Abstract

Background, aim, and scope

The management of contaminated sites requires the investigation of different involved aspects (from socioeconomic to risk and technological issues) and the presentation of useful and condensed information to decision makers. For this purpose, indices are more and more recognized as effective and valuable tools. This paper presents specific indices created within the DEcision Support sYstem for REhabilitation of contaminated sites (DESYRE).

Materials and methods

DESYRE is a software which aids decision making for the rehabilitation of a large contaminated site (i.e., megasite) by the creation and comparison of different rehabilitation alternatives. The software is composed of six modules, each dealing with a specific aspect of the remediation process, ending with the decision module. In this module, scenarios (i.e., suitable solutions for the rehabilitation of the contaminated site including selected land use, socioeconomic benefits, remediation costs, time span, environmental impacts, technology set/s, and residual risk) are created and evaluated by means of suitable indices. Nine indices cover the socioeconomic, risk, technological, cost, time, and environmental impact aspects. Mathematical algorithms are used to calculate these indices by taking into account data collected during the analytical steps of the DESYRE system and elaborated through the support of the spatial analysis, which is embedded in the system.

Results

The case study of Porto Marghera, Venice, Italy is presented in order to document the effectiveness of developed indices in evaluating management solutions and presenting options to decision makers. For the purpose of this study, three different scenarios for the remediation of a part of the site of Porto Marghera (approximately 530 ha) are developed and compared. The three scenarios consider the industrial land use and deal with the contamination in soil caused by inorganic and organic compounds. The scenarios mainly differ for the number of the included remediation technologies and for the spatial distribution of the technologies on the considered area.

Discussion

Indices results allow the user to more easily evaluate the advantages and limits of each scenario in order to select the most appropriate one. For instance, the risk indices allow the user to identify scenarios with good performance in reducing the extension of risk areas and the risk magnitude. Equally, the technological indices support the achievement of efficient remedial solutions characterized by a limited number of technologies, applied to extended areas and with high performance. The environmental impact index allows users to estimate the wider effects on the environment of the selected solutions, while the socioeconomic index is the result of social and economic investigations of the regional and local conditions, which ends with the identification of the best land use (e.g., the industrial one for the Porto Marghera area).

Conclusions

The proposed nine DESYRE indices provide more complete information to investigate suitable management solutions. DESYRE indices facilitate the definition of a consensus among stakeholders and the achievement of a widely shared solution for contaminated site management, even at larger sites, such as Porto Marghera.

Recommendations and perspectives

Further improvements to the system may be adopted, e.g., the possibility to aggregate results of the different assessments into one synthetic index per scenario or the inclusion of a Group Decision Making procedure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

Managers and decision makers dealing with a contaminated site usually face a complex subject, where environmental contamination is only one of several aspects to be considered. In fact, in addition to the spread of chemical contamination which can affect soil, surface water, and groundwater quality, many other aspects must be taken into account when setting up management options for the rehabilitation of a contaminated site. Critical information concerns the risk, posed both to the environment and to human health, whose assessment is needed in order to establish suitable remediation objectives. Risk assessment is also strictly connected to the definition of technological solutions for environmental rehabilitation. The choice of the best technologies to be applied is usually dependent on cost and time evaluations, impacts on the environment, technical efficiency, and logistics (e.g. in situ or ex situ treatments). Moreover, investigation of the socioeconomic conditions at the site and in the surrounding areas is another significant factor because the remediation of a contaminated site is often included in a more general economic redevelopment plan of an area. Redevelopment of a site should be evaluated according to regional economic driving factors and also to defined sustainability goals for the entire region where the site is located (Bardos et al. 2001).

If all the mentioned aspects (environmental characterization, risk assessment, technological implementation, economic benefits and costs, social well-being) are to be taken into account for the definition of the most suitable rehabilitation solution for a given contaminated site, it follows that decision makers need to receive reliable, essential, significant, clear, and thorough information in a easily understandable format to evaluate the current status of the site and to develop economically feasible and environmentally viable management options (Bonano et al. 2000; Schultink 2000; Popp et al. 2001; Lopez-Ridaura et al. 2002; Niemeijer 2002; Aven and Kørte 2003; Ness et al. 2007). This type of essential information is usually provided by indicators and/or indices (Hammond et al. 1995; Malkina-Pykh 2002; Gray and Wiedemann 1997; Hoag et al. 2002; Segnestam 2002).

Considering an indicator as a simple value or measure that describes or provides information, usually quantitatively, on a phenomenon or an environment (EEA 1999; OECD 2002; Ness et al. 2007), an index is derived by the combination of several indicators into one single number in order to provide more condensed information (Gray and Wiedemann 1997; Malkina-Pykh 2002; OECD 2002; Ness et al. 2007). Adopting the policy information flow proposed by Schultink (2000), which starts from the problem identification and ends with the decision making and policy implementation, indicators are used as problem descriptive elements, while integrated indices are used at the last stage of the decision process to evaluate potential solution performances and to assist in the selection of planning alternatives.

This work, therefore, proposes a set of indices which specifically address the contaminated land assessment and management decision process, describing synthetically and comprehensively a management option or alternative. The proposal of different integrated indices is particularly important within the sustainability science, since research efforts are devoted to the definition of indices that provide crosscutting information between nature and society dimensions (Ness et al. 2007).

