Abstract

Chlorinated solvents in groundwater pose threats to human health and the environment due to their carcinogenesis and bioaccumulation. These problems are often more severe in developing countries such as China. Thus, methods for chlorinated solvent-contaminated groundwater remediation are urgently needed. This study presents a technique of in situ remediation via the direct-push amendment injection that enhances the reductive dechlorination of chlorinated solvents in groundwater in the low-permeability aquifer. A field-based pilot test and a following real-world, full-scale application were conducted at an active manufacturing facility in Shanghai, China. The chlorinated solvents found at the clay till site included 1,1,1-trichloroethane (1,1,1-TCA), 1,1-dichloroethane (1,1-DCA), 1,1-dichloroethylene (1,1-DCE), vinyl chloride (VC), and chloroethane (CA). A commercially available amendment (EHC®, Peroxychem, Philadelphia, PA) combining zero-valent iron and organic carbon was used to treat the above pollutants. Pilot test results showed that direct-push EHC injection efficiently facilitated the in situ reductive remediation of groundwater contaminated with chlorinated solvents. The mean removal rates of 1,1,1-TCA, 1,1-DCA, and 1,1-DCE at 270 days post-injection were 99.6, 99.3, and 73.3%, respectively, which were obviously higher than those of VC and CA (42.3 and 37.1%, respectively). Clear decreases in oxidation-reduction potential and dissolved oxygen concentration, and increases in Fe2+ and total organic carbon concentration, were also observed during the monitoring period. These indicate that EHC promotes the anaerobic degradation of chlorinated hydrocarbons primarily via long-term biological reductive dechlorination, with instant chemical reductive dechlorination acting as a secondary pathway. The optimal effective time of EHC injection was 0–90 days, and its radius of influence was 1.5 m. In full-scale application, the maximum concentrations of 1,1,1-TCA and 1,1-DCA in the contaminate plume fell below the relevant Dutch Intervention Values at 180 days post-injection. Moreover, the dynamics of the target pollutant concentrations mirrored those of the pilot test. Thus, we have demonstrated that the direct-push injection of EHC successfully leads to the remediation of chlorinated solvent-contaminated groundwater in a real-world scenario. The parameters determined by this study (e.g., effectiveness, injection amount, injection depth, injection pressures, and radius of influence) are applicable to other low-permeability contaminated sites where in situ remediation by enhanced reductive dechlorination is required.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic chlorinated solvents, such as 1,1,1-trichloroethane (1,1,1-TCA), 1,1-dichloroethane (1,1-DCA), 1,1-dichloroethylene (1,1-DCE), vinyl chloride (VC), are widely used in chemical, electronic, pharmaceutical, dyeing, and other industries (Siemiatycki et al. 2004). They are the most common organic pollutants in groundwater and can cause serious harm to the ecological environment and human health due to their volatile characteristics, carcinogenic effects, and potential for bioaccumulation (Huang et al. 2014; Meng et al. 2013). In China, a country with increasing levels of industrialization, chlorinated solvent pollution of groundwater has become increasingly serious and is in urgent need of mitigation. At present, the remediation methods commonly used for chlorinated solvent-contaminated groundwater include pump-and-treat, in situ chemical oxidation, chemical reduction, bioremediation, etc. (Stroo et al. 2012). Among them, the technique of in situ enhanced (biotic or abiotic) reductive dechlorination (IERD) is widely used in developed countries because of its simple procedure, low cost, and high efficiency (Atashgahi et al. 2016; Nunez et al. 2016). However, in China, most current research on this technique has been laboratory-based, and few field applications have yet been reported (Lien et al. 2016; Xie et al. 2016; Zhang et al. 2016; Zhao et al. 2013).

Recently, zero-valent iron (ZVI) combined with organic carbon amendment has been considered as a novel reactive material that can be used to enhance the reductive dechlorination of chlorinated solvents (Jeon et al. 2016). The major enhancement mechanisms include (i) a process of neutralizing fatty acids by organic carbon fermentation with hydroxyl ions produced from ZVI corrosion, which promotes abiotic degradation via reducing groundwater pH; (ii) the reliable generation of very strongly reducing conditions, which improves abiotic and biotic degradation; and (iii) using organic carbon as growth and metabolism substrates for microbes, which enhances biotic degradation (Baric et al. 2012; Patterson et al. 2016).

