Abstract

The aim of the present study was isolation and molecular identification of lactic acid bacteria from King grass and their application to improve the fermentation quality of sweet Sorghum. Seventy-six strains of LAB were isolated; five strains were selected for Physiological and morphological tests and 16S rRNA sequencing. All five strains grew at different pH 3.5–8.0, different temperature 35, 40, 45, 50 °C and different NaCl concentrations 3, 6.5, 9.5%. Strains HDASK were identified Lactobacillus plantarum and SK3907, SK2A32, SK3A42 and ASKDD Pediococcus acidilactici. Three isolated strains and one commercial strain were added to sweet sorghum. Silage was prepared of four treatments and one control with three replicates as control (SKC, adding 2 ml/kg sterilizing water), L. plantarum commercial bacteria (SKP), L. plantarum (HDASK) isolated from King grass (SKA), P. acidilactici (SK3907) isolated from King grass (SKB) and P. acidilactici (ASKDD) isolated from King grass (SKD). All silage were prepared using polyethylene terephthalate bottles, and incubated at room temperature for different ensiling days. The level of pH, acetic acid, NH3-N, water soluble carbohydrate and butyric acid was significantly (P < 0.05) decreased. Lactic acid, ethanol and propionic acid (PA) was significantly (P < 0.05) increased in treatments compared to control. The dry matter, propionic acid neutral detergent fiber, acid detergent fiber did not significantly (P < 0.05) differ among the treatments but the values were increased and decreased. The number of yeast, mold and LAB were significantly (P < 0.05). It is suggested that the supplementation of LAB could enhanced the fermentation quality of sweet Sorghum silage.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sorghum (Sorghum bicolor) is an important silage crop for beef and dairy producers in China. Sorghum species are native to tropical and subtropical regions of china cultivated in warmer climates. Sorghum is well adapted to the environments with limited rainfall, high temperatures, and low soil fertility, and producers usually harvest greater quantities of forage dry matter (Cecil et al. 2012) than from other crops, such as corn or grain sorghum (Amer et al. 2012). The general constraints to forage sorghum silage production and utilization is due to lower nutritive value than corn or grain sorghum silage, an accumulation of a high level of nitrate under certain environmental stress conditions and prussic acid poisoning in early primary growth or regrowth stages. Sorghum usually produces as much silage per hectares corn. Though sorghum silage contains less grain and high fiber than corn silage. However, the protein content of sorghum silage is similar to or slightly higher than that of corn but it is less digestible (Mutegi et al. 2010).

Ensiling is a traditional way of preservation of animal feed and green plant material. Many researcher use different additives at ensiling process, for example, molasses, lactic acid bacteria, enzyme and acids to stimulate the pH drop during ensiling and improve the fermentation quality of the silage (Shah et al. 2017a; Lima et al. 2010; Reich and Kung 2010; Wrobel et al. 2008). Consequently, in previous studies, more work has focused on how to get better fermentation quality. Isolating LAB is ideally competent to dominate lactic fermentation from epiphytic LAB of forage or silage (Liu et al. 2012). Although a number of studies reported that LAB inoculants as silage additives have positive effects on silage quality, relatively few have reported the effect of LAB isolated from forage crops on silage fermentation. The present study also uses lactic acid bacteria (LAB) as additive, isolated from king grass silage. Although LAB inoculants enhances silage fermentation quality and preservation, mostly those inoculated with homofermentative lactic acid bacteria can be more prone to spoilage than control silage (Nkosi et al. 2012; Shah et al. 2017b).Many researchers used homofermentative LAB strains in different grasses to improve the fermentation quality of the silage. Homofermenters just generate lactic acid and include some species of Lactobacillus like Lactobacillus plantarum, Pediococcus species, and Enterococcus species. LAB can improve the level of acidification and fermentation quality as well as these lactic acid bacteria can decrease the level of pH, dry matter and protein degradation of grass silages (Wrobel et al. 2008; Nkosi et al. 2012; Reyes-Gutiérrez et al. 2015; Shah et al. 2017a, b). Therefore, the present study has mainly focused on the effect of lactic acid bacteria additives associated with silage fermentation and chemical composition on sweet sorghum silage.

Materials and methods

LAB strains

Three strains (SKA, SKB and SKD) were isolated from king grass silage, stored at − 80 °C and used after culturing in deMan, Rogosa and Sharp (MRS) agar medium (Shanghai Bio-way Technology Co., Ltd.) at 37 °C for 24 h. Lactobacillus plantarum (MTD/1CB, Ecosyl Products Inc. USA commercial bacteria).

