Abstract

An analytical method for detecting flame retardants was slightly modified and optimized for the simultaneous determination of 11 organophosphate esters (OPEs) and 26 polyfluoralkyl substances (PFASs) contained in dust. All the analytes were determined in HPLC/MS–MS, and OPEs were also analyzed in GC/MS, and the results were compared. The study was conducted through the investigation of the Standard Reference Material SRM 2585 of the National Institute of Standard and Technology (NIST). The results were compared with the available reference mass fraction reported in the NIST certificate. The mass fraction obtained for the other OPEs and PFASs was compared to available data in the literature. After verifying the reliability of the results, the method was applied to environmental samples of settled dust, collected in four workplaces, where OPE and PFAS content is expected to be higher than in house dust: a mechanical workshop, an electronic repair center, a disassembly site, and a shredding site of two electronic waste recycling plants. By analyzing both PFASs and OPEs in the same samples, the present work demonstrated that the selected working places were more polluted in OPEs than houses; on the contrary, PFAS content in house dust proved to be more than ten times higher than that in workplaces. Additional research is necessary to confirm these data. Nevertheless, because this preliminary study showed not negligible concentrations of OPEs in some workplaces and of PFASs in houses, their monitoring should be extended to other domestic and selected working sites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Both organophosphate esters (OPEs) and per-/poly-fluoroalkyl substances (PFASs) are often studied together for their concurrent occurrence in the dust of many indoor environments, including homes, offices, and electronic stores (Papadopoulou et al. 2016). Dust ingestion or dermal contact can transmit such potential pollutants very rapidly into human body tissue (Melymuk et al. 2020). In particular workplaces, where frequent daily cleaning is not scheduled, settled dust could contain high concentrations of OPEs and PFASs, accumulated on surfaces over time (Buiarelli et al. 2019). Settled dust can also become airborne when persons move or during work operations, leading to additional inhalation exposure. Although these chemicals have been shown to represent a health risk to workers, yet, limited data are found in the literature on OPE and PFAS occurrence in workplaces.

OPEs are well-known ubiquitous toxic and persistent chemicals, extensively used as replacements for brominated flame retardants (BFRs). They are also used as a plasticizer to make the material softer and more flexible. Since physical mixing rather than chemical bonding is mostly used to add OPEs into polymer materials, they are easily released into the environment through volatilization, leaching, abrasion, and dissolution (van der Veen and de Boer 2012). OPEs include a variety of compounds with different substituent groups, characterized by heterogeneous chemical-physical property and environmental behavior. Triethyl phosphate (TEP), tripropyl phosphate (TPrP), tributyl phosphate (TBP), tris(2-ethylhexyl) phosphate (TEHP), triphenylphosphate (TPhP), 2-ethylhexyldiphenyl phosphate (EHDPhP), tributoxy ethyl phosphate (TBEP), tris(1-chloro-2-propyl) phosphate (TCPP), tris(2-chloroethyl) phosphate (TCEP), tris(1,3-dichloro-2-propyl) phosphate (TDCPP), and tri-m-tolyl phosphate (TMTP) are some of the most widespread and studied OPEs. OPE affinity for sediments and soils and their hydrophobicity depends on the large variation in chemical properties due to the variety of substituent groups (Yan et al. 2014). Solubility of halo-alkyl phosphates in water increases with decreasing molecular weight, and selected compounds can be found in aqueous matrices (Lande et al. 1976). TEP, TBP, and TCEP are more volatile; they can be emitted to the atmosphere and soon after can sorb to the airborne particles. Triphenyl phosphate (TPhP), used as an additive flame retardant and/or plasticizer in the plastic material of computers, is not totally retained in the plastic material and is continuously emitted into the indoor air when the machine is running (Carlsson et al. 2000). Alkyl- and aryl-phosphates TPhP, TEP, TPrP, TBP, TBEP, and TDCPP are also used as combustion engine fuel additives and occur at not negligible concentrations in urban airborne PM (Fabiańska et al. 2019).

Human exposure to OPEs occurs from consumption of contaminated food and water, from ingestion of dust, inhalation, and skin absorption (Gbadamosi et al. 2021). Toxicological studies have linked exposure to OPEs with adverse endocrine and reproductive effects and genotoxicity (Young et al. 2021). TPhP and TBP are suspected neurotoxic, and TCPP, TCEP, and TDCPP are suspected carcinogenic (WHO, EHC 112, 1991; IPCS, EHC 111, 1991).

PFASs (polyfluoralkyl substances) are constituted by a carbon chain totally (perfluoroalkyl) or partially (polyfluoroalkyl) fluorinated. Among the most common PFASs, perfluoroalkyl carboxylate (perfluorinated carboxylic acids, PFCAs) and sulfonate (perfluoroalkane sulfonic acids, PFSAs) are persistent chemicals widespread in the environment. Due to the strong chemical bond between the carbon and fluorine atoms, PFASs are human-made chemicals of concern for their persistence in the environment. PFASs have been widely used since the 1950s as water and oil repellents and in industrial surface treatment of several textile and paper products. Although toxicological data are not available for many contaminants, the toxicological profile of some of them and their ascertained presence in human blood plasma make PFASs of particular concern (Workman et al. 2019). The production of the most popular perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA) has been phased out since they are endocrine disruptors with carcinogenic and immunotoxic potential. Nevertheless, similar compounds continue to be employed for comparable applications (Berger et al. 2004). In 2018, a study by OECD (Organisation for Economic Co-operation and Development) [OECD, Series on Risk Management No. 39, 2018] listed 4730 different PFAS all identified by a CAS number, including perfluoroalkylethers and fluorotelomers and including other substances, precursors of environmentally persistent perfluorinated carboxylic acids. Besides these 4730 compounds, there are other PFASs present on the market with unknown CAS numbers. In order to assess human exposure to these chemicals, their occurrence is extensively studied in different environmental matrices, including air, water, food, and consumer products. PFASs examined in this study include thirteen perfluoro carboxylic acids from C4 to C14 and C16 and C18 (PFBA, PFPeA, PFHxA, PFHpA, PFOA, PFNA, PFDA, PFUDA, PFDoA, PFTrDA, PFTeDA, PFHxDA, PFODA); PFSAs including eight C4 to C10 and C12 perfluoro sulfonates (L-PFBS, L-PFPeS, L-PFHxS, L-PFHpS, L-PFOS, L-PFNS, L-PFDS, L-PFDoS); one hexafluoropropylene oxide dimer acid, (2,3,3,3-tetrafluoro-2- (heptafluoropropoxy)-ammonium propanoate, GenX); and one perfluoroalkylether (6:2 chlorinated polyfluoroalkyl ether sulfonate, Cl-PFESA); the perfluorooctanesulfonamide (PFOSA) and its methylated and ethylated forms (MeFOSA, EtFOSA). Neutral and volatile PFAS were not included.

