Abstract

This study aims at qualifying air pollutants and environmental impacts generated from coal-based power plants and providing useful information for decision makers on the management of coal-based power plants in China. Results showed that approximately 9.03, 54.95, 62.08, and 12.12 % of the national carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter emissions, respectively, in 2011were generated from coal-based electricity generation. The air pollutants were mainly generated from east China because of the well-developed economy and energy-intensive industries in the region. Coal-washing technology can simply and significantly reduce the environmental burden because of the relativity low content of coal gangue and sulfur in washed coal. Optimizing the efficiency of raw materials and energy consumption is additional key factor to reduce the potential environmental impacts. In addition, improving the efficiency of air pollutants (e.g., dust, mercury, sulfur dioxide, nitrogen oxides) control system and implementing the strict requirements on air pollutants for power plants are important ways for reducing the potential environmental impacts of coal-based electricity generation in China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

China is well known as the world largest coal consumer and carbon emitter (IEA 2010). Approximately 55 % of China’s coal consumption is used for the power generation industry (Wang and Pang 2011). In the last decade, the amount of coal consumption has grown dramatically because of the vast economic development and rapid urbanization. For instance, coal consumption had increased from 90 million tons to 370 million tons from 2000 to 2012 (China Statistical Yearbook 2012). China’s coal-based energy consumption structure will be retained in the long term because of its wide availability, stability of supply, and cost (Naser and Timothy 2008). However, the large amounts of coal being burned bring about serious environmental impacts. Coal burning releases huge volumes of harmful chemicals (e.g., air black carbon particulates, nitrogen oxides, carbon oxides, sulfur oxides, and polycyclic aromatic hydrocarbons (PAHs)) which can seriously affect atmosphere quality, ecological environment, and human health (Cui et al. 2012). Although the government has invested huge manpower, material, and financial resources, the effectiveness is not significant. These may attribute by the immature practice, theory, and policy and therefore significantly mitigate the effectiveness of air pollutants controlling in China (Hong and Li 2013). Therefore, to avoid pollutant transfer and secondary pollutants generation and to reduce the overall environmental burden generated from coal-based electricity power (CEP) plants, a systematic and reliable assessment is highly needed.

Life-cycle assessment (LCA) is a systematic tool for evaluating the environmental burdens associated with the entire life-cycle treatment of a product, process, or activity (ISO 14040 2006). LCA studies on CEP generation have been widely conducted worldwide (Kim and Bruce 2005; Di et al. 2007; Jaramillo et al. 2007; Xiao et al. 2011; Weisser 2009; Whitaker et al. 2012; Mallia and Lewis 2013; Zhang et al. 2010; Weber et al. 2010; Cui et al. 2012; Liang et al. 2013). Kim and Bruce (2005) and Di et al. (2007) performed life-cycle inventory studies on the US electricity system and on Chinese electricity generation technologies, respectively. However, the environmental impacts were not discussed. In addition, various power generation technologies were compared in America (Jaramillo et al. 2007; Weber et al. 2010; Whitaker et al. 2012), China (Ou et al. 2011; Xiao et al. 2011), Austria (Weisser 2009), and Canada (Mallia and Lewis 2013; Zhang et al. 2010). However, these studies only focused on the global warming impact. Other potential environmental impacts, such as human toxicity and respiratory inorganics, were not examined. Cui et al. (2012) and Liang et al. (2013) further explored the environmental impacts of electricity generation technologies and identified several methods for controlling and reducing environmental impacts in China. However, these studies only focused on on-site data and failed to consider the potential environmental impact at the national level and the improvement potentials of coal burning.

To our knowledge, extremely few studies have evaluated the environmental impacts generated from air pollutants and its improvement potentials of CEP generation at the national level. Thus, to address the aforementioned needs, evaluate the environmental burdens of air pollutants generated from CEP generation industries, and determine the key factors and effective approaches to minimize environmental burdens, the following studies were done: (1) quantify the national air pollutants generated from CEP generation, (2) describe the national environmental impact of air pollutants from CEP generation, and (3) identify the efficient ways to control and minimize air pollutants generated from CEP generation.