In general, indicators and derived indices should fulfill some requirements, such as simplicity, measurability, sensitivity to change, and suitability for monitoring (Niemeijer 2002; Ness et al. 2007). Moreover, in the case of contaminated site assessment and management, indices should have appropriate characteristics which make them suitable for supporting decision making by providing information on all the different aspects. Vik et al. (2001) summarized these different aspects in six categories: drivers and goals for the remediation, sustainable development, risk management, cost-effectiveness, technical suitability and feasibility, and stakeholders’ views. These categories may be further explained as: redevelopment objectives in consideration of local socioeconomic plans; risk-based approach for the environmental restoration; capability of technologies in dealing with a specific problem and their feasibility in the specific conditions; valuation of costs versus benefits; and consideration of multiple stakeholders’ profiles.

Although quite different approaches and frameworks have been proposed for the remediation of contaminated sites (Bonano et al. 2000; Khadam and Kaluarachchi 2003a, b; Aven and Kørte 2003; Marcomini et al. 2009), very few have developed indices which address and include all the interested aspects. Many management frameworks are centered on the cost-effectiveness of risk reduction through a cost–benefit analysis procedure; therefore, their analysis is limited to the evaluation of risk reduction, cost minimization and regulatory compliance (Khadam and Kaluarachchi 2003a, b; Aven and Kørte 2003). Other researchers have also considered additional aspects such as life cycle costs or cultural and historical resources (Bonano et al. 2000). In the case of the Risk reduction, Environmental merit and Costs (REC) system, a proposal of integrated indices for the analysis and evaluation of possible cleanup strategies at a contaminated site has been developed through the evaluation of the three major aspects (Nijboer 1998). Nevertheless, the REC system lacks in addressing the overall complexity of remediation of contaminated sites, giving no specific indications about spatial features of risk assessment and remediation processes, and about the socioeconomic effects of redevelopment of the site. Therefore, the information provided as indices could be inadequate for a comprehensive decision-making process.

In this work, a set of indices that can support the comparison of alternative management solutions for a contaminated site is presented. These indices are the central components of DESYRE, which has been specifically developed to aid experts and stakeholders in the definition of rehabilitation alternatives for large contaminated sites or megasites (Carlon et al. 2007; Marcomini et al. 2009).

2 Materials and methods

2.1 DESYRE decision support system

DESYRE is a software that aids decision making for the rehabilitation of a large contaminated site (i.e., megasite) by the creation and comparison of different rehabilitation alternatives. The rehabilitation alternatives, proposed as different scenarios, are feasible solutions identified by socioeconomic factors, technological options, and risk reduction values. DESYRE is included in a Geographic Information System (GIS) platform and provides assessment tools for the different analytical stages, from site characterization to scenarios development and ranking, in a stepwise and guided procedure (Facchinetti et al. 2003; Critto et al. 2006; Carlon et al. 2007, 2008).

The integration among analytical and decisional phases allows the involvement and collaboration of both experts and stakeholders. In a first phase, DESYRE provides assessment modules for a multidisciplinary team of experts, composed of risk assessors, socioeconomists, and technology engineers. In the last phase, DESYRE provides decision makers and involved nontechnical stakeholders with indices supplying information for comparing alternative rehabilitation scenarios.

The software is composed of six modules, each dealing with a specific aspect of the rehabilitation process: socioeconomic, site characterization, risk assessment, technological, residual risk assessment, and decision modules. Carlon et al. (2007) provided an extensive description of the software characteristics. Here, only some of the main aspects of the different modules are presented in order to facilitate the description and understanding of the indices discussed in the paper.

The socioeconomic module addresses the socioeconomic constraints generated by different land uses. Based on a fuzzy expert system elaboration, the module allows the experts to select the most socioeconomically attractive land use for a considered site (Facchinetti et al. 2003).

The site characterization module supports the analysis of chemical contaminants’ spatial distribution and provides all data necessary to run fate and transport and risk assessment models. The spatial distribution of contaminants, based on concentrations at sampling stations, is obtained by using geostatistical methodologies, specifically variography and Kriging (Isaaks and Srivastava 1989).

The risk assessment modules provide tools for human health risk assessment. The analysis is performed on contaminants present both in soil and in groundwater. The possible chemicals of concern are grouped into six classes: non-halogenated volatile organic compounds, halogenated volatile organic compounds, non-halogenated semivolatile organic compounds, halogenated semi-volatile organic compounds, fuels, and inorganics (FRTR 2002). The considered exposure pathways are ingestion and dermal contact with soil, inhalation of vapor and particulate emissions, groundwater ingestion, and flow into surface water. Risk calculation is based on standard algorithms (USEPA 1989; ASTM 1998), but a novel procedure has been developed and included in order to investigate the spatial distribution of risk (Carlon et al. 2008).

