Abstract

Supply chain disruption caused by environmental uncertainty makes it more difficult for firms to obtain sustainable competitive advantages (SCA). Based on the perspective of dynamic capability, this study explored the effect of three dimensions of supply chain resilience (SCR) (proactive capabilities, reactive capabilities and supply chain design quality) on SCA. In addition, we further adopted operational vulnerability (OV) as a mediated variable to construct a conceptual framework and propose research hypotheses. The theoretical hypotheses were empirically developed based on a survey of 305 firms in China’s manufacturing industry and subsequently tested. Our findings indicate that taking proactive action, properly configuring supply chain systems, and developing rapid reaction capabilities to recover from disruptions provide companies an opportunity to improve and to obtain SCA. Finally, the paper offers managers a management framework and dynamic strategy with which to develop SCR and alleviate the negative impact of OV, thus contributing to a firm’s SCA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Increasing globalization has promoted the worldwide spread of the supply chain business. On the one hand, enterprises can gain competitive advantages through the optimal allocation and utilization of resources. On the other, the links of the supply chain network continue to increase and become more complex. The environment in which firms operate has become more vulnerable, and slight disturbances in the external environment will disrupt the supply chain (Srinivasan et al. 2011). According to the International Monetary Fund (IMF), the COVID-19 outbreak exerted a severe impact on Chinese enterprises and their supply chains over a short period. China’s GDP growth in 2020 will be 1.2%, a decrease of 4.9% from the previous year, resulting in a loss of approximately $4.8 trillion. This Black Swan Event has caused many problems, such as labour shortages, increasing costs, cash-flow problems and increased supply chain uncertainty, which have irreversibly affected the global supply chain (Verma and Gustafsson 2020). As reported in the UK by the Financial Times, American and European automakers found themselves facing the threat of supply chain disruption within mere weeks due to a shortage of Chinese parts, and global industries and companies were threatened by the necessity of making adjustments. The environmental uncertainty posed by COVID-19 represents a crucial challenge to the survival and sustainable development of enterprises. Hence, it is critical to understand how to reduce the negative impact of supply chain disruption on business performance and, at the same time, to gain sustainable competitive advantage (SCA).

Previous studies present a variety of discussions on SCA acquisition. From the perspective of competitive strategy, Porter (1985) argued that enterprises can establish strong competitive advantages through innovation. If enterprises are not prepared to relinquish existing advantages and strive for new ones, they will be replaced by competitors. Subsequently, a resource-based view emerged that distinguished temporary competitive advantage from SCA, arguing that enterprises with strong market positions can only obtain a temporary competitive advantage, while enterprises require various resource elements to obtain SCA (Barney 1991; Teece et al. 1997). Because these element combinations are difficult to parameterize and occur within a process of obtaining and enhancing competitive advantages, traditional core competence theory and resource theory exaggerate the intrinsic characteristics of enterprises without focusing on which resources and capabilities enterprises need. As environmental uncertainty continues to increase, the competitive advantage of any enterprise will not last forever. Only by paying attention to and proactively predicting changes in the environment while developing and creating unique capabilities can an enterprise maintain its vitality. Therefore, enterprises require dynamic capabilities, with which they can effectively use the resources and core capacities they possess, update their abilities according to changes in the internal and external environments and take advantage of potential market opportunities, which represent the source of SCA (Teece and Pisano 1994; Winter 2003).

Supply chain resilience (SCR) has become an indispensable dynamic capability for the development of enterprises in unexpected situations in which environmental uncertainty continues to increase and disruptive events may suddenly negatively affect enterprises (Hohenstein et al. 2015; Ali et al. 2017). Through the establishment of SCR, enterprises can manage the threat of supply chain disruption and recover their original operating level (or reach a better state) at a certain speed within a certain period of time, thus improving the relationship between supply chain partners and obtaining SCA (Wieland and Wallenburg 2013; Roberta Pereira et al. 2014; Hohenstein et al. 2015). The research on SCR focuses on the definition, SCR promotion strategy and the impact of SCR on supply chain performance. SCR is understood to possess two dimensions: the capability dimension and the vulnerability dimension (Macdonald et al. 2018). Regarding the capability dimension, often-cited factors are prediction, adaptation, response, recovery and the ability to learn (Closs and McGarrell 2004; Wieland and Wallenburg 2013; Roberta Pereira et al. 2014; Kamalahmadi and Mellat-Parast 2015; Brusset and Teller 2017). Different scholars place different emphases on one or the other dimension of SCR, and there is no unified view regarding the separation between dimensions. Previous research has focused on how to improve SCR and explored factors relevant to this goal, such as supply chain flexibility (Cheng and Lu 2017), agility (Dubey et al. 2018), visibility (Wang et al. 2017) coordination (Dabhilkar et al. 2016), good interenterprise relations (Wieland and Wallenburg 2013), resilience in supply chain structure design (Birkie et al. 2017) and cultivating a supply chain risk management culture (Macdonald et al. 2018); the function and value of SCR have been relatively ignored. The impact of SCR is mainly considered from the perspective of performance (Brandon-Jones et al. 2014). Here, there are two main types of study. The first type only considers the impact of SCR on enterprise financial performance (Pettit et al. 2010; Li et al. 2017). The second typically uses customer satisfaction, customer loyalty, corporate image or other indicators to measure operational performance, an approach that exhibits certain limitations (Karl et al. 2018). SCR can effectively improve supply chain performance and resistance to supply chain disruption. However, in addition to survival, enterprises desire to maintain continuous performance levels and gain competitive advantage under supply chain disruption. Yet, there are few studies on the impact of SCR on SCA. Therefore, from the perspective of dynamic capability, this paper constructs a theoretical framework with which to study how SCR affects the SCA of enterprises. This endeavour has strong theoretical and practical significance.

The structure of the paper is as follows: “Conceptual framework and research hypothesis” presents the theoretical background and defines the conceptual approach by reviewing the literature and developing appropriate hypotheses. “Methodology” describes the paper’s methodology, describing the main strategies that were adopted and the approach to data collection. “Results” analyses the obtained results through hypothesis testing. “Conclusions and implications” discusses the conclusions, states the limitations of the paper and suggests future lines of research.

Conceptual framework and research hypothesis

Supply chain resilience based on dynamic capability theory

In the supply chain field, SCR generally refers to enterprises’ capability to be alert, respond quickly and adapt to changes caused by supply chain disruptions. However, scholars often refer to “the systematic capability of the supply chain to recover in time or reach a new and more ideal state when a disturbance occurs” (Christopher and Peck 2004) in defining resilience. Resilience is described as an adaptive phenomenon and viewed as an emerging phenomenon. At present, defining SCR has attracted increasing attention from scholars. Most such studies are performed from the perspective of capability, mainly including the topics of flexible capability (Kamalahmadi and Mellat-Parast 2015), responsiveness (Roberta Pereira et al. 2014; Chowdhury and Quaddus 2016) and recovery (Closs and McGarrell 2004; Wieland and Wallenburg 2013; Chowdhury and Quaddus 2016). Closs and McGarrell (2004) were the first to propose a definition of SCR, arguing that supply chains can withstand and recover from destructive events. Pettit et al. (2010) defined resilience as a balanced state consisting of vulnerability and capability. Chowdhury and Quaddus (2016) defined SCR as the supply chain’s capability to prevent supply chain disruption by improving the level of flexibility and to respond quickly to and recover from disruption. Many scholars have discussed the definition of SCR from different perspectives. However, a unified understanding remains lacking. Therefore, views based on dynamic capability theory (Teece et al. 1997) have emerged. Dynamic capability theory (Teece et al. 1997) evolved from the resource-based view (RBV), which concerns responding to a rapidly developing and changing market environment. The characteristics of dynamic capability theory make the study of SCR more applicable. First, using SCR can help enterprises establish knowledge creation practices in a dynamic environment, which is the basic dimension of dynamic capabilities. Second, the use of SCR also reflects the characteristics of dynamic capabilities: the commonality and specificity of key features. The commonality of key characteristics refers to the fact that there are already many identifiable common “best practices” that help enterprises implement SCR for various purposes. The complexity involved means that SCR cannot be applied in the same way across different enterprises. Considering the complexity of different supply chain management processes, SCR must be embedded and integrated into specific supply chain processes when applied. The resilience of the supply chain varies according to different degrees of risk. Each supply chain has its own limits in its matching ability to prepare for emergencies as well as the potential to quickly interrupt its response and can be restored to its original state. In addition, it can lead to a new, more ideal state of customer service while helping increase market share and improve financial performance (Hohenstein et al. 2015). Different scholars place different emphases on how to define the dimensions of SCR, which can be summarized as a focus on the internal and external supply chains, the supply chain structure and the supply chain function. However, there is no unified view of the matter. Table 1 summarizes the opinions of various scholars and presents representative viewpoints regarding the dimensions of SCR.

