Abstract

The degradation of methylparaben (MeP) in water was investigated using a pulsed corona discharge generated in oxygen, above the liquid. A comparison was made between results obtained in semi-batch corona (SBC) configuration (stationary solution, continuous gas flow) and results obtained in a semi-batch corona with recirculation combined with ozonation (SBCR + O3), where the liquid is continuously circulated between a solution reservoir and the plasma reactor and the effluent gas containing ozone is bubbled through the solution in the reservoir. It was found that MeP was completely degraded after 10–15 min of treatment in both configurations. Oxidation by ozone alone, in the absence of plasma, was a slower process. The energy efficiency for MeP removal (Y MeP) and for mineralization (Y TOC) was significantly higher in the SBCR + O3 configuration (Y MeP = 7.1 g/kWh at 90 % MeP removal and Y TOC = 0.41 g/kWh at 50 % total organic carbon (TOC) removal) than in the SBC configuration (Y MeP = 0.6 g/kWh at 90 % MeP removal and Y TOC = 0.11 g/kWh at 50 % TOC removal).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Parabens (R(C6H4(OH)COO), where R is an alkyl group) are alkyl esters of p-hydroxybenzoic acid differing in the ester group, which may be a methyl, ethyl, propyl, or butyl group. They are very effective antimicrobial agents, with a broad spectrum of activity (Soni et al. 2005), and are widely used as preservatives in cosmetics and personal care products, food, and pharmaceuticals (Soni et al. 2005; Boberg et al. 2010). Although parabens have been considered safe and have been employed for many decades, recent studies raise concern about their use, since they indicate that parabens possess weak estrogenic activity (Routledge et al. 1998; Soni et al. 2005). Other studies report the presence of parabens in human breast tumors (Darbre et al. 2004); therefore, an association was suggested between cosmetics containing parabens and the occurrence of breast cancer.

High amounts of parabens are continuously released into wastewater (Gonzalez-Marino et al. 2011), and although significant removal in sewage treatment plants is achieved, the effluents still contain some parabens. Chlorinated parabens have been detected as by-products formed in reactions of parabens with chlorine in tap water (Canosa et al. 2006; Terasaki et al. 2012), and it was found that they are more stable and show higher acute toxicity than that of the corresponding parent parabens (Terasaki et al. 2009). The presence of parabens and their chlorinated derivatives has been reported in influents and effluents of sewage treatment plants and in river water (Kasprzyk-Hordern et al. 2009; Terasaki et al. 2012).

Several advanced oxidation processes (AOPs) have been recently investigated for the degradation of parabens, such as photocatalysis (Lin et al. 2009, 2011; Lam et al. 2013; Fang et al. 2013), ozonation (Tay et al. 2010; Hernandez-Leal et al. 2011), H2O2–UV oxidation (Bledzka et al. 2010), and electrochemical and photoelectrochemical oxidation (Steter et al. 2014; Neumann-Spallart et al. 2013). AOPs rely on in situ generation of highly reactive hydroxyl radicals by the addition of other oxidizers (such as ozone or hydrogen peroxide) and/or UV light and/or catalysts. Lin et al. (2009, 2011) investigated TiO2 photocatalytic degradation of methylparaben (initial concentration 10 mg/L) and benzylparaben and obtained approximately 90 % degradation of the parabens after 120 min of treatment under optimized experimental conditions (related to pH, TiO2 loading, light intensity, initial paraben concentration). However, mineralization was very slow, 80 % total organic carbon (TOC) removal was achieved for methylparaben (Lin et al. 2009) and 90 % for benzylparaben (Lin et al. 2011) after 360 min of treatment. TiO2 photocatalytic treatment of propylparaben (initial concentration, ∼15 mg/L) was done by Fang et al. (2013), who obtained complete degradation after 120 min and a significant reduction of TOC of ∼75 % after 150 min of treatment. Lam et al. (2013) studied the degradation of methylparaben (initial concentration, ∼20 mg/L) with nanoscaled Bi2O3 particles coated on ZnO nanorods. Under optimized conditions, a maximum of 72.6 % degradation was achieved after 360 min (Lam et al. 2013). In ozonation experiments, complete removal of methyl-, ethyl-, propyl-, and butylparaben (initial concentration, ∼1 mg/L) was obtained after only 15 min of treatment with an ozone dosing rate of 1.22 mgL−1 min−1 (Hernandez-Leal et al. 2011). Bledzka et al. (2010) reported even faster degradation of butylparaben (initial concentration, 14.5 mg/L) in a H2O2/UV system: 90 % removal was obtained after 4.5 min of treatment. The authors found an initial linear decrease of the TOC (almost 40 % TOC removal in the first 10 min), followed by a minor abatement, so that at the end of the experiment (20 min) approximately 45 % of the initial TOC was removed (Bledzka et al. 2010). The electrochemical oxidation of methylparaben (initial concentration, 100 mg/L) on a boron-doped diamond anode has been reported by Steter et al. (2014) who achieved a mineralization degree of 92 % after 300 min of treatment.