Physiological and morphological tests

The following methods were used for the identification of LAB. Gram stain, morphology, catalase and gas production from glucose were determined by method of (Kozaki et al. 1992). Growth of LAB at different pH (3.0, 3.5, 4.0, 4.5, 5.0, 6.5, 7.5, 8.0) values were observed in de Man, Rogosa and Sharp (MRS) broth (Shanghai Bio-way Technology Co., Ltd.) at 37 °C for 48 h. Growth at different salts (3.5, 6.5, 9.5%) concentrations was analyzed in MRS broth according to the methods of (Cai et al. 1999). Growth at different temperatures was observed in MRS broth after incubation at 35, 40, 45 and 50 °C (Incubation in anaerobic incubator (YQX-II, CIMO Medical Instrument Manufacturing Co., Ltd., Shanghai, China) for 3 days. Carbohydrate fermentation was examined by API 50 CHL® assay (bioMérieux, Etoile, France). Purified strains were cultivated on MRS plates in anaerobic vessels. Grown colonies were cultivated in 5 ml MRS medium at 37 °C over night. The turbidity of the suspension was determined by the McFarland method. Cell suspension was applied into API 50 CH strip wells, which were coated with liquid paraffin. The strips were incubated at 37 °C. The results were noted after 24 h and verified after 48 h. Fermentation of carbohydrates in the medium was indicated by yellow color, except for esculine (dark brown). Color reactions were scored by a chart provided by the manufacturer.

Extraction of LAB genomic DNA protocol

This LAB was cultivated in 5 ml MRS broth at 37 °C for 24 h. After 24 h, the LAB sample was put in centrifuge tube and was centrifuged at 9000 rpm for 7 min, at 4 °C. After centrifugation, the fluid was removed and bacteria were retained in a tube. Then, 1 ml NaCl (0.85%) was added in all sample and again centrifuged at 13,000 rpm for 6 min at 4 °C. fluid was removed, 600 μl SDS solution was added in bacteria and mixed well in the tube and solution was transferred to a ceramic containing tube. Kept the ceramic containing tube in mini bead beater machine (MBBM) (cell break down machine) for 2 min for converting the sample to ice form and then putting in hot water at 55 °C for 2 h. After 2 h, the samples were centrifuge at 13,000 rpm for 6 min. After centrifugation, a mixture of Trisphenol (Phenol), Trischloromethane (chloroform) and Isopentyl alcohol (isoamyl alcohol) at ratio of 25:24:1{Chemical concentrations Phenol 94.11 (pH 50 g/L, 25 °C; Chloroform 94.11 (pH 4.7–5.5); Iso-pentyl alcohol 88.15 9 http://www.jsyonghua.com)} according to the devised protocol of Doi et al. (2013) was added to stabilize the pH value at 7.8 (3rd layer of this solution), shaken the tube and centrifuged at 13,000 rpm for 6 min at 4 °C. After the centrifugation, took the supernatant into new tube and added 500 μl of Isoplopenol solution to the sample, well shaken the sample and stored at − 20 °C for overnight. Centrifuged the sample again at 13,000 rpm for 10 min at 4 °C. After centrifugation, remove the fluid and retained DNA in the tubes, followed by the addition of 500 µl ethanol (70%) in the tubes. After adding ethanol, again centrifuged the sample at 13,000 rpm for 10 min at 4 °C. After centrifugation, removed the fluid and retained the DNA inside the tube and then kept the tube in sterilized cabin for air drying the DNA tube for about 1 h. After drying DNA tube, added 30 μl of TE buffer to this DNA tube and then mixed well and kept into warm water at 70 °C for 5 min.

Analysis of lactic acid bacteria identification by 16S rRNA sequencing

The 16S rRNA gene sequence was amplified by a PCR thermal cycler (Takara PCR System TP600, Japan). 1 μl of diluted DNA was used as a template for PCR reaction. The PCR reaction mixture (25 μl) was conducted with a sequence kit (Takara Biotech Co, Ltd, Dalian, China) with the prokaryotic 16S rRNA universal primers 27F (5′- AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-GGTTACCTTGTTACGACTT-3′) (Cai et al. 1999). The PCR protocol was followed for 5 min at 94 °C, 30 cycles of denaturizing at 94 °C for 30 s, annealing at 52 °C for 30 s and extended at 72 °C for 1 min and then finally extended for 10 min at 72 °C. A sample of 1 μl of this reaction was analyzed by 1.5% agarose gel electrophoresis in 1 × TAE buffer. The gel was stained with ethidium bromide and the bands were visualized under UV illumination see Fig. 1. PCR products were purified by using a commercial DNA purification kit (Axygen San Francisco, USA). Finally, the products were analyzed for 16S rRNA by 3730xl DNA Analyzer (ABI Applied Biosystems, San Francisco, USA).