Based on the definition of Chowdhury and Quaddus (2017) and on the framework of dynamic capability (perception-grab-reconstruction) (Teece 2007), this paper focuses on three SCR dimensions: proactive capabilities, reactive capabilities and supply chain design quality.

-

1.

Proactive capabilities

The proactive capabilities of the system refer to its capabilities to respond to changes in risks before identifying, predicting, and preventing adverse consequences. Proactive strategies can help companies avoid or reduce the possibility of disruptions. Research in the SCR field emphasizes different proactive capabilities, such as redundancy capability, robustness, collaboration, integration, and visibility (Pettit et al. 2013; Pal et al. 2014). Jüttner and Maklan (2011) focused on proactive capabilities such as flexibility, visibility and collaboration. Chowdhury and Quaddus (2017) explored proactive capabilities from seven perspectives: supply chain preparation, flexibility, storage capacity, integration, efficiency, market advantage and financial strength. Based on the dynamic capability research framework developed by Teece (2007), Christopher and Peck (2004) noted that “Visibility” is unified with “Perception” in the supply chain; based on the former, one can monitor the up- and downstream stock, supply conditions, and production and procurement information. Visibility has always been emphasized as essential to risk and disruption management (Kauppi et al. 2016). Lee and Rha (2016) regarded “Visibility” as the perception stage in the process of dynamic capability. Following them, this paper regards proactive capabilities as the perception stage of dynamic capability. Such capabilities are helpful in enhancing the dynamic capability of the supply chain and improving operational capability (Ponomarov and Holcomb 2009).

-

2.

Reactive capabilities

Prior studies have considered SCR as a combination of proactive and reactive capabilities. Supply chain response focuses on mitigating disruptions in the shortest periods and with minimal losses. When disruption occurs, the capability to respond to market demands in a timely manner is one determinant of SCR (Wieland and Wallenburg 2013; Teece et al. 1997). Specifically, this capability also represents a unique source of competitive advantage in responding to environmental uncertainty quickly (Teece 2007). After “the sensing stage” of dynamic capability, one enters the process of “seizing”, which includes the capability to make timely decisions to develop new opportunities (Kamalahmadi and Mellat-Parast 2015; Christopher and Peck 2004). Swafford et al. (2006) observed that “agility” is consistent with “seizing” in the process of dynamic capability. Agility is the capability of the supply chain to respond to the dynamic market in a timely, accurate manner, which is convenient for gaining competitive advantages. As previously mentioned, this study identifies the “seizing” process of dynamic capability as reactive capabilities, i.e., abilities to quickly respond to market demands and achieve effective integration with supply chain partners.

-

3.

Supply chain design quality

Reconfiguration involves managing and reforming an enterprise using innovative development consciousness and existing enterprise capabilities. Ponis and Koronis (2012) described SCR as the ability of the supply chain to proactively plan and design its network to prevent and respond to disruptions effectively. A supply chain can adapt to environmental uncertainty by relying on the reconfiguration capability and achieving a better stable state, thereby improving the enterprise’s performance and competitive advantage. Barroso et al. (2011) emphasized the role of recovery speed and proposed that redesigning the supply chain can reduce the impact of disruptions and improve SCR adaptability. Eckstein et al. (2014) noted that the supply chain setting and redesigning enable companies to perceive changes and long-term effects of the supply chain and environment (e.g. economic progress, political and social changes, demographic changes and radical technological progress). Certain actions (e.g. developing new supply bases, relocating production facilities, outsourcing) can help improve the rapid response to external impacts and to improve adaptability. Chowdhury and Quaddus (2017) further studied the quality of supply chain design in terms of node density, complexity and node criticality. Against this background, this paper defines the final process, i.e. the “reconfiguration” of dynamic capability, as supply chain design quality. A high-quality supply chain design can maintain high performance while reorganizing the assets, strategies and operations of the supply chain and adapting to changes (Jüttner and Maklan 2011).

Operational vulnerability

In 1974, the concept of “vulnerability” was first proposed by American scholar GF White. In his book Natural Hazards, White refers to a measure of dependence on international political and economic relations. Since then, vulnerability has been widely studied in the natural sciences. In the field of management, “vulnerability” refers to a weakness in enterprise assets that may be affected by external factors and thus cause losses. For example, after the 1989 San Francisco Bay earthquake, it was estimated that 50% of small businesses were directly affected and paralysed for a long period. The resulting unemployment severely affected the region’s economy.

The operational vulnerability (OV) of the supply chain is a relatively new research field. The research is not yet mature, and there is no unified conceptual framework. Nevertheless, scholars have defined OV based on their research directions. OV is caused by enterprises’ overdependence on business time and organizational unit relations in the supply chain in their operational activities. The degree of vulnerability can be interpreted as the degree of such dependence, and vulnerability is directly proportional to the negative consequences of such dependence. Christopher and Peck (2004) provided a specific definition of OV, arguing that OV is a characteristic of a supply chain that is vulnerable to external interference and will exert adverse effects on enterprises. However, the premise of high vulnerability in the operation process of a supply chain is that the supply chain itself has complexity and uncertainty, which affect the probability and degree of occurrence of a disruption and give OV an obvious promoting effect on the disruption of the supply chain. OV is not only the result of environmental turbulence but to a large extent can be explained by the design of the supply chain. Wagner and Neshat (2010) concluded that the source and cause of OV could be studied in depth in terms of both internal and external enterprises.

From the perspective of external enterprises, a single enterprise supply source and overdependence on suppliers and customers directly affect organizational activities. Especially when the competitors of cooperative organizations undertake vertical integration, enterprises will face the risk of supply chain disruptions. In addition to a firm’s relationship with partner organizations, raw material and product issues, such as substandard quality and late delivery, also lead to high levels of vulnerability (Silvis et al. 2017). Product quality is not the only problem. Product characteristics, especially the product life cycle, exert pressure on the production of the supply chain, leading to a high degree of vulnerability (Tubis et al. 2017). External factors also include major changes in the ecological, economic and political environment. Catastrophic events, such as earthquakes and tsunamis, can lead to high levels of vulnerability and supply chain disruptions. Policy promulgation and social recognition of products are also factors that cannot be ignored. From the internal perspective of enterprises, the policies formulated by enterprises for the supply chain and the actual operation of the supply chain have an impact on the vulnerability of the supply chain (Christopher et al. 2006), which is fundamentally due to the globalization trend of product value-added activities and the differentiation of the supply chain. In the supply chain, infrastructure, as the basis of operation, has become an essential factor affecting OV. Imperfect infrastructure cannot support advanced technology and other operational activities, leading to a high degree of vulnerability (Kurniawan et al. 2017). The literature also reveals multiple factors that influence OV, such as utility crises, poor quality, supply issues due to the loss of key suppliers or problems in supplier plants, logistics models and route disruptions, as well as IT system failures (Blos et al. 2009). If these vulnerability factors are not addressed in time, the operation of the entire supply chain system can be seriously affected (Ponomarov and Holcomb 2009). The combination of risk and source of OV will lead to an increase in OV. Juttner and Maklan (2011) explored the OV represented by a supply chain system and found that it was a potential state that would become apparent only when a disruption event occurred.

