Abstract

Coir pith represents ∼50% of the waste from the coir industries and was tested for its potential in serving as a growth substrate for the production of species of oyster mushroom, Pleurotus florida. Due to its high lignin (∼48%) content and amorphous powdery nature, coir pith supported poor mushroom mycelial growth and yields were considerably low (∼25% bioconversion efficiency). Pre-treating coir pith with hot water did not prove economical to produce the mushroom yields. Acid swelling and alkali delignification of coir pith though served to change the structure of coir pith; the mushroom yields were not improved. Amendment of coir pith with rice (Oryza sativa) straw and horse gram (Dolichos biflorus) plant residue tended to greatly modify the physical characteristics of the inoculated mushroom bed. Such a supplementation of coir pith growth substrate resulted in production of mushroom yields with 110–125% bioconversion efficiency. Implications of supplementing coir pith with rice straw/horse gram plant residue in terms of holocellulose:lignin ratio are discussed. Sensorially, the mushrooms so produced did not differ from that on rice straw, the economic growth substrate recommended for production of the mushroom yields on commercial scale. Changes in cellulose, hemicellulose and lignin contents of coir pith amended with rice straw were studied. Cellulase, hemicellulase and protease enzyme activities in the amended coir pith substrate showed a continuous increase from inoculation till the end of fructification, whereas laccase activity decreased during fructification, in consonance with decreased lignin degradation during fructification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is estimated that 5.74 million metric tons of coconut are produced in the world (FAO 2001). India is reported to produce 0.77 million metric tons of coconut (Cocos nucifera) equivalent to the availability of ∼0.35 million metric tons of fibrous husk. About 50% of the husk accounts for the waste of coir industries as coir pith. Because of its high lignin content (∼48%) and amorphous, powdery nature, coir pith is one of the most tough biological materials, highly resistant to biological degradation. Lignin, a main contributor of the total carbon of agro-industrial wastes, produces polycyclic aromatic hydrocarbon components such as benzopyrene, catechol, hydroquinone, phenanthrene and naphthalene when degraded by heat (Kjallstrand et al. 1998). All these compounds can inhibit DNA synthesis and induce cancerous tumors in liver, lung, larynx and cervix in animal and humans (Tsutsui et al. 1997). Coir pith is very poor in nitrogen content, C:N ratio mounting to 112:1 (Nagarajan et al. 1985). Such a high C:N ratio is undesirable for any organic waste for application as organic manure in agricultural farms because it causes deleterious effect to the crops. No economically viable process is available to dispose of coir pith. Because of the sizeable quantities of coir pith produced every year, it was proposed to study the possibility of its use as a growth substrate for the production of oyster mushrooms.

There are numerous literature references on the utilization of agro-residues and conditions for the production of mushroom yields. Traditional use of hard wood logs mainly from oak, for production of fruiting bodies of Lentinula edodes (Kozak and Krawczyk 1993; Sobata and Nall 1994) and its improvement for efficient, faster and more reliable production system through the use of an enriched sawdust substrate (Przybylowicz and Donoghue 1990) is well established. Production of Lentinula edodes on various lignocellulosic residues (Morais et al. 2000, Morales et al. 1991, Salmones et al. 1999), including sawdust (Pire et al. 2001) and stimulation of yield by millet supplementation of wood chip substrate (Royse 1996) has been studied, as has the effect of spawn run time and substrate nutrition on yield and size of shiitake mushrooms (Royse 1985). The potential of shiitake in the bioconversion of viticulture residues is has been described by Gaitan-Hernandez et al. (2006). Further the use of Pleurotus florida for biodegradation of viticulture wastes for transformation into food and feed has been tested (Sanchez et al. 2002).

