Abstract

Introduction

In recent years, growers have used various production types, including high-tunnel systems, to increase the yield of tomatoes (Lycopersicon esculentum). However, the effect of high-tunnel cultivation, in comparison to conventional open-field production, on aroma and flavor volatiles is not fully understood.

Objectives

To optimize the extraction and quantification conditions for the analysis of tomato volatiles using headspace solid phase microextraction (HS-SPME) coupled with gas chromatography–mass spectrometry (GC–MS), and study the effect of production systems on volatile profiles using metabolomics approach.

Methods

The HS-SPME conditions were optimized for extraction and GC–MS was used to quantify the volatiles from four tomato varieties grown in open-field and high-tunnel systems. Univariate and multivariate analyses were performed to identify the influence of production system on tomato volatiles.

Results and conclusions

The extraction of 2 g tomato samples at 60 °C for 45 min using divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber gave the maximum amounts of volatiles. This optimized method was used to identify and quantify 41 volatiles from four tomato varieties. The levels of β-damascenone were higher in the high-tunnel tomatoes and geranylacetone was higher in open-field tomatoes. These two volatile compounds could be considered as biomarkers for tomatoes grown in high-tunnel and open-field production systems. This study is the first report comparing volatiles in tomatoes grown in high-tunnel and open-field conditions, and our results confirmed that there is a critical need to adopt biomarker-specific production systems to improve the nutritional and organoleptic properties of tomatoes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Tomato (Lycopersicum esculentum) is one of the most widely consumed horticultural crops in the world, and an important source of essential nutrients (Davies et al. 1981). In 2015, the tomato market, including fresh and processed products, accounted for more than 2.6 billion dollars in the United States (USDA-NASS 2016). The most important criteria for consumer preference include flavor, color, texture, and appearance (Xiao et al. 2017). Generally, the flavor of a fresh tomato is influenced by the complex interactions of sugars, acids, and volatile compounds. In red tomatoes, glucose and fructose are the major soluble solids and citric acid is the major organic acid, followed by malic acid (Baldwin et al. 2008). Unfortunately, until now, tomato-breeding programs around the globe have mainly focused on improving the productivity, disease resistance, and firmness of tomatoes at the expense of flavor and texture. One main reason for this is the genetic complexity of flavor and the lack of a simple assay that can predict consumer-preferred values of the factors that contribute to flavor (Klee and Tieman 2013). Consequently, important alleles related to aromatic volatiles have been lost and consumers have been disappointed with the lack of flavor in commercial tomatoes (Tieman et al. 2017).

At present, around 400 volatile compounds have been reported in the tomato fruit (Klee and Tieman 2018; Cortina et al. 2018). However, based on the threshold levels of odor detection, only 15–20 volatile compounds are considered to have a strong effect on the human perception of tomato aroma and flavor (Buttery 1993; Klee and Tieman 2018). During ripening, tomatoes produce 2-isobutylthiazole, 3-methylnitrobutane, geranylacetone, and β-ionone. Tomatoes also produce C6 compounds in the lipid oxidation pathway during maceration (Brauss et al. 1998). Several research groups have used genetics and metabolomics approaches to understand the characteristics of aroma-associated volatile compounds of tomato fruits and improve flavor quality. For instance, Klee and Tieman have focused on elucidating the chemistry of consumer flavor preferences, examining the mechanism of flavor deterioration in tomato fruits, and delineating a molecular roadmap for flavor enhancement (Klee and Tieman 2013, 2018). Similarly, the pathways and distinct gene-metabolite regulation involved in fruit acidity and phenylpropanoid-derived volatiles in tomato (Bauchet et al. 2017). Moreover, Tikunov et al. investigated tomato volatile profiles by using a metabolomic strategies with GC–MS datasets and discriminated metabolite variation among different tomato genotypes (Tikunov et al. 2005, 2010).

Previous studies have demonstrated that the sample preparation and analytical methods for analysis of volatile compounds have substantially influences on tomato volatile profiles. In particular, the headspace solid phase microextraction (HS-SPME) method has been widely tested, using fibers coated with different types of polymeric stationary phases that extract the target analytes from a complex sample matrix by absorption. For example, Rambla et al., investigated the effect of four commonly used sample processing methods on volatile levels by HS-SPME using polydimethylsiloxane/divinylbenzene (PDMS/DVB) fibers and demonstrated that each sample processing method produced characteristic volatile profiles (Rambla et al. 2015). Similarly, other studies focused on the extraction efficiency by comparing various fibers and found that divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber had a higher extraction efficiency than PDMS/DVB fiber (Figueira et al. 2014; Cortina et al. 2017). However, from these studies, the effects of sample processing methods on volatile patterns have not been clearly understood, and this is a prerequisite for accurate quantification of volatiles.

Accumulating evidence suggests that several factors influence tomato volatiles, such as ripening stage, genotype, environmental effects, management practices, and postharvest treatments (Hayase et al. 1984; Mayer et al. 2004), but the effect of the production system on specific chemical markers is not fully understood. Among different production systems, unheated greenhouse systems, such as the high-tunnel, have increasingly been adopted to supply local markets throughout the United States (Carey et al. 2009). The main advantages of high-tunnel cultivation are uniform watering, protecting plants from rainfall, wind, snow, insects, and foliar disease (Healy et al. 2017). The properties of the materials used to construct the high tunnels, such as the color or photo-selective nets, may influence the level of health-promoting compounds, including volatiles, in the fruits (Abushita et al. 2000). However, at present, very little information is available about the exact effect of high-tunnel production systems on tomato volatiles. In addition, there is no comparative study on the effect of high-tunnel versus open-field production systems on tomato flavor constituents.