OV can capture the risks that supply chains may face. Thus, researchers often examine it along with supply chain risks. Christopher and Peck (2004) believed that OV was a risk possibility and resulted in sensitivity of the supply chain in the face of disruptions. The more obvious that the OV of the supply chain is, the greater the severity of the loss caused by the disruption event. OV can be effectively measured by the exposure of supply chain systems to environmental, supply network and organizational risks. According to that discussion, OV in this paper can be defined as follows: in the operation of a supply chain, enterprises have the possibility of being damaged by potential internal and external risks and disruption events.

Sustainable competitive advantage

SCA refers to a firm investing in and adopting strategies to gain long-term operating benefits, while its existing or potential competitors are not adopting such strategies or would not obtain the same benefits if they were adopted. A firm’s competitive advantage consists of two parts: the source of competitive advantage (i.e. market position or resources) and the result of competitive advantage (i.e. performance in terms of profitability). Recently, based on the idea of dynamic capability, research has focused on how firms face dynamic and rapidly changing environments. Adopting a case study method, Datta (2017) explored how to combine supply chain strategies with relevant supply chain practices to improve business performance in a changing environment. As previously mentioned, the present paper is based on dynamic capability and defines SCA in terms of firms that adapt their capabilities and resources to dynamic and complex environmental changes and implement key strategies to exceed their competitors in terms of long-term, sustained benefits. Several studies have used market performance as a nonfinancial indicator to explore variables that affect competitive advantages, such as sales growth and customer sustainability, net profit and the capitalization rate (Cao et al. 2018). Therefore, to avoid the deficiency of simple financial performance measurement, this paper measures a firm’s SCA in the two dimensions of sustainable market performance (SMP) and sustainable financial performance (SFP) (Cao et al. 2018).

Research hypothesis

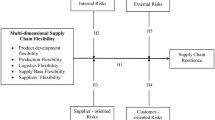

Dynamically reconfiguring resources and refactoring capability of enterprises according to environmental uncertainties could contribute to competitive advantages. According to the theory of dynamic capabilities, Teece (2007) developed a dynamic capability to establish a comprehensive and integrated framework, including perceived opportunities and threats and seizing the opportunity to reconfigure the tangible and intangible assets of the enterprise. The construction of dynamic capability provides favourable conditions for enterprises to obtain sustainable competitiveness, that is, to match the operation status of the contemporary market and create a continuous direction of development capability. Enterprise organizations lack, but require, such dynamic capabilities to accurately and promptly respond to losses and disasters caused by risk and disruption events, thus enabling enterprises to improve SCA. Dynamic capability is a source from which enterprises can obtain SCA in a dynamic changing environment. SCR, a dynamic capability, can respond to dynamic environmental changes from the three perspectives of perception, grasp and reconfiguration, thus improving enterprise performance and promoting the acquisition of competitive advantages. At present, research is scarce regarding how SCR affects SCA and how to improve SCA from the perspective of dynamic capability. Therefore, based on dynamic capability, this paper explores the relationships between the three dimensions of SCR (proactive capabilities, reactive capabilities and supply chain design quality) and firm SCA. Adopting SCR as the independent variable and SCA as the dependent variable, Fig. 1 depicts the conceptual framework.

Supply chain resilience and sustainable competitive advantage

A supply chain requires proactive capabilities against disruptions. The resilience of a system is the capability to identify, predict and defend against risks prior to a negative impact. A critical factor in building SCR is the capability to respond to competition in a timely manner in a crisis (Spiegler et al. 2015). Exploring the resilience of successful companies during the global financial crisis, Jüttner and Maklan (2011) observed that firms with resilience can respond to environmental change more quickly than firms without resilience. The real interests behind resilience, which is a comprehensive system at the strategic level. Resilience is not only a defensive response to disruptions but also a proactive means to transform a disruption into SCA. Most studies have defined proactive capabilities as preventive and as reflecting “The 3Rs of building resilience”: readiness, response and recovery (Manning and Soon 2016).

Reactive capabilities focus on the response to disruptions when a firm in unprepared. In a system, a firm can adopt resilience practices as operational or strategic capabilities (Brusset and Teller 2017). Studies have suggested that the reactive capabilities of resilience can be based on the response to and recovery from disruptions. The relevant practices of reactive capabilities are manifested in operational practices, while proactive capabilities are manifested in strategic practices; thus, firms can adjust their operational activities to gain a competitive advantage (Brusset and Teller 2017; Sheffi and Rice 2005; Ponomarov and Holcomb 2009).

In addition to proactive and reactive capabilities, certain research findings also emphasize that supply chain design quality is an important part of the SCR building process. One definition of SCR is the capability of the supply chain to proactively plan and design its network to predict and respond to disruptions. The critical factor of success in supply chain management is to choose the appropriate strategy and build capability in designing the supply chain. In supply chain design, there are not only proactive behaviours but also reactive ones. However, when the supply chain responds to environmental changes, firms must be reactive in designing their supply chains using practical experience of supply chain disruptions. As previously mentioned, hypotheses regarding the relationship between SCR and SCA are proposed in Table 2.

Supply chain resilience and operational vulnerability

Resilience is closely related to OV because resilience is the inherent ability of a system to adjust its functionality before, during or after change and disruption so as to maintain required operations in both expected and unexpected circumstances. A supply chain forms an organizational network by connecting up- and downstream elements and participating in different processes and activities related to products and services (Christopher 1998). In an uncertain risk environment, the operation of the supply chain may be threatened and become increasingly fragile. Resilience is an obvious solution to this problem, and resilience is consistent with the view that the “supply chain is regarded as an interactive network”. As a result of increasing globalization, supply chain development faces many uncertain internal and external factors. For example, the economic impact of the fuel protests in the UK in 2000 and the outbreak of hand-foot-and-mouth disease early the following year attracted the attention of relevant national policy-makers, and the OV faced by the commercial supply chain was frequently mentioned. As noted regarding the source of OV, there is not only one cause of high vulnerability. As globalization increases, supply chains face many types of unknown risk. Such emergencies increase the vulnerability of a supply chain to varying degrees. In addition, certain studies argue that OV is closely related to supply chain risk in today’s market. Therefore, OV mitigation has become a concern of many enterprises. The challenge facing enterprises today is to coordinate the relationship between OV and risk and reduce the probability of risk occurrence by constructing a supply chain that can prevent and cope with a series of risks.

