Abstract

The aim of this study was to examine the biogas production and the adsorption aspect of microorganism from different coals. Coal samples were obtained from Qianqiu mine and Guandi mine. Microbial populations were cultured from the coal mine drainage. After an anaerobic reaction period at about 35 °C, adsorption rate was determined by the spectrophotometer, while a scanning electron microscopy was used to observe the microorganisms on the coal and the headspace methane was analyzed using gas chromatography. Results show that the coal rank and particle size serve as important factors influencing the adsorption of microorganism and biogenic methane production. With decreasing particle size, the Qianqiu coal produced a considerable adsorption rate between 75 and 79%, while the adsorption rate of Guandi coal was between 52 and 74%. Meanwhile, the density of microorganisms from the Qianqiu coal surface demonstrated a higher level of adsorption than that of Guandi coal following the scanning electron microscopy images. Additionally, Qianqiu coal produced a higher level of biogas production (391.766–629.199 μmol/g) than that of Guandi coal (292.835–393.744 μmol/g) and the Qianqiu coal also generated a higher concentration of methane during the incubation. When the adsorption rate decreasing, the biogas production from various pulverized coals appeared to be decreased and demonstrated a positive correlation to the adsorption rate. The results of this study suggest that the adsorption behavior of microorganisms is closely related to the effect of coal biodegradation and contributes to the biogenic methane production potential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Coalbed methane is one kind of clean energy that is currently abundant in geological reserves. Rightmire et al. were the first to propose two mechanisms for the generation of this kind of methane, either biogenic or thermogenic (Rightmire et al. 1984). Biogenic gas is a very important component of coalbed methane resources; secondary biogenic gas in the northern part of the San Juan basin accounts for about 30% of the total volume of natural resources. This resource has also been discovered in the Sydney and Bowen basins, in the Upper Silesian and Lublin basins in Poland, as well as in Shanxi Province, the Huainan coal field, and the Ordos basin, China (Ahmed and Smith 2001; Guo et al. 2012; Scott 1994; Tao et al. 2005). Biogenic coalbed methane is the result of coal degradation by methanogenic microorganisms under anaerobic conditions. A comprehensive research effort has been focused on the structure and function of microbial communities, metabolic pathways, and the impact factors of the gas production process (Barnhart et al. 2013; Fang et al. 2015; Flores et al. 2008; Jones et al. 2010; Orem et al. 2010; Rotaru et al. 2014; Su et al. 2011; Wang et al. 2016; Wu et al. 2014; Xia et al. 2012). Most companies interested in microbially enhanced coalbed methane (MECBM) have conducted different level commercial test in the Sydney basin, Australia, the Powder River basin, USA, and the Qinshui basin in Shanxi Province, China (Ren et al. 2016; Ritter et al. 2015). However, the adsorption of methanogens on coal matrix often goes unreported and may affect the biogenic methane production.

The adsorption behavior of microorganism is determined by its structure as well as physical and chemical surface properties. Microorganism could produce hydrophobicity, due to the existing of proteins, carbohydrates, and lipids on the surface of microorganisms; additionally, most microbial cell surfaces are negatively charged, attributing to the presence of teichoic acids and lipopolysaccharides (Rao and Subramanian 2007). Thus, adsorption occurs between microorganisms and coal matrix because of the hydrophobic and electrostatic interactions. Meanwhile, some special chemical groups, and extracellular matrix could also lead to chemisorption and hydrogen bond adsorption (Chen 2014; Jia et al. 2010; Wang 2012). The porous and rough matrix of coal may contribute to the adsorption in some way.

Visualizing microorganisms in or on coal is hampered by the coal itself because it has highly adsorptive surfaces and readily binds organic dyes and other markers (van Krevelen 1961; Mittal and Venkobachar 1993). Nutrients transformation between coal and bacteria needs biofilms. Currently, it is clear that biofilms are dynamic, complex, and nonrandom structures that offer a host of benefits to the organisms living therein. These include the creation of an internal environment that is potentially advantageous to avoid the physicochemical extremes of the complex geological environment. Biofilms also provide opportunities to engage in symbiotic and syntrophic processes. If biofilms were to form on coal surfaces, they may host organisms that liberate and transform the organic matter, and some studies suggested that Surfactant Tween20 can change the properties of coal particles surface, increase the adsorption capacity of bacterial on the coal particles surface, and promote the biofilm formation, potentially hold keys to further enhancing coal seam gas production using microbes (Vick et al. 2016; Schlegel et al. 2013; Mahaffey 2012; Yang et al. 2016).