Risk analysis is applied twice: in a pre-remediation phase, to provide a site zoning according to risk levels, and in a post-remediation phase, to evaluate the residual risk after the application of a technological set. In the pre-remediation phase, risk assessment provides maps of risk based on current contamination, highlighting areas of non-acceptable risk for human health related to selected land use risk scenario. After the technological module application, by running a simulation of chosen interventions, the residual risk assessment produces maps of residual risk levels. At this step, a probabilistic estimation of risk and its associated uncertainty is performed, allowing the creation of both risk and uncertainty maps (Carlon et al. 2008).

The technological module between the two risk assessment modules is organized in a stepwise procedure. A detailed description of this module is provided in Critto et al. (2006). For the purpose of this paper, it must be remembered that a ranking system for the technologies is applied, by which a score is assigned to each technology, based on several criteria (e.g., performance, reliability, public acceptability, cost) evaluated through multicriteria analysis (Ramanathan and Ganesh 1994). The output of the module is the definition of several sets of remediation technologies (i.e., combinations of technologies) differently distributed in space and time on the site, created separately for soil and groundwater.

Finally, the decision module provides the description of alternative rehabilitation scenarios. A scenario is a suitable solution for the rehabilitation of the contaminated site, which includes the selected land use and the socioeconomic benefits, the remediation costs, the time span, the environmental impacts, the technology set/s, and the residual risk. Suitable indices describe the generated scenarios.

The main feature of the DESYRE software, which characterizes all the analytical steps and also determines the development of the rehabilitation scenarios, is represented by the spatial analysis. In fact, DESYRE can be defined as a spatial decision support system (Malczewski 1999; Seffino et al. 1999), mainly expressed through the ability of the software to allow the raster representation of contaminant concentrations and of the associated risk levels, as well as the spatial allocation of remediation technologies.

For the definition of the raster maps of contaminant concentrations and of the resulting risk zoning, the software includes geostatistical methodologies (Isaaks and Srivastava 1989), which virtually divide the site into several cells of an interpolation grid. The strong spatiality of the overall analysis and the consideration of the cells contained in the grid are very critical in the calculation of many of the indices used in DESYRE, as they will be described in more detail in the next sections. In fact, current and residual risks are calculated on single cells, and allocation of technologies is also performed by taking into consideration the spatial representation of risk levels. An example of the resulting risk maps is provided in Fig. 1. The overlapping capacity of the GIS platform allows the user to identify each cell in all thematic layers (land use of the site, technological application, and current or residual risk maps) and to use the related values of those attributes for the calculation of indices, which are, therefore, spatially based themselves.

Spatial analysis feature within the DESYRE software. The raster map of contaminant distribution is used to map risk levels and then to allocate spatially different remediation technologies and to evaluate their application and resulting risk reduction. Equally, calculation of many DESYRE indices is performed on the grid cells

2.2 DESYRE indices

The analytical procedures performed during the first five modules of the DESYRE software provide information used for the definition of the rehabilitation options in the decision module. The rehabilitation options, or scenarios, are described by nine main indices, namely:

-

socioeconomic

-

residual risk extension, residual risk magnitude, and risk magnitude reduction

-

technological set quality and logistical set quality

-

environmental impact

-

time

-

cost

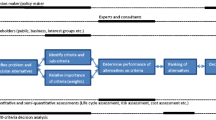

The relationships between the DESYRE indices and the analytical modules are presented in Fig. 2. The indices, elaborated in the analytical modules, are conveyed into the decision module and presented to stakeholders for the evaluation of the rehabilitation alternatives.

Indices within the DESYRE Decision module. Previous modules of the DESYRE software concern the analysis of specific aspects, such as the socioeconomic analysis, the environmental characterization, the risk assessment, and the technological sets definition. Information derived by these analytical modules is included in the decision module in order to produce nine relevant indices for each possible scenario

A detailed description of the indices is provided in the following paragraphs.

2.2.1 The socioeconomic index

The socioeconomic index provides a measure of the attractiveness of a specific land use for the site under consideration. The objective of the socioeconomic module is to provide the best land use alternative for the considered site by taking into account site characteristics and regional socioeconomic constraints and opportunities. In DESYRE, the considered land uses are six:

-

residential

-

recreational

-

tourist

-

industrial

-

services for business and firms

-

population services

The module is based on a fuzzy expert system (Facchinetti et al. 2003). There are several socioeconomic variables that are used to evaluate the land use attractiveness, such as city or province population, number of factories, distance from main roads, costs of square meter of land in and outside the site, local priorities, traffic impact, and so on.

These 15 socioeconomic variables are grouped in order to assess four main aspects: the demand for a specific use, the attraction with respect to alternative sites for the same use, the attraction of that site, and the consistency of that use with the surrounding context (i.e., vocation). Specific variables of the 15 available ones are grouped to characterize each of the four aspects. To define the interactions of the variables grouped for the definition of the values of the four main aspects, the fuzzy methodology creates a tree structure and specific fuzzy rules, connecting the individual variables to produce the final index value for the considered land-use option (Facchinetti et al. 2003). This value is then reported and used in the decision module for the scenario ranking.

2.2.2 The chemical risk indices

The risk indices synthesize the information derived by the integration of current chemical risk levels and the reduction obtained by the technological applications.