The main objective of this study was to optimize the extraction and quantification conditions using HS-SPME coupled with GC–MS to determine the volatile composition of tomatoes as well as measure the influence of the production system on the specific molecular marker, using a metabolomics approach.

2 Materials and methods

2.1 Chemicals and reagents

All chemicals and reagents used in this study were analytical grade. All 21 authentic volatile standards (see Table 1) were procured from Sigma-Aldrich (Sigma-Aldrich Chemical Co, St. Louis, MO, USA).

2.2 Production systems

All samples were obtained from the Texas A&M AgriLife Research and Extension farm located in Bushland, Texas, United States (35°11′25.89″N 102°3′50.08″W). Three tomato cultivars were developed at the Vegetable and Fruit Improvement Center of Texas A&M University by Dr. Kevin Crosby (TAM Hot-Ty, TAM exp 1, TAM Exp 2), and a commercial variety collected at the United grocery chain in Texas (USAT 0121) (Supplementary Fig. S1). These four tomato varieties were grown in the high-tunnel system (96 feet long, 30 feet wide and 12 feet tall) and in the open field. The high-tunnel metal frames were covered with a fiberglass-impregnated tarp to allow sunshine in and keep most of the weather out. The plants were fertigated using drip irrigation. The experimental design was a completely randomized design and each treatment contained five fruits with four replications. At sampling time, whole tomato fruits were obtained after removing the calyx and stem scar. Fruits were harvested in October 2016.

2.3 Sample preparation and basic quality measurement

The five fruits from each replication were cut into pieces, mixed together, and quickly blended for 30 s. For volatile analysis, 2 g of each sample was placed into a 20 mL GC–MS vial containing saturated CaCl2 (2 mL) and 2-octanone (10 µL, 0.025% in ethanol, v/v) as an internal standard and stored at − 20 °C until analysis. The total soluble solids content (TSS) of tomato was determined at 25 °C using a hand refractometer (American Optical Corp., South Bridge, MA, USA). For each sample, 5 g of sample was mixed with 45 mL of nanopure water and total acidity (TA) was measured by titrating with 0.1 M NaOH up to pH 8.1 through a DL 22 Food and beverage analyzer (Mettler Toledo, Columbus, OH, USA). All samples were measured in four replicates and the results were averaged.

2.4 Optimization of HS-SPME conditions

Fresh Roma tomatoes (Solanum lycopersicum) were purchased from a local supermarket (HEB, College Station, TX, USA) for optimizing extraction conditions using HS-SPME. Tomato fruits were washed with deionized water and sliced into six pieces. Then, samples were blended for 30 s to facilitate the release of volatile compounds by solid diffusion. Tomato puree samples (2 g) were put into 20 mL glass headspace vials with 2 mL of saturated CaCl2 solution in nanopure water and kept frozen at − 20 °C until analysis.

2.4.1 Selection of fibers

To compare the extraction efficiency of fiber types on the measurement of volatile compounds in tomatoes, five types of coated fibers, polydimethylsiloxane (PDMS), polydimethylsiloxane/divinylbenzene (PDMS/DVB), carboxen/polydimethylsiloxane (CAR/ PDMS), divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS), and polyacrylate (PA) were used to compare the areas of selected peaks of hexenal, 6-methyl-5-heptene-2-one, hexen-1-ol, linalool, geranyl acetone, and β-ionone. Samples (2 g) with 2 mL of saturated CaCl2 solution in the 20 mL headspace vial were used to evaluate the fibers by extracting at 60 °C for 20 min.

2.4.2 Sample weight

To determine optimal sample weight for the quantification of volatiles, we placed different amounts (0.5, 1, 2, 4, and 8 g) of tomato samples into 20-mL GC–MS glass vials and added equivalent amounts of saturated CaCl2. Then extraction was carried out using DVB/CAR/PDMS fibers at 60 °C for 20 min.

2.4.3 Extraction time and temperature

Two grams of sample and DVB/CAR/PDMS fibers were used to test the effect of temperature and time on the extraction. To identify the best conditions, the GC–MS analysis was performed for various extraction times (15, 30, 45, and 60 min) at different temperatures (40, 60, and 80 °C).

