Abstract

The photocatalytic degradation of three neonicotinoid insecticides (NIs), thiamethoxam (TH), imidacloprid (IM) and acetamiprid (AC), in pure water has been studied using zinc oxide (ZnO) and titanium dioxide (TiO2) as photocatalysts under natural sunlight and artificial light irradiation. Photocatalytic experiments showed that the addition of these chalcogenide oxides in tandem with the electron acceptor (Na2S2O8) strongly enhances the degradation rate of these compounds in comparison with those carried out with ZnO and TiO2 alone and photolytic tests. Comparison of catalysts showed that ZnO is the most efficient for the removal of such insecticides in optimal conditions and at constant volumetric rate of photon absorption. Thus, the complete disappearance of all the studied compounds was achieved after 10 and 30 min of artificial light irradiation, in the ZnO/Na2S2O8 and TiO2/Na2S2O8 systems, respectively. The highest degradation rate was noticed for IM, while the lowest rate constant was obtained for AC under artificial light irradiation. In addition, solar irradiation was more efficient compared to artificial light for the removal of these insecticides from water. The main photocatalytic intermediates detected during the degradation of NIs were identified.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Insecticides are substances used to destroy insect pests. The use of these substances is one of the most important ways to assure good and high quality agricultural production. However, incorrect application practices may cause the contamination of different environmental matrices such as water or soil.

Neonicotinoids are a relatively new group of insecticides, based on their structural similarity to nicotine and their common mode of action. They act on the central nervous system of insects by blocking postsynaptic nicotinic acetylcholine receptors (Roberts and Hutson 1999). Thiamethoxam (TH), imidacloprid (IM) and acetamiprid (AC) are three commercial neonicotinoids used extensively as seed dressings, as soil treatment and as foliar treatment for the control of important agricultural crop pests (Tomlin 2009). Neonicotinoids may leach through the soil profile (González-Pradas et al. 2002; Drozdzyński 2008; Gupta et al. 2008; Tomlin 2009).

Consequently, it is of primary importance to apply remediation strategies to polluted waters in order to protect water resources. Advanced oxidation processes (AOPs) have been widely applied as techniques to destroy organic pollutants in water like pesticides (Malato et al. 2009; Ahmed et al. 2011). Among these AOPs, heterogeneous photocatalysis using semiconductors (SCs), such as TiO2 and ZnO, has been the subject of great research interest due to their favourable catalytic properties. (Pichat et al. 2004; Rao and Chu 2010; Fenoll et al. 2012a). This technique mainly relies on the in situ generation of hydroxyl radicals (•OH) which are strong oxidant, capable of destroying a wide range of organic pollutants under the combined action of SC, an energetic radiation and an oxidizing agent (Malato et al. 2003; Shawaqfeh and Al Momami 2010). In general, with an appropriate light irradiation hν ≥ E g (band gap energy), the SC generates electron/hole pairs with electrons excited from the valence band to the conduction band and leaving positive holes in the valence band. These electron/hole pairs produce hydroxyl radicals, which are capable of initiating a series of chemical reactions that eventually mineralize pesticides to CO2, H2O and inorganic salts (Al Momami et al. 2007; Antoniou et al. 2008). Some excellent reviews have been published in the last decade about the fundaments of this technique and its application to degradation of pesticides in water (Devipriya and Yesodharan 2005; Malato et al. 2009; Ahmed et al. 2011; Reddy and Kim 2015).

Although TiO2 is the most widely used photocatalyst due to their unique blend of properties, ZnO is sometimes preferred over TiO2 for degradation of organic pollutants due to its high efficiency (Sakthivel et al. 2003; Daneshvar et al. 2004; Rao et al. 2009; Fenoll et al. 2012b, 2013). In addition, ZnO has a similar band gap (about 3.2 eV) and follows the same mechanism of photodegradation as TiO2 (Ahmed et al. 2011). However, it is photocorroded in acidic aqueous suspensions (Evgenidou et al. 2005).

In recent years, the photocatalytic degradation of neonicotinoids in aqueous solution has been studied using TiO2 as catalyst (Malato et al. 2001; Cernigoj et al. 2007; Cao et al. 2008; Kitsiou et al. 2009; Bernabeu et al. 2011; Guzsvány et al. 2012; Zabar et al. 2012; Mir et al. 2013). However, the effect of ZnO for the removal of these insecticides from water has received little attention. In a previous study carried out by Papp (2014), the photocatalytic degradation of imidacloprid using ZnO was only studied after 1 h of solar irradiation. In this study, silver-modified zinc oxides showed the highest activity in comparison with unmodified ZnO. Thus, to contribute to the actual application of this technology, the main goal of this research is to assess and compare the effectiveness of the photocatalytic process for the decontamination of water polluted by TH, IM and AC and its generated intermediates using two SC oxides under different types of irradiation.