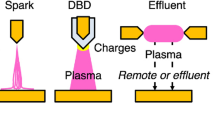

The generation of oxidizing species by non-thermal plasma in liquids and at the gas–liquid interface has been demonstrated in numerous studies. Formation of hydroxyl radicals (OH) by electrical discharges above liquid and their diffusion from gas phase into the liquid have been evidenced (Kanazawa et al. 2011; Marotta et al. 2011). Kanazawa et al. (2011) used laser-induced fluorescence (LIF) to visualize OH radicals formed by a pulsed corona discharge on the liquid surface and found that the primary generation process of OH radicals is closely related to the streamer propagation. Chemical probe measurements provide evidence that a portion of OH radicals diffuse from gas phase to the liquid surface and are dissolved in the liquid (Kanazawa et al. 2011; Marotta et al. 2011). The major reaction channels for the production and consumption of OH in water containing plasmas are discussed in Bruggeman and Schram (2010). The authors confirmed that in almost all plasmas in the ionization phase with large electron temperature (T e > 2 eV), OH is produced by electron dissociation of water molecules. However, at lower electron temperatures, dissociative electron–ion recombination and even positive–negative ion recombination can have a major contribution to the OH production, strongly depending on the ionization degree. It was also mentioned that high densities of radicals can have a positive impact on OH generation.

Ozone (O3) formation in non-thermal plasma in air or oxygen is well-known, and ozone was also detected in electrical discharges above liquid in concentrations of several thousand parts per million (ppm) (Lukes et al. 2004, 2005). Several authors compared the concentration of O3 in the gas phase when the discharge was operated above pure water and above the solution containing an organic compound, such as phenol (Hoeben et al. 1999; Marotta et al. 2011) or the pharmaceutical diclofenac (Dobrin et al. 2013). They found that the O3 concentration was lower in the presence of the organic pollutant, which clearly proves that a part of the ozone transfers into the liquid and is directly involved in the degradation of the organic compound.

Hydrogen peroxide (H2O2) is also formed in a wide range of electrical discharges generated directly in liquids, over liquid surfaces, in humid gas, water droplet sprays, and in aqueous bubble systems. Experimental data on H2O2 generation in such plasma–liquid systems are summarized in a recent review (Locke and Shih 2011). The energy efficiency for H2O2 generation by plasma from water varies over a wide range, with the highest yields found for water droplet spray, followed by water vapor gas. The authors mentioned that plasma generation of H2O2 directly from water compares favorably with other methods, such as electron beam, ultrasound, electrochemical and photochemical methods, and other chemical processes.

All oxidizing species formed in the gas and liquid phase by plasma contribute to the decomposition of organic contaminants in water in different proportions, depending on the nature of organic compounds, experimental conditions, etc. The degradation of various organic pollutants, such as phenols (Hoeben et al. 2000; Lukes and Locke 2005; Marotta et al. 2011), organic dyes (Magureanu et al. 2008, 2013; Dojcinovic et al. 2011), pharmaceutical compounds (Krause et al. 2009; Gerrity et al. 2010; Magureanu et al. 2010, 2013), and pesticides (Hijosa-Valsero et al. 2013; Manoj Kumar Reddy et al. 2014) using non-thermal plasma has been reported.