Materials and methods

Estimated amounts and national environmental impacts of air pollutants generated from CEP generation

Numerous pollutants are directly released to the air, (i.e., CO2, SO2, NOx, particulate matter (PM), CO, CH4, nonmethane volatile organic compounds (NMVOC), heavy metals, and PAHs) during coal burning. Di et al. (2007) had been reported national air emissions generated from CEP industries in 2002. In the present study, to understand the current air emission situation of CEP generation in China, national air pollutants generated from CEP industries in 2011 were calculated based on the report of Di et al. (2007). The national average denitration efficiency, the denitration equipment ratio, the desulfurization equipment ratio, and the removal rate of sulfur dioxide in 2011 were 30, 16.9, 87.6, and 73.2 %, respectively (China Electricity Council 2012). Equation 1 is used to calculate CO2, CO, CH4, and NMVOC emissions (Di et al. 2007). Equation 2 is used to calculate SO2 and NOx emissions (Di et al. 2007). Equation 3 is employed to calculate PM and heavy metal emissions (Di et al. 2007). Equation 4 is employed to calculate PAH emissions (Zhang 2010).

Air pollutants from coal burning were classified into nine midpoint categories (i.e., carcinogens, noncarcinogens, respiratory inorganics, respiratory organics, aquatic ecotoxicity, terrestrial ecotoxicity, aquatic acidification, terrestrial acid/nutri, and climate change) because of the requirements of selection of impact categories demanded by ISO14044 (ISO 14040 2006). The potential environmental impacts generated from CEP generation at the national level are calculated by Eq. 5. All math symbols, their definitions, and values are listed in Table 1.

The environmental impact generated from per kilowatt hour of electricity was calculated using the IMPACT2002+ method which represents the fate of a chemical with regard to multimedia, spatial transport, exposure, and risk assessment (Jolliet et al. 2003). This method is one of the most commonly used indicator approach for LCA analysis. It is a combination of IMPACT2002 (Pennington et al. 2005), Eco-indicator 99 (Goedkoop and Spriensma 2000), and CML (Guinée et al. 2001). It links all types of life-cycle inventory results via 15 midpoint categories (i.e., carcinogens, noncarcinogens, respiratory inorganics, ionizing radiation, ozone layer depletion, respiratory organics, aquatic ecotoxicity, terrestrial ecotoxicity, terrestrial acidification/nutrification, land occupation, aquatic acidification, aquatic eutrophication, global warming, nonrenewable energy, and mineral extraction). The detailed methodology and characterization factors for Impact2002+ method are available on the website of the University of Michigan Risk Science Center website (http://www.sph.umich.edu/riskcenter/jolliet/impact2002+.htm). In addition, to compare midpoint impacts and to analyze the respective share of each midpoint impact to the overall effect, normalization is applied in this paper. The normalized characterization factor is determined by the ratio of the impact per unit of emission divided by the total impact of all substances of the specific category, per person per year (Jolliet et al. 2003). The normalized characterization factor for specific category was calculated by Eq. 6.

where NCF, E, i, P, and I represent the normalized characterization factor, environmental impact per functional unit, substance, regional population, and annual emission amount, respectively.

To add the reliability of the results obtained by IMPACT 2002+, ReCiPe (Goedkoop et al. 2009; Schryver et al. 2009), TRACI (Bare et al. 2003), and CML (Guinée et al. 2001) methods were used in this study. Specifically, the ReCiPe method considers18 midpoint categories (i.e., climate change, ozone depletion, human toxicity, photochemical oxidant formation, particulate matter formation, ionizing radiation, terrestrial acidification, freshwater eutrophication, marine eutrophication, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, agricultural land occupation, urban land occupation, natural land transformation, water depletion, metal depletion, and fossil depletion). The TRACI method has nine midpoint categories (i.e., global warming, acidification, carcinogens, noncarcinogens, respiratory effects, eutrophication, ozone depletion, ecotoxicity, and smog). The CML method has ten midpoint categories (i.e., abiotic depletion, acidification, eutrophication, global warming, ozone layer depletion, human toxicity, fresh water aquatic ecotoxicity, marine aquatic ecotoxicity, terrestrial ecotoxicity, and photochemical oxidation).

Cleaner production in China’s power plants

To identify the efficient ways to control and minimize air pollutants generated from CEP generation, environmental effects of the power generation technologies commonly used in China, source reduction and end treatment of desulfurization, and the necessity for the implementation of strict air requirements on CEP industries were studied.