Experimental

Pesticides and reagents

Analytical standards of IM, AC and TH used for standardization of the analytical procedures were purchased from Dr. Ehrenstorfer (Augsburg, Germany). The commercial formulations (Actara 25WG, thiamethoxam 25 % w/w; Couraze, imidacloprid 20 % w/v SL; and Epik, acetamiprid 20 % w/w SP) used for photocatalytical experiments were purchased from Fitodolores SL (Murcia, Spain). Zinc oxide (ZnO 99.99 %, 5 m2 g−1, <210 nm) was purchased from Alfa Aesar (Karlsruhe, Germany). Titanium dioxide P25 Degussa (99.5 %, 50 m2 g−1, <21 nm) was supplied from Nippon Aerosil Co., Ltd. (Osaka, Japan). Sodium peroxydisulfate (98 %) was purchased from Panreac Química (Barcelona, Spain). Acetonitrile was supplied by Scharlab (Barcelona, Spain).

Preparation of solutions

Several standard solutions (1–200 μg L−1) were prepared in acetonitrile to obtain the linearity of the detector response.

Photocatalysis experiment using artificial light

The photolytic and photocatalytic experiments were performed in a cylindrical glass (250 mm long, 100 mm in diameter) photochemical reactor (SBS, Barcelona, Spain) equipped with a magnetic stirring bar, and a 8-W low-pressure mercury lamp. The photochemical reactor was loaded with 2000 mL of water spiked at 0.1 mg L−1 of each active ingredient. The irradiated volume of suspension (V reactor) was 1660 mL. The intensity of the light was approximately 8.5 mW cm−2 in the wavelength range 300–460 nm with major emission output at 366 nm (based on manufacturer’s data). The photon irradiance at the wall of the lamp (UVA) was approximately 24 W m−2. The photon flux from the lamp was controlled using a portable photoradiometer Delta Ohm HD 2102.2 (Caseelle di Selvazzano, Italy) fitted with a 366-nm UVA sensor (range 315–400 nm). The study was carried out in a batch recirculation mode. The reactant solution containing different amounts of the semiconductor powder (50–300 mg L−1) and Na2S2O8 (50–350 mg L−1) as electron acceptor was circulated at a flow rate of 600 mL min−1. The reaction system was periodically bubbled with air because dissolved oxygen acts as an electron sink in the photodegradation process, forming the superoxide radical (O2 + e− → O2 •−) and avoiding the recombination of h+/e−, continuously stirred to achieve a homogeneous suspension and thermostated by circulating water to keep the temperature at 23 ± 1 °C during 2 h of irradiation. The diagram of the experimental system used is shown in Fig. 1a.

Solar photocatalysis experiment

All photodegradation experiments were carried out in Murcia, SE Spain (latitude 37° 59′ N, longitude 1° 08′ W), in Pyrex glass vessels (110 mm long, 80 mm in diameter) containing 500 mL of water spiked at 0.1 mg L−1 of each active ingredient for effect of nature irradiation and 10 mg L−1 for identification of the transformation products using natural sunlight irradiation during July, 2013 (Fig. 1b). The reaction system was continuously stirred to achieve a homogeneous suspension. The values (mean ± SD) of visible plus near-infrared (400–1100 nm), UVA (315–400 nm) and UVB (280–315 nm) irradiation were measured with the same photoradiometer previously mentioned. Several samples were taken during the photoperiod (120 min), from 12 to 14 h. The mean values of visible plus near-infrared, UVA and UVB at 13 h were 1060.3 ± 56.1, 29.8 ± 3.5 and 2.1 ± 0.2 (all in W m−2), respectively.

For both experiments, initially, 2000 mL (experiment using artificial light) or 500 mL (experiment using sunlight) of type II analytical-grade water (pH 7.1, ORP 225 mV, resistivity >5 MΩ cm (25 °C), conductivity <1.09 μS cm−1, total organic carbon (TOC) <30 μg L−1, microorganisms <10 cfu mL−1) was mixed with commercial formulation, homogenizing the mixture for 20 min in the dark. After this time, the appropriate amount of catalyst (ZnO, 200 mg L−1, and TiO2, 200 mg L−1) and oxidant (Na2S2O8, 250 mg L−1) was added to the reaction solution. The respective mixtures were maintained for 30 min in the dark prior to irradiation in order to achieve the maximum adsorption of each insecticide onto the semiconductor surface. Several samples from 0 to 120 min were taken during the irradiation period. Two parallel blank assays, without semiconductor or oxidant, were carried out (i) to test photolytic process and (ii) to assess the evaporated water volume during the treatments. In all cases, assays were replicated three times.