The present work investigates the degradation of methylparaben (MeP, CH3(C6H4(OH)COO)) by non-thermal plasma generated in a pulsed corona discharge above liquid. The degradation efficiency, mineralization degree, and energy consumption were evaluated. The results obtained in a semi-batch corona (SBC) configuration (stationary solution, gas flow) were compared with those obtained in a semi-batch corona with solution recirculation combined with ozonation (SBCR + O3).

Experimental arrangement

The synthesis of methylparaben was carried out by suspending 1 g of p-hydroxybenzoic acid in 10 mL of methanol. Then, 1 mL concentrated sulfuric acid (∼95 %) was added drop-wise and the mixture heated at 70 °C for 2 h. The reaction mixture was poured into cold water and the resulting solution kept at 4 °C for several hours, when the paraben precipitated as a white solid. The compound was filtered off, washed with cold water, and dried, yielding chromatographically pure paraben.

Two experimental configurations were used. The plasma reactor was the same in both cases and is described in detail in Dobrin et al. (2013). Briefly, two electrodes are attached to the vessel containing the paraben solution: the ground electrode (Al, 122 × 48 mm) placed on the bottom of the vessel and the high voltage electrode, which consists in an array of 15 wires (Cu, 100 μm × 36 mm, 6 mm distance between adjacent wires) placed at 4 mm above the liquid. The reactor is closed and oxygen is flown continuously with a rate of 300 mL/min, so the electrical discharge is generated in the gas between the wires and the solution surface. High voltage pulses of 18 kV amplitude are used. The discharge voltage and current were measured using probes (Tektronix P6015—voltage, Tektronix TCP0150—current) and were monitored by a digital oscilloscope (Tektronix DPO 2024).

In the SBC configuration, the solution (55 mL) is stationary. In the SBCR + O3 configuration (shown in Fig. 1), the paraben solution (330 mL) contained in a solution reservoir is recirculated through the plasma reactor with a flow rate of 160 mL/min. The gas leaving the discharge reactor, which contains ozone formed in the plasma, is bubbled through a porous ceramic into the solution reservoir. Ozone treatment in the absence of plasma was also tested in this set-up, keeping all other experimental parameters the same as in SBCR + O3.

The solution was prepared by dissolving methylparaben in tap water. The obtained solutions had a conductivity of 250 μS/cm and a pH of 7. The initial MeP concentration was 50 mg/L. This concentration is several orders of magnitude higher than that typically found in wastewater samples (up to 80 μg/L (Loraine and Pettigrove 2006)). However, the use of such high initial concentration is convenient for the detection of reaction products and allows the evaluation of degradation efficiency within a measurable time scale.

The MeP concentration was measured by high performance liquid chromatography (HPLC) method. For the chromatographic analysis, a Varian ProStar apparatus equipped with an UV detector (at λ = 255 nm) was employed. An ODS-3 (250 × 4.6 mm) column at 40 °C was used. The mobile phase was a mixture of phosphate buffer solution (20 mM)/acetonitrile, with a ratio of 60/40, flowing with 1.0 mL/min. The degree of mineralization of MeP was followed by TOC analysis. TOC was calculated by subtracting from the value of the total carbon (TC) the value of the total inorganic carbon (TIC). TC and TIC measurements were performed using an analyzer based on carbon dioxide infrared absorption (HiPerTOC Thermo Electron).

The concentration of ozone in the gas phase was measured by an ozone detector (Ozomat MP, Anseros).

