Abstract

Aspergillus niger with mycelium-bound tannase activity was employed to investigate the synthesis of propyl gallate from gallic acid and 1-propanol in organic solvents. The effects of various organic solvents (log P: −1.0 to 6.6) on the enzymatic reactions showed that benzene (log P: 2.0) was the most suitable solvent. The water content and protonation state of mycelium-bound enzyme both had significant effects on the activity of tannase. The maximum molar conversion (65%) was achieved with 7.3% (v/v) 1-propanol and 5.56 mM gallic acid at stirring speeds of 200 rev/min, 40 °C in presence of anhydrous sodium sulfate and PEG-10,000. Enzyme specificity for the alcohol portion (C1–C8) of the ester showed that the optimum synthesis was observed with alcohols ranging from C3 to C5.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tannase (tannin acyl hydrolase, E.C: 3.1.1.20) is an inducible enzyme produced in the presence of tannic acid by microorganisms, among which fungi are the predominant producers. With the ability to hydrolyze the ester linkages of tannic acid, the industrially important enzyme is extensively used in the manufacture of instant tea, wine and gallic acid (Lekha and Lonsane 1997; Chae and Yu 1983; Coggon and Sanderson 1972). Recently tannase has found new applications in non-aqueous enzymology to synthesize gallic acid esters. Propyl gallate is a very important gallic acid ester and widely used as antioxidant in foods, cosmetics, hair products, adhesives, and the lubricants industry, and is also used as a prodrug of trimethoprim, a pharmaceutical antibacterial agent (Gaathon et al. 1989; Hadi et al. 1994; Yamada and Tannaka 1972).

Esterification in non-aqueous media as opposed to aqueous media has several advantages including dramatically higher substrate solubility, the ability to use enzymes synthetically, rather than hydrolytically, and the capability to modify native selectivity by simply tailoring the reaction medium, rather than the enzyme itself. Toth and Hensler (1952) discovered the ability of soluble tannase to produce gallic acid esters. Gaathon et al. (1989) synthesized propyl gallate in a reverse micelle system. Researchers also used immobilization methods to improve the esterification activity of tannase (Sharma and Gupta 2003; Weetal 1985). Under optimum fermentation conditions, tannase is strongly bound to the mycelium (Barthomeuf et al. 1994), and this has also also been found for the tannase from Aspergillus niger in our research. In our previous work, both purified tannase and mycelium-bound tannase were microencapsulated within a chitosan–alginate complex coacervate membrane to investigate the synthesis of propyl gallate in organic solvents. The studies showed that the activity of immobilized mycelium-bound tannase was lower than that of microencapsulated tannase, but more importantly, avoided costly and time-consuming purifications (Yu et al. 2004; Yu and Li 2005). Recently, we found that at proper conditions the use of whole cells as biocatalyst gave a higher conversion of propyl gallate, and this method could also reduce the cost and the time for the immobilization process. In this study, mycelium-bound tannase from A. niger was directly employed to investigate the synthesis of propyl gallate in organic solvents. The esterification scheme is shown in Scheme 1.

Materials and methods

Microorganism, media, and culture conditions

Aspergillus niger (China General Microbiological Culture Collection Center, No. 3.315) was grown in 500-ml Erlenmeyer flasks containing 100 ml of medium containing (g/l) (tannic acid, 20; starch, 4; saccharose, glucose 21; soybean flour, 9; K2HPO4 1; NH4NO3 1; KCl, 0.5; MgSO4, 0.5; CaCl2, 0.2; FeSO4, 0.01) at pH 6.0, 30 °C 180 rev/min. Suspensions of spores (1 × 107) were used as inocula. After cultivation for 72 h, the mycelia were collected by centrifugation, washing thoroughly with 0.145 M NaCl solution and dried.

pH optimization

After washing thoroughly with 0.145 M NaCl solution, the mycelia were suspended in 0.1 M of acetic acid buffer, glycine–HCl buffer or boric acid–NaOH–calcium phosphate–acetic acid buffer at different pH values for 1 h. Thus, the pH of the mycelia was adjusted to the corresponding pH value.

Determination of water content of the mycelia

The mycelia were either freeze-dried or vacuum-dried for 24 h. At regular intervals, part of the mycelia was taken out and weighed; and the difference between the initial weight and the freeze-dried or vacuum-dried weight of the mycelia was measured. This determined the water content of the mycelia. Significant differences (p < 0.05) were measured.

