Abstract

Centrifugal mother liquid (CML) is one of the main sources of wastewater produced during the production of polyvinyl chloride in chlor-alkali industry. CML is a typical poorly biodegradable organic wastewater, containing many kinds of refractory pollutants. Specifically, it contains dissolved refractory polymers, especially polyvinyl alcohol (PVA), which can pass though the biotreatment processes and clog the membranes used for further treatment. In this study, to ensure the CML applicable to biotreatment and membrane treatment, a novel efficient and mild technique, air-Fenton treatment, was employed as a pretreatment technique to improve biodegradability of the CML and to break down the polymers in the CML. Firstly, the technique was optimized for the CML treatment by optimizing the main parameters, including the dosage of ferrous sulfate, initial pH of the wastewater, [H2O2]/[Fe2+], aeration rate, reaction time, and temperature, based on removal efficiency of COD and PVA from the CML. Then, the optimized technique was tested and evaluated. The results indicated that under the optimized conditions, the air-Fenton treatment could remove 66, 98, and 55 % of the COD, PVA, and TOC, respectively, from the CML. After the treatment, biodegradability of the wastewater increased significantly (BOD/COD increased from 0.31 to 0.68), and almost all of the PVA polymers were removed or broken down. Meanwhile, concentration of the remaining iron ions, which were added during the treatment, was also quite low (only 2.9 mg/L). Furthermore, most of the suspended materials and ammonia nitrogen, and some of the phosphorus in the wastewater were removed simultaneously.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Centrifugal mother liquid (CML) is one of the main sources of wastewater generated during the production of polyvinyl chloride (PVC) in chlor-alkali industry. It is released from the polymerization process. Characteristics of CML include: (1) Large amount. To produce 1 t of PVC, 3 to 4 m3 of CML will be produced simultaneously (Zhao et al. 2011). (2) Low biodegradability. It contains relatively low concentrations of refractory organic pollutants. Its COD value usually ranges from about 100 to 300 mg/L, while its BOD/COD value ranges from about 0.2 to 0.3 (Huang 2007). Meanwhile, it also has the characters such as low hardness, low salinity, and high turbidity (Zhao et al. 2011). (3) It contains dissolved polymers, mainly polyvinyl alcohol (PVA), which is used as a dispersing agent in the polymerization process (Zhao et al. 2011). PVA is a stable polymer with water activity. In aquatic environment, PVA usually exists as colloids, and it usually takes about 900 days to be decomposed completely (Zhang and Zhou 2003). PVA can also form a large number of bubbles in water, affecting re-oxygenation process of the water, and can promote the migration of deposited and bound heavy metals in water (Lei 2000). Furthermore, PVA can pass though the biotreatment processes and can clog the membranes used in membrane-based wastewater treatment techniques (Yang et al. 2005). CML may also contain residual vinyl chlorine monomer, which is highly toxic (Labunska et al. 2008). Conventional CML treatment techniques include coagulation/flocculation (Al Mubaddal et al. 2009), filtration (Zhang et al. 2003), biotreatment (Song and Li 2009) and membrane technologies (Liu et al. 2010; Yang et al. 2005), etc. Coagulation/flocculation or filtration can effectively remove suspended solids but cannot remove dissolved pollutants effectively (Huang 2007). Other drawbacks of filtration include low filtration speed, high power consumption, and the need for treating the used filters (Zhao et al. 2011). Due to the low biodegradability, the efficiency of biotreatment to CML is usually low, and this can cause problems such as the bulking of activated sludge, difficulties in microbe culture, and low speed of treatment (Zhao et al. 2011). As pollutants in CML are generally refractory while their total amount is relatively low, membrane technologies are increasingly applied to CML for the regeneration and reuse of the wastewater. These techniques have the advantages such as simple operation and high treatment efficiency. However, the membranes can be easily clogged by residual PVA, and therefore need more periodic reverse cleaning and replacement, adding additional cost to their already higher treatment cost (Huang 2007; Yang et al. 2005). Since 2005, China has become the world’s largest manufacturer of PVC (Huang 2007). In 2011, there were about 110 PVC factories in China. The annual production of PVC in China is about 13 million tons, and consequently, about 50 million m3 of CML is produced each year (Bing 2012). Therefore, an efficient and convenient CML treatment technique is urgently required by most PVC manufactures in China. Currently, most PVC manufacturers in China usually already have secondary biotreatment facilities (Song and Li 2009). Meanwhile, more and more PVC manufacturers began to use membrane technologies for the advanced treatment and reuse of wastewater (Liu et al. 2010). Therefore, for these manufacturers, it would be a better scheme to pretreat the CML first with certain technique to improve its biodegradability and to breakdown the polymer chain of the PVA in it, and then treat the pretreated CML with biotreatment facilities and/or membrane technologies. So, the selection of a suitable pretreatment technique is very vital.