The first aim of the present study was to determine the suitability of an analytical method, previously optimized for other flame retardants in our laboratory, to analyze 11 OPEs and 26 PFASs in the same sample of dust (Simonetti et al. 2020).

The previous method took into account the analysis of five PFASs by HPLC and flame retardants different from OPEs in GC, for a total of 99 compounds, by splitting the extract from the same dust sample in two aliquots. The method was tested for selectivity, calibration, precision, recovery, operating range, limit of quantification, limit of detection, and sensitivity. The determination of different classes of compounds with acceptable analytical performance was so obtained by an easy and rapid treatment of an environmental complex matrix.

Therefore, the method was slightly modified to be extended to the new compounds, using an automated high pressure and temperature extraction system (Astolfi et al. 2017; Buiarelli et al. 2017; Pomata et al. 2020; Simonetti et al. 2020). OPE and PFAS analysis was performed by HPLC/ESI–MS-MS; OPEs were also analyzed in GC/MS, and the results were compared. In order to evaluate the accuracy of the analytical procedure, the method was applied to the standard reference material NIST (National Institute of Standards and Technology, Gaithersburg, MD) SRM 2585 containing OPEs and PFASs (Borsella et al. 2004). The results were compared with the available reference mass fraction reported in the NIST certificate for TBP, TCEP, TCPP, TPhP and for PFBA, PFHxA, PFHpA, PFNA, PFDoA, PFTriA, PFHxS, and PFOS. The mass fraction obtained for the other OPEs and PFASs was compared to available data in the literature if any.

The second purpose of the present work was a preliminary study to evaluate the optimized method by applying it to environmental samples collected in four workplaces, selected to represent sites where occupational exposure to OPEs and PFASs can be significant. Since flame retardants are released during dismantling processes, and in places where computers, printed circuit boards, electric components, and plastics are present (Sjödin et al. 2001), the working places examined were a mechanical workshop, an electronic repair center, a disassembly site, and a shredding site inside two electronic waste recycling plants.

Experimental section

Chemicals and reagents, solvents, materials, and instruments

TPrP, TBP, TPhP, TCEP were purchased from Sigma-Aldrich S.r.l. (Milan, Italy); all the other OPEs and the isotope-labeled internal standards Tributyl-d27 phosphate (TBP-d27), Triphenyl–d15 phosphate (TPhP-d15), and Tris(2-chloroethyl)-d12 phosphate (TCEP-d12) were purchased from Wellington Laboratories (Ontario, Canada).

PFAC-PFAS mixture (PFBA, PFHxA, PFOA, PFNA, PFDA, PFUDA, PFODA), Cl-PFESA, and MeFOSA were purchased from Wellington Laboratories (Ontario, Canada); EtFOSA were purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germania); GenX was purchased from Apollo Scientific (UK).

Mass-labeled PFASs, PFBA, PFHxA, PFOA, PFNA, PFDA, PFUDA, PFDoA, PFHxS, and PFOS (mixture name: MPFAC-MXA) were purchased from Wellington Laboratories (Ontario, Canada).

SRM 2585 is naturally occurring house dust collected from vacuum cleaner bags of homes, cleaning services, motels, and hotels in the USA during 1993 and 1994. The standard was purchased from NIST (National Institute of Standards and Technology, Gaithersburg, MD). HPLC ultra LC–MS grade solvents were obtained from VWR International S.r.l. (Milan, Italy). Phenex-RC 0.15 mm syringe filters (Regenerated Cellulose) 0.20 μm were purchased from Phenomenex (Torrance, CA, USA). Millex-HV PVDF 4 mm syringe filters 0.22 μm were purchased from Merck (Darmstadt, Germany).

Chromatographic columns were a DB17, 50% phenyl-methylpolysiloxane (30 m × 0.25 mm), 0.25 µm (by Agilent J&W Scientific) for GC and XBridge BEH C18 (100 × 2.1 mm, 2.5 µm; Waters, Sesto San Giovanni, MI, Italy), and Discovery®, C18 HPLC Column 5 μm particle size, L × I.D. 30 mm × 2.1 mm (Sigma-Aldrich Inc., Italy) for HPLC. Florisil, MgO3Si, 60–100 mesh was purchased from Sigma-Aldrich S.r.l. (Milan, Italy). Filtration regenerated cellulose membranes Phenex-RC (0.15 mm, 0.20 μm) were purchased from Phenomenex, Torrance, CA, USA. Millex Syringe Filters, Durapore® (PVDF), 4 mm, 0.45 μm, were purchased from Sigma-Aldrich Inc., Italy. Single PFASs were Apollo Scientific Ltd. products, purchased from LabService Analytica srl (Anzola dell’Emilia, BO, Italy).

An Accelerated Solvent Extractor ASE200-Dionex (Thermo Scientific, Rodano, Milan, Italy), operating at high pressure and temperature, allowed to achieve an effective extraction. The extracts were first evaporated by an SE500-Dionex solvent evaporator (Glas-Col, TerreHaute, IN, USA) under a nitrogen stream, and then by a Miulab NDK200-2 N concentrator (Hangzhou Miu Instruments CO., LTD, Zhejiang, China). The analytes were analyzed by both an HPLC/ESI–MS-MS (Agilent 1290, Agilent G4226A, Agilent G6460, Agilent Technologies, Santa Clara, CA, US) and a GC–MS (Agilent 7890B and Agilent G5977B, Agilent Technologies, Santa Clara, CA, US).

Sampling

Samples included in this study are NIST-SRM 2585 and dusts collected in a mechanical workshop, an electronic repair center, a disassembly site, and a shredding site inside two electronic waste recycling plants. In Table 1, a short description of the sampling sites is reported.

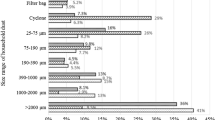

Settled dust samples were collected using a brush, previously cleaned with appropriate solvents, from different surfaces inside the workplaces and stored in a single glass bottle for each workplace. For the sole purpose of homogenizing and removing the “grosser parts,” the dust samples were sieved at 63 μm and stored at − 18 ℃.

Analytical procedure protocol

A set of five NIST SRM 2585 samples of 100 mg each were spiked with a multistandard solution at increasing concentrations of analytes, chosen within the linear calibration range established through solvent calibration curves, previously built and constant concentrations of internal standards. The set of samples was added with the following OPE and PFAS amounts: 0 ng, 12 ng, 25 ng, 50 ng, and 75 ng of OPEs, and 0 ng, 1.25 ng, 3.75 ng, 7.5 ng, and 15 ng of PFASs. OPE internal standards were also added at the following constant amounts in all the samples: 37.5 ng of TBP-d27, 25 ng of TCEP-d12 and TPhP-d15. Perdeuterated PFAS were added at a concentration of 20 ng (§ 2.1).

In parallel, six ASE cells, packed with florisil, were spiked with deuterated internal standards prior to applying the procedure. The averaged results were used as procedural blanks that were subtracted from OPE results in the environmental sample and for LOD and LOQ calculation.

