Abstract

Purpose

Biochar derived from waste biomass is now gaining much attention for its function as a biosorbent for environmental remediation. The objective of this study was to determine the effectiveness of biochar as a sorbent in removing Cd, Cu, and Zn from aqueous solutions.

Methods

Biochar was produced from dairy manure (DM) at two temperatures: 200°C and 350°C, referred to as DM200 and DM350, respectively. The obtained biochars were then equilibrated with 0–5 mM Cu, Zn or Cd in 0.01 M NaNO3 solution for 10 h. The changes in solution metal concentrations after sorption were evaluated for sorption capacity using isotherm modeling and chemical speciation Visual MINTEQ modeling, while the solid was collected for species characterization using infrared spectroscopy and X-ray elemental dot mapping techniques.

Results

The isotherms of Cu, Zn, and Cd sorption by DM200 were better fitted to Langmuir model, whereas Freundlich model well described the sorption of the three metals by DM350. The DM350 were more effective in sorbing all three metals than DM200 with both biochars had the highest affinity for Cu, followed by Zn and Cd. The maximum sorption capacities of Cu, Zn, and Cd by DM200 were 48.4, 31.6, and 31.9 mg g−1, respectively, and those of Cu, Zn, and Cd by DM350 were 54.4, 32.8, and 51.4 mg g−1, respectively. Sorption of the metals by the biochar was mainly attributed to their precipitation with PO 3−4 or CO 2−3 originating in biochar, with less to the surface complexation through –OH groups or delocalized π electrons. At the initial metal concentration of 5 mM, 80–100 % of Cu, Zn, and Cd retention by DM200 resulted from the precipitation, with less than 20 % from surface adsorption through phenonic –OH complexation. Among the precipitation, 20–30 % of the precipitation occurred as metal phosphate and 70–80 % as metal carbonate. For DM350, 75–100 % of Cu, Zn, and Cd retention were due to the precipitation, with less than 25 % to surface adsorption through complexation of heavy metal by phenonic –OH site or delocalized π electrons. Among the precipitation, only less than 10 % of the precipitation was present as metal phosphate and more than 90 % as metal carbonate.

Conclusions

Results indicated that dairy manure waste can be converted into value-added biochar as a sorbent for sorption of heavy metals, and the mineral components originated in the biochar play an important role in the biochar's high sorption capacity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Due to the overgrowth in population, industrialization, and civilization, the demand for water is increasing geometrically. Therefore, wastewater needs to be purified and recycled for the purpose as alternative sources of water (Ngah and Hanafiah 2008; Ali 2010). Among various treatment technologies, adsorption is a fast and universal method which offers significant advantages like the low cost, availability, profitability, ease of operation, and efficiency (Ali and Gupta 2006; Demirbas 2008).

Various sorbents have been developed, ranging from natural materials to synthetic products (Gupta et al. 2009a). Gupta et al. (1997, 2007a) reported that slag, a blast furnace waste material, can be effective in sorbing Zn and Cd from wastewater and that TiO2, a synthetic catalyst, can remove the hazardous dye Safranin-T through sorption and photochemical degradation. Among those sorbents developed, the C-based sorbents have proven to be most cost-effective in removing inorganic as well as organic pollutants from wastewater (Ali 2010). For example, carbon slurry developed from a waste material has been used on the removal of Vertigo Blue 49, Orange DNA13, fluoride, as well as Cr(VI) (Gupta et al. 2007b, 2007c; Gupta et al. 2010). Bagasse fly ash, a by-product generated in sugar industries, was used for the effective removal of Cu, Zn, Cd, Ni, and Cr from wastewater (Gupta et al. 1999; Gupta and Ali 2000; Gupta et al. 2003; Gupta and Sharma 2003). Aspergillus versicolor biomass has high affinity for Hg sorption, with the maximum capacity of 75.6 mg g−1 (Das et al. 2007). The algal biomass Oedogonium sp. exhibited the high uptake of Zn and Cr from aqueous solution, with the sorption capacity of Zn as much as 88.9 mg g−1 (Gupta and Rastogi 2008, 2009). Gupta et al. (2006a, 2007d) indicated that wheat husk and bottom ash can remove Reactofix golden yellow 3 and hazardous azo dye acid orange 7 from aqueous solutions, respectively. Uchimiya et al (2010, 2011) showed that activated carbon derived from broiler litter was effective in immobilizing Cd, Cu, Ni, and Pb in soil and water through cation exchange, π electrons (C═C), as well as precipitation. It should also be noted that accurate determination of each metal pollutant plays a critical role in the treatment of multi-metal contaminated wastewater. Various sensors and membranes have been developed for selective detection of metal pollutants, for example, Nd(III)-selective PVC membrane sensors (Gupta et al. 2009b), Cr(III) or Cr(VI)-selective sensor based on tri-o-thymotide and C-thiophenecalix resorcinarene in PVC matrix (Jain et al. 2005; Gupta et al. 2006b), Pb(II)-selective potentiometric sensor based on 4-tert-Butylcalix arene in PVC matrix (Gupta et al. 2002), Schiff bases as Cd(II) selective ionophores in polymeric membrane electrodes (Gupta et al. 2007e), poly(vinyl chloride)-based membranes of Schiff bases for Cd(II) (Gupta et al. 2009c), organic resin-based membrane sensors for uranyl ions (Jain et al. 1995a, 1997a), PVC-based benzo-15-crown-5 and benzo-24-crown-8 membrane sensors for Cd(II) and Cs(I) (Srivastava et al. 1995, 1996; Gupta and Kumar 1999), PVC membrane-based alizarin sensor for V, Zr, and Mo (Gupta et al. 2009d), and macrocycle-based membrane sensors for Co((II) and Cu(II) (Jain et al. 1995b, 1997b).