The mixture of hydrogen peroxide and ferrous iron is called Fenton’s reagent (Fenton 1894). Fenton oxidation is one of the most commonly used advanced oxidation techniques in wastewater treatment. The effects of Fenton’s regent can be enhanced by the introduction of UV radiation (Hu et al. 2011), ozone (Esplugas et al. 2002), electrolysis (Lin and Chang 2000), etc. These modified techniques are usually referred to as Fenton-like techniques. With advantages such as high oxidation speed and efficiency, mild operating condition, and easy management, these techniques have been successfully applied to many kinds of refractory organic wastewater (Bautista et al. 2008; Hu et al. 2011; Neyens and Baeyens 2003; Trapido et al. 2009; Zhu et al. 2011). However, they also have such limitations as the generation of iron hydroxide sludge (Pignatello et al. 2006), inherent instability of H2O2 (Tan et al. 2012), and relatively high cost. Air-Fenton technique is a novel Fenton-like technique, by introducing air into the conventional Fenton system (Deng 2007; Zhou et al. 2009). Oxygen in the air has a synergistic oxidative effect with the radicals in the system and can reduce the useless decomposition of H2O2 and result in lower cost (Deng 2007; Duesterberg and Waite 2006). Other advantages of this technique include simple operation and mild reaction conditions. However, due to its relatively low oxidation ability, air-Fenton technique is usually coupled with other treatments, such as UV radiation (Zhou et al. 2009). At present, mechanical understanding of the effects of aeration on the oxidation process is still sketchy, and quantitative effects of aeration rate on the reaction have not been reported yet. Furthermore, the application of air-Fenton technique to CML treatment has not been reported yet either. Therefore, in this study, we selected the simple and cost-effective air-Fenton technique as the pretreatment technique for CML. The effects of main parameters and factors of the technique on the treatment of CML were investigated by series of simulated degradation experiments, based on the removal efficiency of COD and PVA. Accordingly, the optimized parameters of the air-Fenton technique were obtained and evaluated.

Materials and methods

Sample collection

CML samples were taken from a large chlor-alkali chemical plant in Jilin Province, China. A typical suspension polymerization technique is employed in the plant for the production of PVC. Concentrations of COD and BOD in CML from this plant usually range from 100 to 200 mg/L and from 30 to 50 mg/L, respectively, and turbidity of CML is around 40 NTU. Concentrations of ammonia nitrogen (NH3-N) and total phosphorus (TP) in CML are relatively low. Concentrations of some important ingredients and some parameters determined for the CML sample used in this study are listed in Table 1.

Air-Fenton simulation experiment

Air-Fenton simulation experiment was conducted in the apparatus shown in Fig. 1, which was made of Plexiglas. The reaction column had a diameter of 50 mm, and its effective length was 450 mm. The column was filled with 400 mL of CML, whose pH and temperature had been adjusted to the expected values. The pH was adjusted by H2SO4 and/or NaOH. The Fenton reaction was initiated by the addition of FeSO4•7H2O and H2O2 into the column. Meanwhile, air was aerated into the bottom of the column at a constant rate by a Plexiglas tube (φ = 5 mm) with a ceramic air diffuser at its end, and the bubbles’ diameter varied from 1 to 3 mm. The aeration also played a role in mixing liquid in the column, as there were no other mixing mechanisms applied. After the expected reaction time approached, the reaction was quenched by adjusting the pH of the reaction solution to 8.0, with 25 % NaOH. This value of pH was optimal for Fe3+ to precipitate (Cheng et al. 2007). After 30-min precipitation, the supernatant was filtered by filter paper, and concentrations of COD and PVA in the filtered supernatant were measured. To obtain the optimal conditions, main parameters of the treatment were optimized one by one, according to their importance. Finally, the optimized parameters were validated, according to the removal efficiency of COD and PVA and the increasing of BOD/COD value. Other parameters, including turbidity and concentrations of TOC, NH3-N, TP, Fe2+, and total iron, were also determined for the treated CML. The optimizing experiments were run in triplicate and the validation experiment was run in quadruplicate. COD was measured using a digital digestion reactor (DRB 200, HACH, USA) and a UV–Vis spectrophotometer (DR 2800, HACH, USA), and was modified by the content of residual H2O2 (Zhang et al. 2001). The measurement of BOD (20 °C, 5 days) was performed by a pressure sensor method using an automated measurement apparatus (BOD Trak II, HACH, USA). PVA was analyzed using the UV–Vis spectrophotometer (DR 2800, HACH) at 690 nm, based on the blue color produced by the reaction of PVA with iodine in the presence of boric acid (Finley 1961). Total organic carbon (TOC) was determined by a TOC analyzer (TOC-L CPH, Shimadzu, Japan). Turbidity, NH3-N, Fe2+ and total iron, and TP were measured according to standard methods #2130B, #4500C, #3500B, and #4500E, respectively (APHA 1995). H2O2 concentration in the treated CML, used for the correction of COD value, was determined by an iodometric method (Jeffery et al. 1989).