The phylogenetic tree of partial 16S rRNA gene sequences of HDASK, SK3907, SK2A32, SK3A42 and ASKDD were compared using Gen Bank and BLAST in NCBI and collected the homologues sequences. Then sequence information of representative organisms were introduced into the Clustal Omega software program (Hitachi Software Engineering Co., Tokyo, Japan) for assembly and alignment (Thompson et al. 1994) Nucleotide substitution rates were calculated (Kimura and Ohta 1972) and phylogenetic trees were used for the neighbour-joining method (Saitou and Nei 1987). The topologies of tree were evaluated by bootstrap analysis of the sequence data with molecular evolutionary genetics analysis MEGA 6 software, based on 1000 random resembling (Eitan et al. 2006). The nucleotides sequences for the 16S rRNA gene were deposited to the Gene Bank under accession numbers: KY078792 (HDASK), KY078793 (SK3907), KY433797 (SK2A32), KY078795 (SK3A42) andKY078794 (ASKDD).

Preparation of silage

Fresh Sorghum (Sorghum bicolor) during the maturity stage of growth was collected from the experimental grassland of Nanjing Agricultural University, China. The grass was chopped in length (1–2 cm) with a chopper and ensiled in anaerobic polyethylene terephthalate bottles of 1 L capacity. Each Polyethylene terephthalate bottle contained 700 g of fresh Sorghum (Sorghum bicolor) and subjected to the following five treatments before ensiling which are LAB inoculation (control SKC, SKP, SKA, SKB and SKD). The number of bacteria of each strain was adjusted at 1 × 106 cfu/g. After treating and integration, each treatment was packed into a polyethylene terephthalate bottles, followed by sealing with a plastic tape and stored at room temperature. Each triplicate silos for each treatment was opened on day 1, 3, 5, 7, 14 and 30.

Chemical and microbial analyses

35 g silage sample was taken from each group and 70 ml distilled water was mixed and put in the refrigerator at 4 °C for 24 h. After 24 h, the silage material was filtered by two layers of cheesecloth. These silage extracts were used for determination of pH, lactic acid (LA), volatile fatty acid (VFAs). The 80 g fresh silage sample was taken from each group and dried in the oven at temperature 65 °C for 3 days, after drying this silage sample was grounded, this grounded powder was used for determination of water soluble carbohydrates (WSC), neutral detergent fiber (NDF), crude protein (CP) and acid detergent fiber (ADF). The DM and CP determined by the International methods (2005), NDF, ADF (Van Soest et al. 1991) and the WSC was analyzed by colorimetric after reaction with anthrone reagent (Arthur Thomas 1977). The silage extract pH was determined by using a glass electrode pH meter (pH221, Hanna Ltd., Italian). NH3–N concentration was determined by the method of (Novozamsky et al. 1974).The content of VFAs in silage was determined by (Shao et al. 2005). 10 g fresh and silage sample was taken from each group and added 90 ml sterilized saline solution (0.85%) and was well shaken in a medium-speed blender for 2 h. After 2 h, the solution was used for microbial analysis. Buffering capacity of fresh material was calculated by using protocol of (Playne and McDonald 1966). LAB was counted on MRS agar medium (Manufacturing Difco Laboratories, Co., Ltd, Shanghai, China), after anaerobic incubation at 37 °C for 3 days. Yeasts were counted on potato dextrose agar (PDA) medium (Shanghai Bio-way Technology Co., Ltd.) and aerobic bacteria were counted on nutrient agar (AN) medium (Qingdao Hope Bio-technology Co., Ltd.), agar plates were kept in incubator at 37 °C for 24–48 h. All microbial data were transformed to log10 and presented on a wet weight basis.

Statistical analysis

The 16S rRNA sequences of the LAB isolates were analyzed by MEGA 6.0 for Windows (The Biodesign Institute, Tempe, AZ). The experiment was conducted in a 5 × 5 factorial design (5 inoculants × 5 fermentation periods) using a randomized design with 3 three replicates. The data of silage fermentation were analyzed using the GLM procedure of SPSS (version 17.0). Means of the significantly affected traits were separated by the Duncan multiple range test (Duncan 1955). A P value less than 0.05 was considered statistically significant.