Biochar is a carbonaceous solid residue of thermal treatment of carbon-rich biomass under O2-limited and low temperatures (<700°C), a process known as low-temperature pyrolysis (Lehmann and Joseph 2009). It has received considerable interest as a soil amendment to improve soil fertility, crop production, and nutrient retention and to serve as a recalcitrant carbon stock (Chan et al. 2007; Lehmann 2007; van Zwieten et al. 2010; Woolf et al. 2010). Recently, some work has shown that biochar can be a sorbent for sorption of heavy metals from waste water and an amendment for immobilization of heavy metals in contaminated soils (Qiu et al. 2008; Beesley et al. 2010, 2011; Chen et al. 2011; ). Qiu et al (2008) indicated that biochar isolated from the burning residues of rice straw and wheat straw retained 22.2–27.7 mg Pb per gram mass. They attributed the high sorption to the three reasons: (1) electrostatic interactions between metal cations and negatively charged carbon surface; (2) ionic exchange between ionizable protons at the surface of acidic carbon and metal cations; and (3) sorptive interaction involving delocalized π electrons of carbon. Chen et al (2011) reported that biochars produced from hardwood and corn straw had high affinities for Cu and Zn, with maximum Cu and Zn adsorption capacities of 12.5 and 11.0 mg g−1, respectively. However, in a recent study, Beesley et al (2010) found that hardwood-derived biochar significantly reduced Zn and Cd in soil pore water, whereas Cu and As concentrations increased more than 30-fold after adding the biochar amendments. All those studies above indicated that the effectiveness of biochars in retaining heavy metals varied with different biochars and metals. Furthermore, the underlying mechanisms for the sorption of different metals by biochars are not fully yet understood.

Our previous work indicated that the biochar derived from dairy manure can effectively sorb Pb, with the maximum sorption capacity of 141 mg g−1 and the sorption of Pb by the biochar is mainly attributed to precipitation of Pb phosphate and carbonated minerals (Cao et al. 2009). The objective of this study is to investigate whether the dairy-manure biochar is also effective in sorbing Cu, Zn, and Cd. The mechanism involved in the retention of metals on the biochar was elucidated at a molecular level using chemical speciation modeling and Fourier transform infrared spectroscopy, scanning electron microscopy, and X-ray dot mapping analysis.

2 Materials and methods

2.1 Preparation of biochar and chemical reagents

The biochars used in this study were produced from dairy manure through a typical slow pyrolysis process. Details on the biochar preparation were described previously (Cao and Harris 2010). Briefly, dairy manure was air-dried and ground to less than 1 mm before they were added into a stainless steel reactor. The reactor was then put in a Muffle Furnace (Thermo Fisher Scientific, Inc., Pittsburgh, PA, USA) and heated under O2-limited condition at either 200 or 350°C. After 4 h of heating, the furnace was turned off and the sample was allowed to cool to room temperature. The solid residue left in the reactor was designated as biochar and those produced from dairy manure at 200 and 350°C were referred to as DM200 and DM350, respectively. The biochar was ground and passed through 0.5-mm sieve for characterization and sorption experiment.

All chemical reagents were of analytical grade. The stock solutions of 5 mM Cu, Zn, and Cd were prepared by dissolving their nitrate salts (Sinopharm Chemical Reagent Co) in a 0.01 M NaNO3 solution.

