Abstract

The effect of pH, sucrose and ammonium sulphate concentrations on the production of nata-de-coco, a form of bacterial cellulose, by Acetobacter xylinum was studied. Comparisons for physical properties like thickness, wet weight, water-holding capacity (WHC), moisture content and hardness, a textural parameter were done on nata-de-coco grown in tender coconut water medium supplemented with varying concentrations of sucrose and ammonium sulphate at different pH values. The results were analysed by fitting a second-order polynomial regression equation. Response surface methodology was used to study the effect of the three variables. The study showed that A. xylinum could effectively use sucrose as the sole carbon source in coconut water medium and that cellulose production was more dependent on pH than either sucrose or ammonium sulphate concentrations. Maximum thickness of nata was obtained at pH 4.0 with 10% sucrose and 0.5% ammonium sulphate concentrations. These conditions also produced good quality nata-de-coco with a smooth surface and soft chewy texture. The study will enable efficient utilization of coconut water, a hitherto wasted byproduct of coconut industry and will also provide a new product dimension to the aggrieved coconut farmers who are not getting the right price for their product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose produced by Acetobacter xylinum at the air- liquid interface of coconut water is popularly known as nata-de-coco. This unconventional product based on coconut water is native to the Philippines and was developed locally first in 1949. Over the years, it has become popular in other countries like Japan, Korea and USA. A. xylinum uses the nutrients in the coconut water medium, forms a thin slimy, transparent layer of cellulose on the surface of the medium, which thickens with age forming a thick whitish sheet after 15–20 days. This thick sheet of cellulose is cut into cubes, washed and boiled in water before cooking in sugar syrup. Nata so formed is more than 90% water imbibed in cellulose and finds use in desserts, fruit cocktails and fruit jellies.

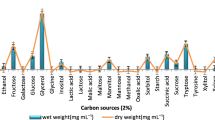

A. xylinum is widely distributed in nature and is a common contaminant in the industrial production of vinegar by A. aceti. A. xylinum has been isolated from rotting fruits (Lapuz et al. 1967), vegetables and fermenting coconut water (de Gallardo et al. 1971). Many strains of A. xylinum are capable of producing cellulose in varying amounts and growing on a wide variety of substrates like glucose, sucrose, fructose, invert sugar, ethanol and glycerol (White and Brown 1989). Cellulose production by A. xylinum has been noted both in static as well as agitated cultures (Chao et al. 2000; Toyosaki et al. 1995; de Gallardo et al. 1971) and is known to be affected by the type and concentration of sugar, nitrogen source and pH (Embuscado et al. 1994). A. xylinum has been shown to be distinctly acid tolerable capable of growing at pH as low as 3.5 (Lapuz et al. 1967) and Verschuren et al. (2000) reported pH 4.0 and 5.0 to be ideal for the development of cellulose.

Being microbial cellulose, nata-de-coco is highly hydrophilic holding water over 100 times its weight. Water holding capacity, a physical property is defined as the ability of a food structure to prevent water being released from the 3-dimensional structure (Hermansson 1986). The water is trapped in the cellulosic matrix and is important both for food and non-food applications of cellulose. Thickness of nata influences the water holding capacity which in turn has a bearing on the physical textural and organoleptic properties. Nata-de-coco has distinct textural properties like a firm chewy, soft and smooth surface which is preferred.

The effect of processing conditions on the physical properties of nata-de-coco has been studied by Chung and Shyu (1999). However there are no studies relating the conditions of growth of A. xylinum to the thickness and subsequently to the physical properties. In this investigation response surface methodology was used to study the effect of pH, sucrose and ammonium sulphate concentrations on the formation of nata-de-coco with comparisons for physical properties like thickness, wet weight, water-holding capacity (WHC), moisture content and hardness, a textural parameter.

Further, nata production by local farmers invariably involves use of a mixed strain culture wherein A. xylinum is present along with various types of yeasts. Hence batch to batch variations and starter failures because of the overgrowth of yeast cells are a common feature, especially when low cost sugar is used. The present work used pure cultures of A. xylinum to obtain a consistent product and will benefit the coconut based farmers and communities to produce good quality nata with superior physical properties.