In addition, three samples of 100 mg of sieved dust from each of the four workplaces were spiked with internal standards at the same concentrations.

All the spiked samples underwent an extraction and purification method (Pomata et al. 2014; Buiarelli et al. 2017; Pomata et al. 2020; Simonetti et al. 2020) by ASE. After 3 twice-cycle extractions with 6 mL n-hexane and 6 mL ethyl acetate, OPEs were completely extracted. PFASs quantitative extraction was reached with a further extraction by 2-propanol-methanol (90:10). As illustrated in previous papers, hexane replaced dichloromethane, deemed unsuitable, due to its capability to solubilize plastic fragments present in the dust samples, providing poorly purified extracts (Simonetti et al. 2020). Florisil for clean-up was directly added to the extraction cell. Hexane and ethyl acetate extracts were collected together in the same vial, and successively, the solution was split into two aliquots, only one of which was reunited with a 2-propanol-methanol extract. Then, the two solutions were concentrated to dryness under nitrogen, filtered through regenerated cellulose filters, using glass syringes, and evaporated again under nitrogen. The solution coming from n-hexane/ethyl acetate extraction was reconstituted in toluene (50 µL) for analysis by GC–MS. The second solution was reconstituted in methanol (50 µL) for analysis by HPLC/MS–MS. Both the solutions were filtered through PVDF membranes just before injection. The analytical procedure is illustrated in the block diagram of Fig. 1.

Calibration curves

For the purpose of studying the instrumental parameters and the linearity range of the compounds under study, calibration curves for each analyte were built starting from six standard solutions with increasing analyte concentrations, and constant concentrations of the labeled internal standard (IS). Concentrations ranged from 10 to 1500 µg/L for OPE and from 10 to 300 µg/L for PFAS; TCEP-d12 and TPhP-d15 concentrations were 750 µg/L, and TBP-d27 concentration was 500 µg/L. PFAS internal standards have been added at a concentration of 400 µg/L, starting from a mixture of deuterated PFBA, PFHxA, PFOA, PFNA, PFDA, PFUDA, PFDoDA, PFHxS, and PFOS.

To carry out the quantitative analysis of the investigated analytes in the environmental samples, matrix curves obtained with the standard addition method were constructed. Standard addition curves were obtained by linear least-squares regression of LC/MS–MS or GC/MS responses (y) versus the added amount of analytes (x) after analysis of spiked SRM samples prepared, as described in “Analytical procedure protocol.” The solutions were also re-injected after dilution of 1:2 and 1:100 for results outside the detectable range.

These standard addition curves were used to determine the concentrations of compounds present in SRM by extrapolation to the x-intercept (obtained by the ratio of the intercept “a” and the slope of regression line “b”). The error on the result was calculated by the error on a and b predicted from all measured values of y, based on the following formula:

where b is the slope of standard addition plot; \(\overline{\mathrm{x} }\) and ӯ are the centroids of the points xi, yi; n is the number of standard addition points; and sy/x is the standard deviation of y/x (Miller and Miller 1993).

Then, the concentrations of analytes already present in the SRM were subtracted to each data point of the line of least squares. The so-shifted curves, passing near the origin of the axes, were used as matrix-matched calibration curves. The matrix-matched calibration curves overcame uncertainties and matrix interferences for the dust samples. Each solution was injected three times.

Recovery

OPE and PFAS recoveries were determined after the evaporation step, after the first extraction (n-hexane/ethyl acetate), and after the second extraction (n-hexane/ethyl acetate/2-propanol/methanol). Upstream and downstream solutions were prepared by adding OPE and PFAS standard solutions (concentrations in the final solutions of 50 µL equal to 240 ng/mL, 1000 ng/mL, and 1500 ng/mL for OPEs, and 25 ng/mL, 150 ng/mL, and 300 ng/mL for PFASs), before and after the analytical procedure, and adding the IS just before chromatographic injections. The results were compared.

Extraction recovery can be considered as the recovery of the method since it includes evaporations and filtrations.

As part of the recovery tests, to demonstrate the negligible extraction of PFASs in n-hexane/ethyl acetate, this extraction solution was also analyzed by HPLC/MS–MS after reconstitution in methanol.

LODs and LOQs

LODs and LOQs were obtained by six blank samples (ASE cells packed with florisil spiked with IS) subjected to the analytical procedure described in Fig. 1. The following formulas were used to calculate LODs and LOQs:

with

and

with

where m and q are slope and y-intercept of the calibration curves, and μB is the mean blank signal intended as the ratio of the areas analyte/IS and σ its standard deviation.\

Intra and inter-day repeatability

The intra and inter-day repeatability was assessed by calculating the relative standard deviation of the instrumental responses obtained through replicate measurements. An RSD <25% was considered acceptable.

Results and discussion

GC/MS conditions

In order to identify quantifier (Q) and qualifier (q) ions, toluene solutions of pure standards at a concentration of 50 µg/mL were injected into GC–MS for the acquisition in full scan. GC–MS conditions were as follows: He flow rate, 1 mL/min; splitless; injection volume, 1 μL; injection temperature, 250 ℃; ionization temperature, 230 ℃; ionization mode, electronic impact at 70 eV; and solvent delay, 10 min. For the alkyl OPEs (TPrP, TBP, and TEHP), a characteristic fragment m/z = 99, corresponding to three successive Mc Lafferty rearrangements (Ma and Hites 2013), was identified and used as Q ion. Their q ions were respectively: 141, 183, 155, 211, and 113. Brandsma et al. (2013) suggest the use of a Q ion different from 99 due to interferences in the dust matrix. In the present study, the use of a DB17 column instead of a DB5 and the direct clean-up at high pressure and temperature in ASE overcame the problem. For the TCPP, the most intense fragment observed (q ion m/z = 125) results from McLafferty rearrangements, while the fragment m/z = 277 (Q ion) results from the loss of an alkyl chloride. The presence of chlorine in the latter fragment is confirmed in the spectrum by an M + 2 ion with an intensity equal to 1/3 (characteristic isotopic pattern of 35Cl and 37Cl). The intensity of the molecular ion in OPEs is generally negligible, exclusively for TPhP (molecular ion = 326) and TMTP (molecular ion = 368) the radical cations coincide with Q, while q ions are 77 (phenyl group) and 215, for TPhP and 91 (methylbenzene group) and 165 for TMTP. The most intense fragment of TCEP, m/z = 249 (Q), results from the loss of an atom of chlorine; m/z = 63 (q) corresponds to ethyl chloride; the fragment m/z = 205 (q) is obtained from the fragmentation in α at the phospho-ester bond. The fragment m/z = 57 (q) of TBEP corresponds to a linear alkyl chain; the ion m/z = 125 (Q) is produced by two McLafferty rearrangements and the loss of an ethereal group; the other q ion is m/z = 85. TDCPP most intense fragment results from three consecutive McLafferty rearrangements (m/z = 99, used as q) and from the generation of alkyl chloride (m/z = 75, used as Q); m/z = 191 is used as an additional q fragment. The degradation in the column of TCEP, TBEP, and TDCPP registered in previous works (Brandsma et al. 2013) was not significant, most probably thanks to the use of the DB17 column, chosen after having ascertained a fast loss of efficiency of the DB5 column, during the setting up of the method. Finally, EHDPhP fragment m/z = 251 (Q) is the result of a McLafferty rearrangement, while the ion m/z = 94 (q) corresponds to the phenol; m/z = 170 is used as an additional qualifier fragment. Similarly to native compounds, the perdeuterated OPEs exhibited the following fragments m/z: TBP-d27 103(Q), 167, and 231 (q); TCEP-d12 261 (Q) 67 and 148 (q); TPhP-d15 341(Q) 82 and 70 (q). Regarding chromatographic conditions, the chromatograph was equipped with a DB17 column and helium was used as the carrier gas at a constant flow rate of 1 mL/min. The temperatures of source, transfer line, and injector were set equal to 230 ℃, 300 ℃, and 250 ℃, respectively. The separation was started at 80 ℃ with the temperature programmed at a ramp rate of 10 ℃ min−1 to 166 ℃, followed by a 30 ℃ min−1 ramp to 235 ℃ (6 min hold); then a ramp rate of 5 ℃ min−1 to 262 ℃, finally a 30 ℃ min−1 ramp to a final temperature of 300 ℃ with a hold time of 5 min. The toluene solutions were injected as they were for TPrP, TMTP, TEHP, and TBP; after a dilution of 1:2 for TCEP, TPhP, TCPP, EHDPhP, and TDCPP, TBEP was analyzed after a dilution of 1:100. Table 2 summarizes ions (m/z) and retention times (RT).

