plants as 1129 gCO2/kWh. The GHG emissions of a 660-MW coal-based power station in Sipat, Chattisgarh, India were estimated by Nagarkatti and Kolar to be 929.12g CO2-eq/kWh (2015). Shah and Unnikrishnan (2020) assessed the GWP impacts of coal-based thermal power generation in Bihar, Chhattisgarh, and Mumbai in India to be 1100, 1287, and 898 g CO2/kWh, respectively. A study of carbon reduction alternatives for India’s coal-based power by Singh and Rao (2016) observed that retrofitting plant with CCS system had a substantial energy penalty of more than 50% and CO2 emission reduced by 80–85%. However, study only focussed on power plant operation with CCS. For the majority of the available studies, the system boundary does not include emission mitigation technologies and transmission losses. In order to contol emissions within norms, FGD, SCR, and CCS need to be installed in addition to the ESP. A precise study of these technologies is required to assess the comprehensive impact on environment. However, there are few LCA studies on power generation available in Indian context. The energy use and environmental impact of emission control technologies have also been ignored.

In order to have a comprehensive and more realistic LCA study, coal mining, power plant operation emission mitigation technologies, and transmission losses were considered in this study. This research used secondary LCA data from various reports and literature. In this study, various implementation strategies are studied for developing nations. This study can provide a decision-making response that meets GWP reduction and other emission norms whilst using the current power plant conditions.

The structure of the article consists of brief explanation of methodology in the “Methodology” section. The modelling of a coal-based, 660-MW thermal power plant using Integrated Environmental Control Model (IECM 2021)is discussed in the “Modelling coal-fired 660-MW thermal power plant for Indian scenario” section for all cases. The LCA model of the power plants using GaBi education software is covered in the “Life cycle model for coal-based thermal plant” section. The results and discussion are covered in the “Results and discussion” section. In the “Conclusions” section, the study concludes with several recommendations and key areas for further study.

Methodology

Brief description about life cycle assessment methodology

LCA follows a standardised process as per the ISO 14040 and 14044. Hence, LCA results are credible and transparent. As per ISO standards, four steps of an LCA are described as goal and scope, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation. Goal and scope define the study’s intended objective, system boundary, reference flows, functional units, and LCA details. The LCI phase quantifies input and output relationships for all unit processes involved in the life cycle. The LCIA phase identifies any potential impacts on the environment. It includes the classification of impact categories, indicators, and a characterisation model. The results from the life cycle inventory and impact assessment stages are integrated in the interpretation phase to achieve the study’s goal. Finally, findings and recommendations are presented.

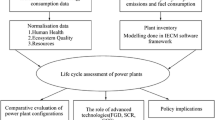

In this research project, a base-case thermal power plant was designed using information from reports and other published literature. Integrated Environmental Control Modelling (IECM 2021) is used in the design and analysis of thermal power plants. GaBi is used for LCA modelling and reporting impacts due to power production. Schematic of methodology is shown in Fig. 1.

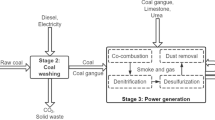

A 660-MW plant was designed based on Indian thermal power plant data available from environmental impact assessment reports and literature available. Initially supercritical coal-based thermal power plant was designed with ESP (case 1), FGD + ESP + SCR (case 2), FGD + ESP + SCR + CCS (case 3), and ESP + CCS (case 4).

Modelling coal-fired 660-MW thermal power plant for Indian scenario

The coal-fired thermal plant is modelled based on an Indian scenario from literature and data available. A model was developed for 660-MW pulverised coal-fired power plants with supercritical steam cycles. The standard technical features are from reports, notices, and recommendations published by agencies. The overall schematic representation of thermal power plant with various cases is shown in Fig. 2.

A gross electrical output of 660-MW plant is modelled using coal and operating under Indian climatic conditions for all the case studies. The power plant is assumed to be operating with supercritical technology with ambient pressure and temperature of location shown in Table 1 (WorldData.info 2022). The data collected from Central Electricity Authority (CEA) annual reports and report are listed in Table 1.

Coal mining is assumed based on research work by Khanda et al. (2018). Coal is assumed to be mined from Mahanadi Coalfield. The coal properties of Indian coal are listed in Table 2 (Mahanadi Coalfields Limited 2020). When compared to coal from other regions of the world, which has an ash percentage of about 15%, Indian coal has a high ash concentration that ranges from 35 to 45%. The ash composition is sourced from study by notice on EOI (Expression of Interest) for setting-up of coal to synthetic natural gas (SNG) plant of Mahanadi Coalfields Limited (2020).

The Mahanadi Coalfield (MCL) is considered a source of coal, with a GCV of 4340 kcal/kg. Mercury is also released by thermal power plants. The majority of mercury emissions (90%) are in the atmosphere, with the remainder to the ground. Mercury levels in Indian coal range from 0.01 to 1.1 parts per million (Rai et al. 2013). This study employed 0.55 ppm of mercury level in coal.

Base plant performance parameters are shown in Table 3 (Central Electricity Authority (CEA) 2013). In order to improve plant efficiency and decrease environmental impact, supercritical units are the focus of the nation’s present thermal power development (Rasheed et al. 2020).