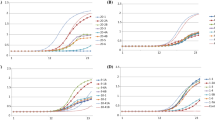

Results

The physiological and morphological characteristics of HDASK, SK3907, SK2A32, SK3A42 and ASKDD are shown in Table 1 and all strains fermented glucose, sucrose, d, fructose and other sugars, (Table 2). The shape of the following strains HDASK and SK2A32 are rod shape and SK3907, SK3A42 and ASKDD are Cocci shape. All strains were positive, homofermentative and catalase negative bacteria. These all strains grew well in different pH levels (3.5, 4.0, 4.5, 5.0, 6.0, 7.5 and 8.0) but grew weakly in 3.0 pH level. These strains grew well in following temperature 35, 40, 45, and 50 °C but SK3907 and ASKDD grew weakly in 50 °C. All strains were able to tolerate salt (MRS with 3, 6.5 and 9.5% NaCl concentration). These all strains were placed on the phylogenetic tree most closely related with L. plantarum and P. acidilactici (Fig. 1). Strain HDASK had rRNA sequence similarities of 99% and bootstrap cluster was 98%. Others strains SK3907, SH2A32, SK3A42 and ASKDD 99% in rRNA sequence similarities 99% and bootstrap cluster were 92, 86 and 89% to each other, as shown in (Fig. 2). Tables 3, 4 and 5 shows that the chemical composition of sweet sorghum before and after ensiling. The DM was not significantly affected among the treatment and control groups at 1, 3, 5, 7, 14 and 30 days of ensiling period. But the value is numerically increased and decreased. Ethanol is not affected in ensiling for 1, 3, 5, and 7 days. However, on day 14, ethanol was significantly (P < 0.05) increased in all treatments compared to the control as shown in Fig. 3. NH3–N concentrations were not effected on day 1, 3, 5 and 7 day. However, on day 14, NH3–N/TN was significantly decreased in SKP, SKA and SKD as compared to control and SKB as shown in Fig. 3a.The WSC levels were significantly reduced during the 1, 3, 5 and 7 day as compared to the control group. However, on day 14, WSC levels reduced significantly (Fig. 3a). The pH and AA in all silage reduced slowly throughout the experimental period. Although silage inoculated with LAB had lower pH as compared to the control from 1 to 14 day, the significant difference occurred in all LAB groups. Lactic acid and propionic acid were increased in 1, 3, 5, and 7 days but was significantly increased in 14 day (Fig. 3c). Butyric acid was not significant but the value was increased and decreased (Fig. 3b; Table 3). Microbial composition of sweet sorghum with lactic acid bacteria strains during ensiling is presented in Table 6. The microbial counting of the sweet sorghum silage during different ensiling 1, 3,5 and 7 day are not significant but in 14 day the microbial counting of the sweet sorghum silage was significantly (P < 0.05) increased in all treatments as compared to control (Fig. 3d). Aerobic bacteria and yeast were significantly decreased in all inoculated groups as compared to the control. Chemical composition and fermentation characteristics of sweet sorghum on 30 day are shown in Table 7. The DM, PA, NDF, ADF, Yeast and aerobic bacteria was not significant but the values were increased and decreased between treatment and control. The pH, AA, NH3–N/TN, WSC and BA was significantly decreased and LA and LAB was significantly increased in all treatments as compared to the control.

Chemical composition of sweet Sorghum silage during 30 day of ensiling a pH, WSC Water soluble carbohydrate g/kg, NH3-N/TN Ammonia/total nitrogen g/kg, b PA Propionic acid g/kg, BA Butyric acid g/kg, Ethanol g/kg, c LA Lactic acid, AA Acetic acid g/kg. d LAB lactic acid bacteria, AB Aerobic bacteria, Yeast log10 cfu/g