Comparison of electricity generation technologies

Three CEP generation technologies which are commonly used or encouraged in China, namely, the subcritical, supercritical, and ultra-supercritical technologies, were considered in this study. The integrated gasification combined cycle (IGCC) technology was also involved in the present study. This is mainly attributed by that IGCC is known to be one of the key technologies for power generation in the future (Liang et al. 2013) because of its relatively low coal consumption. However, extremely few studies have compared the environmental impacts of the aforementioned four technologies. To identify the efficient ways for reducing the air pollutants from CEP industries in China, the environmental impact generated from the four aforementioned power generation technologies was compared. The amounts of air emissions of these four technologies are collected from relevant references (Cui et al. 2012; Liang et al. 2013) (data not shown). The environmental burdens generated from air pollutants produced by each electricity generation technology were calculated using the IMPACT2002+ method as described above.

Source reduction and end treatment of desulfurization

At present, two technologies are mainly used for desulfurization in China, namely, end treatment (i.e., flue gas desulfurization (FGD)) and source treatment (i.e., coal washing) technologies. However, no environmental impact assessment of these two technologies has been compared and published. To identify the environmentally friendly desulfurization technology, the present study compares the environmental burdens generated from the aforementioned two technologies by using IMPACT2002+ method. The system boundary of FGD and coal washing is illustrated in Fig. 1. Both technologies involve the life-cycle processes of coal mining, raw materials and energy production and consumption, direct air emissions (e.g., carbon dioxide, sulfur dioxide), and reuse solid wastes as building materials. To simply and easily assess the environmental impacts, the common processes (i.e., coal mining, CEP generation) of the two technologies are excluded in this study. Infrastructure is also excluded from the coal washing and FGD processes because of the limited information on CEP plants as well as its minimal contribution to the overall environmental impacts (Cui et al. 2012).

Data on FGD (e.g., electricity, water, raw material consumption, and air emissions) are collected from relevant references (Sun and Shao 2010; Feng and Ma 2011). Annual monitoring data on coal washing (i.e., raw materials and energy consumption) are gathered from field research at a power plant in Shandong, China. Data on transport of both technologies are gathered from the reference (Ma et al. 2006). The functional unit in this section is the removal of 1 kg sulfur.

Strict requirement on air pollutants in power plants

Different areas have different air emission requirements. For example, the SO2 emission limits for environmentally sensitive and general areas are 50 and 200 mg/m3, respectively (GB 13223-2011). The strict emission requirements for power plants result in different methods for treating air pollutants. The variety of these methods necessitates the use of additional raw materials and increase energy consumption (e.g., limestone, water, and electricity), all of which may cause secondary pollution and pollution transfer. Therefore, this study checked the necessity for the implementation of strict air requirements on CEP plants. The functional unit in this section is the removal of 1 kg sulfur.

Results

Emission inventory and environmental impacts of gaseous pollutants

Table 2 shows the air pollutant emission factors (i.e., CO2, SO2, NOx, PM, CO, CH4, NMVOC, heavy metals, and PAHs) and the national air pollutants emitted from CEP generation in 2011. The total CO2, SO2, NOx, PM, CO, CH4, NMVOC, heavy metals, and PAHs emissions were approximately 3.07 × 109, 1.22 × 107, 1.49 × 107, 1.55 × 106, 3.98 × 106, 3.01 × 104, 1.72 × 106, 2.62 × 104, and 1.95 × 10−2 Mg, respectively. The national life-cycle impact assessment (LCIA) results generated by those abovementioned air pollutants are shown in Table 3. To confirm and add credibility to the current study, ReCiPe, TRACI, and CML were used as comparison. For the aquatic acidification and global warming impact categories, the LCIA results of the ReCiPe, CML, and TRACI methods are similar to those of the IMPACT2002+ method. For the respiratory inorganic category, the result of the TRACI is similar to that of the IMPACT2002+. Meanwhile, the result of the ReCiPe is higher than that of the IMPACT2002+ because the label substance of the former is PM10; if PM2.5 is considered, the potential impact of respiratory inorganics obtained by using the ReCiPe would be similar to those obtained by using the IMPACT2002+ and TRACI methods. The remaining LCIA results are difficult to compare because of the significant differences between the other categories and the label substances. Overall, these results show that the IMPACT2002+ method is reliable as far as the current study is concerned. Figure 2 depicts the most significant substances that contribute to each category. Results indicated that arsenic is the main contributor to carcinogen and noncarcinogen categories. Sulfur dioxide and nitrogen oxides contributed most to respiratory inorganics and aquatic acidification categories. For aquatic ecotoxicity and terrestrial ecotoxicity categories, lead and zinc are the main contributors. NMVOC, sulfur dioxide, and carbon dioxide contributed most to the respiratory organics, terrestrial acid/nutria, and global warming categories, respectively.