In Fenton and Fenton-like techniques, reaction time, FeSO4•7H2O dosage, and [H2O2]/[Fe2+] are responsible for the generation of OH• and directly affect the oxidizing efficiency (Herney-Ramirez et al. 2010; Pignatello et al. 2006). The pH of the solution influences not only the speciation and stability of PVA, H2O2, and iron ions but also the balance of the reactions. Both the stability of H2O2 and the reaction kinetics are temperature-dependent (Herney-Ramirez et al. 2010; Hu et al. 2011). As mentioned above, oxygen has a synergistic oxidative effect with the radicals and can restrain the useless decomposition of H2O2 (Deng 2007). Therefore, the above factors were selected as the factors to be optimized. According to literatures (Herney-Ramirez et al. 2010; Kang and Hwang 2000; Pignatello et al. 2006; Xie et al. 2010) and preliminary experiments, the rough order of the importance of these factors to the air-Fenton reaction was determined, and their initial values were assigned as well. The importance decreased approximately in the following order: FeSO4•7H2O dosage, pH, [H2O2]/[Fe2+], aeration rate, reaction time, and temperature. The factors were optimized one by one according to this order, until all the factors were optimized: value of the factor to be optimized was changed in a range while values of the other factors were fixed (at initial or optimal values). After the optimal value has been obtained for the specific factor to be optimized, this value was assigned to this factor, in the subsequent optimization experiments. The initial values assigned to the factors were 3 to CML pH, 10 to [H2O2]/[Fe2+], 0.6 L/min to aeration rate, 30 min to reaction time, and 25 ± 2 °C to CML temperature. The range of the factors to be optimized were 0.125, 0.375, 0.625, 0.875, 1.125, and 1.375 mmol/L for FeSO4•7H2O dosage; 2, 3, 4, 5, 6, and 7 for initial CML pH; 1, 2, 4, 6, 8, 10, 12, and 14 for [H2O2]/[Fe2+]; 0, 0.2, 0.4, 0.6, 0.8, and 1 L/min for aeration rate; 5, 10, 20, 30, 40, and 50 min for reaction time; and 20, 30, 40, 50, 60, and 70 °C for initial CML temperature.

Results and discussion

Effect of FeSO4·7H2O dosage

The effect of FeSO4•7H2O dosage on COD and PVA removal was very significant, as shown in Fig. 2a. The removal efficiency of both COD and PVA was increased along with the increase of FeSO4•7H2O dosage, until the dosage reached 0.625 and 0.375 mmol/L, respectively, and then increased slowly with further increase of the dosage. Taking both the removal efficiency and the cost of the treatment into consideration, we selected 0.625 mmol/L as the optimum dosage for FeSO4•7H2O.

Fenton technique used for wastewater treatment proceeds in two steps: oxidation and flocculation/coagulation. Specifically, the ferrous iron initiates and catalyzes the decomposition of H2O2, resulting in the generation of hydroxyl radicals, which are strong oxidants that can degrade the organics. Ferric ions formed during the reactions hydrolyze to produce hydroxide colloids, which account for the flocculation/coagulation (Neyens and Baeyens 2003). The mechanism of Fenton-based reactions can be summarized as follows (k is kinetic constant) (Bautista et al. 2008; Pignatello et al. 2006):

According to this mechanism, it is apparent that Fe2+ plays an important role as catalyst in generating OH• radical, which is the main oxidant responsible for the oxidation of organics in the system. As strong oxidant, OH• radical can oxidize organics fairly quickly, by destroying chemical bonds such as C–H, C–C, C–O, C = C, etc. (Neyens and Baeyens 2003). For PVA in wastewater, like other organics, it can be broken down into smaller pieces (radicals that can be expressed as R•), under the attack of OH•. Further chain scission can occur to the R• radicals, until they are decomposed completely into CO2 and water. Some ketones/enols may be formed during the process of mineralization, with the presence of OH• and O2 (Neyens and Baeyens 2003; Zhang and Yu 2004). Possible pathways of the radical-induced degradation of PVA are described in Fig. 3.