Amendment delivery approach is another important fact affecting the efficiency of IERD. In the low-permeability aquifer, the above granular amendment is typically delivered to the sediment using hydraulic fracturing, which can effectively distribute amendment around an injection zone by creating new fractures (Christiansen et al. 2010). However, the limitations of this approach include the inability to accurately control the final placement of amendments, risks in the geological systems, and requirement of predrilled boreholes and additives (Swift et al. 2012; Arnason et al. 2014). Direct-push injection, a delivery approach developed recently, is usually carried out via direct-push apparatus (e.g., a GeoProbe®) without above limitations (Zhao et al. 2016). This approach allows for the rapid application of amendments but is typically applied in the aquifer with high permeability due to its relatively moderate injection pressure (Christiansen et al. 2010; Arnason et al. 2014).

Therefore, this article describes a pilot field test in which the direct-push injection with increased injection pressures and more injection locations was novelly used to deliver the remediation amendment into the clay subsurface to remediate groundwater contaminated by chlorinated solvents at an active manufacturing facility in China. The commercial amendment used, EHC® (Peroxychem, Philadelphia, PA), is a mixture of ZVI and organic carbon, which can stimulate the reductive dechlorination of chlorinated hydrocarbons (CHCs) through a combination of biotic and abiotic pathways. Furthermore, a full-scale injection was conducted based on the results of the pilot test. To the best of our knowledge, this study is the first field-scale application of direct-push EHC injection for groundwater remediation in the low-permeability aquifer at an active Chinese manufacturing facility. It provides operating parameters and feasible baselines for the development of in situ enhanced reductive dechlorination technique in China.

Materials and methods

Amendment

A granular form of EHC was selected as an electron donor to enhance the degradation of chlorinated solvents at the site. This amendment was comprised of 70% w/w controlled-release, hydrophilic organic carbon (irregular shape, size ca. 350 × 280 μm) and 30% w/w micro-scale ZVI (particle size ca. 30 μm), scanning electron microscopy (SEM), and energy-dispersive spectroscopy (EDS) images of which are shown in Fig. S1 (a, b). Its major treatment mechanism is to simultaneously promote the anaerobic microbial metabolism (sequential dehalogenation) and chemical reductive dechlorination (ZVI-induced beta-elimination and hydrogenolysis) of pollutants (Peale et al. 2008). The controlled-release organic carbon can stimulate the activity of dechlorinating bacteria, and its fermentation can generate a stable low redox potential, which favors continuous anaerobic microbial metabolism (Seech et al. 2008). The degradation pathway of 1,1,1-TCA after EHC addition is shown in Fig. 1.

Field site

The contaminated site was located at an active automobile parts manufacturing factory in Shanghai Pudong New Area, China. During production processes at this factory, chlorinated solvents had been used for degreasing metal parts between approximately 1989 and 2008. The waste stream was directly discharged to the subsurface, resulting in serious pollution of the plant’s groundwater by chlorinated solvents. A previous site assessment showed that the major pollutants in the groundwater included 1,1,1-TCA, 1,1-DCE, and VC at maximum concentrations of 240.105, 15.936, and 10.517 mg/L, respectively; meanwhile, 1,1-DCA and CA were also found. According to the pollutant distribution, the whole plant area included six contaminant plumes: AOC1, AOC2, AOC3, AOC4, AOC5, and the old boiler room (Fig. 2).

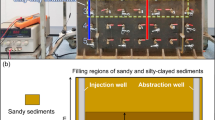

The groundwater table at the site ranges from approximately 0.4 to 1.8 m below ground surface (BGS), and the groundwater flows stably from southwest to northeast. The hydraulic conductivity is 5.73 × 10−6 m/s, based on pumping tests. The mean hydraulic gradient and flow velocity of groundwater at the site are 1.5‰ and 2.56 × 10−3 m/day, respectively. The geology of the site consists of fill (0—2.6 m BGS), underlain by silty clay (2.6—4.0 m BGS), muddy clay (5.5—19.5 m BGS), silty clay (20.1—46.8 m BGS), and sandy silt (46.8—60.0 m BGS), indicating that the aquifer there was relatively low-permeability. The contaminated aquifer was within the muddy clay at depths ranging from 6 to 8 m BGS.

Pilot test

A small pilot test injection was conducted in March 2012 to evaluate the effectiveness of the EHC direct-push method for pollutant reduction at the site and to provide key process parameters for the implementation of full-scale remediation. A pilot test area was designated around monitoring well MW-18 in AOC1, where elevated concentrations of chlorinated hydrocarbons had been recorded. The area requiring treatment was about 30 m2 and contained 172 t of sediments. The effect of EHC emplacement was determined by periodically monitoring the site over 270 days.