2.2 Physical and chemical properties of the biochars

Elemental (C, H, and N) analyses were conducted using the CHNS/O Analyzer (Perkin Elmer, 2400 II). Other elements (P, Ca, Mg, K. Na, etc.) were determined using the USEPA Method 3050B (USEPA 1986). Surface area was measured in triplicate by nitrogen adsorption isotherms at 77 K using a surface area and porosimetry analyzer (Micromeritics Inc., USA). The pH of the biochars was determined at a ratio of 1:10 for solid to deionized water (Cao and Harris 2010). Water soluble PO 3−4 and CO 2−3 were extracted by mixing 5 g biochar with 50 mL deionized H2O and determined using ion chromatography (Waters 2690 Separations Module, Waters Corporation, USA) (Cao and Harris 2010).

2.3 Sorption test

The experiment was conducted in 60-mL polypropylene tubes by mixing 0.125 g biochar with 25 mL 0.01 M NaNO3 solution containing 0, 1, 2, 3, 4, and 5 mM Cu, Zn, or Cd, respectively. The mixture was then agitated on a reciprocating shaker at 100 rpm for 10 h. The time was shown enough for sorption of all metals to reach equilibrium, determined by the preliminary experiment (data not shown). After equilibrium, solid and liquid phases were separated by centrifugation at 4,000 rpm for 15 min and the solution was filtered through a 0.22-μm Millipore filter. The filtrate was immediately acidified to pH < 2 with concentrated HNO3 for chemical analysis. Concentrations of Cu, Zn, and Cd in the filtrate were determined by atomic absorption spectroscopy (AAS) (Jena AAS novAA350) and that of P was determined by colorimetry using the molybdate/ascorbic acid method (Olsen and Sommers 1982). The solids retained on the filter were collected and washed with deionized water for Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope (SEM).

To estimate the sorption capacity and intensity of heavy metals onto biochar, Langmuir and Freundlich models were used to fit the experimental data of the sorption isotherms. The formulas of two models are shown below:

where C e (mM) is the equilibrium concentration in the solution; G (mmol/kg) is the metal adsorbed at equilibrium; G max (mmol/kg) is the maximum adsorption capacity; n is Freundlich constant related to adsorption intensity; and K and K F are the adsorption constants for Langmuir and Freundlich models, respectively.

2.4 Metal speciation modeling

Twenty-five milliliters of 0.01 M NaNO3 solution containing 5 mM Cu, Zn, or Cd was mixed with 0.125 g of biochar. After being shaken for 10 h, separation of solid and liquid was conducted as done in the sorption test in Section 2.3. Half of the filtrate was collected for dissolved organic C (DOC) measurement using organic C analyzer (Multy N/C3000, Jena Corporation, Germany) and for anions (PO 3−4 , SO 2−4 , Cl−, NO −3 , and CO 2−3 ) analysis using ion chromatography. Remaining filtrate was acidified to pH < 2 with HNO3 prior to analysis of Cu, Zn, Cd, Ca, Mg, Fe, Al, Mn, Na, and K using AAS. The analytical results, including pH, DOC, anions, and cations, were used in the speciation model Visual MINTEQ (Gustafsson 2010) to calculate metal species in both solid and liquid phases.

2.5 Quality control

All sorption experiments were conducted at ambient temperature and included three controls: deionized water, metal solution, and biochar + deionized water. Three replicates were used for each treatment. Solution pH was not controlled but recorded at the beginning and the end of the equilibration. Sorption of heavy metals was calculated from the difference between initial and final solution concentrations after taking controls into account.

3 Results and discussion

3.1 Characteristics of biochars

The specific surface areas (SSA) of both DM200 and DM350 were less than 6 m2 g−1 (Table 1), lying within the range (1–50 m2 g−1) of biochar produced from industrial organic waste such as eucalyptus sawdust, activated sludge, or cow biosolids (Shinogi and Kanri 2003; Martins et al. 2007), but they were much smaller than that (50–500 m2 g−1) of biochar derived from plant residue such as wood charcoal, sugarcane bagasse, or wheat residue (Shinogi and Kanri 2003; Chun et al. 2004). Plant residues are abundant in organic C which could produce higher porosity when heated, resulting in biochar with high SSA (Martins et al. 2007). The industrial solid waste generally contains a certain amount of mineral components in addition to rich organic C; for example, the dairy manure contain 2.91 % CaCO3 (Cao and Harris 2010). Presence of minerals in the organic waste reduced porosity when pyrolyzed, resulting in biochar with low SSA. When the pyrolysis temperature increased, the organic C started to become partially ashed and alkali salts began to separate from the organic matrix, increasing the biochar pH from 7.63 at 200°C to almost 10 at 350°C (Table 1).