In air-Fenton system, if the concentration of Fe2+ is low, according to Eq. (1), only limited amount of OH• will be generated. Therefore, the removal efficiency of PVA and COD in the CML was relatively low when the dosage of FeSO4•7H2O was low. With the increase of [Fe2+], the amount of OH• increased, and subsequently the removal efficiency of PVA and COD increased. However, excess Fe2+ can inhibit the further degradation of organics, by competing with the organics for the available OH• (Eq. (2)). This is why the removal efficiency only increased slowly with further increase of FeSO4•7H2O dosage when the dosage >0.625 mmol/L. Furthermore, chromaticity color of the treated water usually increases when excessive Fe2+ is added (Pignatello et al. 2006).

Although Fenton treatment can destroy most organic materials effectively, there are still such refractory organics as methylene chloride, oxalic acid, acetone, etc., that cannot be mineralized or mineralized completely (Trapido et al. 2009). There also may be some organics in the wastewaters that can be oxidized into some of these refractory compounds (Gogate and Pandit 2004). As the composition of CML is very complicated (Zhao et al. 2011), the removal efficiency of COD from the CML by the treatment was not as high as that of PVA. Furthermore, ratio of COD to TOC of the CML was relatively high (COD/TOC = 4.27), which indicated that there were more hydrogen atoms in the molecules of the organic materials in the CML samples (Dong et al. 2012). The hydrogen usually exists in aliphatic hydrocarbons or molecules with aliphatic hydrocarbon chains (Dong et al. 2012). These organics are usually OH• consuming substances (Pignatello et al. 2006).

Effect of initial pH

Effect of pH on COD and PVA removal is shown in Fig. 2b. The maximum PVA and COD removal was obtained in the initial pH range of 3.0∼5.0, and the corresponding removal efficiency was about 60 and 84 %, respectively. Beyond this range, removal efficiency of both COD and PVA decreased, with the increase or decrease of pH. This was consistent with the results of other similar studies on Fenton treatment (Deng 2007). Considering both the efficiency and cost of the treatment, and the erosion of the devices, 5.0 could be decided as the optimal pH.

As H+ or OH− is involved in the Fenton reactions (Eqs. (1), (2), and (3)), and the existence of PVA, H2O2, and Fe3+/Fe2+ in the solution is also affected by the pH value of the solution, pH plays an important role in treating CML by the air-Fenton technique. Generally, acidic conditions are conducive to oxidative reactions (Clark and Cohen 1923). The oxidative capacity of OH• at higher pH is also low (Deng 2007). Besides, at relatively higher pH, the useless decomposition of H2O2 is usually favored (Kang and Hwang 2000), and the concentration of free Fe3+ and Fe2+ decreases due to hydroxylation of the ions (Pignatello et al. 2006). Therefore, the observed removal efficiency of both COD and PVA decreased with the increase of pH when pH >5.0. However, when pH = 2, the observed removal efficiency of COD and PVA was also low. This might be due to the following reasons: (1) OH• can be consumed by excessive H+ when the pH is low (Herney-Ramirez et al. 2010; Deng 2007); (2) low pH inhibits the reduction of Fe3+ to Fe2+ again (Eq. (3); Chen et al. 2009; Herney-Ramirez et al. 2010); and (3) the coagulation/flocculation of the hydroxide colloids is favored in the pH range 3 to 7 (Neyens and Baeyens 2003).

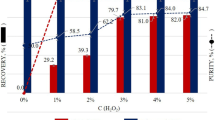

Effect of the ratio of [H2O2] to [Fe2+]

The maximum removal efficiency of PVA and COD was achieved when the molar ratio of [H2O2] to [Fe2+] increased from 1 to 4 (Fig. 2c). Then, the removal efficiency declined gradually with further increase of the ratio. Therefore, the optimal ratio was 4.