The three considered indices (reported in Fig. 2) are:

-

RExt_res, residual risk extension index, which represents the areas of the site where risk still exceeds the acceptable level after remediation

-

RMag_res, residual risk magnitude index, which represents the level of non-acceptable residual risk at the site after remediation

-

RMag_red, risk magnitude reduction index, which is dependent on the reduction of risk magnitude by technological application

As mentioned in the general introduction to the DESYRE software, the main feature of the system is the spatially based analysis, particularly with reference to the risk assessment and technologies allocation. The included geostatistical functionalities allow the user to define raster risk maps for the considered classes of contaminants (see Fig. 1). Therefore, the calculation of risk indices is also linked to the spatial attributes and is performed on the cells comprising the risk maps.

Risk assessment is performed separately for soil and groundwater and on a multiplicity of exposure pathways (e.g., ingestion of soil, inhalation of volatile compounds and dust from soil, dermal contact with soil, leaching and water ingestion).

In each cell of the risk map and for each chemical contaminant, a risk factor for soil is calculated as in the following equation:

where:

- RF:

-

risk factor

- ESC:

-

estimated soil concentration

- MACS:

-

multi-pathway acceptable concentration in soil, which depends on the acceptable chemical concentration of each exposure pathway considered for soil (Carlon et al. 2008).

A similar equation is used with reference to groundwater contamination. In both cases, the risk factor for the category of contaminants in a cell is obtained by taking the maximum value of RF (RFmax) of the contaminants included in the category.

RFmax values are then grouped into five classes:

-

Class 1: RF ≤ 1

-

Class 2: 1 < RF ≤ 3

-

Class 3: 3 < RF ≤ 10

-

Class 4: 10 < RF ≤ 100

-

Class 5: RF > 100

From these risk factors derived for every cell of the considered maps, the risk indices can be calculated.

By considering the raster maps produced for the different classes of contaminants, the main elements used in the calculation of the risk indices are:

-

N i , total number of cells comprising the risk map for each contaminant category i

-

A ij , number of cells with a non-acceptable risk before remediation (i.e., RFclass j, between 2 and 5) within each contaminant category i

-

B ij , number of cells with a non-acceptable risk after remediation (i.e., resRFclass j, between 2 and 5) within each contaminant category i

The R Ext_res is calculated by taking into account the number of cells with non-acceptable residual risk (i.e., resRFclasses 2 to 5) in the six contaminant categories:

The index is fixed to range between 1 and 0, where 0 represents the best value since it means that no cell after remediation, considering each contaminant category, has non-acceptable risk.

The R Mag_res represents an average of the non-acceptable residual risk in post-remediation maps. It is calculated as in Eq. 3:

where resRFclass ij is the class j of non-acceptable residual risk factor (i.e., resRF classes 2 to 5) in each contaminant category i and B ij is the related number of cells.

The index varies between 0 and 5, where 5 represents the worse situation, indicating that the magnitude of risk of each contaminant category in post-remediation maps is included in class 5 (resRF > 100) in every cell of the map.

Finally, the R Mag_red is calculated considering the risk factors’ class before and after remediation in each contaminant category. The formula for the calculation is as follows:

where RFclass ij is the class j of non-acceptable residual risk factor (i.e. RF classes 2 to 5) in each contaminant category i before remediation and A ij is the related number of cells.

This index expresses the reduction of risk magnitude in a 0–1 interval. The worse situation is represented by the 0 value, which means that no reduction of risk has been achieved and the magnitude of risk before and after remediation is equal.

2.2.3 The technological indices

The technological indices allow the user to estimate the extent to which the chosen technological sets represent the best option in terms of risk reduction performance and limited number of selected technologies applied to large portions of the site. The calculation of these indices is dependent upon the overall process of selection and allocation of technologies performed in the technological module, and particularly in the included expert judgment elicitation (Critto et al. 2006).

In the elicitation, each technology is characterized by a score assigned by means of a specific multicriteria decision analysis tool with respect to different criteria, weighted by experts (Critto et al. 2006).

During the technological module, several technological sets, i.e., combination of technologies for a specific rehabilitation scenario, can be created and allocated on the risk maps (Carlon et al. 2007). The choices made during this module affect the calculation of the indices presented here.

Specifically, the considered technological indices are:

-

Ta, the technological set quality index, which measures the technological set efficiency according to the procedure proposed by Critto et al. (2006)

-

Tb, the logistical set quality index, which is a measure of the disadvantage derived by the application of a high number of technologies

For the calculation of these technological indices, the following data are taken into account:

-

M, the number of technologies within each considered set

-

T m , the different technologies in a specific set

-

a m , area where each technology is applied, expressed as a percentage of the site total area

-

w m , the weight, between 0 and 1, associated to a technology m as a function of a m

-

W′ m , the weight of technologies normalized by the equation:

where \( \sum\limits_{m = 1}^M {w\prime_m } = 1 \).

-

p m , the score of a technology, assigned by the system in the technological module to each technology within a group of technologies treating a specific contaminant category, according to the procedure described in Critto et al. (2006).

-

p′m, the normalized score of a technology included in the scoring group of each contaminant category, considering the technology with the minimum score (pmin) and the technology with the maximum score (pmax) within the group, as in the following equation:

The factor δ is used to avoid null scores and, therefore, to also consider technologies that have low scores. As a default, this factor is set equal to 1/V, where V is the number of technologies included in the scoring group for each contaminant category, but experts can change this equivalence. In this case, the normalized values can vary between 0 and 1.