Christopher and Lee (2001) described the complexity of the supply chain network and proposed “visibility, speed and control” as the critical elements of risk management to reduce OV. OV mitigation requires determining specific strategies based on risks with high impact and proposing relevant mitigation strategies from the perspectives of demand, supply and various risks. Effective risk management by enterprises can enhance SCR to mitigate the effects of OV. Sheffi and Rice (2005) assessed the nature of a supply chain and argued that an effective strategy is to improve its resilience and flexibility. Increasing the flexibility of the supply chain can facilitate flexible reactions according to different situations and avoid supply chain disruption so that when a supply chain is subjected to impact, high SCR can maintain the supply chain’s basic functioning and enable normal supply chain operation. Thekdi and Santos (2015) note that OV analysis helps prioritize resources for business projects that improve resilience, thereby minimizing possible future economic losses. Previous studies have confirmed the negative impact relationship between SCR and OV (Juttner and Maklan 2011; Ponomarov and Holcomb 2009; Chowdhury and Quaddus 2017). If SCR reduces the negative consequences of supply chain risk events by ensuring a quick return to the original state or improving operations, this means that SCR can reduce supply chain OV. Based on the preceding arguments, this paper proposes corresponding assumptions regarding OV from three perspectives of the supply chain dimension (Table 2).

Operational vulnerability and sustainable competitive advantage

Accidents, such as disruption events, are common problems in supply chain management and a manifestation of OV. To compete effectively in the market, firms constantly pursue the maximization of efficiency and speed. Such behaviours may increase the possibility of supply chain disruptions. When competition is severe and the environment is fragile, not only is supply chain development affected. An impact on the competitive advantage of enterprises is also inevitable. Currently, “how to mitigate the impact of supply chain OV on enterprises” has become a concern of scholars and managers. Therefore, enterprises must critically assess the consequences of OV if they are to gain SCA in a world of frequent disruptions.

The complexity of the supply chain itself makes the supply chain more vulnerable, which will undoubtedly affect the normal operation of enterprises. Therefore, enterprises with high OV may incur a higher risk of disruption due to the existence of vulnerability. When the OV level is high, it is difficult for enterprises to cope with the adverse effects brought by emergencies. They can no longer guarantee the normal operation of the enterprise supply chain, thus leading to a decline in supply chain performance. Kurniawan et al. (2017) found that supply chain efficiency could be improved by reducing the impact of OV. When discussing the contradiction between supply and demand on the current public health issue of COVID-19, Chen (2020) noted that to reduce the risk of the supply chain, the weakest link of supply risk must be identified first, and corresponding measures should be adopted to strengthen the control of this link. For example, security redundancy should be increased and good cooperation with suppliers should be maintained. To achieve the operational goals of enterprise managers and improve SCA, the key is to mitigate the impact of OV. Based on these views, this paper proposes the following hypotheses regarding the relationship between OV and SCA (Table 2).

Mediating effect on operational vulnerability

OV will bring significant inherent and external risks to the operation of the supply chain system and cause dependence on time and relationships in the supply chain system. However, a supply chain with resilience can mitigate the negative impact of these risks. For example, Ericsson lost nearly $400 million in assets when its supplier’s semiconductor factory caught fire. The increase and decrease in oil prices in 2000 affected much of the supply-side network of British firms. An enterprise’s administration is responsible for managing, maintaining and operating the infrastructure of the enterprise, winning a profit for the enterprise and funding the development of the society. When an organization is faced with an unexpected event (such as a major disaster), the continuous operation capability of the organization will have an important impact on how long basic organization services cannot be provided and the recovery time of the entire system. Supply chain disruption events can even involve the worsening of enterprise performance.

In the process of improving and increasing supply chain performance, enterprises are affected by globalization and technological innovation, resulting in uncertainty and complexity in the market environment and supply chain risk increases accordingly. Here are three examples: because of an error in market demand forecasting, excess inventory increases the storage cost; a change in the international situation will cause turmoil in the raw material market, and price fluctuation increases the procurement cost of enterprises; natural or man-made disasters disrupt the flow of supply chain systems, resulting in system disruptions. Many studies have proven that OV caused by supply chain disruption events negatively affects the financial performance, market performance, product quality and customer satisfaction of enterprises. Using mitigation strategies can enable enterprises to effectively manage operational risks, maintain the normal operation of the supply chain and promptly recover from disruptions (Tang 2006). Mitigating OV is the key to improving SCR (Christopher and Peck 2004; Ponomarov and Holcomb 2009; Pettit et al. 2013).

According to the literature, there is a positive correlation between SCR and supply chain performance (Pettit et al. 2013; Chowdhury and Quaddus 2017), and having a more resilient organization is a key component of transforming into a more resilient enterprise. Resilient supply chains can be created by managing factors that lead to OV. SCR is enhanced with the improvement of capacity and the reduction of OV (Pettit et al. 2010). By mitigating OV, the development of resilience can be achieved by reducing economic losses to maintain supply chain performance (Chowdhury and Quaddus 2017). Therefore, enterprises should build resilience in the development of the supply chain to mitigate OV (Kurniawan et al. 2017). First, the proactive establishment of an SCR strategy can reduce the possibility of supply chain disruption and thus reduce OV. By mitigating OV, economic losses can be reduced to maintain supply chain performance. Ponomarov and Holcomb (2009) argue that SCR can improve the connectivity and control of supply chain structure and function, maintain the continuity of operation, cope with emergencies, respond to fractures and recover from them. Companies redesign their supply chains based on their experience with supply chain disruption events to ensure that OV is mitigated from the supply side in complex, uncertain situations.

Bode et al. (2011) argue that supply chain disruption may reduce an enterprise’s overall efficiency, product quality, adaptability to customer demand and sales and delivery reliability while increasing costs and prices. If an enterprise does not promptly implement strategic control to manage supply chain risks, it may be unable to maintain its financial performance and market performance because the negative impact of supply chain disruption will affect SCR and further aggravate the negative effect of enterprise performance. The relevant literature finds that OV caused by disruption affects enterprises in two main respects: financial and market. “Financial impact” refers to the monetary cost caused by the impact of the disruption; “market impact” often occurs during the period of operation disruption, when enterprises cannot devote as much energy to meet customer demand as they would in a normal operation environment. To achieve the goal of restoring operational status, these negative impacts and their corresponding costs must be minimized. A resilient supply chain can cushion these negative impacts. The establishment of the strategy of supply chain flexibility can eliminate excess inventory, reduce the response time of the supply chain, adjust the production plan, improve product quality according to the requirements of users, maintain the steady growth of supply chain performance (Kurniawan et al. 2017) and positively affect the enterprise’s financial performance, market performance, product quality and customer satisfaction. Therefore, this paper argues that OV plays a mediating role in the relationship between SCR (initiative capability, response capability and supply chain design quality) and enterprise SCA. Corresponding research hypotheses are proposed in Table 2.

Methodology

Sample and data collection

The research questionnaires were distributed and collected by email. Beginning January 2019, they were mainly sent to manufacturing companies located in Shaanxi, Jiangsu, Guangzhou, Shanghai, Chongqing, Suzhou, Shanxi and other cities in China, including the Shaanxi Drum Group, Shaanxi Automobile Group, BYD Company, Foxconn Technology, Samsung Electronics Co., Ltd., and other enterprises. By May 2019, we obtained 305 reliable questionnaires from an initial 365 surveys, with an effective rate of 83.4%. The survey respondents included department managers, project managers, purchasing specialists, technical engineers, supply chain planners, supply chain supervisors and production process personnel. More than 70.8% of the surveyed individuals had been engaged in their occupations for more than 3 years. Thus, in line with the requirements of this study, the surveyed individuals possessed substantial work experience in supply chain management.

Because nonresponse bias interferes with the statistics estimated by a model, to test for nonresponse bias, we compared the difference in number of employees between the questionnaires completed during the early study period with those completed during the later period using the T test. We found no significant nonresponse bias in the sample, indicating that there is no response bias in this study.

Measures

The scale of this paper has been revised based on the relevant literature and further revised in consultation with experts in related fields. Each item uses the Likert five-point scale method, where 1 means high nonconformance and 5 means complete conformity.