Wet cooling tower is used as cooling system in this study. Wet cooling towers (WCT) are commonly utilised in coal thermal power plants to reject the heat that is not being utilised.

By altering the combustion process’ operating and design characteristics, nitrogen oxide formation can be controlled. Some of these important measures include low NOx burners, low excess air firing, flue gas recirculation thermal plants, and water injection for liquid fuels. The base case power plant is initially designed using a low NOx burner and ESP for emission management since the majority of power plants use low NOx burner technology to regulate NOx emissions. Parameters for these are shown in Table 4.

Hot-side SCR is used to minimise NOx gas emissions into the environment (Srinivasan et al. 2018). Hot-side SCR system is installed before the ESP where the flue gas temperature is optimal for SCR system. Wet limestone-type FGD (flue gas desulphurisation) is most widely used system for removing SO2 from flue gases in thermal power plants. The consumption of limestone is influenced by a number of variables, such as the gross station heat rate (SHR), the coal’s GCV and sulphur content, the effectiveness of removing SO2, the stoichiometric ratio, and the purity of the limestone. Carbon capturing and storage (CCS) is the post-combustion capture system for CO2 present in flue gas emitted from power plants. In this study, amine-based absorption systems have been considered. This technology is in very early stages in India and is only applied for pilot projects. Hence, there is not much data available for this technology in the Indian scenario. Study by Singh et al. (2016) is used in this analysis. Parameters for emission mitigation are shown in Table 4.

Life cycle model for coal-based thermal plant

Goal and scope

The goal of this research is to assess the environmental impacts from 660-MW coal-fired thermal power plant operating on Indian coal with emission mitigation techniques. Indian climatic and environmental conditions are assumed for this study as per metrological data.

The scope of this study includes all the stages from coal mining to transmission of electricity. Environmental impacts are assessed for all these phases using life cycle approach. In this study functional unit of 1 kWh of electricity produced is used as basis for comparison of results.

LCA typically comprises a cradle to grave evaluation of any process, procedure, or any new technology. The primary factor used to establish the parameters for any study is the availability of data for the research that is being undertaken. Upstream processes, plant operation, downstream processes, and transmission losses are incorporated in this study.

As shown in Fig. 3, upstream processes mainly involve coal mining and transportation in this study. Operation of a thermal plant is modelled in IECM software and post-combustion control techniques as downstream processes. Finally, the power available at the plant is transmitted and distributed to consumers (Malode et al. 2022). All these processes are assessed for potential environmental impacts using GaBi LCA software. In this study, material and energy input for erection and decommissioning of the power plant are not considered.

The final and most crucial link in the supply chain for electricity is power transmission and distribution, which is unfortunately the weakest in India. It is evident from studies that the impact of this stage is lower but not negligible and transmission loss impact is also maximum (Harrison et al. 2010). As transmission losses in India are substantial, they are taken into account in this study to assess the overall impact of power generation.

Life cycle inventory

A coal-based thermal power plant’s life cycle inventory data has been collected from Central Electricity Authority (CEA) recommendations and from various agencies as mentioned in sections below.

Coal mining and coal transportation

Coal mining data is analysed from Mahanadi CoalFields in the life cycle assessment research by Khanda et al. (2018). Coal properties and ash properties were imported from notice of Mahanadi Coalfields Limited (2020). The limitation of data availability inventory included water, electricity, explosives, and diesel. All these are a major input to the coal mines and are calculated for 1 tonne of coal produced. Inventory input and output of coal mining operation are shown in Table 5.

Coal transportation is one of the major processes as most of the thermal power plants are non-pit head power plants. Indian railways play a vital role in this process. Many rail projects dedicated to coal transport are being implemented. In this study, power plant coal is transported via railways as per the reports; on an average, coal travels a distance of 477 km from the pithead to the power plant (Sengupta 2017). A factor of 2.62 L/1000 GTKM (gross tonne kilometres) is used to assess the diesel consumed to transport coal (Indian Railways 2000). Also, there are transits and handling losses, which vary depending on the states (CERC 2013); for this study, a transit loss of 0.8% is assumed. Inventory for coal transportation stage is shown in Table 6.

Power generation

Generation of power is modelled by using IECM modelling to compute mass fluxes, energy consumption, and heat output utilising stoichiometric processes based on chemical and physical model. Data for an Indian thermal power plant was utilised to describe the disparities in technology and geography. As shown in the “Results and discussion” section of this paper, inventory for power plant operation is shown in Table 7.

Transmission and distribution

It is necessary to quantify the impacts generated due to transmission losses, as in countries like India; the T&D losses range between 20 and 30% (Transmission and Distribution in India 2017). A recent economic survey found that the amount of electricity lost through conversion, transmission, and distribution, as well as electricity that was not accounted for, came to be 20.46% of the total available electricity (Economic survey 2021–22, 2021). Hence, in this study transmission and distribution losses of 20.46% are considered. Equation 1 shows a correlation between the environmental impact and losses during transmission and distribution stages to assess the environmental impact with a holistic approach.

where IFoverall represents the overall impact factor in respective units, IF is the impact factor from coal mining (CM) to power generation (OP) stage, and TDloss is the transmission and distribution losses (%).