Design of monitoring wells and injection points

Pilot monitoring wells PMW1 (4 m BGS) and PMW2 (6 m BGS) were installed near the chlorinated hydrocarbon plume center (MW-18) at the pilot site. Regarding the dispersion and dilution of EHC in the aquifer, another pilot monitoring well (PMW3) was installed at 4 m BGS 4 m downstream from the plume center to observe the remedial effect appearing at longer distances. Monitoring wells were screened in the bottom 1.5-m interval. Three injection points were set around the plume center, forming an equilateral triangle with each point 1.5 m from the center. The detailed locations of pilot monitoring wells and injection points are shown in Fig. 3.

Injection

A total of 0.34 t of EHC was needed for the pilot test based on an application rate of 0.2% of soil mass, which was determined according to the pollutant concentrations and volumes of sediments to be treated. The EHC was injected at three points as a 30% solid slurry (with potable water) using standard Geoprobe equipment (6620DT, GEOPROBE, USA) with a pressure-activated injection tip and a grout unit (Fig. 4). The injection tip had four holes at the sides to direct the slurry horizontally. The injection depth was specified as 7.0 m BGS, which was 1.0 m deeper than the pollution depth. To facilitate the homogenization of EHC slurry in the aquifer, the slurry was injected in equal amounts at 0.5-m intervals between 1.5 and 7.0 m BGS throughout the entire vertical zone. The injection was conducted in a top-down sequence to ensure vertical distribution. Because the permeability of the aquifer was relatively low, injection pressures were deliberately set at high levels (ranging from 100 to 400 psi) with an injection flow rate of approximately 20 L/min, depending upon the injection depths and locations. Five soil cores were collected, 0.5, 1, 1.5, 2, and 3 m, from the injection point at 1 day post-injection to assess the radius of influence (ROI) of EHC for this field site. EHC bands could be found in soil cores within 1.5 m of the injection point, indicating that the ROI of EHC could be determined as 1.5 m. This was the rationale for setting the distance from the injection point to the contaminant plume center at 1.5 m. Moreover, EHC slurry overflow was reduced and its utilization was greatly improved during the injection because the contaminated area was at an active factory where most surfaces were covered by asphalt pavement.

Field monitoring and sampling

A groundwater monitoring program was implemented prior to the pilot injection (i.e., baseline sampling at 0 day) and periodically afterwards (5, 90, 180, and 270 day as the typical post-sampling events), using the three pilot monitoring wells mentioned above, to evaluate the performance of the injection program. Prior to sampling, monitoring wells were purged using a peristaltic pump with a dedicated pipe and the water levels in the monitoring wells were gauged with an electronic water-level meter. Groundwater samples from the monitoring wells were collected using a portable low-flow sampling pump (MicroPurge™, QED, USA) to reflect the actual status of groundwater. Field geochemical parameters, including dissolved oxygen (DO), oxidation-reduction potential (ORP), pH, and electrical conductivity (EC), were measured during sampling by a water quality analyzer (W-20XD, HORIBA, Japan) connected to the sampling pump with an anaerobic cell. The collected groundwater samples were analyzed by an accredited laboratory (SGS-CSTC Standards Technical Services Co., Ltd., Shanghai). The analytical schedule included chlorinated hydrocarbons, total organic carbon (TOC), and ferrous iron. All analyses were done according to standard methodologies and were generally performed in triplicate for each sample to achieve relative differences less than 10%. Specifically, chlorinated hydrocarbons were analyzed using an Agilent 6890/5973 N gas chromatograph-mass spectrometer (GC-MS) equipped with a DB-VRX 60 m × 0.25 mm × 1.4 μm column. Ultrapure helium was employed as the carrier gas with a flow rate of 1.2 mL/min. The temperature was programmed to rise at 20 °C/min from 45 to 250 °C and held for 2 min. The temperature of the injection port was maintained at 240 °C. One microliter of sample was injected with a split ratio of 20:1. Mass spectrometer conditions were as follows: ionization energy 70 eV, source temperature 230 °C, transfer line temperature 250 °C, and mass range scanned from 35 to 275 am.