2.5 GC–MS analysis

2.5.1 Electron impact (EI) analysis

The GC–MS analysis was performed using a Thermo Finnigan GC–MS (Thermo Fisher Scientific, Inc., San Jose, CA, USA) equipped with an electron ionization source with a Dual-Stage Quadrupole (DSQ II) mass spectrometer (Thermo Scientific, Austin, TX, USA). Separation was achieved with a Zebron ZB-Waxplus column coated with 100% polyethylene glycol of 30 m × 0.25 mm i.d., 0.25 µm film thickness (Phenomenex Inc., Torrance, CA). Helium was used as the carrier gas at a constant flow rate of 1 mL/min in splitless mode. For optimizing HS-SPME extraction condition, the initial oven temperature was maintained at 50 °C for 2 °C/min and then increased to 225 °C at a rate of 4 °C/min and the temperature of the column was maintained for 8 min. To determine the effect of production system on the volatile compounds from four tomato varieties, the optimized method consisted of an initial oven temperature of 40 °C, held for 1 min, then increased to 90 °C at a rate of 10 °C/min, and increased to 175 °C at a rate of 3 °C/min. Finally, it was increased to 230 °C at a rate of 35 °C/min and held for 2 min at the final temperature, with a total run time of 38 min. Electron impact (EI) data from m/z 40 to 450 were acquired at a scanning speed of 11.5 scans per sec and with an ionization voltage of 70 eV. The ion source temperature and mass transfer line temperature were maintained at 280 °C. The data were recorded and processed using Xcalibur software (v. 2.0.7., Thermo-Fisher Scientific, San Jose, CA, USA).

2.5.2 Positive-ion chemical ionization (PCI)

Positive-ion chemical ionization was also performed to confirm the volatile compounds. The chromatographic separation conditions used were the same as those used for EI mode, except the ion source temperature and mass transfer line temperature were maintained at 180 and 250 °C, respectively. Methane was used as the ionization source with a flow rate of 1.3 mL/min (Jayaprakasha et al. 2012). The mass spectral data of the separated compounds were acquired in CI mode.

Samples were vortexed for 1 min and sonicated for 30 min at room temperature, and then loaded onto a TriPlus autosampler (Austin, TX, USA). The volatile compounds were extracted by HS-SPME with a 50/30 µm CAR/PDMS/DVB fiber. The incubation and extraction times were 2 and 45 min, respectively, at 60 °C under continuous agitation. Desorption was carried out in the injector at 225 °C for 2 min and fiber conditioning was carried out for 7 min. Forty-one volatile constituents were identified by comparing retention time, Kovat’s index (KI), and mass spectra with those of reported compounds in tomato fruits and the NIST library. KI values were calculated by the retention time of a mixture of n-alkane standards (C10–C24) analyzed under the same conditions as the samples (Adams 1989). Among these, 21 volatiles were confirmed by matching the retention times and mass spectra patterns to their authentic standards. Furthermore, 19 volatiles were confirmed by positive chemical ionization (PCI) mode. The levels of volatiles were expressed relative to 2-octanone, as per published protocols (Zhang et al. 2015).

2.6 Statistical analysis

The univariate statistical analysis was performed using SPSS (v. 23, BM SPSS Statistics, IBM Corp., Chicago, IL, USA). The multiple mean comparisons (P value < 0.05) were carried out using one-way analysis of variance (ANOVA) with Tukey’s Honest Significant Difference (HSD) test. Significant differences between production systems were assessed with Student’s t test (P value < 0.05). The multivariate analysis was performed by exporting GC–MS data in Excel format to MetaboAnalyst 3.0 (http://www.metaboanalyst.ca/).

3 Results

3.1 Optimization of HS-SPME parameters

The present study examined the effect of different fibers on the extraction efficacy of volatiles of tomato. We choose six volatile compounds (hexanal, 6-methyl-5-heptene-2-one, hexen-1-ol, linalool, geranyl acetone, and β-ionone) for detailed analysis, based on their prevalence. In addition, these compounds represent a broad range of retention times and different volatilities, which helps us to understand the factors affecting extraction efficiencies using headspace analysis. In comparing extraction of these six compounds, the lowest amounts of volatiles were extracted with PDMS fiber, except β-ionone, and significantly higher (P < 0.05) amounts of volatile compounds were extracted with 50/30 µm DVB/CAR/PDMS fiber amongst studied fibers (Fig. 1a). Therefore, the 50/30 µm DVB/CAR/PDMS fiber was selected for the extraction of volatile compounds from tomatoes for further experiments to determine the influence of production system on volatile metabolites.

Optimization of HS-SPME conditions. a The effects of coated fibers on the peak areas of the representative volatile compounds of tomato samples. b The effects of sample weights 0.5–8 g on the peak areas of the representative volatile compounds of tomato. Among studied sample weights, the 2 g sample showed extraction of the maximum amount of volatiles. The effects of extraction temperatures and times on the peak areas of the representative volatile compounds of tomatoes. c The extractions of tomato volatiles at 40 °C for 15, 30, 45, and 60 min. d at 60 °C for 15, 30, 45, and 60 min. e at 80 °C for 10, 15, 20, and 30 min. Among these, extraction of volatile at 60 °C for 45 min was found to be optimized condition (desorption for 2 min at 225 °C)

Subsequently, we tested the effect of different amounts of sample (by weight) on the extraction of volatiles from tomatoes (with the equivalent volume of saturated CaCl2) to increase the partition coefficient of the analytes between the gas phase and the sample. Figure 1b shows the efficiency of extraction as determined by analysis of the six compounds from tomato samples. In these tests, the 2-g samples produced the maximum amounts of volatiles. For instance, linalool, geranyl acetone, and β-ionone were significantly higher in 2 g samples, whereas the lower molecular weight compounds hexanal, 3-methyl-5-heptene-2-one, and hexan-1-ol were significantly higher in 4, 1, and 0.5 g samples, respectively.