Environmental impact of different power generation technologies

The potential environmental impacts generated from the four electricity generation technologies using the IMPACT2002+ method (data not shown). The ultra-supercritical and IGCC technologies have the highest environmental benefit in all the categories, whereas the subcritical technology has the lowest environmental benefit. For the respiratory inorganics, respiratory organics, and global warming categories, the IGCC technology is two to four orders of magnitude lower than the subcritical technology. This finding can be mainly attributed to the relatively high energy efficiency of the IGCC technology.

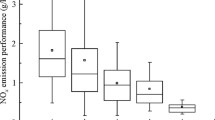

The normalized IMPACT2002+ midpoint result comparison is presented in Fig. 3. The effects found for the respiratory inorganics and global warming categories indicate dominant contributions to environmental degradation. The effect on the remaining categories is negligible. The subcritical technology generated the highest environmental burdens for all the categories because of the large amounts of direct emissions. The IGCC technology has the lowest environmental burdens because it consumes the least amount of raw coal and oil among the technologies under study.

To aid in the understanding of the dominant substances of the four electricity generation technologies, this study identifies the contributions of the most significant substances to the abovementioned key midpoint categories (Fig. 4). The substances that primarily contribute to the respiratory inorganics are direct SO2, PM, and NOx emissions generated from transport, coal production, and electricity generation. For global warming category, carbon dioxide and methane emissions generated from transport, coal production, and electricity generation play significant roles.

Source reduction and end treatment

Table 4 presents the midpoint results of FGD and coal washing. The LCIA results of FGD are higher than those of coal washing in most categories, except for ozone layer depletion and respiratory organics, which show similar results. The normalized results (Fig. 5) from IMPACT2002+ showed that the impacts identified for the respiratory inorganics, global warming, and nonrenewable energy categories significantly influence the overall impacts, whereas the impacts generated from the rest of the categories are negligible. These findings indicate that coal washing technology is useful for reducing the overall environmental burden generated from CEP generation.

Environmental impact of strict requirements on air pollutants for power plants

As mentioned earlier, strict emission requirements for power plants necessitate additional raw materials and high energy consumption, all of which may cause secondary pollution or pollution transfer. Accordingly, the environmental benefit of implementing strict requirements and the environmental burdens generated from the consequential consumption of additional materials are compared to identify whether the implementation of strict requirements is useful for reducing environmental impact (Table 5 and Fig. 6). Although the implementation of strict requirements leads to pollution transfer, it still presents significant environmental benefits. This finding is attributable to the decreased respiratory inorganics, which is the primary contributor to the overall environmental burden. These results suggest that strict requirement on air emissions for power plants helps reduce sulfur dioxide emissions as far as the current study is concerned.

Discussion

China is known as one of the largest energy consumers and GHG emitters in the world because of the rapid industrial development and economic growth. The total electricity generated from thermal power plants in the country reached 3.90 × 1012 kWh in 2011, and approximately 94.3 % of the country’s thermal power is generated from coal burning (Wei 2012). The CO2, SO2, NOx, and PM emissions from CEP generation (Table 2) account for approximately 9.03, 54.95, 62.08, and 12.12 % of the national CO2, SO2, NOx, and PM emissions, respectively, in 2011 (Ministry of Environmental Protection 2012). Figure 2 shows the national environmental impacts of CEP generation and main contributors of gaseous pollutants. At present, desulfurization and denitration technologies are encouraged and mainly used in China to reduce and control the environmental impacts of power plants. However, the national average rates of desulfurization and denitration in 2011 are reached at 73.20 and 30 % (China Electricity Council 2012), respectively. If the desulfurization and denitration rates would increase to 80 and 40 %, respectively, the amount of sulfur dioxide and nitrogen oxide emissions will decrease to approximately 3.10 × 106 Mg and 2.10 × 106 Mg, respectively. Moreover, most CEP plants use electrostatic precipitators because of their low maintenance cost; however, their PM collection efficiency is relatively low (≥95 %) compared with baghouse dust collectors (≥99 %) (Sun 2011). Accordingly, the application of baghouse dust collector and denitration and desulfurization systems as well as their treatment efficiency in CEP plants should be improved to enhance the current air conditions in China.