Full-scale implementation

A full-scale EHC injection was implemented in AOC4 (the plume-center concentration of 1,1,1-TCA was 18.104 mg/L) in September 2013 to evaluate the feasibility of the key process parameters of EHC injection learned from the pilot test. The remediation scope in AOC4, covering an area of approximately 1000 m2 (7312 m3), was calculated based on the most recent baseline monitoring results and Dutch Intervention Values (DIVs). The injection point layout was developed using a 3 × 3 m grid according to the 1.5 m ROI used for the pilot test. Additional injection points were set 1.5 m beyond the remediation boundary to ensure complete coverage of EHC in AOC4. Thus, a total of 100 injection points were set for full-scale injection based on the pollution area (except warehouse and storage areas) and unit grid area (Fig. 5). According to the pollution characteristics in AOC4, the injection depth was specified as 8.0 m BGS and a total of 13.13 t of EHC were injected, resulting in a mean application rate of 0.15% of soil mass. The injection work was completed in 16 days. There were 13 monitoring wells in AOC4 for performance monitoring which were installed during the previous full-scale site monitoring (Fig. 5). Groundwater samples analyzed for chlorinated hydrocarbons, ethane, ethylene, and geochemical parameters were collected from the monitoring wells periodically (0, 30, 90, and 180 days as the typical sampling events). The abundance of Dehalococcoides (Dhc), an organohalide-respiring microorganism, in groundwater was also measured at 180 days via a real-time PCR analysis reported by Kocur et al. (2015). Other implementation parameters and methods for full-scale remediation, such as slurry concentration, injection equipment, injection interval/approach, injection pressures, flow rate, and sampling and analysis methods, were in accordance with those used for the pilot test.

Results and discussion

Performance evaluation of pilot test

Baseline condition in pilot test area

The concentrations of chlorinated hydrocarbons before injection (Table 1) showed that 1,1,1-TCA, 1,1-DCA, 1,1-DCE, CA, and VC were all found in the groundwater of the pilot area. Among them, the concentrations of 1,1,1-TCA, 1,1-DCE, and VC exceeded their relevant DIVs (VROM 2000). In addition, the concentration of each chlorinated hydrocarbon in PMW3 was higher than that in PMW1 and PMW2, which was inconsistent with the result from the previous site monitoring. Clement et al. (2000) also found the similar result from the study of natural attenuation of chlorinated compounds. They demonstrated that it was caused by downstream migration of the contaminant plume, or by faster natural degradation near the original plume center.

The monitoring of geochemical parameters before injection (Table 2) showed that DO concentrations (1.38—1.49 mg/L) and ORP (15.9—39.7 mV) in the groundwater were relatively high. This indicates that the pilot aquifer condition was not strictly anaerobic, which would inhibit the reductive degradation of chlorinated hydrocarbons. Therefore, it was necessary to reduce the ORP level to ensure the feasibility of using in situ reductive remediation for polluted groundwater.

Chlorinated solvent degradation by EHC injection

Figures 6 and S2 show changes in the concentrations and removal rates of chlorinated hydrocarbons in the three pilot monitoring wells during the pilot test period, respectively. On the whole, 1,1,1-TCA concentration decreased obviously within the first 90 days and then decreased more slowly. At 270 days, its mean removal rate was 99.6%. Meanwhile, the concentrations of 1,1-DCA and 1,1-DCE increased rapidly within the first 5 days, then decreased continuously. At 270 days, their mean removal rates were 99.3 and 73.3%, respectively. The concentrations of CA and VC fluctuated over time, and their final mean removal rates were 42.3 and 37.1%, respectively. The above results demonstrate that the direct-push injection of EHC, a ZVI/organic carbon amendment, can effectively enhance the in situ reductive remediation of chlorinated solvent-contaminated groundwater in the low-permeability aquifer. In general, 1,1,1-TCA can be degraded into 1,1-DCA and CA mainly by biotic dechlorination, and 1,1-DCE and VC mainly by abiotic dechlorination (Scheutz et al. 2011). Here, initial faster buildups and later higher removal rates of 1,1-DCA and CA were observed, indicating that the primary degradation pathway of chlorinated hydrocarbons (when enhanced by EHC) is organic carbon-induced biological reductive dechlorination, while the secondary pathway is ZVI-induced chemical reductive dechlorination (He et al. 2015). Baric et al. (2014) simultaneously injected ZVI and an organic substrate (polyhydroxybutyrate) into groundwater and also found that the organic substrate was the key material for promoting the reductive dechlorination of chlorinated hydrocarbons. Lower removal rates of CA and VC were observed in this pilot test because the two chlorinated hydrocarbons are not prone to dechlorination, and as secondary metabolites, their accumulation amounts would increase with the degree of 1,1-DCA and 1,1-DCE degradation (Palau et al. 2014). Moreover, chlorinated hydrocarbon concentrations changed most markedly within the first 90 days, suggesting that the EHC-enhanced degradation of chlorinated hydrocarbons was optimal during this period. Especially, the rapid degradation of 1,1,1-TCA into 1,1-DCE within 5 days after injection further indicates that chemical reductive dechlorination occurred instantly, while 1,1-DCA concentration began to decrease more significantly after 5 days, suggesting that biological pathway mainly appeared in the later period of the pilot test (5—270 days) (He et al. 2010; Kocur et al. 2015). In addition, Table S1 showed that the abundance of Dhc (gene copies/L) in groundwater samples from monitoring wells at 270 days were 2 to 3 orders of magnitude higher than those detected prior to the pilot test. This provides microbial evidence of biotic degradation occurrence following EHC injection.