In this study, we used spectrophotometer and scanning electron microscopy (SEM) to assess the adsorption effect of microorganisms on different coals. Various pulverized coals were investigated for their ability to support microbial methane production in laboratory incubations.

Results of this study advance our understanding of the correlations between the adsorption and biogas production and provide insights for developing strategies to improve the productivity of biogenic methane.

Materials and methods

Coal samples

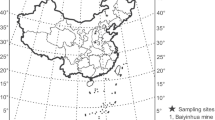

The coal samples were collected from the underground working faces of Qianqiu mine in Henan Province and Guandi mine in Shanxi Province (Fig. 1). The sampling depth in Qianqiu mine and Guandi mine was respectively 798.5 m (Nos. 2–3 coal seam) and 540.5 m (No. 2 coal seam). Proximate analysis was performed by following ISO 17246-2010 and ultimate analysis by following the ISO 17247-2013. Vitrinite reflectance measurements were carried out using incident light polarized at 45° and the reflected light passing through a 546-nm band filter on the path to the photomultiplier. The photometer was calibrated against a series of glass standards of known reflectance (Table 1).

Enrichment culture of methanogens

Studies have shown extensive populations of methanogens in mine water (Beckmann et al. 2011). The mine water from Qianqiu mine and Guandi mine was collected into a sterile glass container and sent to laboratory under anaerobic conditions and sealed at 4 °C. The methanogens medium was added to 1000-mL glass bottle and sterilized at 121 °C, then the mine water collected was added to the glass bottle and stored in 35 °C incubator for 4 days.

Enrichment culture of methanogens: 1000 mL of mine water was added to K2HPO4 0.4 g, MgCl2 2.0 g, KH2PO4 0.4 g, yeast 1.0 g, NH4Cl 1.0 g, resazurin 0.001 g, cysteine 0.5 g, Na2S 0.2 g, NaHCO3 0.2 g, sodium acetate 2.0 g, KCl 0.2 g, NaCl 2.0 g, and 10 mL of trace element solution. Trace element solution: 1000 mL of distilled water was added to triglycolamic acid 1.5 g, MnSO4·2H2O 0.5 g, MgSO4·7H2O 3.0 g, FeSO4·7H2O 0.1 g (Li 1996).

Experiment setup

Firstly, the Qianqiu and Guandi coal samples were respectively prepared into small pillars with a height of 3 mm and a diameter of about 8 mm. After an anaerobic fermentation in the bacteria liquid for 15 days, the coal pillars were soaked using 2.5% glutaraldehyde for between 2 and 4 h, washed with phosphate buffer three times, soaked using 1% osmic acid for between 4 and 6 h, and then subjected to ethanol gradient dehydration at 30%, 50%, 70%, 85%, and 95% concentrations twice, each time for between 15 and 20 min. An isoamyl acetate exchange was also used twice, each time for 20 min and the pillars were finally dried in a drying oven at 35 °C. Following vacuum coating treatment, bacterial adsorption on the surface of each coal pillar was observed using SEM.

Meanwhile, the coal samples were pulverized into 18–35 mesh, 60–80 mesh, and 100–150 mesh. And the microorganisms entering a stable stage were prepared into a bacterial suspension after 4 days of culturing at 35 °C. Then, the mixture of the coal samples and bacterial suspension was shake-cultured in a 1 g:5 mL ratio at a constant temperature for at least 120 min, which was sufficient to balance the adsorption process, and was then centrifuged at 390×g for 5 min. The supernatant of the mixture after centrifugation was then used to determine values of absorbance with a wavelength of 600 nm. The adsorption rate was calculated using the following formula:

In this expression, Q denotes the adsorption rate, while A0 is the absorbance value of the suspension before adsorption, and A is the absorbance value of the supernatant after adsorption.