Results and discussion

Electrical characteristics of the discharge

Typical waveforms of the discharge voltage and current are shown in Fig. 2 for the SBC configuration. The amplitude of the voltage pulses was 18 kV in these experiments, the rise rate was ∼1 kV/ns, and the pulse frequency was 23 Hz. The width of the voltage and current pulses was gradually reduced with increasing operation time. The amplitude of the current pulses increased considerably in time, from 223 A in the beginning of the treatment to 335 A after 30 min of operation. It was found that this behavior is partly due to the rise in electrical conductivity of the solution (up to 350 μS/cm after 30 min of plasma exposure) and partly due to the accumulation of water vapor in the gas phase.

The energy per pulse (determined from the integration of current–voltage product over the pulse duration) declined slightly with treatment time due to the reduction of pulse width, but remained in the range 1.1–1.2 J for the duration of experiments. The average power dissipated in the discharge (calculated by multiplying the energy per pulse by the frequency) was 26–27 W.

For the SBCR + O3 set-up, the current and voltage pulses are similar; however, the increasing trend of the current and the decrease in pulse duration are less marked. Figure 3 illustrates the variation of the current amplitude and current pulse width over the duration of experiments for both configurations used in this work.

The current amplitude increased by less than 10 % after 60 min of treatment in the SBCR + O3 configuration, while in the SBC set-up the current increased by 50 % after 30 min. The pulse width was reduced by less than 10 %, from 345 to 315 ns, after 60 min of treatment in the SBCR + O3 set-up.

Degradation of MeP

Figure 4 shows the concentration of MeP in solution as a function of plasma treatment time for the SBC and SBCR + O3 configurations. Experiments were also performed in the SBCR + O3 set-up without plasma, using ozone from an external source. The ozone concentration and all other experimental parameters (solution volume and flow rate, gas flow rate, initial MeP concentration in solution) were the same as in case of plasma treatment to ensure proper conditions for comparison. MeP was rapidly degraded, after only 10–15 min of plasma treatment the initial MeP was completely removed, while with ozone alone the time required for total removal of MeP was 20 min.

MeP was decomposed slightly faster in the SBC configuration than in the SBCR + O3 set-up, as seen in the insert in Fig. 4. The degradation obeys first-order kinetics, and the rate constant (determined from the line slope) was 0.559 min−1 for SBC and 0.425 min−1 for SBCR + O3. With ozone alone, in the absence of plasma, the degradation was significantly slower; the rate constant was in this case 0.280 min−1. The degradation of MeP in SBCR + O3 configuration can be regarded as the combination of two processes: (i) the oxidation with ozone alone and (ii) the degradation in plasma. The contribution of both processes could be considered important in the MeP degradation, since the rate constant for the ozonation process is 0.280 min−1, slightly more than half of the total rate constant for degradation in SBCR + O3. Since in this set-up, the solution is continuously recirculated between the reservoir and the plasma reactor, the contact time between plasma and solution is several times shorter than in the SBC configuration, which leads to the somewhat slower degradation than in SBC.

In photocatalytic degradation of parabens, the pseudo first-order kinetic constant varied in the range 0.0043–0.025 min−1, strongly depending on the oxygen concentration (Lin et al. 2011). A higher value was reported by Fang et al. (2013) for low concentration of propylparaben in solution (0.1962 min−1). For the degradation of n-butylparaben in a H2O2/UV system, a rate constant of 0.0984 min−1 was found (Bledzka et al. 2010). Steter et al. (2014) reported low values of the pseudo first-order rate constant of the electrochemical oxidation of methylparaben, varying in the range 1.86–3.59 × 10−3 min−1 as a function of applied current density. A comparison between these results and those obtained in the present work suggest that plasma is a promising technique for the degradation of parabens.

Mineralization of MeP

The mineralization degree of MeP solution was determined by TOC analysis. The evolution of TC, TIC, and TOC as a function of treatment time is illustrated in Fig. 5.

The TC, TIC, and TOC decline with increasing treatment time; however, the mineralization is much slower than MeP degradation. A similar behavior was reported during n-butylparaben degradation by H2O2–UV (Bledzka et al. 2010) and in case of benzylparaben and methylparaben TiO2 photocatalytic degradation (Lin et al. 2009, 2011). This result was expected, since degradation is a gradual process, leading first to the formation of organic intermediates and finally to complete decomposition of the target compound to CO2.