Life cycle impact assessment and interpretation

In this study, the impact indicators were assessed using the ReCiPe Midpoint (H) 2016 method (Huijbregts et al. 2016). The ReCiPe Midpoint (H) 2016 method is a dependable, widely accepted, and used LCA methodology. In this stage, the inventory unit flows were classified into various impact categories, and the impact was assessed using a characterisation factor in the GaBi LCA software. The potential midpoint impact indicators assessed are climate change potential, fine particulate matter formation, fossil depletion, freshwater consumption, eco-toxicity, human toxicity (cancer and non-cancer), photochemical ozone formation, terrestrial acidification, and eco-toxicity. The interpretation part discusses the results of the life cycle inventory and impact assessment, draws conclusions, and makes suggestions; these are discussed in subsequent sections.

Results and discussion

Initially, the results obtained by modelling the thermal power plant in IECM are compared with that of literature and studies already carried. Results of 660-MW power plant operating with various post-combustion control techniques are summarised in Table 8.

To simulate the worst-case situations, the power plant has been modelled for maximum heat rate (CERC 2019). Results from power plant operation showed that auxiliary power is primarily consumed in base power plant, cooling tower, and to operate emission control devices. Auxiliary power consumption is an important parameter and it needs to be minimised to increase the overall output of power plant. Initially, net electrical output was 612.2 MW but it was reduced in case 2, case 3, and case 4 due to increase in auxiliary power consumed as shown in Fig. 4, as compared to the base case, i.e. case 1.

As shown in Fig. 4, the auxiliary power consumed in cases 2, 3, and 4 increased by 27.86%, 214.95%, and 192.06%, respectively, due to power consumed in emission control devices as compared the base case, i.e. case 1. The plant electricity requirement at various levels is shown in Fig. 5. Because of the amount of electricity used in the CO2 capture system (74.3 MW in case 3 and 76.6 MW in case 4), the energy penalty was highest in cases 3 and 4. Flow rate of flue gas with emissions was higher without SCR and FGD, resulting in higher power consumed for CO2 capture in case 4. However, for the auxiliary power consumption in ESP, FGD, and SCR, there are not many variations, as evident in Fig. 5.

A sorbent regenerator is used in CCS cases 3 and 4. A regenerator is used to break the weak intermediate compound formed between the MEA-based sorbent and dissolved CO2 with the application of heat, and CO2 gets separated from the sorbent to leave reusable sorbent behind. This heat is obtained through low-pressure steam extracted from a low-pressure or intermediate-pressure turbine. The extracted steam is converted to electrical equivalent and observed to be 157.6 MW (51.2%) in case 3 and increased to 199.5 MW (58.9%) in case 4, as sorbent circulation increased from 15.62 kg/kWh in case 3 to 19.26 kg/kWh in case 4. Also, without FGD and SCR, the emission load increases.

Stack flue gas emissions are shown in Table 7. The CO2 emissions are considerably reduced to 0.135 kg/kWh in case 3 and 0.127 kg/kWh in case 4. Other emissions, such as SO2, NO, NO2, NH3, particulate emissions to the air, and ash, were found to be increased when CCS was installed without SCR and FGD, as shown in case 4. In addition, as shown in Table 8, the use of CCS resulted in a lower overall power output of the plant and a higher water footprint than the previous two cases. Further environmental impacts are discussed in the following section.

Life cycle impact assessment results

In this study LCIA methodology is based on the ReCiPe Midpoint (H); GaBi education software is used to model energy and emission flows in various phases of power generation based on databases available. Major impact indicators are evaluated in the following section shown in Table 9.

Climate change potential

The coal-based thermal power plant releases the fixed carbon stored in the coal as CO2 and CH4, which leads to climate change (CC). The impact score for CC potential has been found for different cases, as shown in Table 9 and Fig. 7. It is observed that with post-combustion control without CCS, CC potential increased to 1.25 kg CO2 eq., mainly because of the increase in fuel consumption and power consumed whilst operating ESP, FGD, and SCR. But with CCS, the CC potential decreased by 77.9% in case 3 and 78.4% in case 4 as shown in Fig. 6. Hence, the CC potential of thermal power plants can be controlled with CCS. The graphical representation for relative plot is shown in Fig. 7.

Similar trends were observed in other LCA studies, such as the study by Jung et al. (2022) observed that with CCS, global warming potential was reduced by 77%. There is also a study by Asante-Okyere et al. (2017) for a coal-based thermal plant with CCS technology in China. Results showed a 71% reduction in CC potential. Singh and Rao (2016) also obtained CO2 emission rates of 0.13 kg/kWh with CCS for the Indian scenario. GHG emission by a coal-fired power plant was assessed to be 990 g CO2-eq./kWh by Odeh and Cockerill (2008); in all these studies, transmission losses were not included in the system boundary. In the Indian scenario, CC potential is higher compared to other countries because of transmission losses considered in this study. It is also suggested that CCS be used to reduce the CC potential of thermal power plants in order to control SOx and NOx emissions with FGD and SCR.

The stage of power plant operation has a significant impact on this CC impact (93%) followed by coal mining and coal transportation, as seen in Fig. 8. It was also observed from Fig. 8 that with CCS, direct CO2 emissions from power plants can be controlled (61%), but coal extraction, transportation, and transmission losses remain unaffected. Hence, for net zero emissions, these stages must also be considered to reduce emissions.