Species of Pleurotus (oyster mushroom) represent the second largest variety of the mushrooms in the world, only next to the button mushroom (Rajarathnam and Zakia Bano 1991; Rajarathnam et al. 1992) with estimated annual production figures of 0.8 and 1.5 million tons respectively (Nieuwenhuijzen 1998). Because of their prominent ligninolytic property, these species can colonize a wide range of natural lignocellulosic wastes, without a requirement for composting (Rajarathnam and Zakia Bano 1989; Rajarathnam et al. 1992; 1998). Rice/wheat straw is the most common lignocellulosic growth substrate recommended for their economic production on commercial scales (Rajarathnam and Zakia Bano 1987, 1988). Pleurotus species produce as much as 1 to 1.4 tons of fresh mushrooms per ton dry rice/wheat straw. In view of the increasing demand, cost and other alternate uses of rice/wheat straw, lignocellulosic wastes of no commercial value were considered for the possibility of production of oyster mushrooms. It is in this context, coir pith was projected for its possible use in oyster mushroom production.

The present paper deals with the pre-treatments of coir pith conducted, and amendment of coir pith required for optimum bioconversion efficiency (BCE) by the oyster mushroom, P. florida. The detailed conditions of coir pith pre-treatment and its amendment favoring the mushroom growth yield are covered under patent filed (Rajarathnam et al. 2000). The research aspects focusing the optimization of conditions in the growth substrate are described here. Further, (a) the implications of amendment of coir pith with rice (Oryza sativa) straw and horse gram (Dolichos biflorus) plant residue, on the compositional changes of the composite growth substrate, and optimizing the production of mushroom yields, (b) degradative changes in lignin, cellulose and hemicellulose of the growth substrate during spawn run and fructification of the mushroom, and (c) enzymatic changes in the growth substrate during the mushroom growth and yield, are also brought out.

Materials and methods

Culture and spawn

Monocultures of Pleurotus florida isolated from tissue cultures of the fruiting primordia were maintained on malt extract (3%) agar (2%) medium at 20 °C. Using this culture, spawn was prepared on cooked jowar (Sorghum vulgare) grains, fortified with 2% calcium carbonate, under aseptic conditions (Rajarathnam and Zakia Bano 1987). A 20-day-old grain spawn was used for inoculating the coir pith substrate.

Cultural conditions

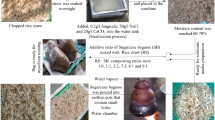

Coir pith or chopped rice straw/horse gram plant residue (5–8 cm long) was soaked in hot water at 70 °C for 20 min unless or otherwise mentioned, to ensure free from contaminants (Rajarathnam et al. 1979a). Wet straw containing ca. 75% water was spawned at 10% on a wet weight basis, along with 1% coarse “horse gram” (Dolichos biflorus) powder (mill size ca. 0.5 to 1.0 mm). The mushroom beds were prepared in perforated polyethylene (50 μm) bags (25 × 40 cm). For each treatment, starting with a dry straw substrate of 2.5 kg, eight replicate mushroom beds were prepared, allotted in randomized blocks (Zakia Bano et al. 1993; Shashirekha et al. 2001). The number of days required for the formation of pinheads was accounted as the spawn run period. Visual degree of contamination (s) in the mushroom beds was recorded on a scale of −, +, ++, +++ (Rajarathnam et al. 1979a).Yield of fresh mushroom fruiting bodies to dry weight of growth substrate as % was expressed as BCE.

Acid swelling and alkali delignification

Batches of 2.5 kg dry coir pith were soaked in 40 L of water containing 0.1–2% phosphoric acid or sodium hydroxide for 3 h at room temperature, excess drained off and pH adjusted to ∼7 using pH papers, by resoaking in dilute alkali (KOH) or phosphoric acid. Mushroom beds were prepared in 50 μm perforated polyethylene bags (25 × 40 cm) (Rajarathnam et al. 1986).

Amendment of coir pith

Coir pith after pre-treatment with hot water at 70 °C for 20 min was amended with chopped (5–8 cm long) rice straw or horse gram plant residue at 5%, 10%, 20% and 25% on wet weight basis. This was done in order to chemically modify the growth substrate conditions involving a physical change for absorption and retention of moisture, with a desired degree of aeration necessary for colonization by the mycelial growth.

Analytical methods

Total sugars, free amino acids and phenolics of the freeze-dried samples were extracted in 70% alcohol (Rajarathnam et al. 1979b) and estimated according to the methods of Dubois et al. (1956), Suzuki (1982) and Swain and Hillis (1959) respectively. Cellulose and hemicellulose(s) were determined according to Updegraff (1969) and Wankhede and Tharanathan (1976) respectively. Lignin was estimated as Klason lignin according to the method of Effland (1977). Total nitrogen in the samples (dried at 60 °C) was estimated by the micro-Kjeldahl method (AOAC 1975). Total ash was determined according to AOAC method (AOAC 1975).