Enzymatic reactions

Unless stated otherwise, the typical enzymatic reaction was carried out by adding 0.35 g mycelia (0.1 g mycelial dry weight, 71.4% water content, pH 3.6) to the reaction mixture, which consisted of 5.56 mM gallic acid, 7.3% (v/v) 1-propanol and 10 ml benzene in 25 ml glass flasks shaken at 40 °C 200 rev/min for 24 h. All solvents had been dried over 3 Ǻ molecular sieves for 72 h. The molar conversion was defined as (molar of propyl gallate/molar of the initial fed gallic acid) × 100%. The initial reaction rate was defined as the amount of propyl gallate formed by 1 g of dry weight of mycelium per hour under the assay conditions.

Analytical procedures

Analyses were performed on a Waters 2,690 HPLC with a LiChrospherC18 column. Samples (200 μl) removed from the systems were vacuum evaporated, diluted with 0.15 mM ethyl p-hydroxybenzoate in methanol and a volume of 20 μl was injected into the HPLC. The solvent system/mobile phase comprised of methanol : water in the ratio of 55:45 adjusted to pH 3 with phosphoric acid at a flow rate of 1 ml/min for 8 min. The ethyl p-hydroxybenzoate was the internal standard. The absorbance analysis was carried out at 275 nm. The reaction product was calculated from a calibration curve plotted (Y = 0.03144X-0.00194, R = 0.9999) as propyl gallate concentration (X, μg/ml) versus the ratio (Y) between propyl gallate peak area and internal standard peak area.

Qualitative analysis was performed by thin layer chromatography. The coating was silica gel-G. The solvent system was chloroform: methanol in the ratio of 8:2 with two drops of glacial acetic acid added per 100 ml of solvent. Visualization was by iodine vapor. The standard value of R t/R f of the peaks/spots was 4/3. All the assays were done in triplicate and significant differences (p < 0.05) were measured.

Results and discussion

Effect of solvent hydrophobicity

In biocatalytic reactions, proper selection of organic solvent is essential. One of the most important criteria for solvent selection is biocompatibility. In general, there is no single parameter for solvent polarity that can consistently correlate the enzyme activity with the hydrophobicity of solvents. Among the parameters of solvent polarity, the logarithm of partition coefficient of the solvent (log P) between octanol and water is recommended as the best parameter relating enzyme activity to solvent nature (Lanne et al. 1987.). The series of solvents chosen for these experiments covers a wide range of log P values (see Table 1). The mycelia catalyzed very low conversion in highly polar solvents, such as N, N-dimethylformamide, acetone 1-propanol, and pyridine. The poor enzyme activity may be the result of the polar solvents incorporating within membrane lipids, which may cause disruption of essential membrane functions, inactivation or denaturation of mycelium-bound enzymes, and at high concentrations lysis of the cells (Inoue and Horikoshi 1991; Sikkema et al. 1994; Vermü et al. 1993). The highest yield was reached at 25.9% molar conversion in benzene (log P 2), although with an increase in the log P value, the organic solvent will be less harmful to biocatalysts. When n-hexane (log P 3.4), octane (log P 4.5), and dodecane (log P 6.6) were used as reaction medium, they did not provide encouraging results. Thus, the more hydrophobic the medium, the lower the tannase activity. Synthesis of propyl gallate by microencapsulated mycelium-bound tannase and microencapsulated tannase also showed the same relationship between yields and log P and showed the highest activity in benzene (Yu et al. 2004; Yu and Li 2005). While the log P value could not be considered the only parameter responsible for the extent of conversion, some investigators proposed a solvent toxicity model based on the notion of a solvent critical membrane concentration that was independent of the solvent type. Beyond this concentration, whole-cell catalytic activity is lost (Bassetti et al. 1995; Osborne et al. 1990). The molar conversion of propyl gallate was still low in benzene. Further experiments were carried out to explore the optimum reaction conditions for mycelium-bound tannase esterfication.

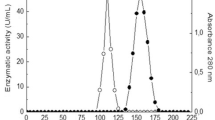

Time-course profile of propyl gallate synthesis in organic media

The time course of the synthesis of propyl gallate in benzene by mycelium-bound tannase is shown in Fig. 1. The initial reaction rate rose quickly in the first hours of incubation, and the reaction reached equilibrium at about 24 h. Thus, the reaction terminus in further experiments was determined at 24 h. In the control test, no product could be detected with the deactivated mycelia, which were boiled for 20 min.