Fine particulate matter formation potential

Fine particulate matter (FPM) is 2.5 μm in diameter, such as those in smog. They have a negative impact on the environment and are a direct result of coal combustion in thermal power plants. As shown in Fig. 9, the plant operating with only ESP had a FPM formation potential of 3.93E−03 kg PM2.5 eq., which decreased by 70% to 1.14E−03 kg PM2.5 eq. with ESP + FGD + SCR and further decreased to 1.58E−04 kg PM2.5 eq. in case 3, but increased to 3.46E−03 kg PM2.5 eq. in case 4. As a result, if CCS is installed without FGD and SCR, it will lead to an increase in FPM potential. It can be interpreted that these mitigation techniques have their own environmental impact as they also increase fuel consumption and auxiliary power consumption to run these devices. Han et al. (2019) study for a supercritical coal-based plant indicated 2.36E−04 kg PM2.5 eq. of FPM formation potential. A study by Asante-Okyere et al. (2017) assessed that FPM increased 209% with a supercritical plant with CCS; as in this study, only CCS is employed without FGD and SCR. Hence, CCS must be used with FGD and SCR to reduce the potential for FPM formation.

Fossil depletion potential

Fossil depletion potential is determined for fossil fuels, minerals, and expressed as kg oil eq. It is observed that with case 2 fossil depletion (FD) potential increased by 2%, 20% with case 3, and 17.43% with case 4 as compared to base case 1, as shown in Figs. 6 and 10. As power consumed to run the emission control devices increases, the coal consumption also increases and leads to increased FD potential. The FD potential with CCS is observed to be 0.544 kg oil eq., maximum in observed cases.

Study by Han et al. (2019) LCA of supercritical coal-based power plant resulted in 0.202 kg oil eq. of FD potential. In the study by Asante-Okyere et al. (2017) for supercritical plant with CCS, FD potential increased by 32%, and study by Jung et al. (2022) results showed 41.43% increase in fossil resource scarcity.

Freshwater consumption potential

The total freshwater consumption was assessed for all the cases. Water is a critical component in power generation using a thermal power plant. Water is consumed during fuel extraction, fuel supply, and power generation. Freshwater consumption (FWC) potential was assessed at 3.98E−03 m3 with ESP in case 1, increased to 4.40E−03 m3 in case 2, 4.11E−03 m3 in case 4, and maximum in case 3 with CCS at 4.98E−03 m3 as shown in Fig. 11. In all cases, 94% of water is used in the power generation stage. It is observed that there was an increase of 10.5%, 25.12%, and 3.11% in cases 2, 3, and 4, respectively, as shown in Fig. 6. The increase in FWC potential in cases 2 and 3 is mainly due to the water consumed in raw material and chemical production, hence the higher FWC potential with CCS. Similar increases in water consumption were observed with CCS in the studies Asante-Okyere et al. (2017) and Jung et al. (2022).

However, according to CPCB norms (CPCB 2017), all current coal-fired power stations are required to reduce their specific water usage to a maximum of 3500 L/MWh. As per the water life cycle assessment study in the IECM software, water withdrawal was assessed to be 3225 L/MWh in case 1, 3568 L/MWh in case 2, 4183 L/MWh in case 3, and 4357 L/MWh in case 4. The major contributor to FWC potential is plant operation, followed by fuel extraction and supply, plant infrastructure, and chemical production. Also, as per norms, new plants installed after 1 January 2017 should reduce their maximum specific water consumption to 2500 L/MWh and achieve zero wastewater discharge. Hence, with CCS, it needs to be optimised.

Human toxicity potential

The human toxicity potential (HTP) is based on two factors that are intrinsic toxicity of substance ant its potential dose. ReCipe uses two effect classes’ cancer and non-cancer cases. The cancer potential of human toxicity (HT) was evaluated, as shown in Table 9 and Fig. 6. It is observed that HT, cancer, and non-cancer potential initially decreased in case 2 by 8.6% and 11% as shown in Fig. 6. But with CCS both increasing in case 3 and case 4, and observed to be maximum in case 4 with HT, the cancer potential is 1.59E−06 kg 1,4-DB eq., and for HT, the non-cancer potential is 4.27E−04 kg 1,4-DB eq., as shown in Figs. 12 and 13. It is mainly because of the lime or limestone, sorbent, and ammonia used in the CCS case.

Also, studies such as those by Jung et al. (2022) showed an increase in this HT impact potential with the application of CCS. A study by Schreiber et al. (2010) evaluated the possible human toxicity of a German coal-fired plant using a CCS technique for different coal grades. For type 1 with high-grade coal, HT potential was 54 g DCB equivalents per kWh, but with poor grade coal, it rose to 105 g DCB equivalents per kWh. A study by Asante-Okyere et al. (2017) for a coal-fired plant with CCS technology in China found that HT potential increased by 33% for supercritical plants with CCS.

Stratosphere ozone depletion potential

The stratospheric ozone plays a crucial role in regulating the earth’s temperature. Health and the ecology are negatively impacted by UVB radiation that reaches the earth’s surface. The stratosphere ozone depletion (SOD) potential for the current study was assessed to be 2.88E−10 kg CFC-11 eq. for case 1, 2.19E−10 kg CFC-11 eq. for case 2, 2.52E−10 kg CFC-11 eq. for case 3, and 3.30E−10 kg CFC-11 eq. as shown in Fig. 14. In case 4 there was an increase of 14.6% in SOD potential with only ESP and CCS. A study by Rasheed et al. (2020) and Asante-Okyere et al. (2017) assessed the SOD potential of 8.27E−08 kg CFC-11 and 8.70E−11 kg CFC-11 eq. for 1 MWh of electricity produced.