There were definite differences in the degrees of degradation of chlorinated hydrocarbons in different pilot monitoring wells. At the end of the pilot test, the removal rates of 1,1,1-TCA and 1,1-DCA in the three monitoring wells were all greater than 99.0%, while 1,1-DCE removal rates in PMW1 and PMW2 were 45.9 and 48.3% higher, respectively, than in the farther well—PMW3 (P < 0.01) (Fig. S2). According to the biotic and abiotic dechlorination pathways of 1,1,1-TCA mentioned above, this result indicates that the influential range of biological reduction was larger than that of chemical reduction in the presence of EHC. The reason was that the controlled-release organic carbon could stably promote the microbial metabolism of chlorinated hydrocarbons during its diffusion in the groundwater, while the chemical promotion effect of ZVI was weakened along the downstream flow because of the striking consumption of ZVI after the initial chemical reduction proceeded at the injection site’s center (Wang et al. 2016). It can be further confirmed by the changes in Fe2+ and TOC concentrations in different monitoring wells during the pilot test period, which would be discussed in the following section. In addition, the overall order of chlorinated hydrocarbon removal rates in the three pilot monitoring wells was PMW2 > PMW1 > PMW3, indicating that the treatment effect of EHC was much better for the pollutants existing in the deeper aquifer.

Geochemical effects of EHC injection

Changes in the geochemical parameters of groundwater during the pilot monitoring period are shown in Table 3. The ORP and DO concentration decreased significantly 5 days after injection and were finally still significantly below baseline in spite of rising again after 90 days. This indicates that the amendment could rapidly induce a relatively anaerobic condition in groundwater that persisted for a long time and was beneficial to the reductive dechlorination of chlorinated hydrocarbons. Swift et al. (2012) figured that this was because the instant oxidation of ZVI and the long-term fermentation of organic carbon resulted in a dramatic decline of oxygen content in groundwater. Patterson et al. (2016) also observed the same phenomenon using a similar amendment to the present study. Fe2+ and TOC concentrations both first increased dramatically and then decreased during the pilot test period; however, at 270 days, TOC concentrations were still higher than those before injection, which was not observed for Fe2+. This is the evidence for the initial rapid consumption of ZVI and the later continuous fermentation of controlled-release organic carbon and can further support the above explanation of changes in the redox conditions of groundwater. The groundwater pH increased slightly at the end of the pilot test. It is likely due to the consumption of hydrogen ions during ZVI-induced hydrogenolysis of chlorinated hydrocarbons in groundwater (Moon et al. 2005); however, more research is needed to confirm this explanation. In addition, no apparent changes of EC in the three pilot monitoring wells were observed during the pilot test, indicating that EHC did not significantly affect ionic concentrations in groundwater.

During the optimal effective time of EHC (0–90 days), the decreases in ORP and DO concentrations in PMW1 and PMW2 were significantly higher than those in PMW3 (P < 0.01), so were the increases in Fe2+ and TOC concentrations. These indicate that the effect of EHC on the enhancement of anaerobic conditions in groundwater was stronger at the center of the injection site than downstream. This was also the reason for the high removal rates of chlorinated hydrocarbons in PMW1 and PMW2 as mentioned above. Moreover, changes in the above parameters in PMW1 were greater than those in PMW2, indicating that EHC more obviously enhanced anaerobic conditions in the shallow aquifer because of easier utilization of rich-oxygen by ZVI and microorganisms in the shallow groundwater (Scheutz et al. 2011).