When [H2O2]/[Fe2+] is low, Fe2+ competes with the organic materials for the available OH• (Eq. (2); Lopez et al. 2004), which results in the low removal efficiency of organics. However, when [H2O2]/[Fe2+] is too high, the scavenging of HO• radicals by excessive H2O2 occurs, as expressed in Eq.(4). Meanwhile, the limited amount of Fe2+ can produce only limited amount of OH• (Eq. (1)). Under these conditions, the main oxidants in the solution should be H2O2 (E 0 = 1.77 V) and HO2• (E 0 = 1.7 V), whose oxidation ability are lower than that of OH• (E 0 = 2.8 V) (Herney-Ramirez et al. 2010). Therefore, the removal efficiency of COD and PVA also declined when the ratio was too high.

Effect of aeration rate

The effect of aeration rate is shown in Fig. 2d. COD removal efficiency increased with the increase of aeration rate from 0 to 0.4 L/min, and then decreased thereafter with further increase of aeration rate. Similar to the trend of COD’s removal, the maximum removal efficiency of PVA was achieved when the aeration rate was in the range of 0.4∼0.6 L/min. When the aeration rate was 0.4 L/min, the removal efficiency of COD and PVA was 65 and 95 %, respectively. Therefore, the optimal aeration rate was 0.4 L/min.

Aerating in the Fenton system can accelerate the oxidation reaction by promoting the mixing of substrates in the solution. Furthermore, the useless decomposition of H2O2 can be inhibited by the presence of relatively high level of O2, as shown in Eq. (5) (Deng 2007; Deng and Englehardt 2009). In addition, R• radicals react with O2 to form R-OO• and R-O• radicals, which also accelerates the mineralization process of the organics (Deng 2007; Neyens and Baeyens 2003). For example, it has been found that in the presence of sufficient O2, HCOOH could be converted to HCOO• or •COOH/•COO−, and finally to CO2, in a Fenton system (Duesterberg et al. 2005; Duesterberg and Waite 2006):

If there was not sufficient O2, disproportionation of the HCOO• and •COO− might occur. Under this condition, only some of the HCOO• and •COO− could be converted to CO2, and others would be converted to some stable organics (Duesterberg et al. 2005; Duesterberg and Waite 2006):

This decreased the removal efficiency of organics in the system. Therefore, appropriate aeration could increase the removal efficiency of both COD and PVA. However, in the present of excessive O2, Fe2+ may be converted to Fe3+ too rapidly. Meanwhile, reducing radicals such as carboxyl radicals in the solution can also be oxidized by the excessive O2, and therefore the reduction of Fe3+ to Fe2+ is restricted (Duesterberg et al. 2005). These decreased the level of Fe2+ ion and subsequently the level of OH• radical in the system, and therefore decreased the removal efficiency of COD and PVA. Another possible explanation for the decreased COD and PVA removal efficiency at high aeration rate is that high level of dissolved CO2 (HCO3 −), also aerated to the solution with air, may act as scavengers to the oxidative free radicals. The mechanism is as follows (Pan et al. 2007):

Effect of reaction time

The effect of reaction time is shown in Fig. 2e. In the first 10 min, removal efficiency of COD increased significantly with reaction time, to about 56 %. Prolonging the reaction time had little improvement in the removal efficiency. While for PVA, its removal efficiency remained almost constant at about 96 to 99 %, after 5 min since the reaction began. Therefore, regarding both the removal efficiency and the reaction time, we selected 10 min as the optimal reaction time.

From the above results, it can be deduced that almost all of the PVA molecules were destroyed or transformed within 5 min, and the decomposition of most other organics in the samples finished in about 10 min. Unlike some other similar studies (e.g., Xiao et al. 2001), the removal of COD was fairly fast in this study. This should be due to the relatively low organic concentration (low COD value), which led to the relatively high ratio of [OH•] to [organics]. CML usually contains PVA, residual vinyl chloride monomer, and small amounts of other additives (biphenyl A, hydroquinone, methanol, etc.), as well as some intermediates, such as some hydrocarbons and carboxylic acids (Zhao et al. 2011). OH• can decompose most of these substrates fairly quickly, although not necessarily very completely (Neyens and Baeyens 2003).

Effect of initial temperature

As shown in Fig. 2f, the removal of COD increased along with the increase of the initial temperature from 20 to 40 °C. Then, the removal efficiency decreased with further increase of the temperature. The maximum removal efficiency of COD was attained (about 61 %) when the initial temperature was 40 °C. The removal efficiency of PVA remained almost constant at about 96 to 98 % when the initial temperature was below 40 °C and decreased significantly with the increase of temperature from 40 to 70 °C. Therefore, 40 °C should be the optimal initial temperature.