HPLC/MS–MS conditions

All the OPEs were also analyzed in HPLC/ESI–MS-MS together with PFASs, in a single run. Solutions of 10 µg/mL in ammonium formate (10 mM)/MeOH (50:50) were infused in ESI–MS-MS to obtain the best parameters to analyze the compounds in MRM mode. The polarity was positive, and the precursor ions were [M + H]+ for all the OPEs; OPE common qualifier fragment was the alkyl chloride group separating from the phosphate group during cell fragmentation. The polarity was, instead, negative, and the precursor ions were [M-H]− for all PFASs. The fragments used for quantifiers and qualifiers are in agreement with the data found in the literature (Arsenault et al. 2007). Briefly, the carboxylate anion fragment [M-H-CO2]− and the small and less intense fragment [C3F7]− were used as qualifiers for perfluorocarboxylic acids. From quasi-molecular ion of perfluoroalkane sulfonic acids, the two fragments [SO3]− and [SO3F]− were generated and used as qualifiers. Gas temperature was 300 ℃, the gas flow was 2 L/min, the nebulizer was set at 60 psi, the capillary voltage at 2000 V, and the nozzle voltage at 1200 V; sheat gas temperature and flow rate were set at 200 ℃ and 11 L/min; collision energy was in the range 1–78 eV, and fragmentor voltages were 70–240 V for OPEs and 71–198 V for PFASs, depending on the analyte. Regarding OPEs, cell accelerator voltage was 1 V for all the analytes, except for TPhP at 0 V and EHDPhP at 4 V; regarding PFASs, the cell accelerator voltage was 0 V. Table 2 summarizes the ions (m/z) used for quantification (Q) and as qualifiers (q) for each compound. HPLC gradient analysis of OPEs and PFASs is performed in about 30 min. The column temperature was maintained at 40℃. The use of a 30 mm C18 guard column, between the pump and the injector, showed some capacity to reduce interferences present in the solvents and due to the detection system itself (Brandsma et al. 2013). The mobile phase, consisting of A, 5 mM in ammonium formate and B methanol added with 5 mM ammonium formate, was used. The water/methanol gradient was run at a flow rate of 0.2 mL/min starting at 30% B that, after 3 min isocratic hold, was increased linearly to 100% in 22 min, kept at 100% for 3 min. The injection volume was 5 µL. The methanol solutions were injected as they were and after a dilution of 1:2 and 1:100. Calibration curves of TCPP, PFOSA, Cl-PFESA, MeFOSA, and EtFOSA in solution had good R2, but the same compounds in the dust matrix did not give an acceptable calibration curve. Table 2 summarizes the retention times (RT) and the ions monitored.

Linearity, repeatability, LOD and LOQ, and recoveries

Solvent calibration curve linearity

Starting from solvent calibration curves, good linearity was obtained in the investigated concentration range for each analyte, as demonstrated by R2 values between 0.928 and 0.988 for OPEs and between 0.948 and 0.999 for PFASs in liquid chromatography. An exception is HPLC analysis of TCPP, suffering from interference that is caused by solvent impurities, despite the use of ultrapure solvents (§ 2.1) and of guard column (§ 3.2). OPEs in GC showed an R2 value range between 0.9934 (EHDPhP) and 0.9978 (TBEP). Interference caused by solvent impurities precluded the determination of TEP.

Solvent calibration curve repeatability

The inter-day repeatability was 1‒17%; the intra-day repeatability was 2‒25% for OPEs in liquid chromatography. Inter-day and intra-day repeatabilities were 1‒4.5% and 1‒5% for OPEs in gas chromatography. For PFASs, the inter and intra-day repeatabilities, expressed as RSD%, were 1‒24% and 1‒25%.

Matrix-matched calibration curve linearity and repeatability

Statistical parameters of the method were also calculated from matrix-matched calibration curves (§ 2.4). OPEs in GC showed R2 values ranging from 0.9365 to 0.9998. The inter-day repeatability was in the range of 1‒12%, and the intra-day repeatability was 0.2‒22%. R2 values of OPEs in HPLC ranged between 0.9287 (TCEP) and 0.9989 (TBP). OPEs showed inter-day repeatability in the range of 5‒22% and intra-day repeatability of 4‒25%. R2 of PFASs ranged between 0.928 (PFNA) and 0.999 (PFNS). PFAS inter-day repeatability was 3‒14%, and intra-day repeatability was 6‒19%.

Matrix-matched calibration curve LODs and LOQs

In GC, OPE LODs ranged from 6.4 ng/g of TMTP to 221.1 ng/g of TEHP; LOQs ranged from 7.6 ng/g of TMTP to 461 ng/g of TBEP. In HPLC, OPE LOD values ranged between 7.9 ng/g (TEP) and 457.1 ng/g (EHDPhP); LOQs ranged between 10.2 ng/g (TEP) and 510.3 ng/g (EHDPhP). For PFAS, the lower LOD was 0.03 ng/g of PFPeS, the higher value was 2.50 ng/g of PFOSA. LOQs values ranged between 0.08 ng/g (PFPeS) and 8.33 ng/g (PFOSA).