Finally, the effect of the extraction temperature and time was also assessed using DVB/CAR/PDMS fiber and 2 g samples. Figure 1c–e depict the efficiency of the extraction time and temperature on the tomato volatile compounds at 40, 60, and 80 °C, respectively. The highest peak area for low molecular weight volatiles was observed for samples extracted at 40 °C compared to 60 and 80 °C. However, the extraction efficacy of the high molecular weight volatiles increased with increasing extraction time and temperature. Based on the extraction efficacy of a maximum number of volatile compounds, 60 °C was chosen for further experiments. Interestingly, we found that comparable amounts of volatiles were extracted at 45 min and 60 min at 60 °C (P < 0.05) (Fig. 1d). Based on statistical significance and a shorter run time, we chose 45 min as the optimal condition for further experiments.

3.2 Chemical composition of the tomato volatiles

The optimized method described above was used to analyze volatiles from high-tunnel and open-field grown tomatoes of four varieties (Supplementary Fig. S2). In total, 41 volatile compounds were identified from all the tomato varieties using authentic standards, mass spectra, and KI values (Table 1). The identification of each metabolite was also performed based on spectral similarity with mass spectral libraries (Wiley registry 8e, Replib, and Mainlib) by considering Metabolomics Standard Initiative (MSI) levels proposed by Chemical Analysis Working Group (Sumner et al. 2007) (Table 1 and Supplementary Table S1, S2). The identified volatiles were classified as alcohols, aldehydes, fatty acids, furans, ketones, and sulfur- and nitrogen-containing compounds. These compounds were quantified and expressed as 2-octanone equivalents (Tables 1, 2). Alcohols, aldehydes, and ketones were the major classes in all studied tomato varieties.

The alcohol 1-hexanol (green, resin and, flowery odor) was the primary contributor to the total alcohol content. In tomato, cis-3-hexen-1-ol contributes green odor and linalool contributes citrus, fruity and sweet odor (Wang et al. 2016). Notably, our results indicated that three varieties (TAM Hot-Ty, TAM EXP 1, and TAM EXP 2) in two different production systems had eugenol (alcohol) contents more than 29 ng/g. Whereas, the commercial variety USAT 012 had the least amount (2 ng/g) of eugenol (Table 1). Among aldehydes, hexanal (green, grassy odor) and trans-2-hexenal (green odor) were found in comparatively higher levels than geranial and trans-2-octenal (green, grassy odor). Similarly, among all identified ketones, geranyl acetone (sweet, floral odor) and 6-methyl-5-hepten-2-one (sweet, fruity odor) were the main components.

Furthermore, we conducted analysis of variance to examine the overall effect of genotype and production system on the tomato volatiles (Table 2). Our results showed that the average levels of alcohols and fatty acids in all four varieties were significantly higher in the tomatoes grown in the high-tunnel system. Conversely, the levels of the total aldehydes, furans, ketones, and nitrogen compounds from all four varieties were higher in the open-field tomatoes. However, the hydrocarbons and sulfur groups were not affected by the production system. The univariate analysis showed that decanal levels were significantly higher in the open-field tomatoes for all four varieties. Moreover, TAM Exp 1 and USAT 0121 grown in the open field showed significantly higher levels of the furan derivative 2-pentyl furan compared with tomatoes grown in the high-tunnel system. The amino acid-derived volatile 1-nitro-3-methylbutane showed the highest levels for all varieties grown in the open field. The levels of neral (lemon odor), geranial (citrus odor), β-ionone (fruity, floral odor), and farnesyl acetone (ethereal floral odor) exhibited higher levels in all open-field tomatoes. In particular, 2-phenylethanone (floral odor) exhibited the highest levels in high-tunnel tomatoes for all varieties studied. Furthermore, tomatoes grown in the high-tunnel system had the highest levels of β-damascenone (fruity odor) while open-field grown tomatoes had the highest levels geranylacetone (sweet, floral odor) of all four varieties.

3.3 Multivariate analysis and potential volatile marker

One-way analysis of variance (ANOVA) was performed to understand the statistical significance of the observed differences in volatile metabolites of tomato varieties grown in high-tunnel and open-field systems. In addition, multivariate analysis of GC–MS data was performed to determine the variance and discriminant features between the production systems in each variety using principal component analysis (PCA) and partial least squares-discriminant analysis (PLS-DA). In PCA analysis, three components explained 80, 73.7, 73.3, and 80.8% of variances in the TAM Hot-Ty, TAM Exp 1, TAM Exp 2, and USAT 0121 varieties, respectively (Fig. 2a–d). The score plots between component 1 and component 2 of four PLS-DA models are shown in Fig. 2e–h. Two clusters of PLS-DA models defined production systems (high-tunnel and open-field) in each variety using four biological replicates. The R2 and Q2 values were calculated by the “Leave one out” cross-validation method to evaluate the goodness of fit and prediction ability of four PLS-DA models (Supplementary Table S3).