Enzyme preparation

The fresh growth substrate samples along with mycelial colonization (25 g; ca. 75% moisture) were homogenized in acetate buffer (50 mM, pH 5.4, 250 mL) and filtered through muslin cloth, and the filtrate clarified by centrifugation at 4,000g for 15 min. The clear centrifugate (the enzyme extract) was used for assaying cellulase and hemicellulase(s).

Acetone powders were used for the measurement of laccase and protease activities (Rajarathnam et al. 1987). Twenty-five grams of fresh samples were homogenized in a minimum volume of sodium phosphate buffer (50 mM, pH 6.5) so as to obtain slurry. This was suspended in 500 mL acetone at −20 °C, and the precipitated material recovered by filtration on a Buchner funnel. The residue was washed thoroughly with cold (−20 °C) acetone, dried under vacuum at ambient temperature, and stored at 4 °C. Five hundred milligrams of acetone powder was extracted in 10 mL of 100 mM phosphate buffer (pH 5.5) at 5 °C for 1 h, filtered through muslin cloth, and clarified by centrifugation at 4000g for 15 min. The clear supernatant was used as the enzyme source.

Enzyme assays

Cellulase activity was measured as cotton activity (C1) and carboxymethylcellulase (CMC-ase) by the method of Mandels and Weber (1969). C1 represents that fraction of cellulase activity on highly ordered crystalline cellulose, measured on absorbent cotton, which is known to attack cellulose fibrils. Here, 50 mg of absorbent cotton 1 mL of suitably diluted enzyme and 2 mL of 50 mM acetate buffer pH 4.8 were incubated at 50 °C for 24 h and the liberated reducing sugar estimated using a glucose standard by Nelson’s method (1944). For carboxymethylcellulase 1% carboxymethylcellulose and for β-glycosidase activity 1% cellobiose in 50 mM acetate buffer pH 4.8 was used as a substrate, followed by the estimation of reducing sugar as above.

Hemicellulase(s) activity was assayed as described by Dekker and Richards (1975). The enzyme was incubated with 1 mL of 0.5% hemi cellulose-B, isolated from rice straw substrate (undegraded) in 50 mM acetate buffer (2 mL) pH 5.4 at 37 °C for 1 h, followed by the measurement of the released free reducing sugar as above using xylose as standard.

Activities of C1, CMC-ase, β-glucosidase and hemicellulase(s) were expressed as mmoles of reducing sugar released per mg protein per minute.

For laccase activity (Kirk and Kelman 1965), the enzyme was incubated with 1 mL of 40 mM guaiacol in 100 mM phosphate buffer pH 5.5 at 40 °C for 30 min, followed by absorbance changes of the colored product, read spectophotometrically at 460 nm.

Laccase and protease activities were expressed as mg protein required to change the absorbance by 0.1 unit per minute.

Protease activity was assayed using casein (1%) as the substrate (Kunitz 1947) in 50 mM Tris–HCl buffer pH 8.0. The reaction mixture was incubated for 30 min at 37 °C. The amount of hydrolyzed products left in the supernatant after precipitation with 15% trichloroacetic acid was estimated by measuring the absorbance at 200 nm.

Results and discussion

Coir pith in its natural form, due to its high degree of porosity is prone to fast desiccation, even after wetting with water that results in poor colonization by the mushroom mycelium (Savithri and Khan 1994). Inoculation of coir pith alone with the mushroom spawn yielded BCE of not more than 25%. Hot water is a physical pre-treatment of pasteurization to control substrate-borne contamination (Rajarathnam et al. 1979a). For rice straw, 60 °C for 10 min was found optimum to effect control of contamination (Rajarathnam et al. 1979a). In the present investigation, coir pith required a relatively higher degree of heat treatment (70 °C for 20 min), to effect control of contaminations (Table 1), possibly due to reckless handling of coir pith in the coir industries, after crushing of coconut husk (pericarp) in wet form, and the wet fibers exposed to pick up contamination. Pre-treating coir pith in hot water at 60 and 70 °C for 10–30 min did not produce mushroom yields compared to that on rice straw (60 °C for 10 min). Spawn run period varied however relatively less than that required for fructification on rice straw. The degree of contamination decreased with increased temperature and duration of hot water treatment of coir pith. Hot water at 70 °C for 20 min rendered the coir pith bed free of contamination.