The kinetic of a reaction is usually severely affected by temperature: high temperature usually enhances the reactivity of the reactants and accelerates the reaction. In the air-Fenton system, the activity of the free radicals increased with the increase of temperature, which caused the increased removal efficiency of COD. However, this effect of temperature was unobvious for the removal of PVA when it was below 40 °C because of the already high PVA removal efficiency. With the further increase of temperature, both the decomposition of H2O2 and the quenching of the OH• became increasingly significant in the system (Hu et al. 2011). This resulted in the decrease of removal efficiency of COD and PVA at higher temperature. It has been reported that for every 10 °C increase in temperature in the range of 20 to 100 °C, the rate of decomposition of H2O2 to O2 and H2O increases by around 2.2 times (Bautista et al. 2008). Besides, in higher temperature range (>65 °C), the coagulation/flocculation of the PVA decreases, as the solubility of PVA increases (Chu 2010), which also lead to the comparatively low PVA removal efficiency.

Treatment of CML under the optimal conditions

According to the above results, the optimized parameters could be summarized as follows: FeSO4•7H2O dosage, 0.625 mmol/L; initial pH, 5; [H2O2]/[Fe2+], 4; aeration rate, 0.4 L/min; reaction time, 10 min; and reaction temperature, 40 °C. Concentrations of some ingredients and some parameters measured for the CML samples which have undergone the air-Fenton treatment under the optimized conditions are also listed in Table 1, as a comparison. As shown in Table 1, for the treatment, the average removal efficiency of COD, PVA, and TOC was 66 ± 4, 98 ± 1, and 55 % ± 3 %, respectively. Apparently, almost all the PVA was removed. The remove efficiency of the treatment to COD and TOC was not very high. However, after the treatment, COD/TOC decreased from 4.27 to 3.24 while BOD/COD increased from 0.31 to 0.68. As deduced previously, the decrease of COD/TOC to 3.24 indicated that most of the aliphatic hydrocarbons or the molecules containing aliphatic hydrocarbon chains presented in the CML have been removed or oxidized (Dong et al. 2012). Some of these substances were hard to be decomposed biologically (Zhao et al. 2011). The significant increase of BOD/COD indicated that the biodegradability of the CML has been improved significantly. The high value of BOD/COD (nearly 0.7) implied that majority of the organics remaining in the treated CML were biodegradable, although they were hard to be further degraded by the air-Fenton treatment. Therefore, it was reasonable to suppose that the subsequent biological treatment would remove most of the remaining COD or TOC from the CML wastewater which has gone through the air-Fenton treatment. In addition, most of the suspended materials and NH3-N, and some of the TP, were also removed by the treatment. Furthermore, after the treatment, total concentration of the remaining iron ions, which were added during the treatment, was also quite low (only 2.9 mg/L).

Therefore, the optimized air-Fenton technique could remove most of the organics from the CML (corresponding to about two thirds of the original COD) and improve the biodegradability of the wastewater significantly. This enabled the pretreated CML to be further treated efficiently by secondary biotreatment facilities, together with other effluents. As PVA, the water soluble polymer, in CML was broken down, the clogging problem, which inhibited the application of membrane techniques, was also resolved. The pretreatment was also a rapid one (finished in 10 min). In addition, the operation of this treatment was easy and the facilities were simple, and the operating costs should be relatively low (according to a rough estimation, cost of the reagents consumed to treat 1 m3 CML was only about 0.4 RMB) (Song and Li 2009; Zhu et al. 2011). One potential problem of this technique is the treatment of the sludge, which is produced during the precipitation and filtration process. This problem is a common one to all Fenton and Fenton-like treatment techniques (Cao et al. 2009; Pignatello et al. 2006). As the sludge is composed mainly of iron hydroxides, recovery and reuse are the most common means to treat this kind of sludge (Cao et al. 2009; Li et al. 2007).

The above results of using of the optimized air-Fenton technique to treat CML were obtained from laboratory bench-scale experiments and may be somewhat different from those obtained from a large-scale treatment. However, this optimized technique is a competitive choice for the pretreatment of CML.

Conclusions

Under the treatment of air-Fenton technique, the removal of COD and PVA form the CML was affected by dosage of FeSO4•7H2O, initial pH, [H2O2]/[Fe2+], aeration rate, reaction time, and reaction temperature. The optimized treatment conditions obtained were: FeSO4•7H2O dosage, 0.625 mmol/L; initial pH, 5; [H2O2]/[Fe2+], 4; aeration rate, 0.4 L/min; reaction time, 10 min; and reaction temperature, 40 °C. Under the optimized treatment conditions, most of the COD was removed from the CML and the biodegradability of the CML increased significantly. Meanwhile, almost all of the PVA in the treated water was broken down. Therefore, the optimized air-Fenton technique could be implemented as an efficient pretreatment technique for CML, with such advantages as relatively high efficiency, mild reaction conditions, and high treatment speed.