Recovery

Evaporation recovery for OPE was in the range 58 ± 9–115 ± 20% (TPrP–TBEP).

n-Hexane/ethylacetate extraction recovery for OPEs analyzed by GC/MS was in the range 57 ± 6–97 ± 8% (TPrP–TEHP); in the second extraction solution (n-hexane/ethylacetate/2-propanol/methanol), recovery of OPE analyzed by HPLC/MS-MS was in the range 49 ± 10–115 ± 15% (TEP–TBEP).

Regarding PFASs, evaporation recovery was in the range 69 ± 25–113 ± 24% (PFPeA–PFNS). PFAS extraction recovery was calculated by both n-hexane/ethylacetate and n-hexane/ethylacetate/2-propanol/methanol solutions (§ 2.5). The first solution recovery was in the range of about 0–5% (most PFASs–PFBS), demonstrating that PFASs were not extracted from either n-hexane or ethyl acetate. In the second extraction solution (after adding 2-propanol/methanol), recovery of PFASs was in the range 45 ± 23–103 ± 24% (PFNA–PFDoS). MeFOSA and EtFOSA recoveries were about 15% and 13%, and these two PFASs were excluded from the following investigations.

OPE and PFAS concentrations in house dust SRM 2585

The concentrations of compounds present in the samples were obtained by extrapolation of the standard addition curves mentioned above to the x-intercept.

Table 3 shows OPE concentrations (ng/g) found with GC/MS and HPLC/ESI–MS-MS compared to the reference mass fraction both reported in the NIST certificate of analysis and found in the literature (Van den Eede et al. 2011; Ali et al. 2012; Bergh et al. 2012; Van den Eede et al. 2012; Brandsma et al. 2013; Cristale and Lacorte 2013; Ionas and Covaci 2013; Murray et al. 2013; Fan et al. 2014; Stapleton et al. 2014; Luongo and Östman 2016; Allgood et al. 2017; Kademoglou et al. 2017; Pawar et al. 2017; Wong et al. 2017; Björnsdotter et al. 2018; Phillips et al. 2018; De la Torre et al. 2020; Gill et al. 2020; Lee et al. 2020; Mercier et al. 2020; Kassotis et al. 2021; Yu et al. 2021).

OPE concentrations (ng/g) found in the literature were averaged over the number of values (n), also shown in Table 3. In brackets, the minimum and maximum concentrations found in the literature are reported.

The comparison of concentrations with NIST-certified data showed good agreement for the four OPE compounds reported in the certificate of analysis. Although the accuracy cannot be determined for all the other OPEs, all values fall within the concentration ranges found in the literature.

Comparison of OPE results from GC and HPLC methods showed a good agreement. Discrepancies were found for TEP, TCPP, and TPrP. The first one was only detected by HPLC; the other two compounds were detected by GC. TEP and TCPP analysis suffered from interference caused by solvent impurities, despite the use of ultrapure solvents and the use of a guard column just before injector in HPLC/MS–MS system (§ 3.2). For TPrP in HPLC, interference from coeluting compounds unfortunately occurs in the extracts of a matrix as complex as dust. As negligible differences are observed for all the other compounds, both chromatographic methods can be used for detecting OPE.

Table 4 shows PFAS results studied here (ng/g), compared to both NIST concentrations in the certificate of analysis and data found in the literature (Björklund et al. 2009; Reiner et al. 2015; Winkens et al. 2018; Giovanoulis et al. 2019; Hall et al. 2020; Harrad et al. 2020; Kassotis et al. 2021; Padilla-Sánchez and Haug 2016). Literature data are reported as the average of the n values found for each compound (last column in Table 4). In brackets, the minimum and maximum values are shown. The present results are in good agreement with data in the NIST certificate and/or are within literature data.

Both OPE and PFAS wide ranges of values found in the literature confirm the difficulty of analysis of these two classes of compounds.

The consistency of the results obtained by the two methods for OPEs and by comparing the OPE and PFAS present data with literature results indicates that the present extraction and clean-up method has a good potential for rapid and effective characterization of both OPEs and PFASs in a matrix as complex as dust. Therefore, the method was applied to environmental samples collected in workplaces.

OPE and PFAS concentrations in dust samples collected in workplaces

Dust samples collected, prepared, and analyzed as described above were quantified using matrix-matched calibration curves obtained, as described in “Calibration curves.” Only OPE blank values (obtained as described in § “Analytical procedure protocol”) were subtracted since PFAS blanks were negligible.

Table 5 shows OPE, and Table 6 shows PFAS concentrations (ng/g) found in the four sampling sites tentatively compared with the data from the literature. Data are expressed as mean value ± uncertainty computed at the 95% level of confidence.

The disassembly site showed a high concentration of OPEs in the settled dust, mainly due to TPhP, TBEP, and TDCPP. OPE high concentrations are expected because all the collected dust originated from the manual fractionation of end-of-life personal computers, printers, scanners, display devices, small household appliances, telecommunication equipment, cellular phones, and electronic systems. The process involves the use of tools such as tongs, screwdrivers, and chisels, to selectively retrieve valuable parts, and hammers to crush larger parts such as plastic cases to make smaller parts (Van Der Veen and De Boer 2012).

High total OPE concentration in electronic repair center is mainly due to TBEP, corresponding to 93% of the total. TBEP is the most common OPE used as plasticizers in plastics and rubber, in acrylic-based polishes, lacquers, paints, textiles, but the high concentration would suggest the use of a washing and cleaning product containing TBEP as leveling agent and defoamer.

Although the mechanical workshop showed lower OPE concentrations, TBEP at this site also showed to be more than 90% of all OPEs. Why TBEP is the OPE present in the largest percentage is unclear. TBEP is a multifunctional additive essential to many polymer formulations and is also used in acrylic-based polishes and in acrylic gloss paint formulations, and these sources may have caused the higher percentage with respect to the other OPEs. The lower concentrations of all the other OPEs in the mechanical workshop were expected since the main operations consisted in manufacturing and repairing complex precision components and prototypes, also made of metal, glass, and wood and electrical devices, had a limited impact on dust production.

Shredding site dust analyses showed OPE results below the limits of detection. In shredding sites, only glass of monitors and television screens were mechanically shredded and reduced to dust. For the same reason, PFASs were also found in very low concentrations. Concerning the PFAS in the other three sites, the concentrations were similar to each other and lower than house dust.