As expected, the biochar was rich in C (25.2–31.1 %) and its concentrations decreased with increasing production temperature (Table 1). The decrease of C resulted probably from the increasing biomass combustion and organic volatilization with increasing temperature. In addition to abundance of C, the biochar contained substantial amounts of macro mineral elements such as Ca, Mg, K, Na, and Fe, with Ca being the highest at 8.89 % (Table 1). Heating the manure from 200 to 350°C reduced biomass, correspondingly increasing concentrations of the mineral elements in the biochar (Table 1). Richness of mineral elements originated from the dairy cow diet input for satisfying nutrient requirement of milk production (NRC 2001). Concentrations of trace elements such as Cu, Cd, and Zn were not higher than 0.03 %, and their contribution to the sorption is less than 0.001 %. Thus, the effect of metals originating from the biochar itself can be negligible. Note that P was rich in biochar and significantly increased from 1.74 % at 200°C to 2.41 % at 350°C (Table 1). Also, the biochar contained calcite (CaCO3) mineral and its concentrations increased from 4.02 % in DM200 to 7.03 % in DM350, correspondingly soluble CO 2−3 increased from 2.52 % in DM200 to 2.94 % in DM350 (Table 1). However, DM350 has a lower soluble P than DM200, probably due to conversion of amorphous to crystallized P-Ca-Mg association (e.g., (Ca,Mg)3(PO4)2) when temperature increased from 200 to 350°C (Cao and Harris 2010).

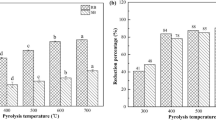

3.2 Sorption of Cu, Zn, and Cd by DM200

The sorption isotherms of Cu, Zn, and Cd by DM200 was of L-type (Fig. 1a) according to the classification of Giles and Smith (1974) and they were better fitted to Langmuir model (R 2 = 0.95–0.99) than Freundlich model (R 2 = 0.74–0.94) (Table 2). The DM200 was effective for sorbing the three metals, with the maximum sorption capacity of Cu, Zn, and Cd being 762, 504, and 285 mmol kg−1, respectively. If converted on the mass basis, the maximum sorption capacity of Cu, Zn, and Cd was 48.4, 31.6, and 31.9 mg g−1, respectively. Sorption of metal ion from aqueous solution is generally governed by surface chemistry and surface area of the sorbent or by precipitation reactions (Echeverria et al. 1998). Since DM200 had the low surface area (5.61 m2 g−1), the surface-area depending sorption would not be expected; whereas surface functional groups or mineral components present in the DM200 may contribute to high sorption ability via complexation or precipitation. As the concentrations of initial Cu, Zn, and Cd increased, soluble PO 3−4 and CO 2−3 were significantly reduced (Fig. 2a, c). It means that PO 3−4 and CO 2−3 were involved in the sorption process of Cu, Zn, and Cd by DM200.

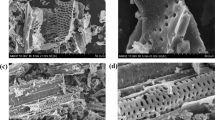

Our previous work indicated that sorption of Pb by the manure biochar was mainly attributed to formation of Pb-phosphate or Pb-carbonate precipitates (Cao et al. 2009). Therefore, we assumed that formation of metal-phosphate and -carbonate precipitates may also be responsible for the sorption of Cu, Zn, and Cd. The hypothesis was confirmed by FTIR and X-ray elemental dot mapping analysis (Figs. 3 and 4). FTIR spectra showed that the sorption of Cu, Zn, and Cd induced the peak of PO 3−4 at 1,093 cm−1 in the DM200 shifted to 1,080, 1,060, and 1,071 cm−1, respectively, and the peak of CO 2−3 at 1,404 cm−1 shifted to 1,417, 1,435, and 1,425 cm−1, respectively (Fig. 3a). The shift of those peaks was attributed to complexation or precipitation of metal-phosphates and -carbonates. Apart from changes of the band PO 3−4 and CO 2−3 , DM200 after Cu or Zn sorption also showed some changes at 3,200–3,500 cm−1 which is assigned to phenolic –OH stretching (Qiu et al. 2008) compared to the control biochar (Fig. 3a), indicating a surface adsorption process via complexation of Cu or Zn with ionized phenolic –O− group. Little change in the peaks at 3,200–3,500 cm−1 for Cd indicated less possibility of surface adsorption via –OH site. X-ray elemental dot mapping evidenced association of P-Cu, P-Zn, and P-Cd (Fig. 4a, b, c) though Ca and Mg may also be complexed with those metals in the biochar. In contrast, C existed as discrete, isolated phase which originated from biochar itself.