Discussion

The Lactobacillus and Pediococcus species are often found in living environment with material, dairy products and foods produced by LAB. Several studies have reported that Lactobacillus and Pediococcus are dominant microbial population on forage crops and silage (Cai et al. 1998, 1999). Some isolates from forage and silage have been identified as a L. plantarum and P. acidilactici. However, available phenotypic procedures to assign isolates to know species are difficult because it is not easy to differentiate clearly between species of Pediococcus (Ávila et al. 2014; Ni et al. 2015). In the present study, the isolates were gram-positive and catalase-negative tetrad Cocci that did not produce gas from glucose. These properties show that these strains belong to the genus L. and Pediococcus (Table 1). The genetic interrelationships of members of the LAB have been studied briefly in 16S rRNA sequence. The current results have evidently indicated that the genera Pediococcus and Lactobacillus show a high level of sequence similarity to each other and form a phylogenetically rational group that is separate from other bacteria. In the present study, the representative strains HDASK was placed in the genus Lactobacillus and SK3907, SK2A32, SK3A421, where, ASKDD were placed in the genus Pediococcus in the phylogenetic tree, confirming that these strains belong to the genus Pediococcus and Lactobacillus that they are the species most directly connected to P. acidilactici and L. plantarum. The LAB species identified in this study were common inhabitants of a variety of forage crops and silages. This finding was consistent with our previous investigations and the results of other studies, which showed that the natural fermentation processes in forage crop and grass silages are dominated by Leuconostoc, Lactococcus, Enterococcus, Pediococcus and Lactobacillus species Rossi and Dellaglio (2007); (Pholsen et al. 2016). In this study, all of these strains had carbohydrate fermentation, the different characteristics and different species of LAB can modify silage fermentation quality (Pang et al. 2012; Shah et al. 2017a, b) and population of ELAB were not always sufficiently enough for better fermentation (Pang et al. 2012).

The high sugar content in sweet Sorghum makes it perfect forage for silage production. High residual sugar content in silage can serve as a nutritional supplement for ruminants. Bacterial inoculants are additional to forage at ensiling to stimulate lactic acid (LA) fermentation by accelerating the decrease in pH, and improving the fermentation quality and silage preservation (Nkosi et al. 2012).The low pH is a key factor to inhibit Clostridium spp. and increased the fermentation quality of sweet sorghum silage. (Tian et al. 2014) reported that for best fermentation quality silage the pH value must be less than 4.2. In the present study, the pH value of silage treated with SKP, SKA, SKB and SKD for 30 days declined the pH value 3.72, 3.60, 3.75 and 3.40, respectively. NH3–N is an important issue to reflect the level of proteolysis during silage fermentation. NH3–N is regularly produced by Clostridium spp. during the decomposing protein in the raw materials (Tian et al. 2014). Wang et al. (2014) reported that Silages inoculated with LP have lower contents of NH3–N compared with the silages inoculate with LB + LP on 2, 4, 8 and 90 days of fermentation. LP alone enhanced the fermentation characteristics better in comparison with LB + LP. In the present study, the NH3–N also significantly decreased on 7, 14 and 30 days in all treatment groups as compared to control group.

The homofermentative LAB are utilized in most commercial inoculants. They make large amounts of LA and decline pH quickly in the beginning of fermentation. However, these microbes have improved aerobic deterioration of silages (Wang et al. 2014; Shah et al. 2017a) probably by two phenomena. First, insufficient VFA are created to reduce fungi and residual WSC and LA can be substrates for fungi (Weinberg et al. 1993) second, LA by itself, is not an effective antimycotic agent (Ni et al. 2015).The probably reason for this, increase LAB and sugar content due to effect of enzymes produced more LA and reduced pH level (Kung et al. 2003). A youthful silage requires that lactobacilli contact point of at smallest amount 105 cfu/g FM at ensiling (Zahiroddini et al. 2004). On the other hand, the number of epiphytic LAB on fresh crops is generally very low, and this incident was also obvious in the present study. Additionally, ensiling is a fermentation procedure connecting with microbiological and enzymatic activity (Wang et al. 2017).Water-soluble carbohydrates are regarded as important substrates for the development of LAB for suitable fermentation. In the present study also WSC decreased significantly and increased LAB. Shah et al. (2017a, b) reported that the WSC concentration levels in king grass silage were also decreased in all LAB inculcated groups. the function of epiphytic bacteria, other factors involved in assessing fermentation quality include the chemical composition of the silage material (Cai et al. 1999), mainly the WSC content. The WSC content, together with the activity of naturally occurring LAB, determines the rate of decline in pH during the early stages of ensiling, which is important for stable silage production (Davies et al. 1998).