Multivariate analysis: a–d principal component analysis (PCA) score plots corresponding to a model aimed at the discrimination between production system (high-tunnel, HT and open-field, OF), influencing tomato volatile profiles. e–h Partial least squares discriminant analysis (PLS-DA) score plots from each tomato variety grown in the different production systems. The colored ellipses indicate 95% confidence intervals for each class. a, e TAM Hot-Ty; b, f TAM Exp1; c, g TAM Exp 2; and d, h USAT 0121

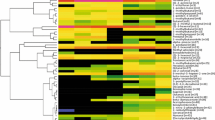

Furthermore, the variable importance on projection (VIP) score plots were derived from the PLS-DA models. The compounds responsible for clustering in four varieties were identified based on their VIP scores exceeding 1.0 (Fig. 3 and Supplementary Table S4) (Eriksson et al. 2005). The VIP score plots showed that the four compounds, 4-methoxy-6-methyl phenol, 1-phenylethanone, β-damascenone, and geranylacetone, were common in the four varieties. In the univariate analysis, β-damascenone and geranylacetone were significantly different between the two production systems (P < 0.05). Therefore, based on the multivariate and univariate analysis, these two compounds could be considered as potential volatile biomarkers to distinguish high-tunnel and open-field grown tomatoes.

The discriminating metabolite features based on variable importance on projection (VIP) scores ≥ 1.0 from partial least squares discriminant analysis (PLS-DA) of each tomato variety. a TAM Hot-Ty, b TAM Exp1, c TAM Exp 2, and d USAT 0121. Red and green on the right indicate relatively high and low concentrations of metabolites from high-tunnel and open-field grown tomatoes

4 Discussion

Flavor has a considerable effect on consumer preferences for tomatoes. As a result, a number of plant breeding and genetic engineering studies have aimed to enhance the flavor of tomato fruits. In addition, researchers have investigated the influence of processing and post-harvest handling on tomato volatiles (Rambla et al. 2015; Farneti et al. 2015). However, consumer-preferred tomato flavors are difficult to attain in many cases, due to the complex interaction between genetics and production system (Cebolla-Cornejo et al. 2011). Furthermore, quantification of flavor-linked metabolites is also difficult due to their complex chemical nature and low concentrations (Tieman et al. 2017). Therefore, there is a critical need to develop efficient quantification methods for flavor-linked volatiles. Moreover, an optimized quantification method to identify flavor-linked volatiles can be used for establishing the relationship between genetics, production system, and specific metabolites. Consequently, this information will provide essential clues for improving tomato flavor.

GC–MS is a valuable technique routinely used for aroma characterization (Fiehn et al. 2000; Peterson et al. 2014; Wang et al. 2016). Previous studies reported that sampling procedures affect the release of volatile metabolites from tomato fruits. Therefore, in these studies, whole and halved fruit, paste, frozen powder, and filtered juice were used to analyze the volatile profiles of tomato fruits (Farneti et al. 2012; Rambla et al. 2015; Xiao et al. 2017). For instance, Tikunov et al. reported the use of blended tomato fruit to identify key glycoconjugated volatiles by fusion approaches using GC–MS and LC–MS (Tikunov et al. 2010). Therefore, selecting proper sample preparation and extraction techniques is crucial for the analysis of tomato volatiles, due to their low concentrations and the complex physicochemical properties of tomato samples. The process of sample preparation and the technique used for analysis have a significant effect on the observed profiles of tomato volatiles (Figueira et al. 2014; Rambla et al. 2015; Cortina et al. 2017). In the present study, blended tomato samples were used for optimization of the method. Previous studies also demonstrated that blended samples were optimal for extraction of volatiles from strawberry and Monstera deliciosa fruits (Vandendriessche et al. 2013; Spínola et al. 2015).

The HS-SPME technique was initially introduced by Arthur and Pawliszyn (1990), and it has been widely used in combination with GC–MS, mainly due to its many advantageous features such as solvent-free sample preparation, robustness, high sensitivity, and reproducibility (Câmara et al. 2007; Mendes et al. 2012). A previous study showed that the HS-SPME method allowed extraction of a wider range of compounds than headspace-trap (HS) and Tenax adsorption-thermal desorption (TD) methods (Rambla et al. 2015). HS-SPME involves many steps, making it important to optimize the extraction conditions to achieve the greatest efficiency. The fibers used, extraction temperature, and time seem to play a major role in the extraction efficiency. Different fibers have different polarities and retention capabilities, depending on their types of coating. A previous report indicated that the majority of volatile metabolites can be extracted at lower extraction temperatures, whereas higher temperatures facilitate the release of higher concentrations of semi-volatile compounds from the matrix (Ma et al. 2013). Additionally, the extraction time influences the distribution of compounds between the sample matrix, the headspace phase, and the fiber coatings; therefore, extraction time will significantly affect the HS-SPME results (Figueira et al. 2014; Cortina et al. 2017). The present study aimed to optimize the extraction method using blended samples. Taken together, the extraction of 2 g blended tomato samples at 60 °C for 45 min with DVB/CAR/PDMS fiber was found to show the maximum amounts of volatiles.

We also aimed to assess the volatile profiles of different tomato varieties grown in two different production systems. The 9 volatiles out of 16 major aroma- and flavor-determining volatiles were found to be common in all studied varieties, such as 1-penten-3-one, hexanal, trans-2-hexenal, trans-2-heptenal, 6-methyl-5-hepten-2-one, cis-3-hexen-1-ol, 2-isobutulthiazole, β-damascenone, and β-ionone (Buttery 1993). Among these compounds, the levels of β-damascenone were significantly influenced by production system and were higher in the high-tunnel tomatoes than in the open-field grown tomatoes. We used four tomato varieties with similar maturity indices (TSS/TA) to determine the effect of the production system on tomato volatile compounds. The TSS and TA contents are important for the tomato flavor, along with aroma-active volatile compounds. However, we did not find significant differences between production systems for TSS and TA (Supplementary Table S5).