The technological set quality index, T a, expresses the value associated with intrinsic characteristics of the selected technologies, giving preferences to sets composed of very efficient technologies applied to large areas of the site.

The index is obtained by the application of the equation:

The index can vary within 0 and 1, where 1 is the best score.

The logistical set quality index, T b, is a function of the number of technologies present in a considered set. The function is a monotone decreasing function, which can be either hyperbolic or exponential:

The system proposes the hyperbolic function as default, but experts can modify this option according to their judgments. In all cases, the index ranges between 0 and 1 depending on the number of chosen technologies. In fact, its value is 1 if one technology is selected, while it decreases to 0 as many more technologies are included in the set.

2.2.4 The environmental impact index

The environmental impact index takes into consideration data collected in the technology ranking, the information on selected technologies composing the set, and the areas of application. In fact, the calculation of the index is based on the abovementioned weights of the technologies (w′ m ) and the experts’ judgement (g m ) of each technology, defined within the technological module, with specific reference to the criterion about community acceptability and impact of the technology (Critto et al. 2006). The judgment of this criterion can be assigned on a scale between 1 (best) and 5 (worst).

The environmental impact index is then obtained by the equation:

The index varies between 1 and 5, where 5 corresponds to the worst value, i.e., the maximum technological impact, caused by the assignment of the worst value of judgment (5) to every technology included in the set under consideration.

2.2.5 The cost and time indices

The calculation of costs is performed differently for soil and groundwater. In both cases the technologies in the set (T m ) and the area of application (area m , in m2), are taken into account.

In addition, other considered parameters are:

-

the costs of the technologies, in Euro/ton (c sm) for soil to be treated, and Euro/1,000 L of water (c gm), for groundwater to be treated;

-

ds, depth of soil to be treated, in m

-

ρs soil density, in g/cm3 as default

-

dg, groundwater thickness, in m

-

pg, groundwater porosity, in cm3 of pores/cm3

Therefore, the soil cost index, considering the whole volume of soil, can be calculated as follows:

Equally, groundwater costs are calculated as:

The total costs evaluation for the scenario is given by the sum of soil and groundwater costs, which represents the cost index figure.

As far as the time index is concerned, expert judgment is required in order to estimate the number of years for each scenario, provided in consideration of the extension of the area of application and the experts’ experience on treatment processes and performances of technologies included in the set. Time can be provided for both soil and groundwater sets and the time index summarizes the two evaluations into a single feature of the number of years required for the overall remediation process.

2.3 Case study

A presentation of preliminary results after application of the software to a case study may be useful in order to understand the potentialities and the functions provided by the presented indices in supporting the decision-making process of rehabilitation of a large contaminated site.

The Porto Marghera case study has been chosen as a representative example of an environmentally complex site or megasite (Carlon et al. 2007). Main characteristics of the site are the large extension, the potential economic impact of the area in the region, and the constraints derived by the high remediation costs (Carlon et al. 2007). Porto Marghera is an industrial area of approximately 3,600 ha, located at the border of the Venice lagoon in Italy. The 300 industries present at the site are mostly involved in chemical and petro-chemical productions. Site characterization revealed heavy and widespread contamination, mostly due to the presence of polycyclic aromatic hydrocarbons, amines, dioxins (PCDD/F), halogenated organic compounds (PCBs, HCB, etc.), and metals (As, Hg, Cd, Pb, Zn, etc.) in both soil and groundwater.

According to the Italian national law 426/1998, Porto Marghera is the largest out of the 50 contaminated sites of national interest. In 1998, an agreement among local and national authorities, representatives of the industries located in the site, and other stakeholders was signed to support sustainable management of this land. The agreement included the definition of a Master Plan for the Porto Marghera site, which ensures an integrated approach to the whole area (Regione Veneto and Comune di Venezia 2004). The Master Plan set up the management actions for the rehabilitation of this large site, encompassing all the remediation activities, the logistical aspects, and the intervention costs. Within 395 ha of identified priority areas in the whole Porto Marghera area, approximately 100 ha represents the industrial contaminated soil to be treated, and the rest is composed of landfills and urban areas. For the treatment of the industrial contaminated soil between 0 and 1.5 m below ground on average (i.e., where contamination was found), biological treatments, solidification/stabilization, thermal desorption, soil washing, and vitrification were the identified remediation technologies. Costs of remediation of the industrial contaminated soil with these proposed technologies over a period of 10 years were estimated around 270 million Euro (Regione Veneto and Comune di Venezia 2004).

2.3.1 Considered scenarios

For the purpose of this study, three different scenarios for the rehabilitation of a part of the site of Porto Marghera (approximately 530 ha) were developed and compared. The three scenarios were built only in consideration of soil contamination and of four exposure pathways (i.e., soil ingestion, soil dermal contact, volatile compounds and dust inhalation, leaching and water ingestion).