In the SBC configuration, the TOC was reduced by 50 % after 30 min of plasma exposure. A similar value was obtained for the TC, while the TIC decreased in the first 10–15 min and remained constant for longer time. In the SBCR + O3 set-up, the mineralization was slower. After 30 min of treatment, the TOC decreased only by 37 %, and by extending the duration of experiments to 60 min, a TOC removal of 62 % was obtained. With ozone treatment, TOC decreased by 32.7 % after 60 min, about half of the TOC removal obtained in the presence of plasma. This proves that the ozone contribution to MeP degradation in the SBCR + O3 set-up is considerable; however, the other oxidizers generated in the plasma also play an important role.

Solution pH may influence the stability of ozone in water; therefore, the pH was measured during the experiments. A steep pH decrease from 7.6 to 7.0 was observed in the first 10 min of treatment, followed by a slower increase, so that after 60 min the pH reached the initial value of 7.6. This variation is likely to be correlated to the formation of organic acids resulting from MeP degradation and their further decomposition. Since the experiments were performed in oxygen, the formation of nitric acid is not expected. In addition, the bicarbonate salts present in tap water prevent the solution pH from becoming acidic, as shown in (Marotta et al. 2012). The small variation of solution pH is not likely to influence significantly the decomposition of ozone in the aqueous solution.

A few of the published works on paraben degradation by various AOPs include also information on mineralization. These reported data are listed in Table 1 together with the results obtained in this work, although an accurate comparison is difficult due to different solution characteristics and energy input of the processes.

A fast initial decrease in TOC was found in Bledzka et al. (2010), amounting to ∼38 % after only 10 min H2O2 + UV treatment; however, an inhibition trend was observed for longer treatment durations. TOC removal was followed only up to 20 min, when it amounted to 45 % (Bledzka et al. 2010). The mineralization observed in TiO2 photocatalytic experiments (Lin et al. 2009, 2011) was considerably slower than in the present work: during the first 60 min of treatment, only 30–40 % of the initial TOC was eliminated. Only after a very long treatment time (360 min), the mineralization degree was substantial, reaching 80–90 % (Lin et al. 2009, 2011). However, Fang et al. (2013) indicated that the estrogenic activity of degraded paraben solution decreased rapidly below detection limits within 90 min of treatment, as the TOC removal efficiency increased, suggesting that the estrogenic activity of by-products formed during photocatalytic degradation can be ignored. Ecotoxicity studies showed that intermediate products of paraben degradation, especially highly hydroxylated phenolic compounds, possess high toxicity; therefore, treatment time is an essential parameter for safe water treatment (Fang et al. 2013). In electrochemical oxidation of methylparaben, it was found that TOC removal increased as a function of the current density (Steter et al. 2014). At low current density, the process is ruled by charge transfer and the removal is inefficient, while above a limit current, where mass transport becomes dominant, significant improvement of removal was observed. Thus, for long treatment times (300 min), the mineralization degree reached 92 % (Steter et al. 2014).

Efficiency of MeP degradation and mineralization

The energy efficiency for MeP degradation (Y MeP) was defined as the amount of MeP degraded per unit of energy consumed in the process. The energy efficiency for mineralization of the MeP solution (Y TOC) was defined as the amount of TOC removed per unit of energy consumed. The consumed energy was calculated considering only the power input in the electrical discharge. Y MeP and Y TOC are plotted in Fig. 6 as a function of MeP and TOC removal, respectively, for the SBC and SBCR + O3 configurations.