In recent years, metabolic markers have been identified that can serve as indicators or predictors of disease outbreak frequency, developmental stage, food sensory evaluation, and crop yield (Fernandez et al. 2016). Usually, in metabolomics studies, chromatographic techniques are coupled with chemometric methods such as PCA and PLS-DA to understand the patterns in the data and to identify molecular markers. PCA is a mathematical algorithm that reduces multidimensional data and provides a graphical interpretation of the data in which similar samples cluster close together and dissimilar samples fall further apart. PLS-DA is a supervised method for classification and discriminant analysis which can be used to describe the relationships among the measured variables (Kasote et al. 2014).

The PCA, PLS-DA, and variable importance of projection (VIP) analyses were performed to identify metabolite markers for tomatoes grown in the two production systems (Figs. 2, 3). The PCA and PLS-DA analysis of tomato volatiles showed that high-tunnel and open-field production systems have a considerable impact on tomato volatile profiles in each of the four varieties (Figs. 2 and 3). Furthermore, using chemometric studies, prominent volatile compounds were ranked from VIP score based on their importance in discriminating production systems. In addition, a one-way ANOVA (analysis of variance) with Tukey’s Honestly Significant Difference (Tukey’s HSD) test was performed on the metabolomics data, to assess which metabolites were mainly involved in each of the various groups. The threshold of significance was set at P < 0.05. In summary, findings of multivariate and univariate analyses confirmed that β-damascenone and geranyl acetone may be considered potential volatile markers for high-tunnel and open-field grown tomatoes. β-Damascenone (sweet, apple odor) has a considerable role in the flavor of tomato due to its extremely low odor threshold, 0.002 ppb compared to 60 ppb for geranylacetone (Buttery 1993; Pineau et al. 2007). Based on our observation, the significantly increased levels of β-damascenone under the high-tunnel system may have an important role in the flavor of the fresh tomato. In addition, several potent health-promoting properties have been reported for β-damascenone, including UV protective potential (Uddin et al. 2012). Similarly, geranylacetone is a well-known antimicrobial agent and has a potential role in the treatment of Alzheimer’s disease (Jirovetz et al. 2007; Marumoto et al. 2017). We believe that the present study will help to select the proper production system to produce aroma-rich tomatoes or to select tomato varieties well-suited for a particular production system.

5 Conclusions

In this study, the volatile metabolite profiles of tomato samples were evaluated using HS-SPME followed by GC–MS. The data revealed that the optimal SPME parameters were found to be 2 g of tomato sample, 50/30 µm DVB/CAR/PDMS-coated fiber, and extraction at 60 °C for 45 min. Furthermore, this optimized HS-SPME/GC–MS method was used to characterize the volatile compounds from four varieties grown under the high-tunnel and open-field production systems as well as to identify the production system-specific volatile markers. In this study, β-damascenone and geranylacetone were identified as potential volatile markers to distinguish high-tunnel and open-field grown tomatoes. However, the production system specific markers may also be influenced by genotype, growing conditions, and harvest periods. Therefore, further studies focusing on more varieties grown in different locations are warranted for the discovery of other possible biomarkers.

Abbreviations

- SPME:

-

Solid phase microextraction

- GC:

-

Gas chromatography

- MS:

-

Mass spectrum

- PLS-DA:

-

Partial least squares-discriminant analysis

- VIP:

-

Variable importance on projection

- HT:

-

High-tunnel

- OF:

-

Open-field

References

Abushita, A. A., Daood, H. G., & Biacs, P. A. (2000). Change in carotenoids and antioxidant vitamins in tomato as a function of varietal and technological factors. Journal of Agricultural and Food Chemistry, 48(6), 2075–2081.

Adams, R. (1989). Identification of essential oils by ion trap mass spectroscopy. San Diego: Academic Press.

Arthur, C. L., & Pawliszyn, J. (1990). Solid phase microextraction with thermal desorption using fused silica optical fibers. Analytical Chemistry, 62, 2145–2148.

Baldwin, E. A., Goodner, K., & Plotto, A. (2008). Interaction of volatiles, sugars, and acids on perception of tomato aroma and flavor descriptors. Journal of Food Science, 73(6), S294–S307. https://doi.org/10.1111/j.1750-3841.2008.00825.x.

Bauchet, G., Grenier, S., Samson, N., Segura, V., Kende, A., Beekwilder, J., et al. (2017). Identification of major loci and genomic regions controlling acid and volatile content in tomato fruit: Implications for flavor improvement. New Phytologist, 215(2), 624–641.

Brauss, M. S., Linforth, R. S. T., & Taylor, A. J. (1998). Effect of variety, time of eating, and fruit-to-fruit variation on volatile release during eating of tomato fruits (Lycopersicon esculentum). Journal of Agricultural and Food Chemistry, 46(6), 2287–2292. https://doi.org/10.1021/jf971019x.

Buttery, R. (1993). Quantitative and sensory aspects of flavor of tomato and other vegetables and fruits. In Flavor science: Sensible principles and techniques (pp. 259–286). Washington, DC: American Chemical Society.