Most of the literature regarding OPEs and PFASs refer to house dust samples and schools and offices dust samples. From literature data, settled dust shows OPE concentrations different from 3 to 5 orders of magnitude, depending on the sampling site (Luongo and Östman 2016). There is very little literature concerning flame retardants in workplaces different from offices. One of the ten sites investigated for OPEs in Stockholm (Bergh et al. 2011) consisted of a small mechanical workshop. In Nanjing (Zhao et al. 2020), an electronic product maintenance center was also investigated for OPEs. PFASs were analyzed in settled dust from a dismantling E-waste area in China (Zhang et al. 2020). Different from the electronic product maintenance center by Zhang, reporting low OPE amounts in settled dust, the small mechanical workshop in Stockholm showed concentrations in the same order of magnitude than the electronic repair center and the disassembly site investigated in the present study (Bergh et al. 2011). PFAS content found in the disassembly area was comparable to that found in an E-waste area in China (Zhang et al. 2020). The results from this study show that, in settled dust of the disassembly site and in the electronic repair center, OPEs detected were more than 1.5 and 8times higher than house dust, respectively. The concentrations found in the different workplaces are quite different, and only two of the four settled dusts examined contain such amounts of flame retardant as to lead to increased adverse health effects in workers. Therefore, also due to the poor predictability in the content of toxic substances, studies are needed to investigate the potential increased exposure of workers in analogous workplaces. On the contrary, house dust was much richer in PFASs than the dusts settled in the workplaces, showing that homes can cause high exposure to pollutants as well.

Conclusions

Human exposure to organophosphates and polyfluorinated organic compounds has been demonstrated to be increasingly widespread. Not negligible indoor concentrations of these toxic compounds have been detected in the dust of houses, offices, day care centers, and schools. The presence of OPEs and PFASs in house dust suggests a continuous high exposure to these pollutants of a large part of the world population. Additional exposure to the same pollutants in the workplace can result in potential chronic human health effects. Yet, scarce literature is found on their occurrence in those workplaces where electric and electronic equipment is manufactured, fixed, stored, or disposed. In this study, an analytical method was evaluated for its suitability to simultaneously analyze 11 OPEs and 26 PFASs in the same sample of dust.

Thanks to the positive results obtained with standard reference material from house dust, the method was used to investigate the settled dust in a mechanical workshop, an electronic repair center, a disassembly site, and a shredding site inside two electronic waste recycling plants.

Although the work is preliminary and consists of only four site results, however, some basic considerations can be made, above all for the consistency of the results obtained with respect to those in literature.

In these sites, we demonstrated that OPE concentrations can be higher than those found in house dust and cause additional exposure for workers.

Future work should focus on identifying flame retardants in specific workplaces with a predominant presence of electric and electronic devices.

Data availability

All data generated or analyzed during this study not included in this published article are available from the corresponding author on request.

References

Ali N, Dirtu AC, Van den Eede N, Goosey E, Harrad S, Neels H,’t Mannetje A, Coakley J, Douwes J, Covaci A (2012) Occurrence of alternative flame retardants in indoor dust from New Zealand: indoor sources and human exposure assessment. Chemosphere 88(11):1276-1282. https://doi.org/10.1016/j.chemosphere.2012.03.100

Allgood JM, Jimah T, McClaskey CM, La Guardia MJ, Hammel SC, Zeineddine MM, Tang IW, Runnerstrom MG, Ogunseitan OA (2017) Potential human exposure to halogenated flame-retardants in elevated surface dust and floor dust in an academic environment. Environ Res 153:55–62. https://doi.org/10.1016/j.envres.2016.11.010

Arsenault G, McAlees A, McCrindle R, Riddell N (2007) Analysis of perfluoroalkyl anion fragmentation pathways for perfluoroalkyl carboxylates and sulfonates during liquid chromatography/tandem mass spectrometry: evidence for fluorine migration prior to secondary and tertiary fragmentation. Rapid Commun Mass Spectrom 21:3803–3814. https://doi.org/10.1002/rcm.3274

Astolfi ML, Di Filippo P, Gentili A, Canepari S (2017) Semiautomatic sequential extraction of polycyclic aromatic hydrocarbons and elemental bio-accessible fraction by accelerated solvent extraction on a single particulate matter sample. Talanta 174:838–844. https://doi.org/10.1016/j.talanta.2017.06.072

Berger U, Jarnberg U, Kallenborn R (2004) Perfluorinated fluorinated POPS alkylated substances (PFAS) in the European nordic environment organohalogen compounds. DIOXIN_324, 66. https://www.osti.gov/etdeweb/servlets/purl/20828463

Bergh C, Torgrip R, Emenius G, Östman C (2011) Organophosphate and phthalate esters in air and settled dust – a multi-location indoor study. Indoor Air 21(1):67–76. https://doi.org/10.1111/j.1600-0668.2010.00684.x

Bergh C, Luongo G, Wise S, Östman C (2012) Organophosphate and phthalate esters in standard reference material 2585 organic contaminants in house dust. Anal Bioanal Chem 402:51–59. https://doi.org/10.1007/s00216-011-5440-2

Björklund JA, Thuresson K, de Wit CA (2009) Perfluoroalkyl compounds (PFCs) in indoor dust: concentrations, human exposure estimates, and sources. Environ Sci Technol 43(7):2276–2281. https://doi.org/10.1021/es803201a

Björnsdotter MK, Romera-García E, Borrull J, de Boer J, Rubio S, Ballesteros-Gómez A (2018) Presence of diphenyl phosphate and aryl-phosphate flame retardants in indoor dust from different microenvironments in Spain and the Netherlands and estimation of human exposure. Environ Int 112:59–67. https://doi.org/10.1016/j.envint.2017.11.028

Borsella E, Di Filippo P, Riccardi C, Spicaglia S, Cecinato A (2004) Data quality of PAH determinations in environmental monitoring. Anal Chim 94(9–10):691–698. https://doi.org/10.1002/adic.200490086

Brandsma SH, de Boer J, Leonards PEG, Cofino WP, Covaci A, Leonards PEG (2013) Organophosphorus flame-retardant and plasticizer analysis, including recommendations from the first worldwide interlaboratory study. TrAC, Trends Anal Chem 43:217–228. https://doi.org/10.1016/j.trac.2012.12.004

Buiarelli F, Di Filippo P, Massimi L, Pomata D, Riccardi C, Simonetti G, Sonego E (2019) Ultrafine, fine and coarse airborne particle mass concentration in workplaces. Atmos Pollut Res 10(5):1685–1690. https://doi.org/10.1016/j.apr.2019.06.009

Buiarelli F, Di Filippo P, Pomata D, Riccardi C, Bartocci M (2017) A liquid chromatography tandem mass spectrometry method for simultaneous analysis of 46 atmospheric particulate-phase persistent organic pollutants and comparison with gas chromatography/mass spectrometry. Int J Environ Anal Chem 97(9):797–818. https://doi.org/10.1080/03067319.2017.1369535

Carlsson H, Nilsson U, Östman C (2000) Video display units: an emission source of the contact allergenic flame retardant triphenyl phosphate in the indoor environment. Environ Sci Technol 34(18):3885–3889. https://doi.org/10.1021/es990768n

Cristale J, Lacorte S (2013) Development and validation of a multiresidue method for the analysis of polybrominated diphenyl ethers, new brominated and organophosphorus flame retardants in sediment, sludge and dust. J Chromatogr A 1305:267–275. https://doi.org/10.1016/j.chroma.2013.07.028