various studies have reported that the application of LAB inoculants, like P. acidilactici and L. plantarum can beneficially enhance the LA concentration and decreased AA (Pieper et al. 2011; Contreras-Govea et al. 2013). (Filya et al. 2007) reported that 10 out of 12 homofermentative commercial inoculants resulted in a higher LA and lower AA. In the present study also LA higher, lower AA, NH3–N/TN and BA. A source of WSC, improved the LAB growth then this LAB enhances the fermentation quality of the silage by declining the pH levels and increasing the total fermentation acids content, similar results reported that (Cai et al. 1999; Lima et al. 2010; Heinritz et al. 2012) reported that L. plantarum FG10, a LAB strain isolated from Italian ryegrass, increased the LA and decreased BA NH3–N/TN and Loss DM in Italian ryegrass, sorghum and soybean silage. The production of acetic acid (AA), butyric acid (BA) and some other additional acids, is the indication of wasteful fermentation or of secondary fermentation of LA to BA and degradation of amino acid to NH3 by way of the construction of AA from the carbon framework of the amino acid (Santoso et al. 2011). The NDF and ADF were lower in the treated silage. This result is agreement with the previous studies of (Yahaya et al. 2004; de; Oliveira et al. 2009; Santoso et al. 2011). One of the justifications for the lower NDF and ADF in the silage is that enzymatic action for example hemicelluloses, cellulose present in the original forage on cell wall during ensiling. The concentration of the NDF and ADF was decreased with treated of the LAB had positive effect of silage nutritive value and enhanced digestibility. In our study, inoculated LAB strains isolated from king grass silage had decreased the amount of NDF and ADF but not significantly. (Arriola et al. 2015) who used the same inoculants product and reported a lower NDF and ADF concentration in corn silage in all treated silage as compared to control. Many studies agree with our result, the silage DM content were unchanged by supplementation of LAB in long ensiling period (Baah et al. 2011; Amanullah et al. 2014). Kim et al. (2015) reported that throughout the 100 days of ensiling, there was no difference in DM, CP, NDF, ADF.

Conclusion

It is suggested that the supplementation of LAB could enhanced the fermentation quality of sweet Sorghum silage.

Abbreviations

- LAB:

-

Lactic acid bacteria

- FW:

-

Fresh weight

- DM:

-

Dry matter

- WSC:

-

Water soluble carbohydrates

- NDF:

-

Neutral detergent fiber

- ADF:

-

Acid detergent fiber

- CP:

-

Crude protein

- WHC:

-

Water holding capacity

References

Amanullah S, Kim D, Lee H, Joo Y, Kim S, Kim S (2014) Effects of microbial additives on chemical composition and fermentation characteristics of barley silage. Asian-Aust J Anim Sci 27(4):511

Amer S, Seguin P, Mustafa A (2012) Short communication: effects of feeding sweet sorghum silage on milk production of lactating dairy cows. J Dairy Sci 95(2):859–863

Arriola K, Queiroz O, Romero J, Casper D, Muniz E, Hamie J, Adesogan A (2015) Effect of microbial inoculants on the quality and aerobic stability of bermudagrass round-bale haylage. J Dairy Sci 98(1):478–485

Arthur Thomas T (1977) An automated procedure for the determination of soluble carbohydrates in herbage. J Sci Food Agric 28(7):639–642

Ávila C, Carvalho B, Pinto J, Duarte W, Schwan R (2014) The use of Lactobacillus species as starter cultures for enhancing the quality of sugar cane silage. J Dairy Sci 97(2):940–951

Baah J, Addah W, Okine E, McAllister T (2011) Effects of homolactic bacterial inoculant alone or combined with an anionic surfactant on fermentation, aerobic stability and in situ ruminal degradability of barley silage. Asian-Aust J Anim Sci 24(3):369–378

Cai Y, Benno Y, Ogawa M, Ohmomo S, Kumai S, Nakase T (1998) Influence of Lactobacillus spp. from an inoculant and of Weissella and Leuconostoc spp. from forage crops on silage fermentation. Appl Environ Microbiol 64(8):2982–2987

Cai Y, Kumai S, Ogawa M, Benno Y, Nakase T (1999) Characterization and identification of pediococcus species isolated from forage crops and their application for silage preparation. Appl Environ Microbiol 65(7):2901–2906

Cecil RLF, Goldman L, Schafer AI (2012) Goldman’s cecil medicine, expert consult premium edition–enhanced online features and print, single volume, 24: goldman’s cecil medicine, vol 2. Elsevier, Amsterdam

Contreras-Govea FE, Muck RE, Broderick GA, Weimer PJ (2013) Lactobacillus plantarum effects on silage fermentation and in vitro microbial yield. Anim Feed Sci Technol 179(1):61–68