Additionally, 10 mL bacteria liquid (after 4 days of culture) and 2 g coal were injected into an anaerobic reactor together while adjusting the pH to 7. Then, the reaction system was placed into a constant temperature incubator for a biogas fermentation simulation experiment.

Analysis methods

A field emission (FE)-SEM (FEI QUANTA FEG 250; Hillsboro, OR, USA) was used to observe methanogens. This system is equipped with a high stability Schottky FE electronic gun, and an acceleration voltage between 200 V and 30 kV was used with a maximum beam flow of 200 nA and sample chamber pressure up to 4000 Pa. Prior to observations, the surface of each coal pillar was coated with gold using a Cressington108Auto (Cressington Scientific, Watford, England) high-performance ion sputtering instrument.

Absorbance was determined using a spectrophotometer (UV-5200; Shanghai Metash, Shanghai, China) with wavelengths set to between 190 and 1100 nm, and with a ± 0.8 nm wavelength accuracy, ≤ 0.2 nm wavelength reproducibility, ± 0.3% T photometric accuracy, ≤ 0.1% T stray light.

Methane was quantified using a gas chromatograph (Agilent 7890 GC; Agilent Technologies Inc., Santa Clara, CA, USA) equipped with a Carbonplot chromatographic column (60 m × 320 μm × 1.5 μm) and a 200 °C TCD detector. The injection volume was 0.5 mL, a 1-mL airtight with a 1-mL airtight syringe.

Results

SEM adsorption observations

SEM observations intuitively show that a large proportion of microorganisms were adsorbed on the coal matrix (Fig. 2). The Qianqiu coal mainly possessed spherical bacteria (Fig. 2a), while the surface of Guandi coal had more bacillus (Fig. 2b). The phenomenon of adhesion and agglomeration of the microorganisms appeared in the electron microscope images. The average diameter of spherical bacteria was about 0.8 μm, while bacillus had approximately an average length of 2.5 μm and a diameter of 0.7 μm. The density of the microbial flora on Qianqiu coal was larger than that of Guandi coal, indicating that the adsorption capacity of Qianqiu coal is much stronger. Results also show that the methanogen adsorption distribution was not uniform across observation area, reflecting the selective characteristics of adsorption.

Methanogens adsorption rate

The methanogens demonstrated a certain adsorption on the surface of different coal samples (Table 2 and Fig. 3). The adsorption rate of Qianqiu coals was between 75 and 79%, while the adsorption rate of Guandi coals was between 52 and 74%. At the same particle size, the Qianqiu coals produced much more adsorption than the Guandi coals (qq-1>gd-1, qq-2>gd-2, qq-3>gd-3). Additionally, Qianqiu and Guandi coals reached lowest adsorption rate of 75% (qq-1) and 52% (gd-1), respectively, corresponding to the maximum particle size of 18–35 mesh; meanwhile, when the particle size was smallest, the Qianqiu and Guandi coals respectively reached the maximum adsorption rate (qq-3, gd-3).

Biogenic methane generation

Results show that anaerobic fermentation lasted about 25 days, until the gas production has been very weak. The sixth day and the thirteenth day were two important turning points, which the gas production rate has changed drastically (Fig. 4). Comparing different particle size samples from the Qianqiu mine, the qq-3 has the highest biogas production and methane concentration; the qq-1 has the lowest biogas production and methane concentration. Comparing different particle size samples from the Guandi mine, the gd-3 has the highest biogas production and methane concentration; the gd-1 has the lowest biogas production and methane concentration (Figs. 4 and 5). It indicates that small particle size is favorable for gas production. When we compared the same particle size, the Guandi coals (gd-1, gd-2, gd-3) produced 98.931, 130.558, and 235.455 μmol less biogas per gram than the Qianqiu coals (qq-1, qq-2, qq-3) respectively; and the methane concentration of Qianqiu coals were increased by 14.452%, 14.100% and 16.740%, respectively, compared to Guandi coals (Table 3).