Photochemical ozone formation potential

A photochemical oxidant is of primary importance in ground-level ozone (O3) formation, which is produced as a result of the emission of the air pollutants NOx and NMVOC during the life cycles of goods and service zones. Photochemical ozone formation (POF) potential decreased with the application of mitigation techniques, as shown in Table 9 and Fig. 15. In case 2, POF potential decreased by 60% and by 53% in case 3 with CCS, but it increased in case 4 with only ESP and CCS, as shown in Fig. 6.

A study by Petrescu et al. (2017) also observed an increase in POF potential with only CCS. A life cycle study by Yu et al. evaluated the photochemical ozone creation (POCP) potential for various cases for the USC system at 0.0566 kg ethene-eq. for a functional unit of 3600-MJ energy output (2019). Annisa et al. (2018) calculated the POCP of a steam cycle and combined cycle plant to be 3.16E−03 kg-C2H4/GWh.

Terrestrial acidification potential

The base cations leaching into the environment are primarily responsible for terrestrial acidification. In this study, for case 1, terrestrial acidification (TA) potential is assessed to be 1.35E−02 kg SO2 eq., whilst for case 2, it decreased to 3.97E−03 kg SO2 eq., and with CCS, it was further reduced to 1.55E−03 kg SO2 eq. for 1 kWh of transmitted power. It was observed that with only ESP and CCS TA potential, it increased significantly, as shown in Figs. 16 and 6.

A similar trend was observed in studies, and when CCS is used with ESP, FGD, and SCR, we can observe a decrease in TA potential. A study by Schreiber et al. (2010) evaluated the acidification potential for a German coal-fired plant using a CCS technique; it was evaluated to be 1.3 g SO2 eq. for higher quality coal and 1.4 g SO2 eq. for lower quality coal with 1 kWh as a functional unit. Asante-Okyere et al. (2017) assessed for supercritical plant with only CCS increased TA by 175%; hence, CCS must be coupled with FGD and SCR as per the study conducted in this paper.

Terrestrial eco-toxicity potential

Terrestrial eco-toxicity (TE) potential assesses the impact of a chemical substance to terrestrial environment. The study assessed TE potential for 1 kWh of functional unit as shown in Table 9 and Fig. 17. The study assessed impact score of 7.98E−02 kg 1,4-DB eq. in case 1 and increased slightly to 8.68E−02 kg 1,4-DB eq. in case 2, 1.48E−03 kg 1,4-DB eq. in case 3, and 1.90E−03 in case 4. The primary contributor to this impact is boiler ash, coal dust, and chemicals used in FGD. Study by Rasheed et al. (2020) assessed TE potential for supercritical coal-fired power plant to be 3.17 kg 1,4 DCB eq. for 1 MWh of electricity generated.

Conclusions

Coal-fired thermal power plants will continue to dominate in the Indian energy sector at least for the next decade because there is no instant alternative for the large installed capacity of coal-fired power plants. As power generation from coal-based thermal power plants emits various pollutants into the environment, emission control techniques are being adopted to abide by the emission norms. Hence, the LCA study of these emission control approaches is necessary in the Indian context.

In this study, a thermal power plant is modelled for Indian scenarios, with four cases based on emission mitigation techniques adopted: in case 1 with ESP, case 2 with FGD + ESP + SCR, case 3 with FGD + ESP + SCR + CCS, and case 4 with ESP + CCS. Initially, it was observed that emission control devices had a substantial energy penalty and reduced the net power output of the plant. The plants in cases 3 and 4 used 74.3 MW and 76.6 MW of energy generated for carbon capture systems, respectively. However, there were not many variations in the amounts of power consumed by ESP, SCR, and FGD.

A detailed LCA study was conducted for every case with a system boundary, including coal mining, coal transportation, power generation, and transmission losses. The LCI is based on data available from the literature, as shown in the “Life cycle inventory” section; all the LCI results are converted to 1 kWh of power generated as a functional unit. LCIA results were analysed for impact indicators shown in Table 9. Major impact categories are assessed and discussed in detail. The climate change potential initially increased in case 2, as coal consumption increased compared to case 1. Subsequently, CC potential decreased by 77.87% in case 3 and 78.43% in case 4, with CCS, but there was a significant increase in other impact categories in case 4 compared to case 3. It can be concluded that the current power plants in India are operating with ESP, and hence, it is preferable to retrofit them with CCS, FGD, and SCR. However, if only CCS is used, then the CC potential will be reduced at the cost of an increase in other environmental impact categories. Also, it was observed that implementing CCS only controls direct emissions from power plant but the emissions from coal mining and transportation are unaffected.