Figure 5 and Table 4 showed that coal washing technology had higher environmental benefit than FGD technology. In the present study, the lignite was used to assess the environmental impact of coal washing and FGD technologies. However, there is a wide range of variations in quality of coal. The sulfur and coal gangue content of coal is around 1 ~ 4 and 15 ~ 20 % (China Statistics Yearbook 2012), respectively. Therefore, the sensitivity of coal quality was studied (Fig. 7). The overall environmental impact generated from the scenarios of FGD and coal washing was approximately 1.59 × 10−3 ~ 2.16 × 10−3 and 3.68 × 10−4 ~ 7.33 × 10−4, respectively. Results showed that a linear correlation between coal gangue and sulfur content and overall environmental impact was observed. This linear relation indicated that if sulfur content is fixed, the 2 % of coal gangue content increase in coal increases about 2.15 × 10−4 and 1.42 × 10−4 in FGD and coal washing technologies, respectively. Similarly, if coal gangue content is fixed, the 1 % of sulfur content increase in coal increases about 2.76 × 10−4 and 1.54 × 10−4 in FGD and coal washing technologies, respectively. In addition, large quantities of coal need to be delivered from north to east or south China because of the ongoing economic growth. The national average railway distance for the transport of raw coal is approximately 400 km (Wang et al. 2009). Cui et al. (2012) mentioned that increasing transport distances specifically for road transport can increase environmental burden. Similar results were also obtained in the present study. Moreover, the coal washing rate of China is currently around 51 % (Chen 2011). If the washing rate is increased to 60 %, approximately 7.77 × 108 Bq C-14 eq, 8.14 × 108 kg triethylene glycol (TEG) water, 2.21 × 108 kg TEG soil, and 1.88 × 108 MJ primary in the ionizing radiation, aquatic ecotoxicity, terrestrial ecotoxicity, and nonrenewable energy categories would be reduced, respectively. The significant decrease in coal gangue transport was the main reason. Consequently, decreasing the transport distance, choosing railway transport, and improving the coal washing rate are important ways to reduce the environmental burdens generated from CEP industries.

The Chinese government is focusing on improving the efficiency of consumption of raw materials and energy in CEP plants. In recent years, many inefficient small-scaled CEP generation sites that cause pollution have been ordered to shut down (Cui et al. 2012). The direct sulfur dioxide and nitrogen oxide emissions of the IGCC technology are significantly lower than those of the three other technologies (Fig. 3). The IGCC technology also shows the lowest environmental impact in all the categories, specifically in the respiratory organics and global warming categories, because of its low coal consumption. Currently, approximately 30.57, 35.43, 30.5, and 3.50 % of the national CEP are generated by subcritical, supercritical, ultra-supercritical, and IGCC technologies, respectively (Cui et al. 2012). As mentioned earlier, subcritical technology has the highest overall environmental burden. Therefore, the conversion of 10 % subcritical technology into supercritical, ultra-supercritical, and IGCC technologies to generate electricity will produce significant environmental benefits (Table 6). Consequently, air pollutants can be reduced and the development of CEP industry can be accelerated by changing the structure of CEP plants, such as reducing low efficiency CEP generation technologies, exploring efficient and clean coal resource, and improving the efficiency of coal use in China.

At present, many researchers have been concerned on whether strict requirements on air emissions for power plants help reduce the environmental impact and mitigate the smog crisis in China. Wang et al. (2012) assessed multiple sustainability demands for wastewater treatment alternatives and concluded that increasing stringent wastewater discharge requirements increases environmental burdens because the additional chemicals and energy are required to operate sludge digesters. However, in the present study, the significant environmental benefits were observed which reveals that strict requirements on air pollutants for power plants help reduce the environmental burden (Table 5 and Fig. 6). This finding differs from that of Wang et al. (2012) because air emissions, such as sulfur dioxide, nitrogen oxides, and particulates, are key contributors to air pollution.