Acid swelling and alkali delignification did not help to increase the mushroom yields significantly, although alkali proved better than acid pre-treatment (Table 2), probably because of decrease in lignin content due to alkali treatment. Acid swelling of coir pith with phosphoric acid recorded maximum mushroom yield of 30% relative to that on rice straw. The beds were invariably contaminated with Chaetomium. Potassium hydroxide treatment resulted in decrease of lignin content (up to 8%), rendering the coir pith softer. However, the mushroom beds recorded Penicillium contamination and the maximum mushroom yield was only 35% as compared to that on rice straw.

Amendment of coir pith with chopped rice straw tended to increase the mushroom mycelial colonization, by a physical conditioning of the coir pith substrate. Twenty percent supplementation of rice straw, proved optimum to enrich the coir pith substrate with mushroom mycelial ramification, resulting in mushroom yields similar to that on rice straw (Table 3a). Possibly this resulted in conditioning the amended substrate for optimum water-holding capacity and aeration, to overcome the anaerobic conditions, promoting the mushroom mycelial growth finally resulting in the production of optimum mushroom yields. Similarly, supplementing the coir pith with horse gram plant residue at 20% level proved optimum for the production of mushroom yields (Table 3b).

A consideration of the chemical analyses of coir pith compared to rice straw and horse gram plant residue provides valuable information on the chemistry of amended coir pith substrate influencing the mushroom growth and yield. Chemically coir pith, rice straw and horse gram plant residue contained low quantities of free sugars and amino acids, with relatively more phenolics (Table 4). Rice straw and horse gram plant residue were similar, in cellulose, hemicellulose and lignin contents. In contrast, coir pith had significantly more lignin with relatively lesser quantities of cellulose and hemicellulose. Total crude protein (Kjeldahl N ×6.25), was high in horse gram plant residue, (as a pulse plant residue), whereas rice straw and coir pith, contained low and very low quantities of protein respectively.

Relative components of cellulose, hemicellulose and lignin available in coir pith as compared to rice straw, horse gram plant residue and amended coir pith substrate are presented in Table 5a. The amendment is based on 80:20 ratio for coir pith and rice straw/horse gram plant residue respectively. In turn, these ratios are related to the maximum BCE of the mushroom. It appears that a certain minimum level of holocellulose:lignin is a pre-requisite for the mushroom to colonize the growth substrate, produce enzymes required for degradation of lignin to set free cellulose and hemicellulose components for further degradation and utilization by the mushroom mycelium, for its metabolism and construction of the fruiting bodies. More strikingly, the holocellulose (cellulose + hemicellulose):lignin ratio appears to greatly influence the production of mushroom yields. As evident, the ratio of 0.75 of coir pith appears to be the limiting value, whereas 0.94 obviously works out as the critical value, and any value above 0.94 favors the production of optimum mushroom yields. Relatively higher mushroom yields on horse gram plant residue/its amendment of coir pith, obviously appear to be related to the high protein content of horse gram plant residue, as it is well documented that organic proteinaceous nitrogen of growth substrate influence in the enhancement of the mushroom yields (Rajarathnam et al. 1979b; Zakia Bano et al. 1993).

Changes in cellulose, hemicellulose and lignin contents of the coir pith amended rice straw substrate were followed. (Table 5b). Lignin was actively decomposed during the spawn run (8.2%) period of 12 days while its decrease during fructification was very less (1.8%). Whereas the decrease in cellulose and hemicellulose contents per unit time was prominent during fructification phase of 3 days (3.8% of cellulose and 2.8% of hemicellulose) compared to 4 and 2% respectively during the spawn run phase of 12 days. This observation is similar to the findings of Rajarathnam et al. (1979b, 1987), wherein the lignin degradation is a pre-requisite to easy access of cellulose and hemicellulose for degradation. Accordingly, lignin degradation is more active during the spawn run phase of 12 days; whereas, the active degradation of cellulose and hemicellulose during fructification phase of 3 days corroborates with the active metabolism of the mushroom mycelium in the construction of the fruiting bodies. Similar changes were observed in coir pith + horse gram plant residue amended substrate (data not provided).