Analytical determinations

Water samples were extracted and analysed according to the procedure described by Fenoll et al. (2011). Analysis of neonicotinoid insecticides (NIs) and transformation products was achieved by using an HPLC system (consisting of vacuum degasser, autosampler and a binary pump; Agilent Series 1100, Agilent Technologies, Santa Clara, CA, USA) equipped with a reversed phase C8 analytical column of 150 × 4.6 mm and 5-μm particle size (Zorbax Eclipse XDB-C8) and an G6410A triple quadrupole mass spectrometer from Agilent equipped with an electrospray ionization (ESI) interface operating in positive ion mode. The mobile phases A and B were acetonitrile and 0.1 % formic acid, respectively. The gradient program started with 10 % A, constant for 5 min, followed by a linear gradient to 100 % A after 35 min. After this 35-min run time, 10 min of post-run time followed using initial 10 % of A. The flow rate was held constant (0.6 mL min−1) during the whole process, and 5 μL of samples was injected in every case. Various fragmentor voltages and collision energies were applied to the compounds under study. Table 1 lists the studied compounds along with their retention times and their optimized SRM transitions.

Blank samples were used to establish the limit of detection (LOD) and the limit of quantification (LOQ). Both LODs and LOQs were calculated from the signal-to-noise (S/N) ratio 3 and 10, respectively. The calibration samples were analysed by spiking pesticides at 1–200 μg L−1 levels into water samples in five replicates. The correlation coefficient was found to be >0.99 and the limits of quantification were 0.1, 0.1 and 0.2 μg L−1 for IM, AC and TH, respectively.

A Shimadzu TOC-L Analyser (Kyoto, Japan) equipped with an NDIR detector (680 °C combustion catalytic oxidation technique) was used. The dissolved organic carbon (DOC) procedure requires the sample be passed through a 0.45-μm filter prior to analysis to remove particulate OC from the sample.

An OPTIMA™ ICP-OES (Perkin Elmer Inc., MA, USA) equipped with double-monochromator, Scott spray chamber, GemTip™ nebulizer and dual backside-illuminated charge-coupled device (DBI-CCD) detector was used for analysis of Zn2+ in water.

Statistical analysis

The curve fitting and statistical data were obtained using SigmaPlot version 12.0 statistical software (Systat, Software Inc., San Jose, CA).

Results and discussion

Effect of photocatalyst loading, Na2S2O8 concentration and pH

Screening experiments were performed to assess the catalytic activity of ZnO and TiO2. The variables studied for optimization of photocatalytic heterogeneous process were catalyst loading, Na2S2O8 concentration and initial pH of the slurries.

The effect of the photocatalyst loading on the degradation kinetics of the studied NIs has been investigated using different concentrations of catalyst (ZnO and TiO2) varying from 50 to 300 mg L−1. The insecticide degradation initially increases by increasing ZnO and TiO2 concentrations from 0 to 200 mg L−1 for both ZnO and TiO2, remaining constant over this concentration. This behaviour can be explained by the increase in the number of active sites as a result of the increasing dosage of catalyst (Mendez-Arriaga et al. 2008). As a consequence, the optimum value for both catalysts was found to be 200 mg L−1.

The addition of electron acceptors, such as inorganic peroxides (S2O8 2−), to a semiconductor suspension usually enhances the photodegradation rate of organic pollutants as a result of increased degradation rates compared to molecular oxygen because these substances capture the photogenerated electrons more efficiently than dissolved oxygen (Ahmed et al. 2011), leading to a reduction in the electron–hole recombination and generating SO4 •− radicals, which are also a very strong oxidizing species (E 0 = 2.6 V). In this study, the effect of adding electron acceptor reactant on the degradation kinetics of the studied NIs has been evaluated using different concentrations of S2O8 2− (from 50 to 350 mg L−1). Increased concentration of peroxydisulfate in tandem with a fixed concentration of ZnO led to an increase on the reaction rate for these pesticides until it reached a plateau. The optimum value for peroxydisulfate was 250 mg L−1. Similar results were observed for TiO2.

The influence of the initial pH value on the rate constant of the process using ZnO and TiO2 was also investigated. The point of zero charge (the pH at which the surface exhibits a neutral net electrical charge) of TiO2 and ZnO is about 6 and 9, respectively (Parks 1965). Therefore, the surface is predominantly positively charged below those pHs and negatively charged above those values. Electrostatic attraction or repulsion between NIs and catalysts could be in place and, consequently, the NI photooxidation rate could be enhanced or inhibited. However, initial pH values from 6 to 8 produce an insignificant effect for TiO2 and ZnO, since NIs are non-ionized compounds at those pHs. Thus, the pH of the water should not be adjusted. As photodegradation progressed, there was a weak decrease in pH (about 0.2–0.3 units).

Similar optimal conditions (photocatalyst = 200 mg L−1, peroxydisulfate = 250 mg L−1. pH0 = 7.1) were obtained under natural sunlight and artificial light irradiation.