Câmara, J. S., Alves, M. A., & Marques, J. C. (2007). Classification of Boal, Malvazia, Sercial and Verdelho wines based on terpenoid patterns. Food Chemistry, 101(2), 475–484.

Carey, E. E., Jett, L., Lamont, W. J., Nennich, T. T., Orzolek, M. D., & Williams, K. A. (2009). Horticultural crop production in high tunnels in the United States: A snapshot. HortTechnology, 19(1), 37–43.

Cebolla-Cornejo, J., Roselló, S., Valcárcel, M., Serrano, E., Beltrán, J., & Nuez, F. (2011). Evaluation of genotype and environment effects on taste and aroma flavor components of Spanish fresh tomato varieties. Journal of Agricultural and Food Chemistry, 59(6), 2440–2450. https://doi.org/10.1021/jf1045427.

Cortina, P. R., Asis, R., Peralta, I. E., Asprelli, P. D., & Santiago, A. N. (2017). Determination of volatile organic compounds in Andean tomato landraces by headspace solid phase microextraction-gas chromatography-mass spectrometry. Journal of the Brazilian Chemical Society, 28(1), 30–41.

Cortina, P. R., Santiago, A. N., Sance, M. M., Peralta, I. E., Carrari, F., & Asis, R. (2018). Neuronal network analyses reveal novel associations between volatile organic compounds and sensory properties of tomato fruits. Metabolomics, 14(5), 57. https://doi.org/10.1007/s11306-018-1355-7.

Davies, J. N., Hobson, G. E., & McGlasson, W. (1981). The constituents of tomato fruit—the influence of environment, nutrition, and genotype. Critical Reviews in Food Science & Nutrition, 15(3), 205–280.

Eriksson, L., Johansson, E., Antti, H., & Holmes, E. (2005). Multi-and megavariate data analysis. In Metabonomics in toxicity assessment (pp. 263–336). Boca Raton: CRC Press.

Farneti, B., Alarcón, A. A., Papasotiriou, F. G., Samudrala, D., Cristescu, S. M., Costa, G., et al. (2015). Chilling-induced changes in aroma volatile profiles in tomato. Food and Bioprocess Technology, 8(7), 1442–1454. https://doi.org/10.1007/s11947-015-1504-1.

Farneti, B., Cristescu, S. M., Costa, G., Harren, F. J., & Woltering, E. J. (2012). Rapid tomato volatile profiling by using proton-transfer reaction mass spectrometry (PTR-MS). Journal of Food Science, 77(5).

Fernandez, O., Urrutia, M., Bernillon, S., Giauffret, C., Tardieu, F., Le Gouis, J., et al. (2016). Fortune telling: Metabolic markers of plant performance. Metabolomics, 12(10), 158. https://doi.org/10.1007/s11306-016-1099-1.

Fiehn, O., Kopka, J., Trethewey, R. N., & Willmitzer, L. (2000). Identification of uncommon plant metabolites based on calculation of elemental compositions using gas chromatography and quadrupole mass spectrometry. Analytical Chemistry, 72(15), 3573–3580. https://doi.org/10.1021/ac991142i.

Figueira, J., Câmara, H., Pereira, J., & Câmara, J. S. (2014). Evaluation of volatile metabolites as markers in Lycopersicon esculentum L. cultivars discrimination by multivariate analysis of headspace solid phase microextraction and mass spectrometry data. Food Chemistry, 145, 653–663.

Hayase, F., Chung, T.-Y., & Kato, H. (1984). Changes of volatile components of tomato fruits during ripening. Food Chemistry, 14(2), 113–124.

Healy, G., Emerson, B., & Dawson, J. (2017). Tomato variety trials for productivity and quality in organic hoop house versus open field management. Renewable Agriculture and Food Systems, 32, 562–572.

Jayaprakasha, G., Murthy, K., & Patil, B. (2012). Inhibition of pancreatic cancer cells by furocoumarins from Poncirus trifoliata. Planta Medica, 78(11), PI175.

Jirovetz, L., Buchbauer, G., Schmidt, E., Stoyanova, A. S., Denkova, Z., Nikolova, R., et al. (2007). Purity, antimicrobial activities and olfactoric evaluations of geraniol/nerol and various of their derivatives. Journal of Essential Oil Research, 19(3), 288–291. https://doi.org/10.1080/10412905.2007.9699283.

Kasote, D., Suleman, T., Chen, W., Sandasi, M., Viljoen, A., & van Vuuren, S. (2014). Chemical profiling and chemometric analysis of South African propolis. Biochemical Systematics and Ecology, 55, 156–163.

Klee, H. J., & Tieman, D. M. (2013). Genetic challenges of flavor improvement in tomato. Trends in Genetics, 29(4), 257–262. https://doi.org/10.1016/j.tig.2012.12.003.

Klee, H. J., & Tieman, D. M. (2018). The genetics of fruit flavour preferences. Nature Reviews Genetics, 1.

Ma, Q. L., Hamid, N., Bekhit, A. E. D., Robertson, J., & Law, T. F. (2013). Optimization of headspace solid phase microextraction (HS-SPME) for gas chromatography mass spectrometry (GC–MS) analysis of aroma compounds in cooked beef using response surface methodology. Microchemical Journal, 111, 16–24.