Effect of biocatalyst concentration

As shown in Fig. 2, the initial reaction rate increased linearly as a result of increasing enzyme concentration from 0.025 to 0.1 g mycelial dry weight per 10 ml benzene. However, further increasing the amount of mycelia, the initial reaction rate increased only slowly. The experimental results suggest that at high enzyme concentration above 0.1 g, the reaction suffered from the internal mass transfer resistances. The molar conversion was constant at the enzyme concentration of 0.025–0.1 g mycelial dry weight per 10 ml benzene, while it decreased with more catalyst due to the internal mass transfer resistances. This would lead to a lack of the substrate at the active site of enzyme and difficulty in maintaining uniform suspension of the mycelia. The optimum enzyme concentration should be 0.1 g mycelial dry weight per 10 ml benzene.

Effect of the concentrations of mycelium-bound tannase on the synthesis of propyl gallate. (■) Initial rates; (▲) molar conversion. Reaction conditions: 5.56 mM gallic acid, 7.3% (v/v) 1-propanol and 10 ml benzene, the mycelia with 60% (w/w) water content, incubated for 24 h at 40 °C, pH 5.0, 200 rev/min

Effect of speed of agitation

External mass transfer limitations can be prevented if adequate hydrodynamic conditions are selected. To assess the extent of external diffusion resistance in the present study, the effect of agitation speed on reaction rate was studied over the range of 100–250 rev/min. The experimental result (see Fig. 3) showed that external mass transfer was apparently not the limiting factor at stirring speeds of 200 rev/min or above. Thus 200 rev/min was taken as the optimum speed and used in all further studies.

Effect of type of mycelial preparation and water content of the mycelia

The role of water in the esterification reaction in organic solvents is one of the major areas of question in non-aqueous enzymology. It has been proven that water molecules provide an essential ingredient for the enzyme to retain the activity, while the enzyme also catalyzes the hydrolysis reaction, which mitigates successful synthesis of esters. In order to control the water content of the mycelia, the mycelium-bound tannase was freeze-dried or vacuum-dried for a period of time. The experimental results (see Fig. 4) showed that the activity of freeze-dried mycelia was much lower than that of vacuum-dried mycelia, probably owing to the disrupted construction of the mycelium-bound enzyme occurring more harshly because of the freeze-dried method. However, when the mycelia were completely dehydrated by both methods, no synthesis reaction occurred. With vacuum-dried mycelia the maximum yield (27%) was gained at water content of 71.4%. The results suggest that the mycelia preparation type and a proper amount of water are essential for esterification by mycelium-bound tannase in organic solvent. Lack of water would cause excessive cell dehydration or the loss of the water barrier between the biocatalyst and the solvent. On the other hand, too much water initiates the reverse hydrolysis reaction and decreases the net production of esters. However, researches have reported that enzymes in the presence of just a little amount of water showed good activity (Converti et al. 2002; Molinari et al. 2000). Therefore it may be concluded that not all enzymes could remain in their active conformation after being completely dried. An appropriate amount of water will help the enzyme conformation between the enzyme and proteins, thereby creating a more “effective” enzyme concentration.

Effect of protonation state of mycelium-bound tannase

The correct protonation state of side chains of amino acid residues of enzymes is important in non-aqueous media as well as in aqueous media (Gupta and Ipsita 2004). In this research, three different types of buffer were used for pH tuning. After pH tuning the mycelium-bound tannase were applied to the synthesis of propyl gallate in benzene. As shown in Fig. 5, these three types of buffer showed different buffering ability in organic solvent and the mycelia treated with 0.1 M pH 3.6 acetic acid buffer presented the highest enzyme activity (33.8% molar conversion). The activity of tannase buffered by the organic acid buffer, acetic acid buffer, was higher than that buffered by the boric acid buffer or the amino acid buffer, which was probably the result of different kinds of buffer having different effects on the enzyme activity, although these buffers were at the same pH and concentration. Schumann et al. (2001) also observed such effects and the mechanism of how the buffers affect the enzyme activity need to be further investigated. On the other hand, after the pH-tuning, mycelia were submerged in the organic reaction media, the protonation state of the enzyme was probably changed due to the acidic substrate, gallic acid (Martinelle and Hult 1995; Maugard et al. 1998). Additionally, organic solvents would also cause changes in the acid-base conditions of the enzyme. In solvents of low dielectric constant, opposite charges interact more strongly, as there is less shielding between them. Therefore, counterions are more closely associated with their opposite charges and their presence must be taken into consideration in determining the protonation state of an enzyme (Harper et al. 2000). Researchers have reported that solid-state acid-base buffers added in organic media could control enzyme activity (Dolman et al. 1997; Zacharis et al. 1997). We also attempted to add solid-state acid–base buffers, such as TES/Na+ salt, MOPS/Na+ salt, MES/Na+ salt, and PIPES/Na+ salt, to control the protonation state of mycelium-bound tannase. While the experimental results showed almost no effects on the tannase activity, probably the protonation state of mycelium-bound enzyme is not likely to be affected in the organic reaction media, or it is necessary to attempt other types of acid-base buffers.