De la Torre A, Navarro I, Sanz P, de los Ángeles Martínez M (2020) Organophosphate compounds, polybrominated diphenyl ethers and novel brominated flame retardants in European indoor house dust: use, evidence for replacements and assessment of human exposure. J Hazard Mater 382:121009. https://doi.org/10.1016/j.jhazmat.2019.121009

Fabiańska MJ, Kozielska B, Konieczyński J, Bielaczyc P (2019) Occurrence of organic phosphates in particulate matter of the vehicle exhausts and outdoor environment – a case study. Environ Pollut 244:351–360. https://doi.org/10.1016/j.envpol.2018.10.060

Fan X, Kubwabo C, Rasmussen PE, Wu F (2014) Simultaneous determination of thirteen organophosphate esters in settled indoor house dust and a comparison between two sampling techniques. Sci Total Environ 491–492:80–86. https://doi.org/10.1016/j.scitotenv.2013.12.127

Gbadamosi MR, Abdallah M, Harrad S (2021) A critical review of human exposure to organophosphate esters with a focus on dietary intake. Sci Total Environ 771(144752):1–13. https://doi.org/10.1016/j.scitotenv.2020.144752

Gill R, Hurley S, Brown R, Tarrant D, Dhaliwal J, Sarala R, Park J-S, Patton S, Petreas M (2020) Polybrominated diphenyl ether and organophosphate flame retardants in Canadian fire station dust. Chemosphere 253:126669. https://doi.org/10.1016/j.chemosphere.2020.126669

Giovanoulis G, Nguyen MA, Arwidsson M, Langer S, Vestergren R, Lagerqvist A (2019) Reduction of hazardous chemicals in Swedish preschool dust through article substitution actions. Environ Int 130:104921. https://doi.org/10.1016/j.envint.2019.104921

Hall SM, Patton S, Petreas M, Zhang S, Phillips AL, Hoffman K, Stapleton HM (2020) Per- and polyfluoroalkyl substances in dust collected from residential homes and fire stations in North America. Environ Sci Technol 54(22):14558–14567. https://doi.org/10.1021/acs.est.0c04869

Harrad S, Drage DS, Sharkey M, Berresheim H (2020) Perfluoroalkyl substances and brominated flame retardants in landfill-related air, soil, and groundwater from Ireland. Sci Total Environ 705:135834. https://doi.org/10.1016/j.scitotenv.2019.135834

Ionas AC, Covaci A (2013) Simplifying multi-residue analysis of flame retardants in indoor dust. Int J Environ Anal Chem 93(10):1074–1083. https://doi.org/10.1080/03067319.2013.763248

IPCS (1991) «Triphenyl phosphate» in Environmental Health Criteria 111, Geneva

Kademoglou K, Xu F, Padilla-Sanchez JA, Småstuen Haug L, Covaci A, Collins CD (2017) Legacy and alternative flame retardants in Norwegian and UK indoor environment: implications of human exposure via dust ingestion. Environ Int 102:48–56. https://doi.org/10.1016/j.envint.2016.12.012

Kassotis CD, Hoffman K, Phillips AL, Zhang S, Cooper EM, Webster TF, Stapleton HM (2021) Characterization of adipogenic, PPARγ, and TRβ activities in house dust extracts and their associations with organic contaminants. Sci Total Environ 758:143707. https://doi.org/10.1016/j.scitotenv.2020.143707

Lande SS, Santodonato J, Howard PH, Greninger D, Christopher DH, Saxena J (1976) Investigation of selected potential environmental contaminants: haloalkyl phosphates. EPA-560/2–76–007 TR 76–513

Lee H-K, Kang H, Lee S, Kim S, Choi K, Moon H-B (2020) Human exposure to legacy and emerging flame retardants in indoor dust: a multiple-exposure assessment of PBDEs. Sci Total Environ 719:137386. https://doi.org/10.1016/j.scitotenv.2020.137386

Luongo G, Östman C (2016) Organophosphate and phthalate esters in settled dust from apartment buildings in Stockholm. Indoor Air 26(3):414–425. https://doi.org/10.1111/ina.12217

Ma Y, Hites RA (2013) Electron impact, electron capture negative ionization and positive chemical ionization mass spectra of organophosphorus flame retardants and plasticizers. J Mass Spectrom 48:931–936. https://doi.org/10.1002/jms.3235

Melymuk L, Demirtepe H, Jílková SR (2020) Indoor dust and associated chemical exposures. Current Opinion in Environmental Science & Health 15:1–6. https://doi.org/10.1016/j.coesh.2020.01.005

Mercier F, Gilles E, Soulard P, Mandin C, Dassonville C, Le Bot B (2020) On-line coupling of thermal extraction with gas chromatography/tandem mass spectrometry for the analysis of semivolatile organic compounds in a few milligrams of indoor dust. J Chromatogr A 1615:460768. https://doi.org/10.1016/j.chroma.2019.460768

Miller JC and Miller JN (1993) Statistics for Analytical Chemistry. 3rd Edition Ed. Ellis Horwood Limited

Murray J, Reiner J, Schantz M (2013) Measurement of selected organophosphate flame retardants in environmental standard reference materials. Poster presented at Sixth International Symposium on Flame Retardants, San Francisco, CA. April 7–10. Available at: https://www.yumpu.com/en/document/read/31359327/measurement-of-select-organophosphate-flame-retardants-in-

OECD Environment, Health and Safety Publications. Series on Risk Management No. 39 ENV/JM/MONO (2018)7. https://www.oecd.org/officialdocuments/publicdisplaydocumentpdf/?cote=ENV-JM-MONO(2018)7&doclanguage=en

Padilla-Sánchez JA, Haug LS (2016) A fast and sensitive method for the simultaneous analysis of a wide range of per- and polyfluoroalkyl substances in indoor dust using on-line solid phase extraction-ultrahigh performance liquid chromatography-time-of-flight-mass spectrometry. J Chromatogr A 1445:36–45. https://doi.org/10.1016/j.chroma.2016.03.058

Papadopoulou E, Padilla-Sanchez JA, Collins CD, Cousins IT, Covaci A, de Wit CA, Leonards PEG, Voorspoels S, Thomsen C, Harrad S, Haug LS (2016) Sampling strategy for estimating human exposure pathways to consumer chemicals. Emerging Contaminants 2(1):26–36. https://doi.org/10.1016/j.emcon.2015.12.002

Pawar G, Abdallah ME, Villaverde de Sáa E, Harrad S (2017) Dermal bioaccessibility of flame retardants from indoor dust and the influence of topically applied cosmetics. J Expo Sci Environ Epidemiol 27:100–105. https://doi.org/10.1038/jes.2015.84