Changes in degradatory enzymatic activities in the coir pith + rice straw substrate (that produced optimum mushroom yield) were studied at 0, 6, 12 and 15 days of spawning i.e., during spawn run and fructification. C1, CMC-ase and β-glucosidase necessary for the complete saccharification of crystalline cellulose (Millett et al. 1976) were observed to be operating. Their relative activities at any particular growth stage are shown in Table 6. Similarly, the hemicellulase activity was observed to show a continuous increase from spawning till the end of fructification, as it is known that hemicellulose also plays a vital role in the mushroom metabolism (Rolz et al. 1987). Laccase activity was studied for its implications in the lignin degradation (Rajarathnam et al. 1998). Laccase showed peak activity till the formation of pinheads (12 days growth) and declined thereafter, coinciding with prominent lignin degradation represented in Table 5a. Protease activity was prominent during fructification, reflecting on its profound role in construction of the mushroom fruiting bodies, since, protein constitutes the second abundant component of the mushroom next to carbohydrates (Rajarathnam et al. 1998). These observations are similar to those of P. flabellatus on rice straw (Rajarathnam et al. 1979b, 1987).

Ragunathan et al. (1996) have recorded a BCE of maximum 30% for Pleurotus sajor-caju, by pre-treating coir pith in water for 4–5 h followed by a dip in boiling water for 30 min. Thomas et al. (1998) have observed a BCE of 40% on coir pith soaked in water for 16 h, with subsequent sterilization at 1.02 Kg cm−2 for 90 min. Compared to these works, the present investigation deals with a simple pre-treatment of coir pith, involving supplementation with rice straw/horse gram plant residue followed by less costlier hot water pasteurization, to produce mushroom yields as high as 100% BCE, similar to that on rice straw. The details of the investigation as applicable to the production of the mushrooms on commercial scales, using the CFTRI-developed vertical model structure are covered under patent (Rajarathnam et al. 2000). Biochemical also, the enhanced mushroom yields are associated with increased secretion of cellulases. Thus, the simple supplementation of coir pith with rice straw/horse gram plant residue in chopped and pasteurized form, in particular proportions, has resulted in the desired change in the physical structure (of increased aeration and water-holding capacity) of the mushroom bed and meeting with the desired holocellulose:lignin ratio (0.94 and above). The conditioned holocellulose:lignin ratio due to supplementation, appears to have provided enough carbohydrate (which is limited in coir pith), aiding the build-up of mycelial biomass, involving active secretion of degradatory enzymes to degrade lignin of coir pith, that could result in increased accessibility of holocellulose of coir pith for easier enzymatic degradation by the mushroom, to keep pace with the fast metabolism of fructification, to result in production of enhanced mushroom yields. Accordingly, the present study has opened wide scope for the economic bioconversion of a lignin-rich substrate like coir pith. This would find obvious useful application to such of those geographic regions in the world, blessed with predominant coconut vegetation, involving easy availability of coir pith in significant quantities.

References

AOAC (1975) Official methods of analysis, 12th edn. Association of Official Analytical Chemists, Washington, DC

Dekker RFH, Richards HN (1975) Purification, properties and mode of action of hemicellulase. I. Produced by Ceratocystis paradoxa. Carbohydr Res 39:97–114

Dubois M, Gilles KA, Hamilton JK, Reben PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Effland MJ (1977) Modified procedure to determine acid insoluble lignin in wood and pulp. Tappi 60:143–144

FAO Production Year Book (2001) vol 55. Food and Agriculture Organization of the United Nations, Rome, Italy

Gaitan-Hernandez R, Esqueda M, Gutierrez A, Sanchez A, Beltran-Garcia M, Mata G (2006) Bioconversion of agro wastes by Lentinula edodes: the high potential of viticulture residues. Appl Microbiol Biotechnol 71:432–439