Davies D, Merry R, Williams A, Bakewell E, Leemans D, Tweed J (1998) Proteolysis during ensilage of forages varying in soluble sugar content. J Dairy Sci 81(2):444–453

De Oliveira SG, Berchielli TT, Reis RA, Vechetini ME, dos Santos Pedreira M (2009) Fermentative characteristics and aerobic stability of sorghum silages containing different tannin levels. Anim Feed Sci Technol 154(1):1–8

Doi K, Nishizaki Y, Kimura H, Kitahara M, Fujino Y, Ohmomo S, Ogata S (2013) Identification of thermo tolerant lactic acid bacteria isolated from silage prepared in the hot and humid climate of Southwestern Japan. Spring Plus 2:485. https://doi.org/10.1186/2193-1801-2-485

Duncan DB (1955) Multiple range and multiple F tests. Biometrics 11(1):1–42

Eitan A, Fisher F, Andrews R, Brinson L, Schadler L (2006) Reinforcement mechanisms in MWCNT-filled polycarbonate. Compos Sci Technol 66(9):1162–1173

Filya I, Muck R, Contreras-Govea F (2007) Inoculant effects on alfalfa silage: fermentation products and nutritive value. J Dairy Sci 90(11):5108–5114

Heinritz SN, Martens SD, Avila P, Hoedtke S (2012) The effect of inoculant and sucrose addition on the silage quality of tropical forage legumes with varying ensilability. Anim Feed Sci Technol 174(3):201–210

Kim DH, Amanullah SM, Lee HJ, Joo YH, Kim SC (2015) Effect of microbial and chemical combo additives on nutritive value and fermentation characteristic of whole crop barley silage. Asian-Aust J Anim Sci 28(9):1274

Kimura M, Ohta T (1972) On the stochastic model for estimation of mutational distance between homologous proteins. J Mol Evol 2(1):87–90

Kozaki M, Uchimura T, Okada S (1992) Experimental manual of lactic acid bacteria. Asakurasyoten, Tokyo, pp 34–37

Kung L, Stokes M, Lin C (2003) Silage additives. Agronomy 42:305–360

Lima R, Lourenco M, Diaz R, Castro A, Fievez V (2010) Effect of combined ensiling of sorghum and soybean with or without molasses and lactobacilli on silage quality and in vitro rumen fermentation. Anim Feed Sci Technol 155(2):122–131

Liu Q, Chen M, Zhang J, Shi S, Cai Y (2012) Characteristics of isolated lactic acid bacteria and their effectiveness to improve stylo (Stylosanthes guianensis Sw.) silage quality at various temperatures. Anim Sci J 83(2):128–135

Mutegi E, Sagnard F, Muraya M, Kanyenji B, Rono B, Mwongera C, Marangu C, Kamau J, Parzies H, de Villiers S (2010) Ecogeographical distribution of wild, weedy and cultivated Sorghum bicolor (L.) Moench in Kenya: implications for conservation and crop-to-wild gene flow. Genetic Resour Crop Evol 57(2):243–253

Ni K, Wang Y, Li D, Cai Y, Pang H (2015) Characterization, identification and application of lactic acid bacteria isolated from forage paddy rice silage. PLoS ONE 10(3):e0121967

Nkosi B, Vadlani P, Brijwani K, Nanjunda A, Meeske R (2012) Effects of bacterial inoculants and an enzyme on the fermentation quality and aerobic stability of ensiled whole-crop sweet sorghum. South Afr J Anim Sci 42(3):232–240

Novozamsky I, Eck Rv, Van Schouwenburg JC, Walinga I (1974) Total nitrogen determination in plant material by means of the indophenol-blue method. Netherlands J Agric Sci

Pang H, Tan Z, Qin G, Wang Y, Li Z, Jin Q, Cai Y (2012) Phenotypic and phylogenetic analysis of lactic acid bacteria isolated from forage crops and grasses in the Tibetan Plateau. J Microbiol 50(1):63–71

Pholsen S, Khota W, Pang H, Higgs D, Cai Y (2016) Characterization and application of lactic acid bacteria for tropical silage preparation. Anim Sci J 87:1202–1211

Pieper R, Hackl W, Korn U, Zeyner A, Souffrant W, Pieper B (2011) Effect of ensiling triticale, barley and wheat grains at different moisture content and addition of Lactobacillus plantarum (DSMZ 8866 and 8862) on fermentation characteristics and nutrient digestibility in pigs. Anim Feed Sci Technol 164(1):96–105