Discussion

Correlations between gas production and adsorption

The cumulative biogas production and methane concentration of Qianqiu and Guandi coal samples increased gradually in concert with the adsorption rates. The order of adsorption rate is qq-3 > qq-2 > qq-1 > gd-3 > gd-2 > gd-1, while cumulative gas production is qq-3 > qq-2 > gd-3 > qq-1 > gd-2 > gd-1; the concentration of methane is qq-3 > qq-2 > qq-1 > gd-3 > gd-2 > gd-1 (Tables 2 and 3). It can be seen that the cumulative biogas production and methane concentration are positively correlated with adsorption rate (Figs. 6 and 7). And the methane concentration has a stronger linear relationship with the adsorption rate. The results of this study reveal that the adsorption of methanogens was an important factor affecting the characteristics of biological methane production.

The influence factors of adsorption and biogenesis

The adsorption rate of qq-2 increased by 2%, compared to qq-1, while qq-3 also increased by 2%, compared to qq-2. And the adsorption rate of gd-2 increased by 15%, compared to gd-1, while gd-3 increased by 7%, compared to gd-2(Table 2 and Fig. 3). Results show that the adsorption rate gradually increased with the particle size decreasing. As the particle size decreasing, it would increase the contact probability between methanogenic bacteria or enzymes and coal matrix (Guo et al. 2016; Gupta and Gupta 2014; Wang et al. 2015). The results of this study revealed that coal with a smaller particle size has a much stronger capacity for adsorption and biogas production.

The results of this study also reveal significant differences between Qianqiu and Guandi coals. The adsorption ability and methanogenesis potential of Qianqiu coal are both stronger than that of Guandi coal under the condition of same particle size, which are considered related to coal metamorphic rank. The maturity of Qianqiu coal (Ro,ran = 0.56%) is lower than Guandi coal (Ro,ran = 1.96%). Thus, it is much easier for Qianqiu coal to convert a large quantity of biogas contrasting to Guandi coal. Then, the bioavailability of organic matter in coal samples reduced with the increasing of metamorphic coal rank (Robbins et al. 2016). Qianqiu coals maybe could adsorb much more bacteria because the higher level of organic matter, which is more susceptible to microbial degradation. In addition, the lower the coals’ rank, the higher the activated polar functional group content on the surface (Zhu et al. 2001). We also speculate that the hydrogen bond association on the surface of Qianqiu coals might be more intense because of the presence of a large number of oxygen (carbonyl, carboxyl, and hydroxyl), nitrogen, and other strong negative ionic groups on the surface of Qianqiu coal samples, which contributes to the adsorption of bacteria.

Conclusions

Results clearly show that the methanogens adsorbed onto Qianqiu and Guandi coal. At the same time, the small particle size and low rank were contributing to a higher level of adsorption rate and biogas production. The adsorption rate was all bigger than 50%, indicating that adsorption of methanogens is a very common behavior and could make an important influence to the coal. This study reveals a significant positive correlation between methanogens adsorption behavior and coal biodegradation, which provides us a new path to increase the production of biogas in coal seams.

References

Ahmed M, Smith JW (2001) Biogenic methane generation in the degradation of eastern Australian Permian coal. Org Geochem 32(6):809–816. https://doi.org/10.1016/S0146-6380(01)00033-X

Barnhart EP, León KBD, Ramsay BD, Cunningham AB, Fields MW (2013) Investigation of coal-associated bacterial and archaeal populations from a diffusive microbial sampler (DMS). Int J Coal Geol 115(4):64–70. https://doi.org/10.1016/j.coal.2013.03.006

Beckmann S, Lueders T, Krüger M, Von NF, Engelen B, Cypionka H (2011) Acetogens and acetoclastic methanosarcinales govern methane formation in abandoned coal mines. Appl Environ Microbiol 77(11):3749–3756

Chen Y (2014) Surface modification effects of microorganisms on coal and the application in flotation. Doctoral Thesis. China Univ. Min. Technol. Beijing