To collect research data by questionnaire survey, the measured variables must be transformed from abstract to measurable index variables. The questionnaire in this paper consists of four parts: an SCA scale, an SCR scale, an OV scale and basic enterprise information. Two main methods were used in designing the scale. (1) Based on previous related research, we directly adopted mature scales successfully applied by other scholars, while requiring the adopted scales to be universal. (2) In scale items used in previous relevant studies performed in foreign settings, several items or research focuses unsuitable for Chinese national conditions and research were modified to make them appropriate for the circumstances of this study or deleted. In addition, and the measurement indicators of certain variables were adjusted to suit the scale and items employed in this study.

SCA

Sustainable competitive advantage (SCA) was measured by respondents’ perceived performance relative to their main competitors over the past 3 years using four items from previous studies (Wagner et al. 2012; Prajogo et al. 2012). Using perceptual measures to obtain SCA may raise questions regarding its effectiveness, but past studies have shown that this approach is consistent with objective performance indicators (Gligor et al. 2014). The operational definition scale for SCA is divided into two dimensions, sustainable financial performance (SFP) and sustainable market performance (SMP), with four questions (Table 3).

SCR

Proactive capabilities are reflected in the subdimensions of supply chain readiness, flexibility, reserve capacity, integration and market advantage. These subdimensions are interrelated and complementary. Improving flexibility, reserve capacity and integration is crucial. In addition, integration and redundancy capabilities are related. Response and recovery are subdimensions of reactive capabilities. Supply chain design quality can be divided into density, complexity and criticality. The questionnaire consists of 19 items, of which proactive capabilities were addressed by 7 items and reactive capabilities by 5 items. The remaining 7 items addressed supply chain design quality (Table 4).

OV

This study draws on the operational vulnerability (OV) scale of Chowdhury and Quaddus (2017) to focus on the mediation effect. The operational definition of the variable is addressed by 6 items, and each item is measured by a Likert five-level scale (Table 5).

Control variables

Due to the relationship between establishment age, firm scales and customer relationships in the supply chain, we adopted the age and size of enterprises as control variables. This study controls the firm’s age and size, which is measured by the operational years of companies and consists of employees, annual sales and total assets.

Reliability and validity test

Based on the data from the 305 valid completed surveys, the reliability and validity of the scales are analysed using confirmatory factor analysis (CFA), and the quality of the sample data is evaluated based on the results.

Reliability analysis of scale

According to the analysis results, the Cronbach’s α values of SCA, SCR and OV are all larger than 0.700, indicating that the fit of the scale is good. As shown in Table 6, the CR values are all in line with CR > 0.700, and the AVE values are greater than 0.500, indicating acceptable internal consistency of the scale. These outcomes imply a high level of reliability in the measurement indicators.

Validity analysis of scale

Confirmatory factor analysis (CFA) was performed using AMOS software to evaluate the fit index for each scale (Table 7) and then to evaluate the fitting effect of the entire measurement model. The analysis results indicate that the fit is good.

Results

Pearson correlation analysis

SPSS 20.0 was used to obtain the descriptive statistics and Pearson correlation analysis results of each variable (Table 8). SFP is significantly related to SCR’s proactive capabilities, reactive capabilities, and supply chain design quality. Hypotheses H1a, H2a, H3a, H1b, H2b and H3b are preliminarily verified, as are the three dimensions of SCR. OV is significantly correlated, if one assumes that H4a, H4b and H4c have been initially verified. The two dimensions of SCA have an obvious correlation with OV and, assuming H5a and H5b, we can state that they have been initially verified.

Hypothesis testing

Main hypothesis testing

Effect of SCR on SCA

According to Tables 9 and 10, proactive capabilities (MF1, β = 0.361, p < 0.001), reactive capabilities (MF2, β = 0.273, p < 0.001), supply chain design quality (MF3, β = 0.330, p < 0.001) and SFP have a significant positive relationship. H1a, H2a and H3a are verified. Proactive capabilities (MM1, β = 0.428, p < 0.001), reactive capabilities (MM2, β = 0.242, p < 0.001) and supply chain design quality (MM3, β = 0.398, p < 0.001) have a significant positive relationship with SMP, verifying Hypotheses H1b, H2b and H3b.

Effect of SCR on OV

The regression analysis is shown in Table 11. Proactive capabilities (MO1, β = −0.341, p < 0.001), reactive capabilities (MO2, β = -0.248, p < 0.001) and supply chain design quality (MO3, β = −0.508, p < 0.001) have significant negative relationships with OV. Hypotheses H4a, H4b and H4c are verified.

Effect of OV on SCA

According to the regression results presented in Table 12, OV has a significant negative relationship with SFP (M1, β = −0.265, p < 0.001) and SMP (M2, β = −0.338, p < 0.001). H5a and H5b are verified.

Hypothesis test of the mediating effect

According to the regression results presented in Tables 9, 10, 11, 12, for the three independent variables proactive capabilities, reactive capabilities and supply chain design quality, it can be inferred that OV plays a mediating role between SCR and SCA. The mediating effect of OV will be verified using SPSS 20.0 The plug-in process is as follows. This paper is based on the method described by Hayes (2018). Bootstrapping was further used to test the mediating effect of OV. Table 12 shows the bootstrapping test results of the mediating effect of OV between SCR and SCA. Here, the dependent variables in the table are SFP and SMP, and SCR (proactive capabilities, reactive capabilities and supply chain design quality) is the independent variable. First, the mediating effect of OV on the relationship between proactive capabilities and SFP was 0.0593, with a 95% CI of 0.0188/0.1083, excluding 0. The mediating effect of OV on the relationship between reactive capabilities and sustainable financial performance was 0.0494, with a 95% CI of 0.0205/0.0844, excluding 0. The mediating effect of OV on the relationship between supply chain design quality and SFP was 0.0612, with a 95% CI of 0.0027/0.1206, excluding 0. These findings indicate that OV has a mediating effect on SCR and SFP. It was assumed that H6a, H6b and H6c were verified. Second, the mediating effect of OV on the relationship between proactive capabilities and SMP is 0.0780, with a 95% CI of 0.0377/0.1279, excluding 0. The mediating effect of OV on the relationship between reactive capabilities and SMP is 0.0680, with a 95% CI of 0.0336/0.1106, excluding 0. The mediating effect of OV on the relationship between supply chain design quality and SMP is 0.0832, with a 95% CI of 0.0271/0.1414, excluding 0. These findings indicate that OV has a mediating effect on SCR and SMP. It was assumed that H7a, H7b and H7c were verified. The mediating effect test results of OV on the relationship between SCR and SCA are shown in Table 12. Table 13 shows that OV satisfies the mediating effect between SCR and SCA.

Conclusions and implications

Findings and discussion

This paper is mainly based on dynamic capability theory, using OV as a mediating variable and constructing a relationship model between SCR and SCA. Relevant companies in the Chinese manufacturing industry were taken as a research sample to verify the hypothesis using empirical tests, and all of the hypotheses were eventually supported.

Main hypothesis results

Relationship between SCR and SCA

Our research results indicate that SCR capability can improve enterprise performance and enhance enterprise SCA. H1a, H2a and H3a are validated, and there is a significant correlation between proactive capabilities, reactive capabilities, supply chain design quality and SFP, which positively affects SFP. H1b, H2b and H3b are supported, confirming there is a significant relationship between proactive capabilities, reactive capabilities, supply chain design quality and SMP, which positively affects SMP. That is, by building SCR capabilities, enterprises can improve the relationship between supply chain partners by being prepared before risks or disruptions and return to their original operational level or better. A key element in building SCR is the ability to respond quickly to market demand in a crisis (Sheffi and Rice 2005;Wieland and Wallenburg 2013). In addition, enterprises must reconfigure their supply chains according to the frequency and impact of supply chain disruptions. Subsequent to a disruption, they can then recover to a higher level of operation while improving their SCA. In summary, SCR is a valuable capability that managers can use to help their companies achieve a SCA.