Visual MINTEQ modeling further supported precipitation mechanism. When initial metal concentration was 5 mM for each metal, there were 80–100 % of Cu, Zn, and Cd sorption via the precipitation of metal-phosphate and -carbonate, with less than 20 % of sorption from surface sorption. Among precipitation, 21–31 % resulted from metal phosphate precipitates and 69–79 % from metal carbonate precipitates (Table 3). Sorption of Cd nearly completely resulted from precipitation (100 %), which is consistent with the FTIR data.

Based on the results of chemical speciation, SEM and FTIR analysis, and MINTEQ modeling above, the mechanism of sorption of Cu, Zn, and Cd by BC200 can be proposed as follows:

Cd:

Cu and Zn:

3.3 Sorption of Cu, Zn, and Cd by DM350

The sorption isotherms of Cu, Zn, and Cd by DM350 was of H-type (Fig. 1b) and they were better fitted to Freundlich model (R 2 = 0.86–0.98) than Langmuir model (R 2 = 0.74–0.98) (Table 2). Compared to DM200, DM350 had high affinity for sorption of Cu, Zn, and Cd, with their maximum sorption capacity being 810, 487, and 486 mmol kg−1, respectively. If converted on the mass basis, the maximum sorption capacity of Cu, Zn, and Cd was 54.4, 32.8, and 51.4 mg g−1, respectively. As the initial concentrations of Cu, Zn, and Cd increased, soluble CO 2−3 were significantly reduced (Fig. 2d) and soluble PO 3−4 , though less, also decreased (Fig. 2b). This observation indicated that PO 3−4 and CO 2−3 were involved in the sorption of Cu, Zn, and Cd by DM350.

Like DM200, sorption of Cu, Zn, and Cd by DM350 may also be attributed to formation of metal-phosphate and -carbonate precipitates. The hypothesis was confirmed by FTIR and X-ray elemental dot mapping analysis (Figs. 3 and 4). FTIR spectra showed that the sorption of Cu, Zn, and Cd induced the peak of PO 3−4 at 1,080 cm−1 in the DM350 shifted to 1,041 and 1,055 cm−1, and the peak of CO 2−3 at 1,431 cm−1 for Cu and Zn shifted to 1,445 and 1,450 cm−1, respectively (Fig. 3b). Little change of the CO 23 − peak in the Cd-sorbed DM350 was probably due to the overlap by the change of the peak at 1,600 cm−1. Disappearance of the peak for Zn and Cd at 1,600 cm−1 which represent aromatic C═C and C═O (Uchimiya et al. 2011) indicated surface complexation of heavy metal by delocalized π electrons. The change in the peak of –OH between 3,200 and 3,500 cm−1 with Zn and Cd sorption indicated the possibility of surface adsorption through their complexation with phenolic –OH (Fig. 3b). For Cu, however, there was little change at the peaks of phenolic –OH and aromatic C═C and C═O, indicating less possibility of surface adsorption. X-ray elemental dot mapping evidenced association of P-Cu, P-Zn, and P-Cd (Fig. 4d, e, f). Visual MINTEQ modeling further supported that 75–100 % of Cu, Zn, and Cd sorption were attributed to the precipitation of metal-phosphate and -carbonate, with less than 25 % of sorption from surface sorption when metal concentration was 5 mM for each. Among the precipitation, however, only less 7 % of precipitation resulted from metal phosphate precipitates due to less soluble PO 3−4 , while carbonate precipitates accounted for as high as 98 % (Table 3). Sorption of Cu almost completely resulted from precipitation (100 %), which is consistent with the FTIR data.

Based on the results of chemical speciation, SEM and FTIR analysis, and MINTEQ modeling above, the mechanism of sorption of Cu, Zn, and Cd by BC350 can be proposed as follows:

Cu:

Zn and Cd:

3.4 Comparison of Cu, Zn, and Cd sorption by the biochar with other C-based biosorbents

Compared to DM200, the DM350 shows higher sorptive ability to the metals except for Zn (Table 2). This is probably due to higher equilibrium pH (5.85–6.98) in the DM350 solution than that (5.18–6.69) in the DM200 solution (data not shown). As discussed above, the retention of three metals by both biochars is mainly attributed to their precipitation with PO 3−4 and CO 2−3 originated in the biochars themselves. Thus, high pH in DM350 would be favorable for the precipitation. It should be pointed out that sorption of Cu, Zn, and Cd by DM200 and DM350 in all initial metal concentrations ranging from 1 to 5 mM allowed pH range of 5.85–6.45, 6.32–6.81, and 6.32–6.98, respectively, with alteration of less than 0.6 unit (data not shown). The observation indicated that the equilibrium pH for all metals remained little changed with the increasing initial metal concentrations. That is why the pH of whole sorption system was not controlled during the sorption test (Section 2.3). The relative stability of pH is related to high pH buffer capacity of the biochar due to its abundance of polyprotic PO 3−4 and CO 2−3 . On the other hand, higher CO 2−3 in the DM350 than that in the DM200 (Fig. 2b, d) may also contribute to its higher precipitation which is evidenced by the results of MINTEQ modeling where more than 93 % of metals was precipitated as carbonate compounds in the DM350, while in DM200, there was less than 78 % of metals precipitated as carbonate compounds (Table 3).