Degradation of chlorinated hydrocarbons in full-scale application

Table 4 shows the mean residual concentrations and removal rates of chlorinated hydrocarbons in groundwater at various times during the full-scale application. Overall, the concentrations of chlorinated hydrocarbons in AOC4 decreased to different degrees over the 180-day monitoring period. Specifically, the concentrations of 1,1,1-TCA, 1,1-DCA, and 1,1-DCE decreased significantly within the first 90 days. Their mean removal rates at 180 days post-injection were 98.2, 98.9, and 76.8%, respectively. Residual concentrations of CA and VC were both lowest at 90 days, and their mean removal rates were 39.5 and 32.6%, respectively, 180 days after injection. Furthermore, a fairly slight increase in concentrations of nonchlorinated daughter products (ethane and ethylene) was observed (Table S2). It confirms that complete dehalogenation was occurring during the full-scale application but was not a major step of chlorinated hydrocarbon degradation due to difficult dechlorination of CA and VC (Palau et al. 2014). The final mean removal rates of chlorinated hydrocarbons in full-scale remediation were substantially lower than those in the pilot test (except for 1,1-DCE, P < 0.01). This was not only due to the higher initial concentrations of chlorinated hydrocarbons in the full-scale area but also due to the longer monitoring period and more thorough degradation of pollutants in the pilot test. Similarly, mean values of most geochemical parameters (Table S3) were inferior to those observed in the pilot test at the same sampling time, indicating that the reducing condition appeared to be weaker in the full-scale area with EHC injection. However, the patterns of chlorinated hydrocarbon concentration and geochemical parameter changes in full-scale application were consistent with the results of the pilot test, suggesting that the effect of EHC injection had good reproducibility, and the pilot operating parameters (e.g., ROI, injection system, injection approach, injection pressures, and flow rate) were reasonable and feasible for full-scale application.

The changes in distribution of 1,1,1-TCA (the main target pollutant) in AOC4 at concentrations exceeding the relevant DIV over time are profiled in Fig. 7. The initial 1,1,1-TCA plume was centered at MW-30-6 (the plume-center concentration, 18.104 mg/L). Over the first 30 days after EHC injection, the 1,1,1-TCA concentration at the plume center (which shifted to MW-30-4) decreased rapidly (5.131 mg/L), and the whole plume area showed a significant shrinking trend. By 90 days, 1,1,1-TCA concentrations in all monitoring wells in AOC4 (up to 0.282 mg/L) had declined to below its DIV, resulting in the disappearance of the plume. Concentrations did not increase again during the remainder of the 180-day monitoring period. This result indicates that 1,1,1-TCA was largely removed within 90 days after EHC injection. Plume areas of other chlorinated hydrocarbons also shrank evidently at the end of the full-scale application (Fig. S3).

The full-scale remediation effect was evaluated according to the DIV standard, and the results showed that 1,1,1-TCA (up to 0.195 mg/L) and 1,1-DCA (up to 0.763 mg/L) concentrations in AOC4 groundwater were well below the relevant DIVs 180 days after injection. This indicates that EHC injection also had a perfect removal efficiency of the above two pollutants in full-scale application. Although final mean concentrations of 1,1-DCE and VC exceeded the relevant DIVs, real excesses (up to 0.147 mg/L for 1,1-DCE and up to 0.021 mg/L for VC) were only observed in 2 or 3 monitoring wells out of 13. In addition, final concentrations of 1,1-DCE and VC in all monitoring wells were well below their site-specific target levels (SSTLs, 0.137 mg/L for 1,1-DCE and 0.009 mg/L for VC), indicating that there were no potential risks to human health and environment posed by the above two pollutants 180 days after injection. Thus, it can be considered that direct-push EHC injection was largely successful in the full-scale remediation of chlorinated solvent-contaminated groundwater in the low-permeability aquifer. However, for the sake of conservatism, longer-term monitoring is needed to determine whether supplementary EHC injections are necessary to reduce chlorinated hydrocarbon concentrations below DIV limits (Lemming et al. 2012; Muegge and Hadley 2009).

Conclusions

This study reports a field-based pilot test for the remediation of groundwater contaminated with chlorinated solvents in the low-permeability aquifer by using direct-push EHC injection that enhances the reductive dechlorination. The pilot test was then validated by a successful full-scale application at an active manufacturing facility in China. The data from this study support the following conclusions:

Chlorinated solvent-contaminated groundwater in the aquifer with low permeability can be effectively remediated in situ using direct-push injection of amendments combining ZVI and organic carbon such as EHC®.

In the pilot test, the mean final removal rates of 1,1,1-TCA and 1,1-DCA were both over 99%, which was higher than that of 1,1-DCE (73.3%). Meanwhile, the mean final removal rates of VC and CA were relatively lower (42.3 and 37.1%, respectively). These indicate that the EHC enhancement of anaerobic degradation of chlorinated hydrocarbons in groundwater primarily acts via long-term biological reductive dechlorination induced by controlled-released organic carbons. The instant chemical reductive dechlorination induced by ZVI acts as a secondary pathway. The EHC enhancement effect was considered to be optimal during the first 90 days after injection, and the ROI was set as 1.5 m. The ORP and DO concentrations decreased significantly while, in contrast, concentrations of Fe2+ and TOC increased during this time, especially at the center of the injection site and in the shallow aquifer. The EHC slightly elevated the groundwater pH but did not significantly affect the groundwater EC at the end of the pilot test.