The energy efficiency for MeP degradation decreased with increasing removal in both configurations. In the SBC set-up, Y MeP was 1.4 g/kWh (2.56 × 10−9 mol/J) for 44 % MeP degradation and declined to 0.6 g/kWh (1.1 × 10−9 mol/J) for 90 % removal. The efficiency obtained in the SBCR + O3 configuration was more than one order of magnitude higher: 7.1 g/kWh (12.96 × 10−9 mol/J) for 90 % MeP removal. These results clearly show that ozone bubbling and solution recirculation had a beneficial effect, leading to a considerable rise in efficiency.

The energy efficiency for TOC removal was also higher in the SBCR + O3 as compared to the SBC configuration. However, the increase in efficiency is not so marked as for Y MeP. At 50 % TOC removal, Y TOC was 0.41 g/kWh in the SBCR + O3 and 0.11 g/kWh in the SBC set-up.

These results suggest that ozonation is effective for MeP degradation, which was also suggested by the experiments performed with ozone alone, in the absence of plasma, but the contribution to TOC removal is not as important. In order to further verify this assumption, the ozone consumption was investigated. The concentration of ozone in gas phase was measured during the experiment, when the discharge was operated above water and above the MeP solution. The difference between these two values represents the ozone consumed in reactions with MeP and its degradation products. The concentration of O3 formed in the plasma above water was 3 g/m3. It was found that in the SBC configuration, very little O3 was consumed due to inefficient diffusion in the liquid. Ozone consumption was observed only in the first minutes, amounting to 0.4 mg O3, while after 7 min of treatment time, the concentration of O3 was the same as for the discharge above water. In the SBCR + O3, a much larger amount of ozone was consumed than in the SBC experiments. O3 consumption was substantial in the first minutes of MeP treatment, reaching 5.6 mg O3 during 15 min of treatment. For longer treatment, the ozone consumption declined, so that after 20 min the decrease in concentration was only 0.2 g/m3 O3 and this value remained constant up to 60 min. This behavior can be correlated with the degradation of MeP, which occurred fast and was completed after 10–15 min of treatment. The degradation by-products appear to be molecules which react with ozone to a smaller extent than the parent compound. This evolution might be explained by the affinity of ozone to nucleophilic substrates. Thus, the MeP molecule, which has high electronic density, is more susceptible to the attack of molecular ozone than the non-aromatic by-products formed during the oxidation reaction (e.g. carboxylic acids). Therefore, the temporal evolution of ozone consumption also suggests that ozone bubbling through the solution significantly enhances the degradation of MeP; however, its effect on TOC removal is less significant. Other oxidizers formed in the electrical discharge (most likely OH radicals) contribute to mineralization to a greater extent than ozone.

Conclusions

Methylparaben in water was readily degraded using non-thermal plasma in contact with liquid. Plasma treatment was combined with ozonation with no additional costs, since ozone is formed in plasma in high amounts. The SBCR + O3 configuration allowed the treatment of larger solution volumes with only little increase in treatment duration as compared to the SBC set-up, most likely a consequence of shorter contact time between the solution and the plasma due to solution recirculation. The energy efficiency for MeP removal was more than one order of magnitude higher in SBCR + O3 than in SBC, reaching 7.1 g/kWh (12.96 × 10−9 mol/J) at 90 % removal. Although ozone was effective for MeP degradation, as proved by ozonation experiments in the absence of plasma, it was found that its contribution to mineralization was less important. Still, the energy efficiency for TOC removal was also improved in the combined plasma–ozonation system.

References

Bledzka D, Gryglik D, Olak M, Gebicki JL, Miller JS (2010) Degradation of n-butylparaben and 4-tert-octylphenol in H2O2/UV system. Radiat Phys Chem 79:409–416

Boberg J, Taxvig C, Christiansen S, Hass U (2010) Possible endocrine disrupting effects of parabens and their metabolites. Reprod Toxicol 30:301–312

Bruggeman P, Schram DC (2010) On OH production in water containing atmospheric pressure plasmas. Plasma Sources Sci Technol 19:045025

Canosa P, Rodriguez I, Rubi E, Negreira N, Cela R (2006) Formation of halogenated by-products of parabens in chlorinated water. Anal Chim Acta 575:106–113