In case 2, there was an increase in CC potential but reductions in FPM, SOD, HTC, HT-NC, POF, and TA impact categories. In case 3 CC, FPM, SOD, POF, TA, and TE decreased substantially, as it also possessed SO2, NO2, and HCl removal capacities. However, in case 4, it was observed that the CC potential was reduced but led to a substantial increase in all other impact categories except FPM and TE. Fossil depletion potential increased by 20% and 17.4% in cases 3 and 4, respectively, because extra coal was consumed to produce auxiliary power to run the combustion control equipment. Coal mining, coal transportation, power generation, and power transmission all use water, so thermal power plants have a large water footprint. Freshwater consumption potential also increased by 26.6% in case 3 because of the water consumed in chemical production, plant operation, and fuel supply. Because of the chemicals used and the scrubber solids disposed of to the environment, human toxicity was observed to be increased in cases 3 and 4 with CCS for both cancer and non-cancer categories.

Therefore, the study suggests that the current thermal power plants in India with only ESP are not sufficient to reduce emissions. According to this study, focusing on an individual impact potential may result in an increase in other potential impacts. Hence, power plants with ESP + FGD + SCR + CCS can reduce CC potential and other impact categories optimally as compared to other cases. Although there are technological and economic challenges to be considered, future studies will be carried out to evaluate various CCS techniques and viable options for India, and economic analysis for the same can also be carried out.

Data availability

Online literature has been compiled with data about Indian thermal power.

References

Agrawal KK, Jain S, Jain AK, Dahiya S (2013) Assessment of greenhouse gas emissions from coal and natural gas thermal power plants using life cycle approach. Int J Environ Sci Technol 2014(11):1157–1164. https://doi.org/10.1007/s13762-013-0420-z

Agrawal KK, Jain S, Jain AK, Dahiya S (2014) A life cycle environmental impact assessment of natural gas combined cycle thermal powerplant in Andhra Pradesh, India. Environ Dev 11:162–174. https://doi.org/10.1016/j.envdev.2014.04.002

Annisa R, Faridah L, Yuliawan D, Sinisuka N, Dinata I (2018) Environmental impact assessment of steam cycle and combine cycle power plants using life cycle assessment methodology. In: The 4th IEEE Conference on Power Engineering and Renewable Energy. IEEE

Asante-Okyere S, Daqing T, Enemuoh E, Kwofie S (2017) Life cycle assessment of supercritical coal power plant with carbon capture and sequestration in China. Asian Journal of Environment & Ecology 1(2):1–8. https://doi.org/10.9734/AJEE/2016/31400

CEA (2014) Recommendations on operation norms for thermal power stations tariff period — 2014–19. Central electricity authority (CEA) Retrieved from https://cercind.gov.in/2013/whatsnew/Sop.pdf

CEA Annual Report 2020–2021 (2020) Central Electricity Authority Ministry of Power, Government of India. Retrieved from https://cea.nic.in/annual-report/?lang=en

CEA Recommendatons on Operation Norms for Thermal Generating Stations (2019) Retrieved from CEA. https://cercind.gov.in/2020/draft_reg/Appendix%20I.pdf

Central Electricity Authority (CEA) (2013) Standard technical features of BTG system for supercritical 660/800 MW thermal units

Central Pollution Control Board (2018) Retrieved from MoEFCC: https://cpcb.nic.in/NGT/Annexure_3.1_27.02.2018.pdf

CERC (2013) Summary of the comments and suggestions received on Approach Paper on Terms and Conditions of Tariff Regulations for the tariff period 1.4.2014 to 31.3.2019. Central Electricity Regulatory Commission Retrieved from https://cercind.gov.in/2013/regulation/Comments/Transit_Handling_Losses.pdf

CERC (2019) Recommendations on operation norms for thermal generating stations for the tariff period 2019–24. CEA, MoP, GOI Retrieved from https://cercind.gov.in/2018/draft_reg/CEA%20Recommendations%20for%20thermal%20generating%20stations%20for%20tariff%20period%202109-24.pdf

Cho HH, Strezov V (2020) A comparative review on the environmental impacts of combustion-based electricity generation technologies. Energy Fuels 34(9):10486–10502. https://doi.org/10.1021/acs.energyfuels.0c02139

Coal (2021) Analysis and forecast to 2024. International Energy Agency Retrieved from www.iea.org

CPCB (2017) Thermal power plants overview. CPCB Central Pollution Control Board Retrieved from https://cpcb.nic.in/uploads/Thermal_Power_Plant_overview.pdf

Dunmade I, Madushele N, Adedeji PA, Akinlabi ET (2019) A streamlined life cycle assessment of a coal-fired power plant: the South African case study. Environ Sci Pollut Res 26:18484–18492. https://doi.org/10.1007/s11356-019-05227-6

Economic survey 2021-2022 (2021) Retrieved from https://www.thehinducentre.com/resources/article38354164.ece/binary/Economic%20Survey%20Complete%20PDF.pdf

Ganguly D, Dey S, Arora LK, Sharma S, Singh I, Shubham, Nandi I (2022) Study to assess the compliance of thermal power plants in India to new SO2 emission norms (2015) and lay out phased plan for FGD implementation. Centre for Atmospheric Sciences Indian Institute of Technology Delhi. Retrieved from https://cas.iitd.ac.in/

Gilardi M, Rigamonti L (2021) LCA methodology application to assess the environmental impact of CCS and CCU: A review. Atti del XIV Convegno della Rete Italiana LCA-IX Convegno dell’Associazione Rete Italiana LCA: La sostenibilità della LCA tra sfide globali e competitività delle organizzazioni 155–164. Retrieved from https://hdl.handle.net/11311/1189425