Phillips AL, Hammel SC, Hoffman K, Lorenzo AM, Chen A, Webster TF, Stapleton HM (2018) Children’s residential exposure to organophosphate ester flame retardants and plasticizers: investigating exposure pathways in the TESIE study. Environ Int 116:176–185. https://doi.org/10.1016/j.envint.2018.04.013

Pomata D, Di Filippo P, Riccardi C, Buiarelli F, Gallo V (2014) Determination of non-certified levoglucosan, sugar polyols and ergosterol in NIST Standard Reference Material 1649a. Atmos Environ 84:332–338. https://doi.org/10.1016/j.atmosenv.2013.11.069

Pomata D, Di Filippo P, Riccardi C, Rossi V, Simonetti G, Sonego E, Buiarelli F (2020) Method optimisation for the simultaneous determination of legacy and emerging halogenated flame retardants in particulate matter collected in an electronic waste recycling facility. Int J Environ Anal Chem 100(13):1479–1496. https://doi.org/10.1080/03067319.2019.1655007

Reiner JL, Blaine AC, Higgins CP, Huset C, Jenkins TM, Kwadijk CJAF, Lange CC, Muir DCG, Reagen WK, Rich C, Small JM, Strynar MJ, Washington JW, Yoo H, Keller JM (2015) Polyfluorinated substances in abiotic standard reference materials. Anal Bioanal Chem 407:2975–2983. https://doi.org/10.1007/s00216-013-7330-2

Simonetti G, Di Filippo P, Riccardi C, Pomata D, Sonego E, Buiarelli F (2020) Occurrence of halogenated pollutants in domestic and occupational indoor dust. Int J Environ Res Public Health 17:3813. https://doi.org/10.3390/ijerph17113813

Sjödin A, Carlsson H, Thuresson K, Sjölin S, Bergman Å, Östman C (2001) Flame Retardants in indoor air at an electronics recycling plant and at other work environments. Environ Sci Technol 35, 448–454. https://pubs.acs.org/doi/abs/10.1021/es000077n

Stapleton HM, Misenheimer J, Hoffman K, Webster TF (2014) Flame retardant associations between children’s handwipes and house dust. Chemosphere 116:54–60. https://doi.org/10.1016/j.chemosphere.2013.12.100

Van den Eede N, Dirtu AC, Ali N, Neels H, Covaci A (2012) Multi-residue method for the determination of brominated and organophosphate flame retardants in indoor dust. Talanta 89:292–300. https://doi.org/10.1016/j.talanta.2011.12.031

Van den Eede N, Dirtu AC, Neels H, Covaci A (2011) Analytical developments and preliminary assessment of human exposure to organophosphate flame retardants from indoor dust. Environ Int 37(2):454–461. https://doi.org/10.1016/j.envint.2010.11.010

Van Der Veen I, De Boer J (2012) Phosphorus flame retardants: properties, production, environmental occurrence, toxicity and analysis. Chemosphere 88(10):1119–1153. https://doi.org/10.1016/j.chemosphere.2012.03.067

WHO (1991) «Tri-n-butyl phosphate» in environmental health criteria. WHO, Geneva, p 112. http://apps.who.int/iris/bitstream/handle/10665/39857/WHO_EHC_112_eng.pdf;jsessionid=C5D7CA5875405A7480AD7861F6AE7336?sequence=1

Winkens K, Giovanoulis G, Koponen J, Vestergren R, Berger U, Karvonen AM, Pekkanen J, Kiviranta H, Cousins IT (2018) Perfluoroalkyl acids and their precursors in floor dust of children’s bedrooms – implications for indoor exposure. Environ Int 119:493–502. https://doi.org/10.1016/j.envint.2018.06.009

Wong F, Suzuki G, Michinaka C, Yuan B, Takigami H, De Wit CA (2017) Dioxin-like activities, halogenated flame retardants, organophosphate esters and chlorinated paraffins in dust from Australia, the United Kingdom, Canada, Sweden and China. Chemosphere. 168(1248–125). https://doi.org/10.1016/j.chemosphere.2016.10.074

Workman CE, Becker AB, Azad MB, Moraes TJ, Mandhane PJ, Turvey SE, Subbarao P, Brook JR, Sears MR, Wong CS (2019) Associations between concentrations of perfluoroalkyl substances in human plasma and maternal, infant, and home characteristics in Winnipeg. Canada Environ Pollut 249:758–766. https://doi.org/10.1016/j.envpol.2019.03.054

Yan W, Yan L, Duan J, Jing C (2014) Sorption of organophosphate esters by carbon nanotubes. J Hazard Mater 273:53–60. https://doi.org/10.1016/j.jhazmat.2014.03.030

Young AS, Zoeller T, Hauser R, James-Todd T, Coull BA, Behnisch PA, Brouwer A, Zhu H, Kannan K, Allen JG (2021) Assessing indoor dust interference with human nuclear hormone receptors in cell-based luciferase reporter assays. Environmental Health Perspectives 129(4):047010–1‒047010–13. https://doi.org/10.1289/ehp8054

Yu L, Ru S, Zheng X, Chen S, Guo H, Gao G, Zeng Y, Tang Y, Mai B (2021) Brominated and phosphate flame retardants from interior and surface dust of personal computers: insights into sources for human dermal exposure. Environ Sci Pollut Res 28:12566–12575. https://doi.org/10.1007/s11356-020-11132-0

Zhang B, He Y, Huang Y, Hong D, Yao Y, Wang L, Sun W, Yang B, Huang X, Song S, Bai X, Guo Y, Zhang T, Sun H (2020) Novel and legacy poly- and perfluoroalkyl substances (PFASs) in indoor dust from urban, industrial, and e-waste dismantling areas: the emergence of PFAS alternatives in China. Environmental Pollution Part A 263:114461. https://doi.org/10.1016/j.envpol.2020.114461

Zhao L, Zhang Y, Deng Y, Jiana K, Li J, Ya M, Su G (2020) Traditional and emerging organophosphate esters (OPEs) in indoor dust of Nanjing, eastern China: occurrence, human exposure, and risk assessment. Sci Total Environ 712:136494. https://doi.org/10.1016/j.scitotenv.2020.136494

Funding

This study was funded by the Italian Workers’ Compensation Authority (INAIL) (Bando Ricerche in Collaborazione (BRiC); grant number BRIC2019 ID13, INAIL, Italy).

Author information

Authors and Affiliations

Contributions

PDF, CR, FB, GS, and DP contributed to funding acquisition, supervision and project administration, conceptualization, methodology, and interpretation of data. ES, GS, AF, and MO contributed to laboratory and formal analysis. PDF, CR, and GS were the major contributors in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interest

The authors declare no competing interests.

Additional information

Responsible Editor: Gerhard Lammel

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sonego, E., Simonetti, G., Di Filippo, P. et al. Characterization of organophosphate esters (OPEs) and polyfluoralkyl substances (PFASs) in settled dust in specific workplaces. Environ Sci Pollut Res 29, 52302–52316 (2022). https://doi.org/10.1007/s11356-022-19486-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19486-3