References

Al Mubaddal F, Al Rumaihi K, Ajbar A (2009) Performance optimization of coagulation/flocculation in the treatment of wastewater from a polyvinyl chloride plant. J Hazard Mater 161:431–438

APHA (1995) Standard methods for the examination of water and wastewater, 19th edn. American Public Health Association, Washington, DC

Bautista P, Mohedano AF, Casas JA, Zazo JA, Rodriguez JJ (2008) An overview of the application of Fenton oxidation to industrial wastewaters treatment. J Chem Technol Biotechnol 83:1323–1338

Bing J (2012) Analysis on situations of China’s PVC industry in the year 2011. Polyvinyl Chloride 40:1–8 (in Chinese)

Cao G, Sheng M, Niu W, Fei Y, Li D (2009) Regeneration and reuse of iron catalyst for Fenton-like reactions. J Hazard Mater 172:1446–1449

Chen Q, Wu P, Li Y, Zhu N, Zhi D (2009) Heterogeneous photo-Fenton photodegradation of reactive brilliant orange X-GN over iron-pillared montmorillonite under visible irradiation. J Hazard Mater 168:901–908

Cheng H, Xu W, Liu J, Wang H, He Y, Chen G (2007) Pretreatment of wastewater from triazine manufacturing by coagulation, electrolysis, and internal microelectrolysis. J Hazard Mater 146:385–392

Chu X (2010) PVA degradation by a combined method of advanced oxidation pre-treatment and bio-degradation. Dissertation, Qingdao University of Science & Technology (in Chinese)

Clark WM, Cohen B (1923) Studies on oxidation-reduction. II. An analysis of the theoretical relations between reduction potentials and pH. Public Health Rep 38:666–683

Deng Y (2007) Physical and oxidative removal of organics during Fenton treatment of mature municipal landfill leachate. J Hazard Mater 146:334–340

Deng Y, Englehardt J (2009) Kinetics and oxidative mechanism for H2O2 enhanced iron-mediated aeration (IMA) treatment of recalcitrant organic compounds in mature landfill leachate. J Hazard Mater 169:370–375

Dong D, Song X, Hua X, Yuan M, Liang J, Guo Z, Liang D (2012) Relationship between COD and TOC of typical wastewaters in Jilin Province and mechanism and main influencing factor. J Jilin Univ (Earth Sci Ed) 42:1446–1455 (in Chinese)

Duesterberg CK, Waite TD (2006) Process optimization of Fenton oxidation using kinetic modeling. Environ Sci Technol 40:4189–4195

Duesterberg CK, Cooper WJ, Waite TD (2005) Fenton-mediated oxidation in the presence and absence of oxygen. Environ Sci Technol 39:5052–5058

Esplugas S, Gimenez J, Contreras S, Pascual E, Rodríguez M (2002) Comparison of different advanced oxidation processes for phenol degradation. Water Res 36:1034–1042

Fenton HJH (1894) LXXIII.—Oxidation of tartaric acid in presence of iron. J Chem Soc Trans 65:899–910

Finley JH (1961) Spectrophotometric determination of polyvinyl alcohol in paper coatings. Anal Chem 33:1925–1927

Gogate PR, Pandit AB (2004) A review of imperative technologies for wastewater treatment I: oxidation technologies at ambient conditions. Adv Environ Res 8:501–551

Herney-Ramirez J, Vicente MA, Madeira LM (2010) Heterogeneous photo-Fenton oxidation with pillared clay-based catalysts for wastewater treatment: a review. Appl Catal, B 98:10–26

Hu X, Wang X, Ban Y, Ren B (2011) A comparative study of UV–Fenton, UV–H2O2 and Fenton reaction treatment of landfill leachate. Environ Technol 32:945–951

Huang P (2007) Study on treatment of thermophilic PVC wastewater in aerobic moving bed biofilm reactor. Dissertation, Harbin Institute of Technology (in Chinese)

Jeffery GH, Basset J, Mendham J, Denny RC (1989) Vogel’s textbook of quantitative chemical analysis, 5th edn. Longman Scientific & Technical, Essex, pp 368–395