Government of India Ministry of Power (2022) Retrieved 2022, from https://powermin.gov.in/en/content/power-sector-glance-all-india

Han X, Chen N, Yan J, Liu J, Liu M, Karellas S (2019) Thermodynamic analysis and life cycle assessment of supercritical pulverized coal-fired power plant integrated with No. 0 feedwater preheater partial loads. J Clean Prod 233:1106–1122. https://doi.org/10.1016/j.jclepro.2019.06.159

Harrison GP, Karamanlis S, Ochoa LF (2010) Life cycle assessment of the transmission network in Great Britain. Energy Policy 38(7):3622–3631. https://doi.org/10.1016/j.enpol.2010.02.039

Huijbregts MA, Steinmann ZJ, Elshout PM, Stam G, Verones F, Vieira MDM, Hollander A, Zijp M, van Zelm R (2016) ReCiPe 2016: A harmonized life cycle impact assessment method at midpoint and endpoint level report I: characterization. Retrieved from https://rivm.openrepository.com/handle/10029/620793

IECM (2021) Integrated Environmental Control Model (IECM) Version 11.5. Carnegie Mellon University https://www.cmu.edu/epp/iecm/index.html

India’s Intended Nationally Determined Contribution (2015) Retrieved from https://www4.unfccc.int/sites/ndcstaging/PublishedDocuments/India%20First/INDIA%20INDC%20TO%20UNFCCC.pdf.

Indian Railways (2000) Retrieved from https://irimee.indianrailways.gov.in/instt/uploads/files/1477552238861-Specific_Fuel_Consumption.pdf

International Finance Corporation (IFC) (2017) Environmental, health, and safety guidelines for thermal power plants. International Finance Corporation World Bank Group. Retrieved from https://www.ifc.org/wps/wcm/connect/9ec08f40-9bc9-4c6b-9445-b3aed5c9afad/Thermal+Power+Guideline+2017+clean.pdf?MOD=AJPERES&CVID=lNwcJZX

Jung HS, Ryoo SG, Kang YT (2022) Life cycle environmental impact assessment of Taean coal power plant with CO2 capture module. J Clean Prod. Retrieved from https://doi.org/10.1016/j.jclepro.2022.131663

Khanda DK, Pal BK, Mahananda MR (2018) Assessment of environmental impacts of coal mining in Lakhanpur Opencast Project of Ib Valley Coalfield, Odisha using Life Cycle Assessment (LCA) model. ICOMS Retrieved 2018 from http://dspace.nitrkl.ac.in/dspace/bitstream/2080/3195/1/2018_ICOMS%20_BKPal_AssessmentEnvironmental.pdf

Liang X, Wang Z, Zhou Z, Huang Z, Zhou J, Cen K (2013) Up-to-date life cycle assessment and comparison study of clean coal power generation technologies in China. J Clean Prod 39(2013):24–31. https://doi.org/10.1016/j.jclepro.2012.08.003

Mahanadi Coalfields Limited (2020) https://www.mahanadicoal.in. Retrieved from https://www.cgijoburg.gov.in/pdf/Notice+EoI%20document.pdf

Malode S, Mohanta J, Prakash R (2022) A review on life cycle assessment approach on thermal power generation. Mater Today: Proc 56:791–798. https://doi.org/10.1016/j.matpr.2022.02.258

Matin NS, Flanagan WP (2022) Life cycle assessment of amine-based versus ammonia-based post combustion CO2 capture in coal-fired power plants. Int J Greenhouse Gas Control 113:103535. https://doi.org/10.1016/j.ijggc.2021.103535

Mingjia L, Ge W, Jinliang X, Jingwei N, Enhui S (2020) Life cycle assessment analysis and comparison of 1000 MW S-CO2 coal fired power plant and 1000 MW USC water-steam coal-fired power plant. J Therm Sci 31(2):463–484. https://doi.org/10.1007/s11630-020-1327-x

Nagarkatti A, Kolar A (2015) Assessment of life cycle greenhouse gas emissions from coal fired power plants in India. Appl Mech Mater 704(2015):487–490. https://doi.org/10.4028/www.scientific.net/AMM.704.487

NOx control technologies for thermal power stations (2018) Centre for Science and Environment. Retrieved from https://cdn.cseindia.org/attachments/0.76763300_1533289119_NOx-Control-Technologies-for-Thermal-Power-Stations-Factsheet.pdf

Odeh NA, Cockerill T (2008) Life cycle analysis of UK coal fired power plants. Energy Convers Manag 49(2):212–220. https://doi.org/10.1016/j.enconman.2007.06.014

Pachouri R, Saxena AK (2020) Emissions control in thermal power stations: issues, challenges, and the way forward. The Energy and Resources Institute, New Delhi

Paris Agreement. United Nations. (2015)

Petrescu L, Bonalumi D, Valenti G, Cormos A-M, Cormos C-C (2017) Life cycle assessment for supercritical pulverized coal power plants with post-combustion carbon capture and storage. J Clean Prod 157:10–21. https://doi.org/10.1016/j.jclepro.2017.03.225