Compared to its sorption for Pb as high as 141 mg kg−1 reported by Cao et al.(2009), the dairy manure biochar is less effective for sorbing Cu, Zn, and Cd with their maximum sorption capacities of 54.4, 32.8, and 51.4 mg kg−1, respectively. That means the sorption effectiveness varied with types of different metals. Nevertheless, the dairy manure biochar still showed the high affinity for Cu, Zn, and Cd, compared with traditional C-rich biosorbents reported previously (Table 4). The greater sorption in the biochar was contributed to their abundant PO 3−4 and CO 2−3 which can complex with Pb, Cu, Zn, and Cd. It agrees with the idea that mineral elements in the biochar can serve as additional sorption sites (Uchimiya et al. 2010). Therefore, considering its recycling of solid waste and lacking of post-activation process, dairy manure biochar can be used as a promising cost-effective sorbent to remove metals, e.g., Pb, Cu, Zn, or Cd, from wastewaters.

4 Conclusions

The biochar produced form dairy manure at 200°C and 350°C (DM200 and DM350) were characteristic of rich C, PO 3−4 , and CO 2−3 which contributed to their high potential of the sorption of heavy metals. The results indicated that both DM200 and DM350 were effective for sorbing Cu, Zn, and Cd from aqueous solutions, with the highest sorption for Cu. DM350 had higher affinity for Cu, Zn, and Cd sorption than DM200 probably due to its higher concentration of CO 2−3 . The retention of Cu, Zn, and Cd by the biochar was mainly attributed to their precipitation with PO 3−4 and CO 2−3 , with less from surface adsorption through complexation of heavy metal by phenonic –OH site or delocalized π electrons. Overall, the dairy manure can be converted into value-added biochar as an effective sorbent for various heavy metals; the sorption effectiveness is varied with the different metals and affected by the biochar production temperature; and the mineral components (e.g., PO 3−4 , CO 2−3 ) originated in the biochar serve as additional sorption sites, contributing to the biochar's high sorption capacity. Turning dairy manure into biochar as a sorbent has many environmental implications, e.g., reuse of solid waste and remediation of contaminated water.

References

Ahluwalia SS, Goyal D (2007) Microbial and plant derived biomass for removal of heavy metals from wastewater. Bioresour Technol 98:2243–2257

Ali I (2010) The quest for active carbon adsorbent substitutes: inexpensive adsorbents for toxic metal ions removal from wastewater. Sepn Purifn Rev 39:95–171

Ali I, Gupta VK (2006) Advances in water treatment by adsorption technology. Nat Protoc 1:2661–2667

Beesley L, Moreno-Jimenez E, Gomez-Eyles JL (2010) Effects of biochar and greenwaste compost amendments on mobility, bioavailability and toxicity of inorganic and organic contaminants in a multi-element polluted soil. Environ Pollut 158:2282–2287

Beesley L, Moreno-Jimenez E, Gomez-Eyles JL, Harris E, Robinson B, Sizmur T (2011) A review of biochars' potential role in the remediation, revegetation and restoration of contaminated soils. Environ Pollut 159:3269–3282

Cao XD, Ma LQ, Gao B, Harris W (2009) Dairy-manure derived biochar effectively sorbs lead and atrazine. Environ Sci Technol 43:3285–3291

Cao XD, Harris W (2010) Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour Technol 101:5222–5228

Chan KY, van Zwiete L, Meazaros I (2007) Agronomic values of greenwaste biochar as a soil amendment. Austra J Soil Res 45:629–634

Chen X, Chen G, Chen L, Chen Y, Lehmann J, McBride MB, Hay AG (2011) Adsorption of copper and zinc by biochars produced from pyrolysis of hardwood and corn straw in aqueous solution. Bioresour Technol 102:8877–8884

Chun Y, Sheng GY, Choiu CT (2004) Compositions and sorptive properties of crop residue-derived chars. Environ Sci Technol 38:4649–4655

Das SK, Das AR, Guha AK (2007) A study on the adsorption mechanism of mercury on Aspergillus versicolor biomass. Environ Sci Technol 41:8281–8287

Demirbas A (2008) Heavy metal adsorption onto agro-based waste materials: a review. J Hazard Mater 157:220–229