Evolution of NI residues

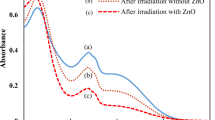

The photocatalytic oxidation of NIs both in the absence and in the presence of semiconductor catalysts is presented in Fig. 2. It is clear that the photocatalytic degradation of all NIs in the presence of the semiconductor oxides leads to the disappearance of these substances. Thus, the residual levels of TH, IM and AC at the end of the experiment using ZnO were 3.0, 2.6 and 14.3 μg L−1, respectively. In the case of TiO2, the residual levels after 120 min of light exposure were 8.9, 6.6 and 22.0 μg L−1, respectively. In the absence of a catalyst, the photolytic decomposition of these compounds occurs at a very slow rate and only a 30 % reduction of its concentration is achieved after 120 min of irradiation.

The photocatalytic degradation of the studied neonicotinoids using the tandem ZnO/Na2S2O8 and TiO2/Na2S2O8 is also presented in Fig. 2. In the presence of ZnO/Na2S2O8 and TiO2/Na2S2O8, complete disappearance was achieved after 10 and 30 min of irradiation, respectively.

Effect of solar irradiation on the photocatalytic degradation rate of NIs using ZnO and TiO2 as catalysts

In the photocatalytic oxidation process, pesticides are degraded in the presence of ZnO and TiO2, an energetic light source and an oxidizing agent such as oxygen or air. However, only photons with energy (λ < 387 nm) greater than the wide band gap energy (−3.2 eV) can result in the excitation of valence band electrons which then promote the possible reactions with pesticides (Ahmed et al. 2011). The effect of solar irradiation, a renewable source of energy, on the photodegradation rate of NIs (as mean value) using ZnO/Na2S2O8, ZnO, TiO2/Na2S2O8 and TiO2 was also studied in an area as SE of Spain receiving more than 3000 h of sunlight per year. As can be seen in Fig. 3, under solar irradiation, complete disappearance was achieved after 5 and 30 min of illumination using ZnO/Na2S2O8 and TiO2/Na2S2O8, respectively.

Kinetics of photo-assisted catalysis in ZnO and TiO2 suspensions

The Langmuir–Hinshelwood (L-H) model (Eq. 1) (Konstantinou and Albanis 2003; Herrmann 2005) considers photocatalytic reactions of contaminants adsorbed on the catalyst surface following a Langmuir isotherm and is commonly used to model photocatalytic degradation of chemical contaminants:

in which r is the rate of reaction, C is the concentration of the target compound, k LH is the apparent L-H rate constant for the reaction, and K L is the Langmuir adsorption constant. However, this model is not able in some cases to explain the photodegradation when the pollutant is not adsorbed on the surface of catalyst (Minero 1999). Nonetheless, it will undoubtedly continue to be used by many researchers because of its simplicity in fitting the experimental results (Malato et al. 2009). At low substrate concentrations (k L C << 1), the photocatalytic degradation rate of organic compounds, including pesticides, can be described by a pseudo-first-order kinetic equation, which is rationalized in terms of the L-H kinetic model:

where C P is the concentration of the organic compound and k ap (in units of time−1) is the apparent first-order rate constant and, by integration, we obtain:

The kinetic parameters of NIs in optimal conditions under artificial and sunlight irradiation are shown in Table 2 where the apparent rate constants and half-lives are listed. The degradation fitted well the exponential decay curve, following first-order behaviour consistent to the Langmuir-Hinshelwood model with R 2 ranging from 0.957 to 0.999. This behaviour is in accordance with other studies performed on neonicotinoids. However, the apparent rate constants and half-lives calculated within our study differ in comparison to other photocatalytic works, due to the different experimental setups and conditions such as photon flux, photocatalyst concentration and Na2S2O8 concentration (Malato et al. 2001; Cernigoj et al. 2007; Kitsiou et al. 2009; Zabar et al. 2012). Therefore, a comparison of photocatalytic degradation of NIs with ZnO and TiO2 was evaluated at equal level of photon absorption following the method proposed by Dolat et al. (2012). This can be easily realized under solar and artificial irradiation by adding the correct amount of catalyst in the suspension until the photon irradiance emerging from a particular reactor wall transparent to UV radiation remains equal. The absorbed percentage of light for the catalyst under solar and artificial irradiation was calculated bearing in mind the photon irradiance (UV lamp and sunlight) and absorbed light (water and glass). Table 3 shows the catalyst concentration (C w) that achieves the same proportion of photon absorption in the reactor for each catalyst, the observed rate constant of the catalyst per gram of catalyst (K w) and per unit surface area of catalyst (K s):

where k is the apparent first-order rate constant obtained by a catalyst concentration C w, V reactor is the irradiated volume of the reactor, and A c is the BET surface area.