Fang X, Li JB, Rui J, Li XZ (2015) Research progress in biochemical pathways of methanogenesis. Chin J Appl Environ Biol 21(1):1–9. https://doi.org/10.3724/SP.J.1145.2014.08019

Flores RM, Rice CA, Stricker GD, Warden A, Ellis MS (2008) Methanogenic pathways of coal-bed gas in the Powder River Basin, United States: the geologic factor. Int J Coal Geol 76(1):52–75. https://doi.org/10.1016/j.coal.2008.02.005

Guo HG, Liu RY, Yu ZS, Zhang HX, Yun JL, Li YM, Liu X, Pan JG (2012) Pyrosequencing reveals the dominance of methylotrophic methanogenesis in a coal bed methane reservoir associated with Eastern Ordos Basin in China. Int J Coal Geol 93(1):56–61. https://doi.org/10.1016/j.coal.2012.01.014

Guo HY, Liu XL, Bai Y, Chen SL (2016) Impact of coal particle size on biogenic methane metabolism and its significance. J Comput Theor Nanosci 13(2):1297–1301. https://doi.org/10.1166/jctn.2016.5046

Gupta P, Gupta A (2014) Biogas production from coal via anaerobic fermentation. Fuel 118(1):238–242. https://doi.org/10.1016/j.fuel.2013.10.075

Jia CY, Li PJ, Wei DZ, Zhang HR, Liu W (2010) Research advances on adsorption of bacteria to mineral surface. Microbiol China 37(4):607–613. https://doi.org/10.13344/j.microbiol.china.2010.04.003

Jones EJP, Voytek MA, Corum MD, Orem WH (2010) Stimulation of methane generation from nonproductive coal by addition of nutrients or a microbial consortium. Appl. Environ. Microbiol 76(21):7013–7022. https://doi.org/10.1128/AEM.00728-10

Li FD (1996) Experimental methods of agricultural microbiology. China Agric. Press, Beijing

Mahaffey WR (2012) Presentation at secondary biogenic coal bed natural gas international conference. http://wyocast.uwyo.edu/WyoCast/Play/1d376f5703c44109905b36effbcb49321d

Mittal AK, Venkobachar C (1993) Sorption and desorption of dyes by sulfonated coal. J Environ Eng 119:366–368. https://doi.org/10.1061/(ASCE)0733-9372(1993)119:2(366)

Orem WH, Voytek MA, Jones EJ, Lerch HE, Bates AL, Corum MD, Warwick PD, Clark AC (2010) Organic intermediates in the anaerobic biodegradation of coal to methane under laboratory conditions. Org Geochem 41(9):997–1000. https://doi.org/10.1016/j.orggeochem.2010.03.005

Rao KH, Subramanian S (2007) Bioflotation and bioflocculation of relevance to minerals bioprocessing. Microbial Process Metal Sulfides. https://doi.org/10.1007/1-4020-5589-7_14

Ren FP, Han CS, Wang LX, Zheng Y, Guo SZ, Liu B (2016) Microbially enhanced CBM well production rate technology and its application. Oil Drill Prod Technol 38(3):395–399 https://doi.org/10.13639/j.odpt.2016.03.023

Rightmire CT, Eddy GE, Kirr JN (1984) Coalbed methane resources of the United States. https://doi.org/10.1306/St17437

Ritter D, Vinson D, Barnhart E, Akob DM, Fields MW, Cunningham AB, Orem W, McIntosh JC (2015) Enhanced microbial coalbed methane generation: a review of research, commercial activity, and remaining challenges. Int J Coal Geol 146:28–41. https://doi.org/10.1016/j.coal.2015.04.013

Robbins SJ, Evans PN, Esterle JS, Golding SD, Tyson GW (2016) The effect of coal rank on biogenic methane potential and microbial composition. Int J Coal Geol 154:205–212. https://doi.org/10.1016/j.coal.2016.01.001

Rotaru AE, Shrestha PM, Liu F, Shrestha M, Shrestha D, Embree M, Zengle K, Wardman C, Nevin KP, Lovely DR (2014) A new model for electron flow during anaerobic digestion: direct interspecies electron transfer to methanosaeta for the reduction of carbon dioxide to methane. Energy Environ Sci 7(1):408–415. http://ir.yic.ac.cn/handle/133337/7026