Echeverria JC, Morera MT, Mazkiaran C, Garrido JJ (1998) Competitive sorption of heavy metal by soils: isotherms and fractional factorial experiments. Environ Pollut 101:275–284

Giles CH, Smith DA (1974) General treatment and classification of the solute adsorption isotherm, Part I: theoretical. J Colloid Interface Sci 47:755–765

Gupta VK, Ali I (2000) Utilisation of bagasse fly ash (a sugar industry waste) for the removal of copper and zinc from wastewater. Sepn Purifn Technol 18:131–140

Gupta VK, Ali I, Saini VK (2007a) Adsorption studies on the removal of Vertigo Blue 49 and Orange DNA13 from aqueous solutions using carbon slurry developed from a waste material. J Colloid Interface Sci 315:87–93

Gupta VK, Ali I, Saini VK (2007b) Defluoridation of wastewaters using waste carbon slurry. Water Res 41:3307–3316

Gupta VK, Al Hayat M, Singh AK, Pal MK (2009a) Nano level detection of Cd(II) using poly(vinyl chloride) based membranes of Schiff bases. Anal Chim Acta 634:36–43

Gupta VK, Carrott PJM, Ribeiro Carrott MML, Suhas (2009b) Low cost adsorbents: growing approach to wastewater treatment—a review. Crit Rev Environ Sci Technol 39:783–842

Gupta VK, Goyal RN, Sharma RA (2009c) Comparative studies of neodymium (III)-selective PVC membrane sensors. Anal Chim Acta 647:66–71

Gupta VK, Goyal RN, Sharma RA (2009d) Novel PVC membrane based alizarin sensor and its application; Determination of vanadium, zirconium and molybdenum. Inter J Electrochem Sci 4:156–172

Gupta VK, Jain CK, Ali I, Sharmaa M, Sainia VK (2003) Removal of cadmium and nickel from wastewater using bagasse fly ash–a sugar industry waste. Water Res 37:4038–4044

Gupta VK, Jain AK, Kumar P, Agarwal S, Maheshwari G (2006a) Chromium(III)-selective sensor based on tri-o-thymotide in PVC matrix. Sensors Actuators B Chem 113:182–186

Gupta VK, Jain R, Mittal A, Mathur M, Sikarwar S (2007c) Photochemical degradation of the hazardous dye Safranin-T using TiO2 catalyst. J Colloid and Interface Sc 309:464–469

Gupta VK, Jain R, Varshney S (2007d) Removal of Reactofix golden yellow 3 RFN from aqueous solution using wheat husk—an agricultural waste. J Hazard Mater 142:443–448

Gupta VK, Kumar P (1999) Cadmium (II)-selective sensors based on dibenzo-24-crown-8 in PVC matrix. Anal Chim Acta 389:205–212

Gupta VK, Mittal A, Gajbe V, Mittal J (2006b) Removal and recovery of the hazardous azo dye acid orange 7 through adsorption over waste materials: bottom ash and de-oiled soya. Ind Eng Chem Res 45:1446–1453

Gupta VK, Mohan D, Sharma S, Park KT (1999) Removal of chromium (VI) from electroplating industry wastewater using bagasse fly ash–a sugar industry waste material. Environmentalist 19:129–136

Gupta VK, Mangla R, Agarwal S (2002) Pb (II) selective potentiometric sensor based on 4-tert-Butylcalix [4] arene in PVC matrix. Electroanalysis 14:1127–1132

Gupta VK, Rastogi A (2008) Equilibrium and kinetic modelling of cadmium(II) biosorption by nonliving algal biomass Oedogonium sp from aqueous phase. J Hazard Mater 153:759–766

Gupta VK, Rastogi A (2009) Biosorption of hexavalent chromium by raw and acid-treated green alga Oedogonium hatei from aqueous solutions. J Hazard Mater 163:396–402

Gupta VK, Rastogi A, Dwivedi MK, Mohan D (1997) Process development for the removal of zinc and cadmium from wastewater using slag—a blast furnace waste material Sepn. Part Sci Technol 32:2883–2912

Gupta VK, Rastogi A, Nayak A (2010) Adsorption studies on the removal of hexavalent chromium from aqueous solution using a low cost fertilizer industry waste material. J Colloid Interface Sci 342:135–141

Gupta VK, Sharma S (2003) Removal of zinc from aqueous solutions using bagasse fly ash a low cost adsorbent. Ind Engr Chem Res 42:6619–6624

Gupta VK, Singh AK, Gupta B (2007e) Schiff bases as cadmium(II) selective ionophores in polymeric membrane electrodes. Anal Chim Acta 583:340–348