ZnO appears to be more effective on NI oxidation than TiO2 under different types of irradiation. This result is in agreement with other studies with different pesticides (Fenoll et al. 2012a, b, c, 2013). The observed differences between ZnO and TiO2 are certainly related to the crystallinity, particle size, surface area, concentration of the impurities and optical properties of the photocatalyst (Salah et al. 2004). ZnO has a lower specific surface area (5 m2 g−1) and higher particle size (<210 nm) than TiO2 (50 m2 g−1, <21 nm). However, it has the advantage of higher electronic mobility, indicating lower charge recombination (Kitsiou et al. 2009). Moreover, the apparent extra reaction rate of ZnO under solar irradiation is very likely due to the fact that it absorbs large fraction of the solar spectrum and absorption of more light quanta than TiO2 (Sakthivel et al. 2003; Malato et al. 2009). In contrast, the main disadvantage when ZnO is used as photocatalyst is that it can be photocorroded under band gap excitation (Kudo and Miseki 2009). Toxicity in the illuminated ZnO system may be magnified by the release of Zn2+ into water as consequence of the attack of Zn-O bonds by the photogenerated holes according to the following equation: ZnO + 2 h+ → Zn2+ + ½O2. The maximum admissible Zn2+ concentration in industrial discharges established in the Segura River Basin (Region of Murcia, SE of Spain) according to Decree-Laws 1664/1998 and 16/1999 varies from 5 to 15 mg L−1, depending to the discharge area. On the other hand, the World Health Organization and the US Environmental Protection Agency (EPA) propose a legal limit in drinking water of 3 and 5 mg L−1, respectively to avoid human health concerns. In our experiment, we observed a weak increase in the concentration of Zn2+ during the degradation process. Thus, the maximum concentration of Zn2+ obtained (2.2 mg L−1) in the range of pH studied during the irradiation time was below the legal limit recommended in drinking water. If necessary, the concentration of Zn2+ can be decreased by adjusting the pH of water to about 9.5 after heterogeneous photocatalytic treatment to form the insoluble hydroxide salt (Fenoll et al. 2012c). Thus, the concentration of Zn2+ in water after precipitation treatment was below 0.1 mg L−1. Zinc removal is not complete until the metal solid is physically removed from the water, by subsequent sedimentation and filtration. However, this proposal presents some disadvantages, such as an increase of salinity and cost treatment. In addition, these results obtained under the same experimental conditions suggest that the difference in calculated rate constants is only due to the different chemical properties of selected insecticides. The highest degradation rate was noticed for IM followed by TH showing AC the lowest rate constant and the higher half-life. Similarly, Banić et al. (2014) found that thiamethoxam and imidacloprid exhibited low persistence to photolysis due to the presence of a nitroguanidine functional group, whereas acetamiprid, containing a cyanoimine functional group, was stable to photolysis.

On other hand, at equal level of photon absorption, TiO2 and ZnO present a better efficiency for catalysing the removal of these insecticides under natural sunlight than that exhibited under UV artificial light (Table 3). This behaviour is due to the higher percentage of light absorbed for the catalysts under solar irradiation (41 %), while only a 17 % of light is absorbed using artificial light. Therefore, solar irradiation was selected for further experiments, avoiding the relatively high cost of UV lamps and electricity.

Identification and evolution of the organic intermediates

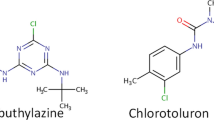

The degradation of TH, IM, and AC under photocatalytic processes leads to the formation of several transformation products (TPs). The identification of the most relevant TPs is a very important task to predict the environmental impact of the parent compound or to evaluate the efficiency of the photocatalytic treatment. In order to investigate and elucidate the yielded TPs during insecticide degradation, the kinetic evolution of the main intermediates was also followed during the solar irradiation experiment by HPLC-ESI+-MS/MS (Fig. 4). This study was carried out using a high concentration of NIs so that photoproducts could be identified. Several samples from 0 to 240 min were taken during the illumination period. Complete disappearance of all the studied compounds was achieved after 60 and 240 min of illumination, in the ZnO/Na2S2O8 and TiO2/Na2S2O8 systems, respectively. Several TPs of TH (2), IM (4), and AC (2) were isolated and identified using two transitions for each TP. These transitions obtained by HPLC-ESI+-MS/MS were correlated with previously published data (Kim et al. 2012a, b; Zabar et al. 2012; Yamamuro et al. 2014).

Evolution of transition intensity (SRM1) of NIs (10 mg L−1 of each compound) and their derivatives detected by HPLC-ESI+-MS/MS in water during the photocatalytic experiment with ZnO/Na2S2O8 and TiO2/Na2S2O8 under solar irradiation. ZnO = 200 mg L−1, TiO2 = 200 mg L−1 and Na2S2O8 = 250 mg L−1]. Error bars denote standard deviation. Inset: magnification of the plot at low levels. a AC + TiO2/Na2S2O8, b AC + ZnO/Na2S2O8, c IM + TiO2/Na2S2O8, d IM + ZnO/Na20S2O8, e TH + TiO2/Na2S2O8, f TH + ZnO/Na2S2O8

For TH, two transformation products, clothianidin (TH-1) and thiamethoxam urea (TH-2), were found during the experiment. TH-1, with the major ESI+ fragment m/z 250 (M + H), was identified with the major MS2 fragments with m/z 169 [M + H-NO2-Cl] and m/z 132 [M + H-C2H6N4O2]. The formation of TH-2, with the major ESI+ fragment m/z 248 (M + H), by the replacement of the more polar nitro group, with a carboxyl one, was also identified. The major MS2 fragments m/z 132 to [M + H-C4H8O2N2] and m/z 99 could correspond to [M + H-C4H4NOClS]. However, the two transformation products found by Zabar et al. (2012) with major ESI+ fragment m/z 206 and 208 were not detected, probably due to a higher degradation rate obtained by solar irradiation in the present study.