Conclusion

This study identifies the national air pollutants and environmental impacts generated from CEP production and approaches to reduce the overall environmental impact. Air pollutants, especially sulfur dioxide, nitrogen oxides, and particulates, are major contributors to national air pollution. Therefore, choosing coal washing technology, improving the utilization efficiency of raw materials and coal, and changing the structure of CEP plants (e.g., reducing low efficiency CEP generation technologies) are efficient ways for reducing the aforementioned air pollutants and the overall environmental burden. The inventories, potential impacts, and improvement approaches presented in this study could inform managers and policy makers in making decisions regarding the construction and retrofitting of CEP plants in China. However, this study has several limitations. A more sustainable and systematic evaluation method needs to be developed which needs to access the environmental, economic, and social LCA of CEP generation at the national level. In addition, uncertainty analysis, which is essential to define the quality of LCA analysis, is recommended to improve the reliability of the study.

References

Bare JC, Norris GA, Pennington DW, McKone T (2003) TRACI e the tool for the reduction and assessment of chemical and other environmental impacts. J Ind Ecol 6:56–68

Chen G (2011) The direction of clean coal technology during the 12th five-year period for concern. China Energy 33(8):5–8 (in Chinese)

China Electricity Council (2012) CEC issued the information of flue gas desulfurization and denitration in thermal power plants in 2011 (in Chinese) http://huanzi.cec.org.cn/dongtai/2012-02-28/80830.html

China Statistics Yearbook (2012) National Bureau of Statistic of China. Available from: http://www.stats.gov.cn/tjsj/ndsj/2012/indexch.htm

Cui XW, Hong JL, Gao MM (2012) Environmental impact assessment of three coal-based electricity generation scenarios in China. Energy 45:952–959

Di XH, Nie ZR, Yuan BR, Zuo TY (2007) Life cycle inventory for electricity generation in China. Int J Life Cycle Assess 12:217–224

IEA (International Energy Agency) (2010) World Energy Outlook 2010. http://www.iea.org/techno/etp/etp10/Chinese_Executive_Summary.pdf

Feng C, Ma X (2011) Life cycle assessment on limestone/gypsum wet flue-gas desulphurization. Electr Energy 32:379–382 (in Chinese)

GB 13223-2011. Ministry of Environmental Protection (2011) (in Chinese) Available from: http://kjs.mep.gov.cn/hjbhbz/bzwb/dqhjbh/dqgdwrywrwpfbz/201109/W020110923324406748154.pdf

Goedkoop M, Spriensma R (2000) VROM, Ministry of Housing, Spatial Planning and the Environment. VROM, Ministry of Housing, Spatial Planning and the Environment, Netherlands

Goedkoop M, Heijungs R, Huijbregts M, De Schryver A, Struijs J, Van Zelm R (2009) A life cycle impact assessment method which comprises harmonised category indicators at the mid-point and the end-point level, first ed. ReCiPe. Report I: Characterisation http://www.pre-sustainability.com/reports. Accessed May 2013

Guinée J, Gorrée M, Heijungs R, Huppes G, Kleijin R, Koning A, Oers L, Sleeswijk A, Suh S, Haes H, Bruijn H, Duin R, Huijbregts M, Lindeijer E, Roorda A, Weidema B (2001) Life cycle assessment; An operational guide to the ISO standards, Part 3: scientific background. Ministry of Housing, Spatial Planning and Environment (VROM) and Centre of Environmental Science (CML), Den Hag and Leiden, the Netherlands

Hong JL, Li XZ (2013) Speeding up cleaner production in China through the improvement of cleaner production audit. J Clean Prod 40:129–135

ISO (International Organization for Standardization) (2006) Environmental management-life cycle assessment-general principles and framework. ISO 14040, Geneva, Switzerland

Jaramillo P, Griffin WM, Matthews HS (2007) Comparative life-cycle air emissions of coal, domestic natural gas, LNG, and SNG for electricity generation. Environ Sci Technol 41:6290–6629

Jolliet O, Margni M, Charles R, Humbert S, Payet J, Rebitze G, Rosenbaum R (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8:324–330