Playne M, McDonald P (1966) The buffering constituents of herbage and of silage. J Sci Food Agric 17(6):264–268

Reich LJ, Kung L (2010) Effects of combining Lactobacillus buchneri 40788 with various lactic acid bacteria on the fermentation and aerobic stability of corn silage. Anim Feed Sci Technol 159(3):105–109

Reyes-Gutiérrez JA, Montañez-Valdez OD, Rodríguez-Macias R, Ruíz-López M, Salcedo-Pérez E, Guerra-Medina CE (2015) Effect of a bacterial inoculum and additive on dry matter in situ degradability of sugarcane silage. J Integrat Agric 14(3):497–502

Rossi F, Dellaglio F (2007) Quality of silages from Italian farms as attested by number and identity of microbial indicators. J Appl Microbiol 103(5):1707–1715

Saitou N, Nei M (1987) The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol biol evol 4(4):406–425

Santoso B, Hariadia BT, Manik H, Abubakar H (2011) Silage quality of king grass (Pennisetum purpureophoides) treated with epiphytic lactic acid bacteria and tannin of acacia. Media Peternakan 34(2):140

Shah AA, Yuan X, Zhihao D, Siran W, Tao S (2017a) Effects of lactic acid bacteria on ensiling characteristics, chemical composition and aerobic stability of king grass. J Anim Plant Sci 3:747–755

Shah AA, Yuan X, Zhihao D, Li J, Tao S (2017b) Microbiological and chemical profile of elephant grass inoculated with and without Lactobacillus plantarum and Pediococcus acidilactici. Arch Microbiol. https://doi.org/10.1007/s00203-017-1447-1

Shao T, Zhang Z, Shimojo M, Wang T, Masuda Y (2005) Comparison of fermentation characteristics of Italian ryegrass (Lolium multiflorum Lam.) and guineagrass (Panicum maximum Jacq.) during the early stage of ensiling. Asian Aust J Anim Sci 18(12):1727

Thompson JD, Higgins DG, Gibson TJ (1994) CLUSTAL W: improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice. Nucleic Acids Res 22(22):4673–4680

Tian J, Yu Y, Yu Z, Shao T, Na R, Zhao M (2014) Effects of lactic acid bacteria inoculants and cellulase on fermentation quality and in vitro digestibility of Leymus chinensis silage. Grassland Sci 60(4):199–205

Van Soest PV, Robertson J, Lewis B (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74(10):3583–3597

Wang M, Yang C, Jia L, Yu K (2014) Effect of Lactobacillus buchneri and Lactobacillus plantarum on the fermentation characteristics and aerobic stability of whipgrass silage in laboratory silos. Grassland Sci 60(4):233–239

Wang S, Yuan X, Dong Z, Li J, Guo G, Bai Y, Zhang J, Shao T (2017) Characteristics of isolated lactic acid bacteria and their effects on the silage quality. Asian-Aust J Anim Sci 30(6):819

Weinberg Z, Ashbell G, Hen Y, Azrieli A (1993) The effect of applying lactic acid bacteria at ensiling on the aerobic stability of silages. J Appl Microbiol 75(6):512–518

Wrobel B, Zielinska A, Suterska A Evaluation of quality and aerobic stability of grass silage treated with bacterial inoculants containing Lactobacillus buchneri. In: Proceedings, 13th International Conference on Forage Conservation, Nitra, Slovak Republic, 2008. pp 122–123

Yahaya M, Goto M, Yimiti W, Smerjai B, Kawamoto Y (2004) Evaluation of fermentation quality of a tropical and temperate forage crops ensiled with additives of fermented juice of epiphytic lactic acid bacteria (FJLB). Cellulose 31:28.25

Zahiroddini H, Baah J, Absalom W, McAllister T (2004) Effect of an inoculant and hydrolytic enzymes on fermentation and nutritive value of whole crop barley silage. Anim Feed Sci Technol 117(3):317–330

Acknowledgements

This work were supported by 31672488, 2016YFC0502005 and 2016ZDKJZC. We thank the team of Native English Editing (Native EE) for critical reading and editing of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interests.

Rights and permissions

About this article

Cite this article

Shah, A.A., Xianjun, Y., Zhihao, D. et al. Isolation and molecular identification of lactic acid bacteria from King grass and their application to improve the fermentation quality of sweet Sorghum. World J Microbiol Biotechnol 34, 4 (2018). https://doi.org/10.1007/s11274-017-2387-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-017-2387-2