In full-scale application, the dynamics of chlorinated hydrocarbon concentrations were consistent with those of the pilot test. All 1,1,1-TCA and 1,1-DCA concentrations in groundwater declined to levels below the relevant DIVs by the end of the application. Similar results were also observed for 1,1-DCE and VC in most monitoring wells. Furthermore, the contaminated plume of 1,1,1-TCA had disappeared by 90 days post-injection. These results suggest that the use of direct-push EHC injection in the full-scale remediation test was largely successful, and that the operation parameters (such as injection volume, injection depth, and injection pressure) derived from the pilot test were reasonable and feasible.

This study provides a useful example of the design and application of in situ enhanced reductive dechlorination technique for large-scale remediation of similar low-permeability sites contaminated with chlorinated solvents, especially in China.

References

Arnason JG, Harkness M, Butler-Veytia B (2014) Evaluating the subsurface distribution of zero-valent iron using magnetic susceptibility. Ground Water Monit Rem 34:96–106

Atashgahi S, Lu Y, Zheng Y, Saccenti E, Suarez-Diez M, Ramiro-Garcia J, Eisenmann H, Elsner M, Stams AJM, Springael D, Dejonghe W, Smidt H (2016) Geochemical and microbial community determinants of reductive dechlorination at a site biostimulated with glycerol. Environ Microbiol. doi:10.1111/1462-2920.13531

Baric M, Majone M, Beccari M, Papini MP (2012) Coupling of polyhydroxybutyrate (PHB) and zero valent iron (ZVI) for enhanced treatment of chlorinated ethanes in permeable reactive barriers (PRBs). Chem Eng J 195:22–30

Baric M, Pierro L, Pietrangeli B, Papini MP (2014) Polyhydroxyalkanoate (PHB) as a slow-release electron donor for advanced in situ bioremediation of chlorinated solvent-contaminated aquifers. New Biotechnol 31:377–382

Christiansen CM, Damgaard I, Broholm M, Kessler T, Klint KE, Nilsson B, Bjerg PL (2010) Comparison of delivery methods for enhanced in situ remediation in clay till. Ground Water Monit Rem 30:107–122

Clement TP, Johnson CD, Sun Y, Klecka GM, Bartlett C (2000) Natural attenuation of chlorinated ethene compounds: model development and field-scale application at the Dover site. J Contam Hydrol 42:113–140

He YT, Wilson JT, Su C, Wilkin RT (2015) Review of abiotic degradation of chlorinated solvents by reactive iron minerals in aquifers. Ground Water Monit Rem 35:57–75

He F, Zhao DY, Paul C (2010) Field assessment of carboxymethyl cellulose stabilized iron nanoparticles for in situ destruction of chlorinated solvents in source zones. Water Res 44:2360–2370

Huang BB, Lei C, Wei CH, Zeng GM (2014) Chlorinated volatile organic compounds (Cl-VOCs) in environment-sources, potential human health impacts and current remediation technologies. Environ Int 71:118–138

Jeon JR, Murugesan K, Baldrian P, Schmidt S, Chang YS (2016) Aerobic bacterial catabolism of persistent organic pollutants—potential impact of biotic and abiotic interaction. Curr Opin Biotechnol 38:71–78

Kocur CMD, Lomheim L, Boparai HK, Chowdhury AIA, Weber KP, Austrins LM, Edwards EA, Sleep BE, O’Carroll DM (2015) Contributions of abiotic and biotic dechlorination following carboxymethyl cellulose stabilized nanoscale zero valent iron injection. Environ Sci Technol 49:8648–8656

Lemming G, Chambon JC, Binning PJ, Bjerg PL (2012) Is there an environmental benefit from remediation of a contaminated site? Combined assessments of the risk reduction and life cycle impact of remediation. J Environ Manag 112:392–403

Lien PJ, Yang ZH, Chang YM, Tu YT, Kao CM (2016) Enhanced bioremediation of TCE-contaminated groundwater with coexistence of fuel oil: effectiveness and mechanism study. Chem Eng J 289:525–536

Meng J, Wang TY, Wang P, Giesy JP, Lu Y (2013) Perfluorinated compounds and organochlorine pesticides in soils around Huaihe River: a heavily contaminated watershed in Central China. Environ Sci Pollut Res 20:3965–3974

Moon JW, Moon HS, Kim H, Roh Y (2005) Remediation of TCE-contaminated groundwater using zero valent iron and direct current: experimental results and electron competition model. Environ Geol 48:805–817

Muegge JP, Hadley PW (2009) An evaluation of permeable reactive barrier projects in California. Remediat J 20:41–57