Experts were called to apply the technological module of the software (Carlon et al. 2007) and to follow the procedure in order to select the most appropriate remediation technology options for the situation under consideration (Critto et al. 2006). Due to the present contaminants and the level of risks, the extension of the area and the experts’ experience and knowledge, and through the support of the information elaborated by the software, the three scenarios were characterized by the chosen technologies as follows:

-

Scenario 1: soil vapor extraction and soil washing. The objective of this scenario is to have a good performance in reduction of contaminants, with particular focus on the organic and inorganic compounds specifically treated by the two technologies. Moreover, it is chosen to apply the two technologies to the whole area of the site

-

Scenario 2: soil washing and thermal desorption. As in the previous case, two technologies are selected and applied in the whole area as train technologies. There is a good interaction between the two technologies since the soil washing results partly in a separate fraction that can be subsequently treated by thermal desorption

-

Scenario 3: soil vapor extraction, enhanced bioremediation, electrokinetic separation, and phytoremediation. In this case, a completely different approach from the previous choices is adopted. Firstly, more technologies are selected, trying to cover all contaminant categories. Secondly, the technologies are allocated differently in the site area, following the distribution of risks on the risk map. As reported in Table 3, soil vapor extraction is applied to 85.5% of the total considered area, enhanced bioremediation to 66.9%, electrokinetic separation to 76.6%, and finally, phytoremediation to 87.5%.

The DESYRE decision module was tested, after the application of the previous modules of the software and on each of these produced scenarios, to calculate the indices characterizing the alternatives (Carlon et al. 2007). The results of these calculations are reported in Tables 1, 2, 3, 4, and 5.

3 Results and discussion

The application of the socioeconomic module (Facchinetti et al. 2003) generated the results reported in Table 1, characterized by the four main aspects estimated by means of the fuzzy logic system, and the final index. The index calculation reveals that the most appropriate land use for the site under consideration is the industrial one, which in fact scores 0.67. Therefore, this land use is selected for all the three scenarios in the application of the following DESYRE modules.

Table 2 refers instead to the risk values indices. As previously explained, three indices are calculated here: residual risk extension (R Ext-res) and magnitude (R Mag-res) and risk magnitude reduction (R Mag-red). Looking at the results in the three scenarios, Scenarios 1 and 2 have similar values, with good performances in reducing the extension of risk areas (R Ext_res = 0.17), as well as in the reduction of risk magnitude (R Mag_red = 0.77). In fact, the details about the single contaminant categories in both scenarios reveal that the technology pairs included in the scenarios are able to treat the volatile and semi-volatile organic compounds and fuels very well, and the inorganic compounds partially well.

The performance of Scenario 3 risk indices is instead somewhat worse than the other two scenarios, with a higher number of residual cells of classes of non-acceptable risk (classes 2 to 5) in different contaminant categories (and, therefore, a higher residual risk extension index, R Ext-res = 0.22).

In Table 3 the results of the technological indices are reported. Scenarios 1 and 3 have very close performances (0.75 and 0.73, respectively) in the technological set quality index, and only Scenario 2 is different (0.51). The lower score of Scenario 3 in the logistical set quality index is due to the higher number of technologies included in the set (four with respect to the two in the other scenarios), while the good score in the technological set quality index is an outcome of the application of the technologies to different percentages of the site area, as well as the inclusion of technologies with higher expert scores (e.g., enhanced bioremediation and electrokinetic separation). The application of technologies that scored well to the whole site is the reason for the higher value of the technological set quality index of Scenario 1.

Results of time and costs values are reported in Table 4. Scenario 3 has the highest cost (2,700 million Euros) and is characterized by a longer implementation time (10 years, instead of the 5 years of Scenarios 1 and 2). A comparison with the Master Plan estimation of costs reveals a difference in cost figures. In fact, as mentioned above, the cost for the remediation of contaminated soil within the Porto Marghera high priority areas was estimated in the Master Plan at about 270 million Euros for an area of approximately 100 ha, where different technologies are considered. In the DESYRE scenarios, the remediation costs vary from 2,000 million to 2,700 million Euros. This difference is due to the area where the technologies are applied. In the DESYRE scenarios, the considered area is almost five times larger (around 500 ha) than in the area taken into consideration in the Master Plan. Moreover, the technologies in the Master Plan are distributed in different parts of the total area, while in both DESYRE Scenarios 1 and 2 the technologies are applied to the whole area, or in almost the total extension in Scenario 3.

As far as the environmental impact is concerned, Scenarios 1 and 3, whose impact value is 2.0 (closer to the best value of 1), generally represent solutions with less impact than Scenario 2, which shows a moderately higher impact of 2.5.

Table 5 presents the results of the indices all together. This presentation to stakeholders makes it possible to discuss the advantages and limits of each option more easily, in order to select the most appropriate one. Although indices results are derived by complex and detailed assessment procedures included in the system, results that can also be visualized in the form of graphs are more easily understood by relevant decision makers and stakeholders who prefer to argue about options by comparing a few informative characteristics. DESYRE indices support this need and foster discussion on the main aspects and effects of the rehabilitation process.

For instance, the environmental impact index makes it possible to estimate the wider effects on the environment of the selected solutions, by taking into account the technological judgments and the weight of each technology within the technology set assigned to specific areas (Eq. 10). Moreover, the DESYRE socioeconomic index is the result of social and economic investigations of the regional and local conditions, which ends with the identification of the best land use (e.g., the industrial one for the Porto Marghera area).