Kim S, Bruce ED (2005) Life cycle inventory information of the United States electricity system. Int J Life Cycle Assess 10:294–304

Liang X, Wang Z, Zhou Z, Huang Z, Zhou J, Cen K (2013) Up-to-date life cycle assessment and comparison study of clean coal power generation technologies in China. J Clean Prod 39:24–31

Ma L, Wang Z, Gong X, Nie Z (2006) Life cycle inventory analysis of two types of freight transport on city roads. Conference of Chinese Materials Research, Beijing (in Chinese)

Mallia M, Lewis G (2013) Life cycle greenhouse gas emissions of electricity generation in the province of Ontario, Canada. Int J Life Cycle Assess 18:377–391

Ministry of Environmental Protection (2012) Report on the state of environment in China. (in Chinese)

Naser AO, Timothy TC (2008) Life cycle analysis of UK coal fired power plants. Energy Convers Manag 49:212–220

Ou X, Yan X, Zhang X (2011) Life-cycle energy consumption and greenhouse gas emissions for electricity generation and supply in China. Appl Energy 88:289–297

Pennington DW, Margni M, Ammann C, Jolliet O (2005) Multimedia fate and human intake modeling: spatial versus noncapital insights for chemical emissions in Western Europe. Environ Sci Technol 39:1119–1128

Schryver A, Brakkee K, Goedkoop M, Huijbregts M (2009) Characterization factors for global warming in life cycle assessment based on damages to humans and ecosystems. Environ Sci Technol 43:1689–1695

Sun Z (2011) Techno-economic analysis on hybrid electrostatic-bag filter in the large-scale power plant boiler. Electr Power Technol Econ 23:58–61 (in Chinese)

Sun ZJ, Shao W (2010) Discussion on optimization operation for flue gas desulfurization system in thermal power plants. Electr Power Technol Environ Prot 26:54–56

Wang Z, Pang H (2011) Empirical analysis on coal-fired power generation and impaction atmospheric environment in Henan province. Coal Technol 30:43–45 (in Chinese)

Wang C, Mo H, Wang J (2009) Regularity and pattern of Chinese coal resources flow field. J Nat Res 24:1402–1411

Wang X, Liu J, Ren N, Yu H, Lee D, Guo X (2012) Assessment of multiple sustainability demands for wastewater treatment alternatives: a refined evaluation scheme and case study. Environ Sci Technol 46:5542–5549

Weber CL, Jaramillo P, Marriott J, Samaras C (2010) Life cycle assessment and grid electricity: what do we know and what can we know? Environ Sci Technol 44:1895–1901

Wei ZF (2012) China Electric Power Yearbook. China Electric Power Press (in Chinese)

Weisser D (2009) A guide to life-cycle greenhouse gas (GHG) emissions from electric supply technologies. Energy 32:1543–1559

Whitaker M, Garvin AH, Patrick O, Vorum M (2012) Life cycle greenhouse gas emissions of coal-fired electricity generation. J Ind Ecol 16:53–72

Xiao B, Suo C, Yan X (2011) Comparing Chinese clean coal power generation technologies with life cycle inventory. Energy Procedia 5:2195–2200

Zhang YX (2010) Polycyclic aromatic hydrocarbons in China: emission, atmospheric transport and lung cancer risk. PhD thesis of Peking University

Zhang Y, McKechnie J, Cormier D, Lyng R, Mabee W, Ogino A, Maclean H (2010) Life cycle emissions and cost of producing electricity from coal, natural gas, and wood pellets in Ontario, Canada. Environ Sci Technol 44:538–544

Acknowledgments

We gratefully acknowledge financial support from the Institute of plateau meteorology, CMA, Chengdu, China (LPM2014002), China Energy Conservation and Emission Reduction Co. Ltd (GJN-14-07), The Fundamental Research Funds of Shandong University, and National high-tech R&D program of China (863 program, grant no. 2012AA061705).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Gerhard Lammel

Rights and permissions

About this article

Cite this article

Xu, C., Hong, J., Ren, Y. et al. Approaches for controlling air pollutants and their environmental impacts generated from coal-based electricity generation in China. Environ Sci Pollut Res 22, 12384–12395 (2015). https://doi.org/10.1007/s11356-015-4539-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-4539-y