Kirk TK, Kelman A (1965) Lignin degradation as related to the phenol oxidases of selected wood decaying basidiomycetes. Phytopathology 55:739–745

Kjallstrand J, Ramna O, Petersson G (1998) Gas chromatographic and mass spectrometric analysis of 36 lignin- related methoxyphenols from uncontrolled combustion of wood. J Chromatogr 824:205–210

Kozak ME, Krawczyk J (1993) Growing shiitake mushroom in a continental climate. Marinette, Wisconsin

Kunitz M (1947) Crystalline soyabean trypsin inhibitor pollen. II. general properties. J Gen Physiol 30:291–310

Mandels M, Weber J (1969) Cellulases and their applications. In: Advances in chemistry series, vol 95, p 393. American Chemical Society, Washington DC, USA

Millett MA, Baker AJ, Satter LD (1976) In: Enzymatic conversion of cellulose materials, technology and applications. Advances in chemistry series, vol 6, p 125. John Wiley & Sons, New York

Morais MH, Ramos AC, Matos N, Santos-Olivera EJ (2000) Production of shiitake mushroom (Lentinula edodes) on lignocelluloses residues. Food Sci Technol Int 6:123–128

Morales P, Martinez-Carrera D, Martinez-Sanchez W (1991) Cultivo de shiitake sobre diversos substratos en Mexico. Micologia Neotropical Aplicada 4:75–81

Nagarajan R, Manickam TS, Kothandaraman GV (1985) Manurial value of coir pith. Madras Agric J 72:533–535

Nelson N (1944) A colorimetric method for estimation of reducing sugars. J Biol Chem 153:375–386

Nieuwenhuijzen BV (1998) Quality: keyword for the mushroom industry. Mushroom J 579:13–19

Pire DG, Wright JE, Alberto E (2001) Cultivation on shiitake using sawdust from widely available local woods in Argentina. Micol Apl Int 13:87–91

Przybylowicz P, Donoghue J (1990) Shiitake grower’s handbook. The art and science of mushroom cultivation. Kendall Hunt, Dubuque

Ragunathan R, Gurusamy R, Palaniswamy M, Swaminathan K (1996) Cultivation of Pleurotus spp. on various agro-residues. Food Chem 55:139–144

Rajarathnam S, Zakia Bano (1988) Pleurotus mushrooms. Part IB. Pathology, in vitro and in vivo growth requirements and world status. CRC Crit Rev Food Sci Nutr 26:243–311

Rajarathnam S, Zakia Bano (1989) Pleurotus mushrooms. Part III. Biotransformation of natural lignocellulosic wastes: commercial applications and implications. CRC Crit Rev Food Sci Nutr 28:31–113

Rajarathnam S, Zakia Bano (1991) Biological utilization of edible fruiting fungi. In: Arora DK, Mukerji KG, Mathe EH (eds) Handbook of applied mycology: foods and feeds, vol 3. Marcel Dekker Press, Wisconsin, USA, 241–292. ISBN 082478491X

Rajarathnam S, Singh NS, Zakia Bano (1979a) Efficacy of carboxin and heat treatment for controlling the growth of Sclerotium rolfsii during culture of the mushroom Pleurotus flabellatus. Ann Appl Biol 92:323–328

Rajarathnam S, Wankhede DB, Patwardhan MV (1979b) Some chemical and biochemical changes in straw constituents during growth of Pleurotus flabellatus (Berk and Br.) Sacc. Eur J Appl Microbiol Biotechnol 8:125–134

Rajarathnam S, Wankhede DB, Patwardhan MV (1986) Nutrition of the mushroom Pleurotus flabellatus during its growth on paddy straw substrate. J Hortic Sci 61:223–232

Rajarathnam S, Wankhede DB, Zakia Bano (1987) Degradation of rice straw by Pleurotus flabellatus. J Chem Technol Biotechnol 37:203–214

Rajarathnam S, Shashirekha MN, Zakia Bano (1992) Biopotentialities of basidiomacromycetes. Adv Appl Microbiol 37:233–361