The effect of SCR on OV

The study verified H4a, H4b and H4c. According to our results, there are significant negative effects between proactive capabilities, reactive capabilities, supply chain design quality and OV. Enterprises can prepare for disruptions or risky events and reduce OVs along the entire supply chain. Effective risk management can reduce the OV of the supply chain by creating SCR. Here, proactive capability identifies, predicts and defends against adverse consequences in response to risk changes; thus, the establishment of proactive capability can reduce the basic factors of supply chain risks, including reducing OV. Response capability is based on the response and recovery capability of an organization and involves whether it can respond to disruption events in a timely manner and reduce the impact of OV. In addition, OV is derived not only from external environmental uncertainties but also to a large extent from the design of the supply chain system. Therefore, reconfiguring the supply chain can help mitigate the impact of OV. OV analysis helps in prioritizing resources for business projects that increase resilience, thereby minimizing possible economic losses in the future.

The effect of OV on SCA. H5a and H5b have passed the verification process, indicating that OV negatively impacts an enterprise’s SCA. This relationship means that the larger that a vulnerability is, the greater its potential impact on financial performance and market performance, and the less likely the firm is to achieve an SCA. Only when the operation of the supply chain reaches a balance between cost and efficiency can an enterprise achieve the goal of financial performance and market performance. Therefore, to the extent that feasibility and enterprise cost permit, the enterprise should choose a strategic approach to insulate the supply chain from any or most disasters. Supply chain operational strategy plays a key role in improving performance and makes a strategic contribution to the effectiveness of the entire supply chain. Therefore, mitigating the impact of OV is conducive to the acquisition of a SCA.

Mediating effect results

SCR is a balanced state consisting of vulnerability and capability. An increase in resilience will lead to a decrease in vulnerability (Pettit et al. 2010). When resilience and vulnerability are in balance, enterprise performance will be improved. In this paper, the intermediary effect of validation from proactive capabilities and SFP as well as proactive capabilities and SMP, reactive capabilities and SFP as well as reactive capabilities and SMP, supply chain design quality and SFP as well as supply chain design quality, and SMPs were tested in six relations. The mediating role of OV in each group of correlations is discussed separately. First, H6a, H6b and H6c were all supported, indicating that OV has a mediating effect between SCR and SFP. Any type of loss caused by OV will affect SCR, disrupt the operation of the supply chain, affect the delivery time of products and ultimately cause profit losses. When OV and SCR are in balance, OV is reduced, which improves SCR. The normal operation of the supply chain ensures a balance of cost and efficiency, resulting in the expected financial performance of the enterprise.

Second, H7a, H7b and H7c all pass the testing procedure, and OV has mediating effects on proactive capabilities, reactive capabilities, supply chain design quality and SMP. Previous research results prove that there is a negative correlation between SCR and OV and a positive correlation between SCR and supply chain performance. By building SCR proactive capabilities and improving supply chain design quality, disruption of the supply chain can be prevented. Reallocating assets and changing the organizational structure to improve the supply chain structure can relieve system vulnerability in disruption events or circumstances of risk, reduce the enterprise’s loss of market share and market growth, ensure sales growth and competitive advantage, and achieve SMP. This paper’s findings represent a useful complement to the conclusions of Chowdhury and Quaddus (2017) and are consistent with the dynamic capability view. Therefore, practitioners should enhance their awareness of OV mitigation and effectively prevent risks.

Management implications

From the perspective of dynamic capability, research on the impact of SCR on a firm’s SCA shows that in the face of risk and disruption events, enterprises should build SCR capability more proactively or passively to varying degrees and mitigate the loss caused by OV to help obtain SCA. Combining research conclusions with practical actions, this study provides the following meaningful insights.

First, the research path of the impact of SCR on enterprises’ SCA is clarified: there is currently no relevant literature on the impact of SCR on enterprises’ SCA. Most studies are focused on the impact of SCR on enterprise performance, whereby the relevant research on SCR also lacks a unified understanding of SCR’s dimensions. This paper should help managers perceive the value of SCR. Therefore, based on the dynamic capability perspective, this paper examined SCR as a dynamic capability in terms of the three dimensions proactive capabilities, reactive capabilities and supply chain design quality so as to help firms build SCR. The paper’s results also indicate that supply chain managers should undertake proactive measures to design and configure supply chain systems while developing their firms’ ability to respond to disruption events and improve SCA. For example, SCR should be preembedded in the structure design of the supply chain as a design capability, which can effectively prevent the occurrence of disruption risk. From a relationship perspective, SCR strengthens supply chain relationships through its positive performance and ensures strategic support. Directly assessing the external environment in an effort to establish a dynamic strategy is necessary if a firm is to remain fresh and vital.

Second, the findings suggest that managers pay attention to OV. It is important to control the risks that may affect the supply chain. The study can help enterprises choose mitigation strategies, with the ultimate purpose of improving supply chain management and obtaining SCA. For example, by strengthening profit sharing and risk sharing among supply chain partners and encouraging node cooperative enterprises to optimize the supply chain system and ensure the stability of the supply chain, the performance of supply chain operations can be improved.

Finally, the results also suggest that companies should continue to seek creative ways to solve supply chain problems and explore new opportunities for supply chain management to develop dynamic capabilities to adapt to environmental uncertainty. In addition, the research sample is based on the current situation of Chinese manufacturing enterprises. Our research findings can help Chinese enterprises’ supply chain managers formulate SCR strategies. Supply chain entities are often highly diverse in their industry composition and characteristics. Therefore, business managers must focus on coordinating and synchronizing the efforts of these entities. In turbulent times in the external environment, supply chain entities should cooperate more to ensure the acquisition and maintenance of competitive advantages. Managers should use SCR at the appropriate time, focus on improving their sensitivity to environmental changes, respond to environmental changes by configuring different SCR capabilities (e.g. proactive capabilities, reactive capabilities and high supply chain design quality) and monitor important performance characteristics (e.g. sales level, revenue growth rate) to obtain SCA.

Limitations and future research

Although this study provides new insights into the literature and discusses the practical implications of its findings, the following limitations might require further exploration.

The research sample is based on Chinese manufacturing companies. Therefore, the research results may not be generalized to other types of firms with different cultural backgrounds. Although the survey of a single industry has advantages, it ignores the circumstances of other industries. Certain studies have shown that industry characteristics (e.g. the nonstorable, perishable and intangible nature of the service, customer-supply duality and service heterogeneity) have a significant moderating effect on the supply chain (Noordewier and Lucas 2020). This leads to differences in the production, storage and delivery of supply chain operations. Therefore, future research can further expand the types of research sample, possibly including firms from developed countries, firms with different cultural backgrounds, and firms from different industries, so as to expand the applicability of the findings to supply chain management in different situations.

The study uses the dynamic capability perspective to explore the relationship between SCR and SCA. However, it is far from sufficient to construct the influence mechanism between SCR and SCA from a dynamic perspective. In the future, perspectives such as information processing and network structure can be considered in investigating the relationship between SCR and SCA (Wong et al. 2020; Kim et al. 2015) so as to provide more valuable suggestions for enterprises seeking to obtain SCA.

Data availability

The datasets used and/or analysed during this study are available from the corresponding author on reasonable request. All the data generated or analysed during this study are included in the text of the article.