Materials and methods

Maintenance of A. xylinum

Acetobacter xylinum (NCIM 2526) culture obtained from National Collection of Industrial Microorganisms (NCIM), National Chemical Laboratory, Pune India was maintained on tomato agar slants. Two hundred gram of fresh tomatoes and 500 ml of distilled water was boiled for 30 min. This tomato infusion was filtered and mixed with 100 g yeast extract, 50 g sucrose, 2.5 g peptone and 20 g agar. The volume was made up to 1,000 ml with distilled water and sterilized at 121°C for 15 min. A. xylinum was streaked on these slants and incubated at 30°C for 4 days.

Preparation of nata-de-coco starter

A. xylinum grown on tomato agar slants was inoculated into sterilized media containing 20 g−l glucose, 5 g−l yeast extract, 5 g−l peptone and 2.7 g−l K2HPO4. The original glucose medium by Hestrin and Schramm (1954) was modified to exclude citrate and the pH adjusted to 4.2 with glacial acetic acid. The inoculated media was incubated statically at 30°C for 7 days.

Tender coconut water (TCW) medium

Tender coconut water was obtained from nuts purchased locally in Mysore, India. The water from several nuts were pooled, steamed for 30 min in a laboratory autoclave, supplemented with varying amounts of ammonium sulphate and sucrose adjusting the pH with glacial acetic acid according to the experimental design (Table 1). The surface pellicle from the nata-de-coco starter left over broth was removed and inoculated (1:5 ratio) into 2,000 ml TCW medium taken in trays (L × B × H::30 × 25 × 6 cm). The trays were covered with muslin cloth and allowed to stand for 15–20 days.

Harvesting and processing of nata

The sheet of nata formed after 15–20 days was harvested when it was about 0.8–1.0 cm thick, washed repeatedly with water to remove glacial acetic acid and cut into cubes of equal dimensions. The cut cubes of nata were immersed in water for 24 h with repeated changing of water to remove the sour odour.

Experimental design

The effect of pH, sucrose and ammonium sulphate concentration on the thickness of nata-de-coco was studied using a central composite design (CCD) with each variable taken at five levels (Design Expert 7.1 Trial Version, Statease Inc., Minneapolis, USA).

Wet weight and moisture content

The cubes of nata were allowed to drip for 30 s and the wet weight was determined (Watanabe and Yamanaka 1995).

The moisture content (%w/w) of nata was determined based on the weight loss of the cut cubes when dried under vacuum for 8 h at 25 bar pressure and at 75°C.

Water holding capacity (WHC)

WHC was determined according to the method of Jiang et al. (1985). Nata was cut into cubes of equal dimensions, wrapped in filter paper and centrifuged at 5,000 g for 10 min. During centrifugation the water released is absorbed by the filter paper. The percentage ratio of the moisture in the centrifuged nata to the original moisture content provided the WHC.

Thickness and hardness

Thickness and hardness of nata-de-coco was determined using a TA-XT2 Texture Analyser (Stable Microsystem, Surrey, UK) with 75 mm diameter compression plate. The conditions for the test were set at 1.0 mm s−1 for the pretest speed; 0.50 mm s−1 for the test and post test speed with compression to 30% of sample original height. Nata was compressed twice in a reciprocating motion that imitated the action of the jaw. Hardness is defined as the peak force (unit: Newton, N) in the first compression cycle (Bourne 2002) Texture Expert Version 1.22 was used to generate a plot of compression force as a function of time.

Data analysis

A second order polynomial was used to study the linear, quadratic as well as interactive effects of pH, sucrose and ammonium sulphate concentrations on the thickness of nata formed.

The general form of the equation was:

where, bo is the intersect, b1–b9 are the regression coefficients and T, pH, S and A represent thickness (mm), pH of the coconut water medium, % sucrose concentration and % ammonium sulphate concentrations respectively.

The coefficients derived by multiple linear regression analysis were used to generate response surface graphs using Microsoft Excel (version 7.0 1995, Microsoft Corporation, Redmond, WA, USA).

Results and discussion

There was no visible nata formation in the initial stages i.e., up to 2–3 days except for the appearance of turbidity in the TCW medium and the rate of formation of nata varied in the 20 experimental combinations studied. Table 1 shows the thickness, wet weight, moisture content, water holding capacity and hardness of nata for the 20 experimental conditions. The values shown are mean ± standard deviation of three replicates.