The technological indices provide information on remediation efficiency in terms of engineering and technical solutions. In fact, the technological set quality index, as in Eq. 8, is directly dependent upon the score of each technology and its spatial application in the interested area. Linking this information with the extension of residual risk areas, it is possible to have a clearer and more straightforward picture of the post remediation effects. As a result of the guided and area-specific allocation of technologies to different risk zones identified within the risk maps, the technological indices support the achievement of efficient remedial solutions characterized by a limited number of technologies, applied to extended areas and with high performances.

4 Conclusions

The complexity of contaminated site management highlights the need of developing decision support frameworks and tools that aid stakeholders’ choices for site rehabilitation. Integrated and complete information by suitable indices is required in order to perform successful management strategies.

Indeed, decisions about risk management options and remediation alternatives should always be evaluated in consideration of three main concerns: the effectiveness of the remedial techniques in dealing with the identified risks, the wider environmental effects, and the broader considerations of the relevant economic, social, and political values (Vik et al. 2001). Many other frameworks propose investigation and subsequent ranking and selection of solutions based on particular aspects, such as only the risk or the cost-effectiveness (Khadam and Kaluarachchi 2003a, b) or a mix of these with social and/or economic considerations (Bonano et al. 2000; Nijboer 1998).

In the case of DESYRE, the proposed nine indices provide more complete information to investigate suitable management solutions. DESYRE indices facilitate the definition of a consensus among stakeholders and the achievement of a widely shared solution for contaminated site management, even at larger sites, such as Porto Marghera.

5 Recommendations and perspectives

Further improvements to the DESYRE system are under development.

Aggregation of indices can be a challenging aspect, particularly when indices represent quite different aspects (e.g., technological costs, environmental, socioeconomic). In fact, integration can be a grouping of indices of the same area of assessment or a weighting of indices characterizing different areas (Lindholm et al. 2007). In the case of DESYRE indices, it should be taken into account that the nine current indices (one for socioeconomic, three for risk, and five for technological aspects) may somehow provide an unbalanced evaluation of rehabilitation scenarios (more consideration for the technological feasibility than for the remaining factors). Therefore, aggregation may be needed and planned for each main aspect (e.g., risk, technological, socioeconomic) as well as for the overall scenario.

The aggregation would also include a weighting framework for the indices considered, thus, taking into account stakeholders’ dissimilar and sometimes conflicting perspectives in the scenarios construction and comparison, aimed at the achievement of a consensus within a group decision making procedure (Ramanathan and Ganesh 1994; Lootsma 2000).

Linked to the aggregation, sensitivity analysis is an important issue to consider since it should allow to evaluate the influence of the different inputs and indices both on the rehabilitation alternatives generation and comparison, and on the aggregation phase. All these issues are currently under discussion and beyond the scope of the present paper.

Another improvement may deal with the opportunity for decision makers to evaluate rehabilitation scenarios on the basis of additional aspects beyond those already provided; for instance, political and regulatory issues are important elements that could be more clearly included.

References

ASTM (American Society for Testing and Materials) (1998) Standard provisional guide for risk-based corrective action. ASTM, Philadephia, p 100

Aven T, Kørte J (2003) On the use of risk and decision analysis to support decision-making. Rel Engin Sys Saf 79:289–299

Bardos RP, Mariotti C, Marot F, Sullivan T (2001) Framework for decision support used in contaminated land management in Europe and North America. Land Contam Reclam 9(1):149–163

Bonano EJ, Apostolakis GE, Salter PF, Ghassemi A, Jennings J (2000) Application of risk assessment and decision analysis to the evaluation, ranking and selection of environmental remediation alternatives. J Hazard Mater 71:35–57

Carlon C, Critto A, Ramieri E, Marcomini A (2007) DESYRE decision support system for the rehabilitation of contaminated mega-sites. Integ Environ Assess Manage 3:211–222

Carlon C, Pizzol L, Critto A, Marcomini A (2008) A spatial risk assessment methodology to support the remediation of contaminated land. Environ Int 34(3):397–411

Critto A, Cantarella L, Giove S, Petruzzelli GA, Marcomini A (2006) Decision support oriented selection of remediation technologies to rehabilitate contaminated sites. Integ Environ Assess Manage 2:273–285

EEA (European Environment Agency) (1999) Environmental indicators: typology and overview, EEA Technical report 25. EEA, Copenhagen

Facchinetti G, Mastroleo G, Mannino I, Soriani S (2003) A fuzzy expert system for the socio-economic analysis of contaminated sites. In: Pejas J, Piegat A (eds) Enhanced methods in computer security, biometric and artificial intelligence system. Springer, New York, pp 255–265

FRTR (Federal Remediation Technology Roundtable) (2002) Remediation technologies screening matrix and reference guide, 4th ed. www.frtr.gov/matrix2/ visited on March 2006

Gray PCR, Wiedemann PM (1997) Risk and sustainability: mutual lessons from approaches to the use of indicators, 2nd edn. Arbeiten zur Risiko-Kommunikation, Juelich