Gustafsson JP (2010) Visual MINTEQ ver. 3.0. Available at http://www2.lwr.kth.se/English/OurSoftware/vminteq/index.htm

Jain AK, Gupta VK, Khurana U, Singh LP (1997a) A new membrane sensor for UO2+, based on 2-hydroxyacetophenoneoxime -thioureatrioxane resin. Electroanalysis 9:857–860

Jain AK, Gupta VK, Sahoo BB, Singh LP (1995a) Copper (II)-selective electrodes based on macrocyclic compounds. Anal Proc including Anal Commun 32:99–101

Jain AK, Gupta VK, Singh LP (1995b) Neutral carrier and organic resin based membranes as sensors for uranyl ions. Anal Proc including Anal Commun 32:263–265

Jain AK, Gupta VK, Singh LP, Khurana U (1997b) Macrocycle based membrane sensors for the determination of cobalt (II) ions. Analyst 122:583–586

Jain AK, Gupta VK, Singh LP, Srivastava P, Raisoni JR (2005) Anion recognition through novel C-thiophenecalix[4] resorcinarene: PVC based sensor for chromate ions. Talanta 65:716–721

Lehmann J (2007) A handful of carbon. Nature 443:143–144

Lehmann J, Joseph S (2009) Biochar for environmental management. Science and Technology Earthscan, Ltd., London

Martins AF, de Cardoso AL, Stahl JA, Diniz J (2007) Low temperature conversion of rice husks, eucalyptus sawdust and peach stones for the production of carbon-like adsorbent. Bioresour Technol 98:1095–1100

Mohan D, Iittman PCU Jr, Bricka M, Smith F, Yancey B, Mohammad J, Steele PH, Alexandre-Franco MF, Gómez-Serrano V, Gong H (2007) Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during bio-oil production. J Colloid Interface Sci 310:57–73

National Research Council (NRC) (2001) Nutrient requirements of dairy cattle, 7 revth edn. National Academy Press, Washington, DC

Olsen SR, Sommers LE (1982) Phosphorus. In: Page AL et al (eds) methods of soil analyses: part 2 chemical and microbiological properties. Am. Soc. Agron, WI, USA, pp 403–430

Qiu YP, Cheng HY, Xu C, Sheng G (2008) Surface characteristics of crop-residue-derived black carbon and lead(II) adsorption. Water Res 42:567–574

Shinogi Y, Kanri Y (2003) Pyrolysis of plant, animal and human waste: physical and chemical characterization of the pyrolytic products. Bioresour Technol 90:241–247

Srivastava SK, Gupta VK, Dwivedi MK, Jain S (1995) Caesium PVC-Crown (dibenzo-24-crown-8) based membrane sensor. Anal Pro including Anal Commun 32:21–23

Srivastava SK, Gupta VK, Jain S (1996) A PVC-based benzo-15-crown-5 membrane sensor for cadmium. Electroanalysis 8:938–940

Uchimiya M, Lima IM, Klasson KT, Chang SC, Wartelle LH, Rodgers JE (2010) Immobilization of heavy metal ions (Cu(II), Cd(II), Ni(II), and Pb(II)) by broiler litter-derived biochars in water and soil. J Agr Food Chem 58:5538–5544

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agr Food Chem 59:2501–2510

United States Environmental Protection Agency (USEPA) (1986) Test methods for evaluating solid waste, Laboratory Manual Physical/Chemical Methods. U.S. Gov. Print Office, Washington, DC

van Zwieten L, Kimber S, Morris S, Chan KY, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246

Villaescusa I, Fiol N, Martinez M, Miralles N, Pocj J, Serarols J (2004) Removal of copper and nickel ions from aqueous solutions by grape stalks wastes. Water Res 38:992–1002

Woolf D, Amonette JE, Street-Perrott FA, Lehmann J, Joseph S (2010) Sustainable biochar to mitigate global climate change. Nature Commun 1:56

Wan Ngah WS, Hanafiah MAKM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol 99:3935–3948

Acknowledgments

This work was supported in part by National Natural Science Foundation of China (No. 20877056, 21077072), China Ministry of Education Returned Overseas Scholar Scientific Foundation, China Ministry of Education Doctor Scientific Foundation, Shanghai Pujiang Talent Project (11PJ1404600), and the SJTU University Innovative Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vinod Kumar Gupta

Rights and permissions

About this article

Cite this article

Xu, X., Cao, X., Zhao, L. et al. Removal of Cu, Zn, and Cd from aqueous solutions by the dairy manure-derived biochar. Environ Sci Pollut Res 20, 358–368 (2013). https://doi.org/10.1007/s11356-012-0873-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0873-5