Schlegel ME, McIntosh JC, Petsch ST, Orem WH, Jones EJ, Martini AM (2013) Extent and limits of biodegradation by in situ methanogenic consortia in shale and formation fluids. Appl Geochem 28(28):172–184. https://doi.org/10.1016/j.apgeochem.2012.10.008

Scott AR (1994) Thermogenic and secondary biogenic gases, San Juan Basin, Colorado and New Mexico-implications for coalbed gas producibility. Am Assoc Pet Geol Bull 78(8):1186–1209

Su XB, Xu Y, Wu Y, Xia DP, Chen X (2011) Effect of salinity and pH on biogenic methane production of low rank coal. J China Coal Soc 36(8):1302–1306

Tao MX, Wang WC, Xie GX, Li JY, Wang YL, Zhang XJ, Zhang H, Shi BG, Gao B (2005) Secondary biogenic coalbed methane found in partial coalfields in China. Chin Sci Bull 50:14–18. https://doi.org/10.1007/BF03184079

van Krevelen DW (1961) Coal: typology, chemistry, physics. Elsevier Publishing Company, Constitution

Vick SHW, Tetu SG, Sherwood N, Pinetown K, Sestak S, Vallotton P (2016) Revealing colonisation and biofilm formation of an adherent coal seam associated microbial community on a coal surface. Int J Coal Geol 160-161:42–50

Wang LY(2012) Screening of microorganisms from lignite and surface modification to fine coals by Rhodotorula mucilaginosa. Doctoral Thesis. China Univ. Min. Technol. Beijing

Wang AK, Qin Y, Shao P (2015) Effect characteristics of coal particle size on lignite biogas generation. China Coalbed Methane 12(3):3–6

Wang AK, Qin Y, Shao P (2016) Chemical factors influencing lignite biogenic gas production in laboratory condition. J. China Coal Soc 41(4):948–953. https://doi.org/10.13225/j.cnki.jccs.2015.0767

Wu M, Zhang R, Zhou J, Xie XX, Yong XY, Yan ZY, Ge MM, Zheng T (2014) Effect of temperature on methanogens metabolic pathway and structures of predominant bacteria. CIESC J 65(5):1602–1606. https://doi.org/10.3969/j.issn.0438-1157.2014.05.007

Xia DP, Chen X, Su XB, Wu Y (2012) Impact of oxidation-reduction potential on the generation of biogenic methane in low-rank coals. Nat Gas Ind 32(11):107–110. https://doi.org/10.3787/j.issn.1000-0976.2012.11.025

Yang Y, Zhang MJ, Ren GM, Zhu ZY (2016) Study on the influence of surfactants on biological desulfurization of coal. 18th Annu. Meeting Chin. Assoc. Sci. technol. 1-5, Xian, September. http://www.wanfangdata.com.cn/details/detail.do?_type=conference&id=8968958#. Accessed 21 August 2018

Zhu H, Li HL, Ou ZS, Wang DZ, Lv XL (2001) Study on surface modification of different rank coals by using FTIR. J China Univ Min Technol 30(4):366–370. https://doi.org/10.1016/j.coal.2016.04.012

Funding

This study was funded by the National Science Foundation of China (Grant no. 41472127, 41472129, and 41502158), Program for Innovative Research Team in University of Ministry of Education of China (IRT_16R22), Shanxi Provincial Program for Tackling Key Problems of Coal-based Science and Technology (Grant no. MQ2014-01), Shanxi Province Joint Research Fund of Coalbed Methane (Grant no. 2013012004), and Scientific and Technological Research Projects of Henan Province (Grant no. 172102310717).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Guo, H., Dong, Z., Liu, X. et al. Analysis of methanogens adsorption and biogas production characteristics from different coal surfaces. Environ Sci Pollut Res 26, 13825–13832 (2019). https://doi.org/10.1007/s11356-018-3219-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3219-0