Nunez A, Boparai HK, O'Carroll DM (2016) Enhanced dechlorination of 1, 2-dichloroethane by coupled nano iron-dithionite treatment. Environ Sci Technol 50:5243–5251

Palau J, Shouakar-Stash O, Hunkeler D (2014) Carbon and chlorine isotope analysis to identify abiotic degradation pathways of 1, 1, 1-trichloroethane. Environ Sci Technol 48:14400–14408

Patterson BM, Lee M, Bastow TP, Wilson JT, Donn MJ, Furness A, Goodwin B, Manefield M (2016) Concentration effects on biotic and abiotic processes in the removal of 1,1,2-trichloroethane and vinyl chloride using carbon-amended ZVI. J Contam Hydrol 188:1–11

Peale JGD, Bakkom E, Lakhwala F, Mueller J, Molin J (2008) TCE plume remediation via ISCR-enhanced bioremediation utilizing EHC® and KB-1®. Remediat J 18:19–31

Scheutz C, Durant ND, Hansen MH, Bjerg PL (2011) Natural and enhanced anaerobic degradation of 1,1,1-trichloroethane and its degradation products in the subsurface–a critical review. Water Res 45:2701–2723

Seech A, Bolanos-Shaw K, Hill D, Molin J (2008) In situ bioremediation of pesticides in soil and groundwater. Remediat J 19:87–98

Siemiatycki J, Richardson L, Straif K, Latreille B, Lakhani R, Campbell S, Rousseau M, Boffetta P (2004) Listing occupational carcinogens. Environ Health Perspect 112:1447–1459

Stroo HF, Leeson A, Marqusee JA, Johnson PC, Ward CH, Kavanaugh MC, Sale TC, Newell CJ, Pennell CA, Unger M (2012) Chlorinated ethene source remediation: lessons learned. Environ Sci Technol 46:6438–6447

Swift D, Rothermel J, Peterson L, Orr B, Bures GH, Weidhaas J (2012) Remediating TCE-contaminated groundwater in low-permeability media using hydraulic fracturing to emplace zero-valent iron/organic carbon amendment. Remediat J 22:49–67

VROM (2000) Circular on target values and intervention values for soil remediation. Ministry of Housing, Spatial Planing and Environment (VROM). Directorate-General for Environmental Protection, Department of Soil Protection, Hague, Netherlands. http://www.minvrom.nl/minvrom/docs/bodem/S&I2000.pdf

Wang SQ, Chen SY, Wang Y, Low A, Lu QH, Qiu RL (2016) Integration of organohalide-respiring bacteria and nanoscale zero-valent iron (Bio-nZVI-RD): a perfect marriage for the remediation of organohalide pollutants? Biotechnol Adv 34:1384–1395

Xie YH, Yi Y, Qin YH, Wang LT, Liu GM, Wu YL, Diao ZQ, Zhou TH, Xu M (2016) Perchlorate degradation in aqueous solution using chitosan-stabilized zero-valent iron nanoparticles. Sep Purif Technol 171:164–173

Zhang S, Hou Z, Du XM, Li DM, Lu XX (2016) Assessment of biostimulation and bioaugmentation for removing chlorinated volatile organic compounds from groundwater at a former manufacture plant. Biodegradation 27:223–236

Zhao DM, Li M, Zhang DX, Baig SA, Xu XH (2013) Reductive dechlorination of 2, 4-dichlorophenol by Pd/Fe nanoparticles prepared in the presence of ultrasonic irradiation. Ultrason Sonochem 20:864–871

Zhao X, Liu W, Cai ZQ, Han B, Qian TW, Zhao DY (2016) An overview of preparation and applications of stabilized zero-valent iron nanoparticles for soil and groundwater remediation. Water Res 100:245–266

Acknowledgments

This work was supported by the Shanghai Science and Technology Commission of Shanghai Municipality, China (15DZ1205800, 15DZ2251300); the National Natural Science Foundation of China (41401357); the Shanghai Professional Development Funding, China (201528, 201644); the National High Technology Research and Development Program of China (SS2013AA062608); the Shanghai Municipal Natural Science Foundation, China (13ZR1460200); and the Technology Innovation Foundation of Shanghai Academy of Environmental Sciences, China (CX201407).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 4374 kb)

Rights and permissions

About this article

Cite this article

Yang, J., Meng, L. & Guo, L. In situ remediation of chlorinated solvent-contaminated groundwater using ZVI/organic carbon amendment in China: field pilot test and full-scale application. Environ Sci Pollut Res 25, 5051–5062 (2018). https://doi.org/10.1007/s11356-017-9903-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9903-7