References

Ali A, Mahfouz A, Arisha A (2017) Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag 22:16–39. https://doi.org/10.1108/scm-06-2016-0197

Azadeh A, Atrchin N, Salehi V, Shojaei H (2013) Modelling and improvement of supply chain with imprecise transportation delays and resilience factors. Int J Logist-Res App 17:269–282. https://doi.org/10.1080/13675567.2013.846308

Barney JB (1991) Firm Resources and sustained competitive advantage. Adv Strateg Manag 203–227. https://doi.org/10.1016/s0742-3322(00)17018-4

Barroso AP, Machado VH, Cruz V (2011) Supply chain resilience using the mapping approach. Supply Chain Manag. https://doi.org/10.5772/15006

Birkie SE, Trucco P, Fernandez Campos P (2017) Effectiveness of resilience capabilities in mitigating disruptions: leveraging on supply chain structural complexity. Supply Chain Manag 22:506–521. https://doi.org/10.1108/scm-01-2017-0009

Blos MF, Quaddus M, Wee HM, Watanabe K (2009) Supply chain risk management (SCRM): a case study on the automotive and electronic industries in Brazil. Supply Chain Manag 14:247–252. https://doi.org/10.1108/13598540910970072

Bode C, Wagner SM, Petersen KJ, Ellram LM (2011) Understanding responses to supply chain disruptions: Insights from Information processing and resource dependence perspectives. Acad Manag J 54:833–856. https://doi.org/10.5465/amj.2011.64870145

Brandon-Jones E, Squire B, Autry CW, Petersen KJ (2014) A contingent resource-based perspective of supply chain resilience and robustness. J Supply Chain Manag 50:55–73. https://doi.org/10.1111/jscm.12050

Brusset X, Teller C (2017) Supply chain capabilities, risks, and resilience. Int J Prod Econ 184:59–68. https://doi.org/10.1016/j.ijpe.2016.09.008

Cai Z-Y, Xiao R-B (2014) Resilient operation and optimization of supply chains under disruption environment. Systems Engineering ——Theory & Practice 34:1443-1452. https://doi.org/10.12011/1000-6788(2014)6-1443

Cao G, Duan Y, El Banna A (2018) A dynamic capability view of marketing analytics: evidence from UK firms. Ind Mark Manag 76:72–83. https://doi.org/10.1016/j.indmarman.2018.08.002

Chen F-R (2020) Supply chain thinking amid the COVID-19 outbreak: lessons from beer game. Bull Chin Acad Sci 35:289–296. https://doi.org/10.16418/j.issn.1000-3045.20200221001

Cheng J-H, Lu K-L (2017) Enhancing effects of supply chain resilience: Insights from trajectory and resource-based perspectives. Supply Chain Manag 22:329–340. https://doi.org/10.1108/scm-06-2016-0190

Chowdhury MM, Quaddus M (2016) Supply chain readiness, response and recovery for resilience. Supply Chain Manag 21:709–731. https://doi.org/10.1108/scm-12-2015-0463

Chowdhury MM, Quaddus M (2017) Supply chain resilience: conceptualization and scale development using dynamic capability theory. Int J Prod Econ 188:185–204. https://doi.org/10.1016/j.ijpe.2017.03.020

Christopher M (1998) logistics and supply chain management: strategies for reducing cost and improving service (second edition). Int J Logist-Res App 2:103–104. https://doi.org/10.1080/13675569908901575

Christopher M, Lee H (2001) Supply chain confidence – The key to effective supply chains through improved visibility and reliability. Vatera Inc. white paper, Global Trade Management. https://www.gsb.stanford.edu/sites/gsb/files/publication-pdf/white-paper-supply-chain-confidence%20.pdf

Christopher M, Peck H (2004) Building the resilient supply chain. Int J Logist Manag 15:1–14. https://doi.org/10.1108/09574090410700275

Christopher M, Peck H, Towill DR (2006) A taxonomy for selecting global supply chain strategies. Int J Logist Manag 17:277–287. https://doi.org/10.1108/09574090610689998

Closs DJ, McGarrell EF (2004) Enhancing security throughout the supply chain. IBM Center for the Business of Government, Washington, D.C.

Colicchia C, Dallari F, Melacini M (2010) Increasing supply chain resilience in a global sourcing context. Prod Plan Control 21:680–694. https://doi.org/10.1080/09537280903551969

Dabhilkar M, Birkie SE, Kaulio M (2016) Supply-side resilience as practice bundles: a critical incident study. Int J Oper Prod Manag 36:948–970. https://doi.org/10.1108/ijopm-12-2014-0614

Datta PP (2017) Enhancing competitive advantage by constructing supply chains to achieve superior performance. Prod Plan Control 28:57–74. https://doi.org/10.1080/09537287.2016.1231854

Dubey R, Altay N, Gunasekaran A, Blome C, Papadopoulos T, Childe SJ (2018) Supply chain agility, adaptability and alignment. Int J Oper Prod Manag 38:129–148. https://doi.org/10.1108/IJOPM-04-2016-0173

Eckstein D, Goellner M, Blome C, Henke M (2014) The performance impact of supply chain agility and supply chain adaptability: the moderating effect of product complexity. Int J Prod Res 53:3028–3046. https://doi.org/10.1080/00207543.2014.970707

Gligor DM, Esmark CL, Holcomb MC (2014) Performance outcomes of supply chain agility: when should you be agile? J Oper Manag 33-34:71–82. https://doi.org/10.1016/j.jom.2014.10.008

Hayes AF (2018) Introduction to mediation, moderation, and conditional process analysis: a regression-based approach. The Guilford Press, New York

Hohenstein N-O, Feisel E, Hartmann E, Giunipero L (2015) Research on the phenomenon of supply chain resilience. Int J Phys Distr Log 45:90–117. https://doi.org/10.1108/ijpdlm-05-2013-0128

Jüttner U, Maklan S (2011) Supply chain resilience in the global financial crisis: an empirical study. Supply Chain Manag 16:246–259. https://doi.org/10.1108/13598541111139062

Kamalahmadi M, Mellat-Parast M (2015) Developing a resilient supply chain through supplier flexibility and reliability assessment. Int J Prod Res 54:302–321. https://doi.org/10.1080/00207543.2015.1088971

Karl AA, Micheluzzi J, Leite LR, Pereira CR (2018) Supply chain resilience and key performance indicators: a systematic literature review. Production 28:1–16. https://doi.org/10.1590/0103-6513.20180020

Kauppi K, Longoni A, Caniato F, Kuula M (2016) Managing country disruption risks and improving operational performance: risk management along integrated supply chains. Int J Prod Econ 182:484–495. https://doi.org/10.1016/j.ijpe.2016.10.006

Kim Y, Chen Y-S, Linderman K (2015) Supply network disruption and resilience: a network structural perspective. Int J Oper Prod Manag 33-34:43–59. https://doi.org/10.1016/j.jom.2014.10.006

Kurniawan R, Zailani SH, Iranmanesh M, Rajagopal P (2017) The effects of vulnerability mitigation strategies on supply chain effectiveness: risk culture as moderator. Supply Chain Manag 22:1–15. https://doi.org/10.1108/scm-12-2015-0482

Lee SM, Rha JS (2016) Ambidextrous supply chain as a dynamic capability: building a resilient supply chain. Manag Decis 54:2–23. https://doi.org/10.1108/md-12-2014-0674

Li X, Wu Q, Holsapple CW, Goldsby T (2017) An empirical examination of firm financial performance along dimensions of supply chain resilience. Manag Res Rev 40:254–269. https://doi.org/10.1108/mrr-02-2016-0030

Liu C-L, Shang K-C, Lirn T-C et al (2018) Supply chain resilience, firm performance, and management policies in the liner shipping industry. Transport Res A-Pol 110:202–219. https://doi.org/10.1016/j.tra.2017.02.004