There was no appreciable nata formation at pH 3.5 even after 20 days and only a thin layer (~1 mm) of nata was formed irrespective of the sucrose and ammonium sulphate concentrations. Earlier studies have indicated lower pH of 4.0 to be good for the static fermentation by A. xylinum (Verschuren et al. 2000). A. xylinum exhibits slow growth under static conditions. Doubling time for A. xylinum is 8–10 h under static conditions while it is 4–6 h in aerated cultures. Although aeration ensures faster cell growth, it reduces cellulose formation (Cannon and Anderson 1991) and cellulose produced is in the form of pellets which is not suitable for nata.

In the present study the glucose medium of Hestrin and Schramm (1954) modified to exclude citrate and adjusted to pH 4.2 with acetic acid was suitable for growing A. xylinum. The use of acetic acid to bring down the pH of TCW had a better effect as compared to other acids on the growth of A. xylinum and nata formation (data not shown). Vandamme et al. (1998) opined that the role of acetic acid is that of an in situ control of pH. Acetic acid breaks down to CO2 and water generating extra ATP and thereby leading to more efficient utilization of sugars for cellulose synthesis.

Further the bacteria were able to grow equally well in media containing glucose as the sole carbon source and also in TCW containing sucrose as the carbon source. The bacteria were able to make this transition effectively as evidenced by the good yield of nata obtained. The precursor in cellulose synthesis is uridine diphosphoglucose and hence bacterial cellulose production involves use of sucrose or glucose as a carbon source for growth and polysaccharide formation (Vandamme et al. 1998). Various undefined and synthetic media have been developed for A. xylinum (Hestrin and Schramm 1954; Forng et al. 1989), but cultures grown in minimal medium are reported to produce far less cellulose than cultures grown in undefined medium (Forng et al. 1989).

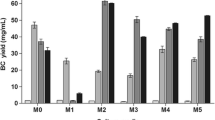

The moisture content of nata for all the 20 experimental combinations were in the region of 94–98% and WHC varied from 38% to 88%. Maximum thickness and water holding capacity of nata was seen for the central runs of the experiment i.e., at pH 4.0, 10% sucrose and 0.5% ammonium sulphate concentrations (Table 1). The nata formed showed least hardness at these experimental conditions, as measured by the peak force required in the first compression cycle imitating the first bite of the jaws (Bourne 2002).

The data were subjected to multiple regression analysis. The intercept, coefficients standard errors and P-value of the second order polynomial equation estimated by least squares principle are given in Table 2. The multiple regression equation for the thickness of nata yielded an R2 of 0.82 indicating that 82% of the variability in thickness is explained by the three variables studied. The regression coefficients and P value indicate that pH of the coconut water medium has a significant effect on the thickness of nata produced. Oxygen concentration also influences nata formation. However this was not included in the present study as rarely we have situations in actual production wherein we can increase the availability of oxygen beyond a certain level especially under static conditions. The growth of A. xylinum in trays ensured adequate aeration even under static conditions. The work of Verschuren et al. (2000) has established that the first stage of cellulose fermentation is entirely oxygen controlled. When the dissolved oxygen in the medium is used up, bacteria existing only in the vicinity of the surface can maintain their activity and produce cellulose in the form of gel (Budhiono et al. 1999).

Response surface graphs were generated at pH 3.5, 4.0 and 4.5 varying the concentrations of sucrose and ammonium sulphate concentrations (Fig. 1). Maximum thickness of nata was obtained at pH 4.0, 10% sucrose concentration and at 0.5% ammonium sulphate in the growth medium. At pH 4.5 also the thickness of nata was higher reaching a maximum of 8.1 mm at 10% sucrose and 0.5% ammonium sulphate concentrations. However this was lower as compared to the thickness of nata (8.8 mm) obtained at pH 4.0 under identical conditions.

Figure 2 shows response surface graphs for thickness of nata at 5%, 10% and 15% sucrose concentrations. Maximum thickness of up to 9.0 mm is predicted at pH 4.2, 10% sucrose and 0.5% ammonium sulphate concentrations. As the sucrose concentration increased from 10% the thickness of nata formed decreased.