Rajarathnam S, Shashirekha MN, Zakia Bano (1998) Biodegradative and biosynthetic capacities of mushrooms: present and future strategies. Crit Rev Biotechnol 18:91–236

Rajarathnam S, Zakia Bano, Shashirekha MN (2000) A process for manufacture of high yielding substrate for cultivation of mushrooms using coir waste. Patent: NF 35/2000

Rolz C, Leon R, De Arriola MO, De Cabrera SC (1987) White rot fungal growth on sugarcane lignocellulosic residue. Appl Microbiol Biotechnol 25:535–541

Royse DJ (1985) Effect of spawn run time and substrate nutrition on yield and size of shiitake mushroom. Mycologia 77:756–762

Royse DJ (1996) Yield stimulation of shiitake by millet supplementation of wood chip substrate. In: Royse DJ (ed) Mushroom biology and mushroom products. Penn State University Press, Pennsylvania, pp 277–283. ISBN 1883956013

Salmones D, Mata G, Ramos LM, Waliszewski KN (1999) Cultivation of shiitake mushroom, Lentinula edodes, in several lignocellulosic materials originating from the subtropics. Agronomie 19:13–19

Sanchez A, Ysunza F, Beltran-Garcia MJ, Esqueda M (2002) Biodegradation of viticulture wastes by Pleurotus: a source of microbial and human food and its potential use in animal feeding. J Agric Food Chem 50:2537–2542

Savithri P, Khan HH (1994) Characteristics of coconut coir pith and its utilization in agriculture. J Plantation Crops 22:1–18

Shashirekha MN, Rajarathnam S, Zakia Bano (2001) Chemical and biochemical changes in the rice straw substrate related to the morphogenesis, cropping pattern and yield of Pleurotus florida (Block & Tsao). J Hortic Sci Biotechnol 76:332–337

Sobata C, Nall H (1994) Shiitake mushroom production on logs. Alabama Co-operative Extension Program, Alabama

Suzuki T (1982) Changes in total nitrogen and free amino acids in stem cuttings of mulberry (Morus alba, L.). J Exp Bot 33:21–28

Swain T, Hillis WE (1959) Phenolic constituents of Prunus domestica. I. Qualitative analysis of phenolic constituents. J Sci Food Agric 10:63–68

Thomas GV, Prabhu SR, Reeny MZ, Bopaiah BM (1998) Evaluation of lignocellulosic biomass from coconut palm as substrate for cultivation of Pleurotus sajor-caju (Fr.) singer. World J Microbiol Biotechnol 14:879–882

Tsutsui T, Hayashi N, Maizumi H, Huff J, Barrett JC (1997) Benzene, catechol, hydroquinone and phenol induced cell transformation, gene mutations, chromosome aberrations, aneuploidy, sister chromatid exchangers and unscheduled DNA synthesis in Syrian Hamster embryo cells. Mutant Res 373:113–123

Updegraff DM (1969) Semi-micro determination of cellulose in biological materials. Anal Biochem 32:420–424

Wankhede DB, Tharanathan RN (1976) Sesame (Sesamum indicum) carbohydrates. J Agric Food Chem 24:655–659

Zakia Bano (1987) Pleurotus mushrooms. Part IA. Morphology, life cycle, taxonomy, breeding and cultivation. CRC Crit Rev Food Sci Nutr 26:157–223

Zakia Bano, Shashirekha MN, Rajarathnam S (1993) Improvement of the bioconversion and biotransformation efficiencies of the oyster mushroom (Pleurotus sajor-caju) by supplementation of its rice straw substrate with oil seed cakes. Enzyme Microb Technol 15:985–989

Acknowledgements

The authors sincerely thank Dr. V. Prakash, Director, CFTRI for his encouragement during this investigation. The sponsorship of the mushroom project by the Department of Biotechnology, New Delhi is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shashirekha, M.N., Rajarathnam, S. Bioconversion and biotransformation of coir pith for economic production of Pleurotus florida: chemical and biochemical changes in coir pith during the mushroom growth and fructification. World J Microbiol Biotechnol 23, 1107–1114 (2007). https://doi.org/10.1007/s11274-006-9340-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-006-9340-0