Four photoproducts were identified for IM during the irradiation time: 6-chloronicotinic acid (IM-1) with the major ESI+ fragment m/z 158 (M + H) and MS2 fragments m/z 122 [M + H-Cl] and m/z 132 [M + H-COOH-Cl], hydroxy imidacloprid (IM-2) with the major ESI+ fragment m/z 272 (M + H) and MS2 fragments m/z 226 [M + H-NO2] and m/z 191 [M + H-NO2-Cl], imidacloprid urea (IM-3) with the major ESI+ fragment m/z 212 (M + H) and MS2 fragments m/z 128 [M + H-C3H4N2O] and m/z 78 [M + H-C4H7N2OCl] and imidacloprid olefin (IM-4) with the major ESI+ fragment m/z 254 (M + H) and MS2 fragments m/z 205 [M + H-H-NO2] and m/z 171 [M + H-NO2-Cl]. Other intermediates as imidacloprid urea keto or imidacloprid olefin desnitro were not detected due to a high degradation rate of this compound obtained by solar irradiation.

Finally, two transformation products for AC were found. Acetamiprid desmethyl (AC-1) with the major ESI+ fragment m/z 209 (M + H) and MS2 fragments m/z 126 [M + H-C3H5N3] and m/z 90 [M + H-C3H6N3-Cl], and acetamiprid acetate (AC-2) with the major ESI+ fragment m/z 199 (M + H) and MS2 fragments m/z 156 [M + H-C2H3O] and m/z 126 [M + H-C3H7NO]. Other intermediates for AC described by Yamamuro et al. (2014) in human serum and urine were not detected.

For ZnO/Na2S2O8 system, none of the above mentioned transformation products were found in the end of the experiment (240 min), except IM-2, while IM-1, IM-2 and AC-1 were found using TiO2/Na2S2O8 at the end of the experiment. The observed differences in the number and concentration of intermediates for both systems can be attributed to the relationship between mineralizarion/transformation processes. Apparently, the mineralization processes seemed to be slower than transformation processes since the degradation of transformation products showed to be slower than degradation of parent compounds. The investigation of mineralization degree for all three insecticides was additionally performed by dissolved organic carbon (DOC) measurements. As expected, the DOC analyses confirmed a very low mineralization rate. Thus, decay in the DOC was observed during the irradiation time (240 min). In ZnO/Na2S2O8 system, 22.5, 36.9 and 37.6 % of the organic carbon was still present after 240 min for TH, IM and AC, respectively, while in TiO2/Na2S2O8 system, 35.4, 40.1 and 59.0 % of the organic carbon was still present for TH, IM and AC, respectively. These percentages should be due to the formation of non-degradable organic intermediates produced during the experiments and/or other organic compounds (coadjuvants) present in the commercial insecticide samples.

Conclusions

TH, IM and AC were totally degraded in aqueous suspensions of ZnO/Na2S2O8 and TiO2/Na2S2O8 under artificial light irradiation after 10 and 30 min, respectively. However, these systems present a better efficiency for catalysing the removal of these insecticides under natural sunlight than that exhibited by these catalysts under UV artificial light. ZnO proved to be the more efficient photocatalyst since the oxidation and decomposition of these NIs proceeded at higher reaction rates. The rate constants of the NIs using ZnO/Na2S2O8 and TiO2/Na2S2O8 under artificial light irradiation were in the order IM > TH > AC. In addition, the main photocatalytic intermediates were identified by HPLC-MS/MS during the experiments under solar irradiation. Finally, the DOC analyses confirmed a very low mineralization rate indicating that several non-degradable organic intermediates were formed.