Contour plots indicate the area of operability within the experimental domain and helps to characterize the response i.e., thickness of nata in this case. Figure 3 shows the contour plot for the thickness of nata at 10% sucrose concentration with varying concentrations of ammonium sulphate and at different pH values. The contour plot indicates that, at pH 4.0–4.2 and ammonium sulphate concentrations 0.45–0.5 and 10% sucrose concentration maximum thickness of nata is formed.

Sucrose concentration of 10% and ammonium sulphate concentration of 0.5% at pH 4.0 was found to maximize the thickness of nata produced. These conditions also positively influenced the quality of nata in terms of water holding capacity and hardness. Thickness has a direct effect on the amount of water that nata can hold which in turn affects the softness of the final product. Nata has high hydrophilicity and has significant water holding capacity. The cellulose is about 1% of the total weight, with the rest being water (Yamanaka et al. 1989). However sugar levels greater than 5% have been reported to have no advantage as they do not increase the efficiency of cellulose production (Embuscado et al. 1994). In the present study the combination of low pH of 4.0 and sucrose concentration of 10% proved to produce good nata. Hutchens et al. (2007) confirmed that carbon source, ethanol addition and temperature are significant factors in the production of cellulose by Gluconacetobacter hansenii. Further the same authors noted different sugars produced optimal cellulose yields at different pH values. In the present study it was found that pH bears an important role in the production of nata cellulose when sucrose was used as the carbon source. The use of sucrose has one demerit as the media gets prone to contamination by yeasts and extreme care has to be taken to maintain aseptic conditions.

Apart from coconut water other unconventional media like corn steep liquor (Bae et al. 2004), fruit skin or fruit wastes (Lacadin and Millan 1980) are used for the production of nata. Studies are underway in our laboratory to identify and promote low cost substrates for the production of safe and good quality nata.

Bacterial cellulose in the form of nata is virtually indigestible and therein lies its importance. Nata is gaining popularity because of its high dietary fiber content. Many health benefits like prevention of colon cancer, heart attack, increase in blood pressure or hypertension have been attributed to nata. Philippines has reaped the benefits of nata-de-coco exports in the 1990s. However the lack of organized study, apart from other reasons has led to the decline of nata exports worldwide in the last few years and there are no accepted international specifications for nata-de-coco meant for export. Specifications are usually governed by the importing nation and specifications for texture, color, pH, sugar concentration, levels of preservatives if used, microbial standards, size and shape of the product are urgently needed.

Further as mentioned earlier, there is a tendency to use many different substrates/agricultural byproducts (cane molasses, beet molasses, pineapple skin, cheese whey permeate, high solids potato effluents for the manufacture of nata-de-coco (Keshk and Sameshima 2006). Under such circumstances there is a greater need for standardization of the manufacturing process and for stricter controls/specifications. The present study contributes towards the same in terms of process optimization to enhance quality with minimal inputs in the batch cultures suitable for small scale industry.

The use of coconut water for nata production is important and relies on expertise. The work will not only enable efficient use of coconut water a byproduct of coconut processing industry that was hitherto wasted but also give a new product dimension to the aggrieved coconut farmers who are not getting proper price for their produce.

References

Bae S, Sugano Y, Shoda M (2004) Improvement of bacterial cellulose production by addition of agar in a jar fermentor. J Biosci Bioeng 97(1):33–38

Bourne MC (2002) Food texture and viscosity: concepts and measurements. Academic Press, UK

Budhiono A, Rosidi B, Taher H, Iguchi M (1999) Kinetic aspects of bacterial cellulose formation in nata-de-coco culture system. Carbohydr Polymers 40:137–143. doi:10.1016/S0144-8617(99)00050-8

Cannon RE, Anderson SM (1991) Biogenesis of bacterial cellulose. Crit Rev Microbiol 17:435–447. doi:10.3109/10408419109115207

Chao Y, Ishida T, Sugano Y, Shoda M (2000) Bacterial cellulose production by Acetobacter xylinum in a 50-l internal-loop airlift reactor. Biotechnol Bioeng 68:345–352. doi:10.1002/(SICI)1097-0290(20000505)68:3≤345::AID-BIT13≥3.0.CO;2-M