Hammond A, Adriansee A, Rodenburg E, Bryant D, Woodward R (1995) Environmental Indicators: a systematic approach to measuring and reporting on environmental policy performance in the context of sustainable development. World Resource Institute, Washington, D.C

Hoag DL, Ascough JC II, Engler-Palma A (2002) The impact matrix approach and decision rules to enhance index dimensionality, flexibility and representation. Ecol Indicat 2:161–168

Isaaks EH, Srivastava RM (1989) An introduction to applied geostatistics. Oxford University Press, Oxford

Khadam I, Kaluarachchi JJ (2003a) Multi-criteria decision analysis with probabilistic risk assessment for the management of contaminated ground water. Environ Impact Asses Rev 23:683–721

Khadam I, Kaluarachchi JJ (2003b) Applicability of risk-based management and the need for risk-based economic decision analysis at hazardous waste contaminated sites. Environ Int 29:503–519

Lindholm O, Greatorex JM, Paruch A (2007) Comparison of methods for calculation of sustainability indices for alternative sewerage systems—theoretical and practical considerations. Eco Indicat 7:71–78

Lootsma FA (2000) Multi-criteria decision analysis via ratio and difference. Kluwer, Norwell

Lopez-Ridaura S, Masera O, Aster M (2002) Evaluating the sustainability of complex socio-environmental systems. The MESMIS framework. Ecol Indicat 2:135–148

Malkina-Pykh I (2002) Integrated assessment models and response function models: pros and cons for sustainable development indices design. Ecol Indicat 2:93–108

Malczewski J (1999) GIS and multicriteria decision analysis. Wiley, New York, p 388

Marcomini A, Suter GW II, Critto A (eds) (2009) Decision support systems for risk-based management of contaminated sites. Springer, New York, p 436

Ness B, Urbel-Piirsalu E, Anderberg S, Olsson L (2007) Categorising tools for sustainability assessment. Ecol Econom 60:498–508

Niemeijer D (2002) Developing indicators for environmental policy: data-driven and theory-driven approaches examined by example. Ecol Sci Pol 5:91–103

Nijboer MN (1998) REC: a decision support system for comparing soil remediation options based on risk reduction, environmental merit and costs. Contaminated soil. Thomas Telford, Oxford, pp 1173–1174

OECD (Organisation for Economic Co-operation, Development) (2002) Aggregated environmental indices. Review of aggregation methodologies in use. OECD, Paris, p 43 Report of the Working Group on Environmental Information and Outlooks, WGEIO

Popp J, Hoag D, Hyatt DE (2001) Sustainability indices with multiple objectives. Ecol Indicat 1:37–47

Ramanathan R, Ganesh LS (1994) Group preference aggregation methods employed in AHP: an evaluation and an intrinsic process for deriving members’ weights. Eur J Operat Res 79:249–265

Regione Veneto, Comune di Venezia (2004) Master plan per la bonifica dei siti inquinati. p 185 (in Italian; http://www.ambiente.venezia.it/suolo/doc/MasterPlan-parte%201.pdf)

Schultink G (2000) Critical environmental indicators: performance indices and assessment models for sustainable rural development planning. Ecol Model 130:47–58

Seffino L, Bauzer Medeiros C, Rocha JV, Yi B (1999) WOODSS—a spatial decision support system based on workflows. Dec Supp Sys 27:105–123

Segnestam L (2002) Indicators of environment and sustainable development. Theories and practical experience. The World Bank Environment, Washington, D.C., pp 3–26

USEPA (United States Environmental Protection Agency) (1989) Risk assessment guidance for superfund Vol 1, Human health evaluation manual. USEPA, Washington DC: EPA/540/1-89/002

Vik EA, Bardos P, Brogan J, Edwards D, Gondi F, Henrysson T, Jensen BK, Jorge C, Mariotti C, Nathanail P, Papassiopi N (2001) Towards a framework for selecting remediation technologies for contaminated sites. Land Contam Reclam 9(1):119–127

Acknowledgements

The DESYRE project was funded by the Italian Ministry of University and Scientific Research and developed by the Venice Research Consortium with the support of the University Ca’ Foscari of Venice and Thetis S.p.A. The authors are grateful to the wide group of scientists involved in the development of specific modules and functions; in particular, special thanks go to Antonio Marcomini (scientific supervision); Claudio Carlon (project management and coordination); Silvio Giove and Stefano Silvoni (multicriteria analysis); Manuela Samiolo and Gian Antonio Petruzzelli (technology selection); Nadia Nadal and Lisa Pizzol (risk assessment); Ilaria Bazzanella, Stefano Foramiti, and Luca Dentone (GIS application); and Stefano Soriani, Ilda Mannino, Gisella Facchinetti, and Antonio Mastroleo (socioeconomic and fuzzy analysis).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ulrich Förstner

Rights and permissions

About this article

Cite this article

Critto, A., Agostini, P. Using multiple indices to evaluate scenarios for the remediation of contaminated land: the Porto Marghera (Venice, Italy) contaminated site. Environ Sci Pollut Res 16, 649–662 (2009). https://doi.org/10.1007/s11356-009-0194-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-009-0194-5