Macdonald JR, Zobel CW, Melnyk SA, Griffis SE (2018) Supply chain risk and resilience: theory building through structured experiments and Simulation. Int J Prod Res 56:4337–4355. https://doi.org/10.1080/00207543.2017.1421787

Manning L, Soon JM (2016) Building strategic resilience in the food supply chain. Brit Food J 118:1477–1493. https://doi.org/10.1108/bfj-10-2015-0350

Noordewier TG, Lucas MT (2020) On being green and profitable: does industry context matter? Int J Prod Econ 223:107528. https://doi.org/10.1016/j.ijpe.2019.107528

Pal R, Torstensson H, Mattila H (2014) Antecedents of organizational resilience in economic crises—an empirical study of Swedish textile and clothing SMES. Int J Prod Econ 147:410–428. https://doi.org/10.1016/j.ijpe.2013.02.031

Pettit TJ, Croxton KL, Fiksel J (2013) Ensuring supply chain resilience: development and implementation of an assessment tool. J Bus Logist 34:46–76. https://doi.org/10.1111/jbl.12009

Pettit TJ, Fiksel J, Croxton KL (2010) Ensuring supply chain resilience: development of a conceptual framework. J Bus Logist 31:1–21. https://doi.org/10.1002/j.2158-1592.2010.tb00125.x

Pires Ribeiro J, Barbosa-Povoa A (2018) Supply chain resilience: definitions and quantitative modelling approaches – a literature review. Comput Ind Eng 115:109–122. https://doi.org/10.1016/j.cie.2017.11.006

Ponis ST, Koronis E (2012) Supply chain resilience: definition of concept and its formative elements. J Appl Bus Res 28:921. https://doi.org/10.19030/jabr.v28i5.7234

Ponomarov SY, Holcomb MC (2009) Understanding the concept of supply chain resilience. Int J Logist Manag 20:124–143. https://doi.org/10.1108/09574090910954873

Porter ME (1985) Competitive advantage: creating and sustaining superior performance. The Free Press, New York

Prajogo D, Huo B, Han Z (2012) The effects of different aspects of ISO 9000 implementation on key supply chain management practices and operational performance. Supply Chain Manag 17:306–322. https://doi.org/10.1108/13598541211227135

Prajogo D, Oke A, Olhager J (2016) Supply chain processes. Int J Oper Prod Manag 36:220–238. https://doi.org/10.1108/ijopm-03-2014-0129

Roberta Pereira C, Christopher M, Lago Da Silva A (2014) Achieving supply chain resilience: the role of procurement. Supply Chain Manag 19:626–642. https://doi.org/10.1108/scm-09-2013-0346

Sheffi Y, Rice JBJ (2005) Supply chain view of the resilient enterprise. MIT Sloan Manag Rev 47:41–48. https://doi.org/10.1007/s10107-005-0578-3

Silvis ICJ, van Ruth SM, van der Fels-Klerx HJ, Luning PA (2017) Assessment of food fraud vulnerability in the spices chain: an explorative study. Food Control 81:80–87. https://doi.org/10.1016/j.foodcont.2017.05.019

Spiegler VLM, Potter AT, Naim MM, Towill DR (2015) The value of nonlinear control theory in investigating the underlying dynamics and resilience of a grocery supply chain. Int J Prod Res 54:265–286. https://doi.org/10.1080/00207543.2015.1076945

Srinivasan M, Mukherjee D, Gaur AS (2011) Buyer–supplier partnership quality and supply chain performance: Moderating role of risks, and environmental uncertainty. Eur Manag J 29:260–271. https://doi.org/10.1016/j.emj.2011.02.004

Swafford PM, Ghosh S, Murthy N (2006) The antecedents of supply chain agility of a firm: scale development and model testing. J Oper Manag 24:170–188. https://doi.org/10.1016/j.jom.2005.05.002

Tang Y-J (2006) On implementation model of inter-organization system (IOS) in the supply chain: a perspective of relationship management. China Industrial Economy 12:81–89

Teece DJ (2007) Explicating dynamic capabilities: the nature and microfoundations of (sustainable) enterprise performance. Strateg Manag J 28:1319–1350. https://doi.org/10.1002/smj.640

Teece DJ, Pisano G (1994) The dynamic capabilities of firms: an introduction. Ind Corp Chang 3:537–556. https://doi.org/10.1093/icc/3.3.537-a

Teece DJ, Pisano G, Shuen A (1997) Dynamic capabilities and strategic management. Strateg Manag J 18:509–533. https://doi.org/10.1002/(sici)1097-0266(199708)18:7<509::aid-smj882>3.0.co;2-z

Thekdi SA, Santos JR (2015) Supply chain vulnerability analysis using scenario-based input-output modeling: application to port operations. Risk Anal 36:1025–1039. https://doi.org/10.1111/risa.12473

Tubis A, Nowakowski T, Werbińska-Wojciechowska S (2017) Supply chain vulnerability and resilience – case study of footwear retail distribution network. Logistics and Transport 1. http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-a3aac731-2419-448a-8901-b3502b07a5ee/c/2_Tubis_i_inni_logistics_and_transport_1_2017.pdf

Tukamuhabwa BR, Stevenson M, Busby J, Zorzini M (2015) Supply chain resilience: definition, review and theoretical foundations for further study. Int J Prod Res 53:5592–5623. https://doi.org/10.1080/00207543.2015.1037934

Verma S, Gustafsson A (2020) Investigating the emerging COVID-19 research trends in the field of business and management: a bibliometric analysis approach. J Bus Res 118:253–261. https://doi.org/10.1016/j.jbusres.2020.06.057

Wagner SM, Grosse-Ruyken PT, Erhun F (2012) The link between supply chain fit and financial performance of the firm. J Oper Manag 30:340–353. https://doi.org/10.1016/j.jom.2012.01.001

Wagner SM, Neshat N (2010) Assessing the vulnerability of supply chains using graph theory. Int J Prod Econ 126:121–129. https://doi.org/10.1016/j.ijpe.2009.10.007

Wang Y-Q, Gao Y, Teng C-X (2017) Literature review and research prospects of supply chain resilience under disruption. Manag Rev 29:204–216. https://doi.org/10.14120/j.cnki.cn11-5057/f.2017.12.019

Wieland A, Wallenburg CM (2013) The influence of relational competencies on supply chain resilience: a relational view. Int J Phys Distr Log 43:300–320. https://doi.org/10.1108/ijpdlm-08-2012-0243

Winter SG (2003) Understanding dynamic capabilities. Strateg Manag J 24:991–995. https://doi.org/10.1002/smj.318

Wong CWY, Lirn T-C, Yang C-C, Shang K-C (2020) Supply chain and external conditions under which supply chain resilience pays: an organizational information processing theorization. Int J Prod Econ 226:107610. https://doi.org/10.1016/j.ijpe.2019.107610

Funding

This research was carried out with financial support provided by the National Natural Science Foundation of China (71972153), the Philosophy and Social Science Foundation of Shaanxi Province of China (2017S007), the Key Research Base Project of Philosophy and Social Sciences of the Department of Education of Shaanxi Province, China (21JZ042), and the Youth Social Science Innovation Team of Xi’an University of Technology.

Author information

Authors and Affiliations

Contributions

Professor Guoli Pu: conceptualization, resources, writing—review and editing, funding acquisition; Miss Shuting Li: methodology, software, writing—original draft and editing; Miss Ju Bai: methodology and visualization.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pu, G., Li, S. & Bai, J. Effect of supply chain resilience on firm’s sustainable competitive advantage: a dynamic capability perspective. Environ Sci Pollut Res 30, 4881–4898 (2023). https://doi.org/10.1007/s11356-022-22483-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22483-1