Chung Y, Shyu Y (1999) The effects of pH, salt, heating and freezing on the physical properties of bacterial cellulose-nata. Int J Food Sci Technol 34:23–26. doi:10.1046/j.1365-2621.1999.00231.x

De Gallardo DEJ, Andres RM, Magno ET (1971) A study on the isolation and screening of microorganisms for production of diverse-textured nata. Philipp J Sci 100:41–49

Embuscado ME, Marks JS, BeMiller JN (1994) Bacterial cellulose. I. Factors affecting the production of cellulose by Acetobacter xylinum. Food Hydrocoll 8(5):407–418

Forng ER, Anderson SM, Cannon RE (1989) Synthetic medium for Acetobacter xylinum that can be used for isolation of auxotrophic mutants and study of cellulose biosynthesis. Appl Environ Microbiol 55(5):1317–1319

Hermansson AM (1986) Water and fat holding. In: Mitchell JR, Ledward DA (eds) Functional properties of food macromolecules. Elsevier Applied Science Publications, London, England and New York

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum: preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Hutchens SA, Leon RV, O’Neill HM, Evans BR (2007) Statistical analysis of optimal culture conditions for Gluconacetobacter hansenii cellulose production. Lett Appl Microbiol 44:175–180. doi:10.1111/j.1472-765X.2006.02055.x

Jiang ST, Ho ML, Lee TC (1985) Optimization of the freezing conditions on mackerel and amberfish for manufacturing minced fish. J Food Sci 50:727–732. doi:10.1111/j.1365-2621.1985.tb13783.x

Keshk S, Sameshima K (2006) The utilization of sugar cane molasses with/without the presence of lignosulfonate for the production of bacterial cellulose. Appl Microbiol Biotechnol 72(2):291–296. doi:10.1007/s00253-005-0265-6

Lacadin AL, Millan ER (1980) Relative effectiveness of coconut, dalanghita, incale and tomato as media for producing nata. TCA Res J 2(3):235–245

Lapuz MM, Gallardo EG, Palo MA (1967) The nata organism-cultural requirements, characteristics and identity. Philipp J Sci 96(2):91–108

Toyosaki H, Kojima Y, Tsuchida T, Hoshino K, Yamada Y, Yoshinaga F (1995) The characterization of an acetic acid bacterium useful for producing bacterial cellulose in agitation cultures: the proposal of Acetobacter xylinum sub sp. sucrofermentans subsp. Nov. J Gen Appl Microbiol 41:307–314. doi:10.2323/jgam.41.307

Vandamme EJ, de Baets S, Vanbaelen A, Joris K, de Wulf P (1998) Improved production of bacterial cellulose and its application potential. Polym Degrad Stab 59:93–99. doi:10.1016/S0141-3910(97)00185-7

Verschuren PG, Carodona TD, Nout MJR, de Gooijer KD, van den Heuvel JC (2000) Location and limitation of cellulose production by Acetobacter xylinum established from oxygen profiles. J Biosci Bioeng 89(5):414–419. doi:10.1016/S1389-1723(00)89089-1

Watanabe K, Yamanaka S (1995) Effects of oxygen-tension in the gaseous-phase on production and physical-properties of bacterial cellulose formed under static culture conditions. Biosci Biotechnol Biochem 59:65–68

White DG, Brown RM Jr (1989) Prospects for the commercialization of the biosynthesis of microbial cellulose. In: Schuerech C (ed) Cellulose and wood-chemistry and technology. Wiley, New York

Yamanaka S, Watanabe K, Kitamura N (1989) The structure and mechanical properties of sheets prepared from bacterial cellulose. J Mater Sci 24:3141–3145. doi:10.1007/BF01139032

Acknowledgement

We would like to acknowledge the Coconut Development Board, Kochi, India for funding this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jagannath, A., Kalaiselvan, A., Manjunatha, S.S. et al. The effect of pH, sucrose and ammonium sulphate concentrations on the production of bacterial cellulose (Nata-de-coco) by Acetobacter xylinum . World J Microbiol Biotechnol 24, 2593–2599 (2008). https://doi.org/10.1007/s11274-008-9781-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-008-9781-8