Marumoto, S., Okuno, Y., & Miyazawa, M. (2017). Inhibition of β-secretase activity by monoterpenes, sesquiterpenes, and C13 norisoprenoids. Journal of Oleo Science, 66, 851–855.

Mayer, F., Takeoka, G., Buttery, R., Whitehand, L., Bezman, Y., Naim, M., et al. (2004). Differences in the aroma of selected fresh tomato cultivars. In Handbook of flavor characterization. Sensory analysis, chemistry, and physiology (pp. 189–205). New York: Marcel Dekker.

Mendes, B., Gonçalves, J., & Câmara, J. S. (2012). Effectiveness of high-throughput miniaturized sorbent- and solid phase microextraction techniques combined with gas chromatography–mass spectrometry analysis for a rapid screening of volatile and semi-volatile composition of wines—A comparative study. Talanta, 88, 79–94.

Peterson, A. C., Hauschild, J.-P., Quarmby, S. T., Krumwiede, D., Lange, O., Lemke, R. A. S., et al. (2014). Development of a GC/Quadrupole-Orbitrap mass spectrometer, part I: Design and characterization. Analytical Chemistry, 86(20), 10036–10043. https://doi.org/10.1021/ac5014767.

Pineau, B., Barbe, J.-C., Van Leeuwen, C., & Dubourdieu, D. (2007). Which impact for β-damascenone on red wines aroma? Journal of Agricultural and Food Chemistry, 55(10), 4103–4108.

Rambla, J. L., Alfaro, C., Medina, A., Zarzo, M., Primo, J., & Granell, A. (2015). Tomato fruit volatile profiles are highly dependent on sample processing and capturing methods. Metabolomics, 11(6), 1708–1720.

Spínola, V., Perestrelo, R., Câmara, J. S., & Castilho, P. C. (2015). Establishment of Monstera deliciosa fruit volatile metabolomic profile at different ripening stages using solid-phase microextraction combined with gas chromatography–mass spectrometry. Food Research International, 67, 409–417.

Sumner, L. W., Amberg, A., Barrett, D., Beale, M. H., Beger, R., Daykin, C. A., et al. (2007). Proposed minimum reporting standards for chemical analysis. Metabolomics, 3(3), 211–221.

Tieman, D., Zhu, G., Resende, M. F. R., Lin, T., Nguyen, C., Bies, D., et al. (2017). A chemical genetic roadmap to improved tomato flavor. Science, 355(6323), 391–394.

Tikunov, Y., Lommen, A., De Vos, C. R., Verhoeven, H. A., Bino, R. J., Hall, R. D., et al. (2005). A novel approach for nontargeted data analysis for metabolomics. Large-scale profiling of tomato fruit volatiles. Plant Physiology, 139(3), 1125–1137.

Tikunov, Y. M., de Vos, R. C., Paramás, A. M. G., Hall, R. D., & Bovy, A. G. (2010). A role for differential glycoconjugation in the emission of phenylpropanoid volatiles from tomato fruit discovered using a metabolic data fusion approach. Plant Physiology, 152(1), 55–70.

Uddin, A. N., Labuda, I., & Burns, F. J. (2012). A novel mechanism of filaggrin induction and sunburn prevention by β-damascenone in Skh-1 mice. Toxicology and Applied Pharmacology, 265(3), 335–341. https://doi.org/10.1016/j.taap.2012.08.035.

USDA-NASS (2016). Vegetables 2015 summary (February 2016).

Vandendriessche, T., Nicolai, B. M., & Hertog, M. L. A. T. M. (2013). Optimization of HS SPME fast GC-MS for high-throughput analysis of strawberry aroma. Food Analytical Methods, 6(2), 512–520. https://doi.org/10.1007/s12161-012-9471-x.

Wang, L. B., Baldwin, E. A., & Bai, J. H. (2016). Recent advance in aromatic volatile research in tomato fruit: The metabolisms and regulations. Food and Bioprocess Technology, 9(2), 203–216. https://doi.org/10.1007/s11947-015-1638-1.

Xiao, Z., Wu, Q., Niu, Y., Liu, Q., Chen, F., Ma, N., et al. (2017). Optimization of headspace solid-phase micro-extraction and its application in analysis of volatile compounds in cherry tomato by gas chromatography. Food Analytical Methods, 10, 596-609.

Zhang, J., Zhao, J., Xu, Y., Liang, J., Chang, P., Yan, F., et al. (2015). Genome-wide association mapping for tomato volatiles positively contributing to tomato flavor. Frontiers in Plant Science, 6, 1042.

Acknowledgements

This study was supported by Texas State Funding 2015-121277 VFIC-TX state appropriation.

Author information

Authors and Affiliations

Contributions

JHJL, CMR, KMC, GKJ, and BSP designed the experiments. CMR performed field work. JHJL and GKJ carried out all analytical work. JHJL conduced metabolomics studies, interpreted results, and drafted manuscript. All the authors read, and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research involving human and animal participants

This article does not contain any studies with human or animal subjects.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lee, J.H.J., Jayaprakasha, G.K., Rush, C.M. et al. Production system influences volatile biomarkers in tomato. Metabolomics 14, 99 (2018). https://doi.org/10.1007/s11306-018-1385-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11306-018-1385-1