Darbre PD, Aljarrah A, Miller WR, Coldham NG, Sauer MJ, Pope GS (2004) Concentrations of parabens in human breast tumours. J Appl Toxicol 24:5–13

Dobrin D, Bradu C, Magureanu M, Mandache NB, Parvulescu VI (2013) Degradation of diclofenac in water using a pulsed corona discharge. Chem Eng J 234:389–396

Dojcinovic BP, Roglic GM, Obradovic BM, Kuraica MM, Kostic MM, Nesic J, Manojlovic DD (2011) Decolorization of reactive textile dyes using water falling film dielectric barrier discharge. J Hazard Mater 192:763–771

Fang H, Gao Y, Li G, An J, Wong P-K, Fu H, Yao S, Nie X, An T (2013) Advanced oxidation kinetics and mechanism of preservative propylparaben degradation in aqueous suspension of TiO2 and risk assessment of its degradation products. Environ Sci Technol 47:2704–2712

Gerrity D, Stanford BD, Trenholm RA, Snyder SA (2010) An evaluation of a pilot-scale nonthermal plasma advanced oxidation process for trace organic compound degradation. Water Res 44:493–504

Gonzalez-Marino I, Benito Quintana J, Rodriguez I, Cela R (2011) Evaluation of the occurrence and biodegradation of parabens and halogenated by-products in wastewater by accurate mass liquid chromatography-quadrupole-time-of-flight-mass spectrometry (LC-QTOF-MS). Water Res 45:6770–6780

Hernandez-Leal L, Temmink H, Zeeman G, Buisman CJN (2011) Removal of micropollutants from aerobically treated grey water via ozone and activated carbon. Water Res 45:2887–2896

Hijosa-Valsero M, Molina R, Schikora H, Müller M, Bayona JM (2013) Removal of priority pollutants from water by means of dielectric barrier discharge atmospheric plasma. J Hazard Mater 262:664–673

Hoeben WFLM, van Veldhuizen EM, Rutgers WR, Kroesen GMW (1999) Gas phase corona discharges for oxidation of phenol in an aqueous solution. J Phys D Appl Phys 32:L133–L137

Hoeben WFLM, van Veldhuizen EM, Rutgers WR, Cramers CAMG, Kroesen GMW (2000) The degradation of aqueous phenol solutions by pulsed positive corona discharges. Plasma Sources Sci Technol 9:361–369

Kanazawa S, Kawano H, Watanabe S, Furuki T, Akamine S, Ichiki R, Ohkubo T, Kocik M, Mizeraczyk J (2011) Observation of OH radicals produced by pulsed discharges on the surface of a liquid. Plasma Sources Sci Technol 20:034010

Kasprzyk-Hordern B, Dinsdale RM, Guwy AJ (2009) The removal of pharmaceuticals, personal care products, endocrine disruptors and illicit drugs during wastewater treatment and its impact on the quality of receiving waters. Water Res 43:363–380

Krause H, Schweiger B, Schuhmacher J, Scholl S, Steinfeld U (2009) Degradation of the endocrine disrupting chemicals (EDCs) carbamazepine, clofibric acid, and iopromide by corona discharge over water. Chemosphere 75:163–168

Lam S-M, Sin J-C, Abdullah AZ, Mohamed AR (2013) Efficient photodegradation of endocrine-disrupting chemicals with Bi2O3–ZnO nanorods under a compact fluorescent lamp. Water Air Soil Pollut 224:1565

Lin Y, Ferronato C, Deng N, Wu F, Chovelon J-M (2009) Photocatalytic degradation of methylparaben by TiO2: Multivariable experimental design and mechanism. Appl Catal B Environ 88:32–41

Lin Y, Ferronato C, Deng N, Chovelon J-M (2011) Study of benzylparaben photocatalytic degradation by TiO2. Appl Catal B Environ 104:353–360

Locke BR, Shih K-Y (2011) Review of the methods to form hydrogen peroxide in electrical discharge plasma with liquid water. Plasma Sources Sci Technol 20:034006