References

Ahmed S, Rasul MG, Brown R, Hashib MA (2011) Influence of parameters on the heterogeneous photocatalytic degradation of pesticides and phenolic contaminants in wastewater: a short review. J Environ Manag 92:311–330

Al Momami FA, Shawaqfeh AT, Shawaqfeh MS (2007) Solar wastewater treatment plant for aqueous solution of pesticide. Sol Energy 81:1213–1218

Antoniou MG, Shoemaker JA, De La Cruz AA, Dionysiou DD (2008) Unveiling new degradation intermediates/pathways from the photocatalytic degradation of microcystin-LR. Environ Sci Technol 42:8877–8883

Banić ND, Šojić DV, Krstić JB, Abramović BF (2014) Photodegradation of neonicotinoid active ingredients and their commercial formulations in water by different advanced oxidation processes. Water Air Soil Pollut 225:1954

Bernabeu A, Vercher RF, Santos-Juanes L, Simon PJ, Lardin C, Martinez MA, Vicente JA, Gonzalez R, Llosa C, Arques A, Amat AM (2011) Solar photocatalysis as a tertiary treatment to remove emerging pollutants from wastewater treatment plant effluents. Catal Today 161:235–240

Cao YS, Tan HH, Shi TY, Tang T, Li JQ (2008) Preparation of Ag-doped TiO2 nanoparticles for photocatalytic degradation of acetamiprid in water. J Chem Technol Biot 83:546–552

Cernigoj U, Stangar UL, Trebse P (2007) Degradation of neonicotinoid insecticides by different advanced oxidation processes and studying the effect of ozone on TiO2 photocatalysis. Appl Catal B Environ 75:229–238

Daneshvar N, Salari D, Khataee AR (2004) Photocatalytic degradation of azo dye acid red 14 in water on ZnO as an alternative catalyst to TiO2. J Photochem Photobiol A 162:317–322

Devipriya S, Yesodharan S (2005) Photocatalytic degradation of pesticide contaminants in water. Sol Energy Mater Sol Cells 86:309–348

Dolat D, Quici N, Kusiak-Nejman E, Morawski AW, Puma GL (2012) One-step, hydrothermal synthesis of nitrogen, carbon co-doped titanium dioxide (N, C-TiO2) photocatalysts. Effect of alcohol degree and chain length as carbon dopant precursors on photocatalytic activity and catalyst deactivation. Appl Catal B Environ 115:81–89

Drozdzyński D (2008) Studies on residues of pesticides used in rape plants protection in surface waters of intensively exploited arable lands in wielkopolsa province of Poland. Ann Agric Environ Med 15:231–235

Evgenidou E, Fytianos K, Poulios I (2005) Semiconductor-sensitized photodegradation of dichlorvos in water using TiO2 and ZnO as catalysts. Appl Catal B Environ 59:81–89

Fenoll J, Hellin P, Martinez CM, Flores P, Navarro S (2011) Determination of 48 pesticides and their main metabolites in water samples by employing sonication and liquid chromatography–tandem mass spectrometry. Talanta 85:975–982

Fenoll J, Flores P, Hellín P, Martínez CM, Navarro S (2012a) Photodegradation of eight miscellaneous pesticides in drinking water after treatment with semiconductor materials under sunlight at pilot plant scale. Chem Eng J 204–206:54–64

Fenoll J, Hellín P, Flores P, Martínez CM, Navarro S (2012b) Photocatalytic degradation of five sulfonylurea herbicides in aqueous semiconductor suspensions under natural sunlight. Chemosphere 87:954–961

Fenoll J, Hellin P, Martinez CM, Flores P, Navarro S (2012c) Semiconductor oxides-sensitized photodegradation of fenamiphos in leaching water under natural sunlight. Appl Catal B Environ 115–116:31–37

Fenoll J, Sabater P, Navarro G, Pérez-Lucas G, Navarro S (2013) Photocatalytic transformation of sixteen substituted phenylurea herbicides in aqueous semiconductor suspensions: intermediates and degradation pathways. J Hazard Mater 244–245:370–379

González-Pradas E, Ureña-Amate MD, Flores-Céspedes F, Fernández-Pérez M, Garratt J, Wilkins R (2002) Leaching of imidacloprid and procimidone in a greenhouse of southeast of Spain. Soil Sci Soc Am 66:1821–1828

Gupta S, Gajbhiye VT, Gupta RK (2008) Soil dissipation and leaching behavior of a neonicotinoid insecticide thiamethoxam. Bull Environ Contam Toxicol 80:431–437

Guzsvány V, Rajić L, Jović B, Orčić D, Csanádi J, Lazić S, Abramović B (2012) Spectroscopic monitoring of photocatalytic degradation of the insecticide acetamiprid and its degradation product 6-chloronicotinic acid on TiO2 catalyst. J Environ Sci Health A 47:1919–1929

Herrmann JM (2005) Heterogeneous photocatalysis: state of the art and present applications. Top Catal 34:49–65

Kim BM, Park JS, Choi JH, Abd El-Aty AM, Na TW, Shim JH (2012) Residual determination of clothianidin and its metabolites in three minor crops via tandem mass spectrometry. Food Chem 131:1546–1551

Kitsiou V, Filippidis N, Mantzavinos D, Pouios I (2009) Heterogeneous and homogeneous photocatalytic degradation of the insecticide imidacloprid in aqueous solutions. Appl Catal B Environ 86:27–35

Konstantinou IK, Albanis TA (2003) Photocatalytic transformation of pesticides in aqueous titanium dioxide suspensions using artificial and solar light: intermediates and degradation pathways. Appl Catal B Environ 42:319–335