Kang YW, Hwang KY (2000) Effects of reaction conditions on the oxidation efficiency in the Fenton process. Water Res 34:2786–2790

Labunska I, Brigden K, Santillo D, Johnston P, Walters A (2008) Characterisation of wastewater discharges from chloralkali plants and associated chlorinated chemical production facilities in Spain. Greenpeace Research Laboratories Technical Note (12/2008), University of Exeter, Exeter

Lei L (2000) Advanced oxidation of polyvinyl-alcohol by the photo-Fenton reaction. Acta Sci Circumst 20:139–144 (in Chinese)

Li C, Chen Y, Chiou Y, Liu C (2007) Dye wastewater treated by Fenton process with ferrous ions electrolytically generated from iron-containing sludge. J Hazard Mater 144:570–576

Lin SH, Chang CC (2000) Treatment of landfill leachate by combined electro-Fenton oxidation and sequencing batch reactor method. Water Res 34:4243–4249

Liu F, Wang S, Liu X, Zhang Y (2010) Operation summary of PVC centrifugal mother liquid recycling. China Chlor-Alkal 2:41–43 (in Chinese)

Lopez A, Pagano M, Volpe A, Pinto ACD (2004) Fenton’s pre-treatment of mature landfill leachate. Chemosphere 54:1005–1010

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98:33–50

Pan J, Sun T, Li H (2007) Effects and mechanisms of inorganic anions in water on degradation of LAS by UV/H2O2 combination process. Environ Sci 28:2539–2543 (in Chinese)

Pignatello JJ, Oliveros E, MacKay A (2006) Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related chemistry. Crit Rev Environ Sci Technol 36:1–84

Song Y, Li Y (2009) Reutilization of mother liquid of PVC and biological treatment technology. China Chlor-Alkal 1:36–39 (in Chinese)

Tan C, Gao N, Chu W, Li C, Templeton MR (2012) Degradation of diuron by persulfate activated with ferrous ion. Sep Purif Technol 95:44–48

Trapido M, Kulik N, Goi A, Veressinina Y, Munter R (2009) Fenton treatment efficacy for the purification of different kinds of wastewater. Water Sci Technol 60:1795–1801

Xiao Y, Chen Y, Zhang J, Zhao H, Sun C, Wu M (2001) Affecting factors and biodegradability in pretreating H-acid wastewater by Fenton’s reagent. Environ Chem 20:281–285 (in Chinese)

Xie B, Lv Z, Lv B, Gu Y (2010) Treatment of mature landfill leachate by biofilters and Fenton oxidation. Waste Manag 30:2108–2112

Yang Z, Xu Z, Gao W, Huang S, Song Y (2005) Study on the treatment of polyvinyl chloride industrial wastewater by membrane bioreactor. Water Purify Technol 24:21–23 (in Chinese)

Zhang B, Zhou Y (2003) The sizing pollution and environmental protection. Cotton Text Technol 31:17–20 (in Chinese)

Zhang S, Yu H (2004) Radiation-induced degradation of polyvinyl alcohol in aqueous solutions. Water Res 38:309–316

Zhang N, Lv M, Meng X (2001) The measurement of COD in Fenton system. J Harbin Univ Commer (Nat Sci Ed) 2:27–28 (in Chinese)

Zhang X, Lv Y, Jin Q (2003) Testing on treatment of emulsified wastewater from PVC production by conventional coagulation–filtration method. Ind Water Wastewater 34:47–49 (in Chinese)

Zhao D, Wei Y, Wang Y (2011) Treatment and use of PVC mother liquid. China Chlor-Alkal 5:11–13 (in Chinese)

Zhou T, Lu X, Wang J, Wong F, Li Y (2009) Rapid decolorization and mineralization of simulated textile wastewater in a heterogeneous Fenton like system with/without external energy. J Hazard Mater 165:193–199

Zhu Z, Niu Z, Gao X, Wang D (2011) Treatment of PVC wastewater through steam stripping combined with oxidation process. Chem Bioeng 28:77–80 (in Chinese)

Acknowledgments

This study was supported by the Major Science and Technology Program for Water Pollution Control and Treatment in China (no. 2012ZX07202009) and Jilin Environmental Protection Bureau (2009-19). The authors also thank three anonymous reviewers for improving the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Sun, Y., Hua, X., Ge, R. et al. Investigation on pretreatment of centrifugal mother liquid produced in the production of polyvinyl chloride by air-Fenton technique. Environ Sci Pollut Res 20, 5797–5805 (2013). https://doi.org/10.1007/s11356-013-1604-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-013-1604-2