Prakash R (2021) Net energy and feasible economic growth: a developing country perspective from India. Insights Into Reg Dev 3(3):106–113. https://doi.org/10.9770/IRD.2021.3.3(6)

Rai V, Raman N, Choudhary S (2013) Mercury emissions control from coal fired thermal power plants in India: Critical review & suggested Policy measures. Int J Eng Res Technol 2(11):2278–0181

Rasheed R, Javed H, Rizwan A, Sharif F, Yasar A, Tabinda A, Su Y (2020) Life cycle assessment of a cleaner supercritical coal-fired power plant. J Clean Prod 279:123869. https://doi.org/10.1016/j.jclepro.2020.123869

Restrepo A, Bazzo E, Miyake R (2015) A life cycle assessment of the Brazilian coal used for electric power generation. J Clean Prod 92:179–186. https://doi.org/10.1016/j.jclepro.2014.12.065

Roychoudhury S, Khanda DK (2016) Application of Life Cycle Assessment (LCA) in coal mining. 6th Asian Mining Congress, pp 23–26

Schreiber A, Zapp P, Markewitz P, Vogele S (2010) Environmental analysis of a German strategy for carbon capture and storage of coal powe rplants. Energy Policy 38:7873–7883. https://doi.org/10.1016/j.enpol.2010.09.006

Sengupta D (2017) Coal India looks to cut power producers’ transport costs. The Economic Times: Industry Retrieved from https://economictimes.indiatimes.com/industry/indl-goods/svs/metals-mining/coal-india-looks-to-cut-power-producers-transport-costs/articleshow/61192411.cms?from=mdr

Shah B, Unnikrishnan S (2020) Model for life cycle sustainability assessment of coal based electricity generation in India. Research Square. https://doi.org/10.21203/rs.3.rs-223443/v1

Singh U, Rao A (2016) Techno-economic assessment of carbon mitigation options for existing coal-fired power plants in India. Energy Procedia:326–335. https://doi.org/10.1016/j.egypro.2016.11.200

Singh U, Sharma N, Mahapatra S (2016) Environmental life cycle assessment of Indian coal-fired power plants. Int J Coal Sci Technol 3(2):215–225. https://doi.org/10.1007/s40789-016-0136-z

Srinivasan S, Kholod N, Chaturvedi V, Ghosh P, Mathur R, Clarke L, Sharma K (2018) Water for electricity in India: A multi-model study of future challenges and linkages to climate change mitigation. Appl Energy 210:673–684. https://doi.org/10.1016/j.apenergy.2017.04.079

Sultan H, Bhatti UH, Muhammad HA, Nam SC, Baek IH (2021) Modification of post-combustion CO2 capture process: a techno-economic analysis. Greenhouse Gases Sci Technol 11(1):165–118. https://doi.org/10.1002/ghg.2042

Tang L, Yokoyamaa T, Kubota H, Shimota A (2014) Life cycle assessment of a pulverized coal-fired power plant with CCS technology in Japan. Energy Procedia 63:7437–7443. https://doi.org/10.1016/j.egypro.2014.11.780

Transmission and Distribution in India (2017) POWERGRID. Retrieved from https://npti.gov.in/sites/default/files/download-document/world_energy_council_report.pdf.

Wang Y, Pan Z, Zhang W, Borhani TN, Li R, Zhang Z (2022) Life cycle assessment of combustion-based electricity generation technologies integrated with carbon capture and storage: A review. Environ Res 207:112219. https://doi.org/10.1016/j.envres.2021.112219

WorldData.info (2022) Retrieved from https://www.worlddata.info/asia/india/climate.php#:~:text=The%20climate%20in%20India%20is,of%20the%20country%20is%20Rajasthan

Yu P, Luo Z, Wang Q, Fang M (2019) Life cycle assessment of transformation from a sub-critical power plant into a polygeneration plant. Energy Convers Manag 198:11180

Yujia W, Zhaofeng X, Zheng L (2014) Lifecycle analysis of coal-fired power plants with CCS in China. Energy Procedia 63:7444–7451. https://doi.org/10.1016/j.egypro.2014.11.781

Zhang Y, Zheng C, Liu S, Qu R, Yang Y, Zhao H, Yang Z, Zhu Y, Gao X (2019) An investigation of SO3 control routes in ultra-low emission coal-fired power plants. Aerosol Air Qual Res 19(12):2908–2916. https://doi.org/10.4209/aaqr.2019.09.042

Author information

Authors and Affiliations

Contributions

Satyajit Malode: conception, data collection, analysis, interpretation, and drafting the article. Ravi Prakash: review, editing, and supervising the work. Jagdish Chandra Mohanta: supervision and review of work.

Corresponding author

Ethics declarations

Ethical approval

The authors declare that this material is the authors’ own original work, which has not been previously published elsewhere.

Consent to participate

The authors understand that their participation is voluntary and that they are free to withdraw at any time and authors voluntarily agree to take part in this study.

Consent for publication

The authors give their consent for the publication of identifiable details, which can include case history and details within the text to be published in the above Journal and Article.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Loubet

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Malode, S., Prakash, R. & Mohanta, J.C. A life cycle assessment of coal-fired thermal power plants with post-combustion control techniques: an India scenario. Environ Sci Pollut Res 30, 90639–90655 (2023). https://doi.org/10.1007/s11356-023-28447-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-28447-3