Kudo A, Miseki Y (2009) Heterogeneous photocatalyst materials for water splitting. Chem Soc Rev 38:253–278

Malato S, Caceres J, Agüera A, Mezcua M, Hernando D, Vial J, Fernández-Alba AR (2001) Degradation of imidacloprid in water by photo-Fenton and TiO2 photocatalysis at a solar pilot plant: a comparative study. Environ Sci Technol 35:4359–4366

Malato S, Blanco J, Vidal A, Alarcón D, Maldonado MI, Cáceres J, Gernjak W (2003) Applied studies in solar photocatalytic detoxification: an overview. Sol Energy 75:329–336

Malato S, Fernández-Ibañez P, Maldonado MI, Blanco J, Gernjak W (2009) Decontamination and disinfection of water by solar photocatalysis: recent overview and trends. Catal Today 147:1–59

Mendez-Arriaga F, Esplugas S, Gimenez J (2008) Photocatalytic degradation of non-steroidal anti-inflammatory drugs with TiO2 and simulated solar irradiation. Water Res 42:585–594

Minero C (1999) Kinetic analysis of photoinduced reactions at the water semiconductor interface. Catal Today 54:205–216

Mir NA, Khan A, Muneer M, Vijayalakhsmi S (2013) Photocatalytic degradation of a widely used insecticide thiamethoxam in aqueous suspension of TiO2: adsorption, kinetics, product analysis and toxicity assessment. Sci Total Environ 458–460:388–398

Papp Z (2014) Different silver-modified zinc oxides for photocatalytic degradation of imidacloprid. Chemija 25:1–4

Parks GA (1965) The isoelectric points of solid oxides, solid hydroxides, and aqueous hydroxo complex systems. Chem Rev 65:177–198

Pichat P, Vannier S, Dussaud J, Rubis JP (2004) Field solar photocatalytic purification of pesticides-containing rinse waters from tractor cisterns used for grapevine treatment. Sol Energy 77:533–542

Rao YF, Chu W (2010) Linuron decomposition in aqueous semiconductor suspension under visible light irradiation with and without H2O2. Chem Eng J 158:181–187

Rao AN, Sivasankar B, Sadasivam V (2009) Kinetic study on the photocatalytic degradation of salicylic acid using ZnO catalyst. J Hazard Mater 166:1357–1361

Reddy PV, Kim KH (2015) A review of photochemical approaches for the treatment of a wide range of pesticides. J Hazard Mater 285:325–335

Roberts T, Hutson D (1999) Metabolic pathways of agrochemicals. In: Roberts T, Hutson D (eds) Part two: insecticides and fungicides. The royal society of chemistry, Thomas Grahan house, Science Park, Milton road. CB4 0WF, Cambridge

Sakthivel S, Neppolian B, Shankar MV, Arabindoo B, Palanichamy M, Murugesan V (2003) Solar photocatalytic degradation of azo dye: comparison of photocatalytic efficiency of ZnO and TiO2. Sol Energy Mater Sol Cells 77:65–82

Salah NH, Bouhelassa M, Bekkouche S, Boultif A (2004) Study of photocatalytic degradation of phenol. Desalination 166:347–354

Shawaqfeh AT, Al Momami FA (2010) Photocatalytic treatment of water soluble pesticide by advanced oxidation technologies using UV light and solar energy. Sol Energy 84:1157–1165

Tomlin CDS (ed) (2009) The pesticide manual, 15th edn. British Crop Protection Council, Surrey, UK

Yamamuro T, Ohta H, Aoyama M, Watanabe D (2014) Simultaneous determination of neonicotinoid insecticides in human serum and urine using diatomaceous earth-assisted extraction and liquid chromatography-tandem mass spectrometry. J Chromatogr B 969:85–94

Zabar R, Komel T, Fabjan J, Kralj MB, Trebse P (2012) Photocatalytic degradation with immobilised TiO2 of three selected neonicotinoid insecticides: imidacloprid, thiamethoxam and clothianidin. Chemosphere 89:293–301

Acknowledgments

The authors acknowledge financial support received from Ramón and Cajal Subprogram, and the Instituto Nacional de Investigación y Tecnología Agraria y Alimentaria (Project RTA2011-00022-00-00). We are also grateful to European Social Funds, FEDER and to J. Cava, M. V. Molina and I. Garrido for technical assistance.

Conflict of interest and author agreement

We wish to confirm that there are no known conflicts of interest associated with this manuscript and there has been no significant financial support for this work that could have influenced its outcome. All named authors have read and approved this version of the manuscript, and there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Fenoll, J., Garrido, I., Hellín, P. et al. Photodegradation of neonicotinoid insecticides in water by semiconductor oxides. Environ Sci Pollut Res 22, 15055–15066 (2015). https://doi.org/10.1007/s11356-015-4721-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-4721-2