Loraine GA, Pettigrove ME (2006) Seasonal variations in concentrations of pharmaceuticals and personal care products in drinking water and reclaimed wastewater in Southern California. Environ Sci Technol 40:687–695

Lukes P, Locke BR (2005) Plasmachemical oxidation processes in a hybrid gas–liquid electrical discharge reactor. J Phys D Appl Phys 38:4074–4081

Lukes P, Appleton AT, Locke BR (2004) Hydrogen peroxide and ozone formation in hybrid gas–liquid electrical discharge reactors. IEEE Trans Ind Appl 40:60–67

Lukes P, Clupek M, Babicky V, Janda V, Sunka P (2005) Generation of ozone by pulsed corona discharge over water surface in hybrid gas–liquid electrical discharge reactor. J Phys D Appl Phys 38:409–416

Magureanu M, Piroi D, Mandache NB, Parvulescu V (2008) Decomposition of methylene blue in water using a dielectric barrier discharge: Optimization of the operating parameters. J Appl Phys 104:103306

Magureanu M, Piroi D, Mandache NB, David V, Medvedovici A, Parvulescu VI (2010) Degradation of pharmaceutical compound pentoxifylline in water by non-thermal plasma treatment. Water Res 44:3445–3453

Magureanu M, Bradu C, Piroi D, Mandache NB, Parvulescu VI (2013) Pulsed corona discharge for degradation of methylene blue in water. Plasma Chem Plasma Process 33:51–64

Manoj Kumar Reddy P, Sk M, Subrahmanyam C (2014) Catalytic non-thermal plasma reactor for mineralization of endosulfan in aqueous medium: A green approach for the treatment of pesticide contaminated water. Chem Eng J 238:157–163

Marotta E, Schiorlin M, Ren X, Rea M, Paradisi C (2011) Advanced oxidation process for degradation of aqueous phenol in a dielectric barrier discharge reactor. Plasma Process Polym 8:867–875

Marotta E, Ceriani E, Schiorlin M, Ceretta C, Paradisi C (2012) Comparison of the rates of phenol advanced oxidation in deionized and tap water within a dielectric barrier discharge reactor. Water Res 46:6239–6246

Neumann-Spallart M, Shinde SS, Mahadik M, Bhosale CH (2013) Photoelectrochemical degradation of selected aromatic molecules. Electrochim Acta 111:830–836

Routledge EJ, Parker J, Odum J, Ashby J, Sumpter JP (1998) Some alkyl hydroxy benzoate preservatives (parabens) are estrogenic. Toxicol Appl Pharm 153:12–19

Soni MG, Carabin IG, Burdock GA (2005) Safety assessment of esters of p-hydroxybenzoic acid (parabens). Food Chem Toxicol 43:985–1015

Steter JR, Rocha RS, Dionísio D, Lanza MRV, Motheo AJ (2014) Electrochemical oxidation route of methyl paraben on a boron-doped diamond anode. Electrochim Acta 117:127–133

Tay KS, Rahman NA, Bin Abas MR (2010) Ozonation of parabens in aqueous solution: kinetics and mechanism of degradation. Chemosphere 81:1446–1453

Terasaki M, Makino M, Tatarazako N (2009) Acute toxicity of parabens and their chlorinated by-products with Daphnia magna and Vibrio fischeri bioassays. J Appl Toxicol 29:242–247

Terasaki M, Takemura Y, Makino M (2012) Paraben-chlorinated derivatives in river waters. Environ Chem Lett 10:401–406

Acknowledgments

This work was supported by a grant of the Romanian National Authority for Scientific Research, CNCS–UEFISCDI, project number PN-II-RU-TE-2011-3-0015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Dobrin, D., Magureanu, M., Bradu, C. et al. Degradation of methylparaben in water by corona plasma coupled with ozonation. Environ Sci Pollut Res 21, 12190–12197 (2014). https://doi.org/10.1007/s11356-014-2964-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-2964-y