Effect of pH on the synthesis of propyl gallate. (▲) Acetic acid buffer; (■) boric acid–NaOH–calcium phosphate–acetic acid buffer; (●) glycine–HCl buffer. Reaction conditions: 5.56 mM gallic acid, 7.3% (v/v) 1-propanol and 10 ml benzene, 0.35 g mycelia (0.1 g mycelial dry weight, 71.4% (w/w) water content), incubated for 24 h at 40 °C, 200 rev/min

Effect of reaction temperature

Based on the pre-experiment, the range of the reaction temperature was selected from 30 to 50 °C, out of which the enzyme activity was quite low. As shown in Fig. 6, the yield of propyl gallate for the mycelium-bound tannase esterification in benzene increased with increasing temperature from 30 to 40 °C, and resulted in a maximum of around 40 °C. At higher reaction temperatures the yield of product decreased and the initial reaction rate rose more quickly. The reaction equilibrium was reached earlier at about 18 h than that at low temperature. These results indicated that at high temperature tannase inactivated faster with time and at a temperature around 40 °C tannase showed both good activity and stability. Therefore, 40 °C was selected as the optimum reaction temperature for the following experiments.

Effect of reaction temperature on the synthesis of propyl gallate. (▲) 40 °C, (□) 35 °C, (●) 30 °C, (△) 45 °C, (◯) 50 °C. Reaction conditions: 5.56 mM gallic acid, 7.3% (v/v) 1-propanol and 10 ml benzene, 0.35 g mycelia (0.1 g mycelial dry weight, 71.4% (w/w) water content), incubated for 48 h at pH 3.6 200 rev/min

Effect of substrate concentrations

The effects of 1-propanol and gallic acid concentrations were investigated by varying one of the substrate’s concentrations, whereas the other was held constant. As shown in Fig. 7, the initial rate was nearly constant at 1-propanol concentration varied from 3.6 to 12.7% (v/v) because even the lowest 1-propanol concentration was far beyond the concentration of another substrate, gallic acid. If the amount of 1-propanol was decreased further, gallic acid could not be dissolved completely. The yield of product propyl gallate increased as a result of increasing the concentration of 1-propanol and reached a maximum at 7.3% 1-propanol, then gradually decreased at higher concentration of 1-propanol. Increasing the amount of 1-propanol from 3.6 to 7.3% (v/v) favored the yield of product, which is probably due to the fact that the propyl gallate produced could be transformed from the microenvironment of enzyme to the reaction media in time, and thus could avoid the inhibition effect on enzyme activity. At higher alcohol concentration above 7.3% (v/v), the toxic effect of 1-propanol, causing disruption of essential membrane functions and denaturation of enzyme, became notable and resulted in the decreased yield of propyl gallate. Similarly, gallic acid (see Fig. 8) also showed an inhibiting effect on the reaction. The maximum yield (33.8%) was achieved at a gallic acid concentration of 5.56 mM.

Effect of 1-propanol concentration on the synthesis of propyl gallate. (▲) Initial reaction rate; (■) yield of propyl gallate. Reaction conditions: 5.56 mM gallic acid and 10 ml benzene, 0.35 g mycelia (71.4% (w/w) water content, 0.1 g mycelial dry weight), incubated for 24 h at 40 °C, pH 3.6, 200 rev/min

Effect of gallic acid concentration on the synthesis of propyl gallate. (▲) Initial reaction rate; (■) yield of propyl gallate. Reaction conditions: 7.3% (v/v) 1-propanol and 10 ml benzene, 0.35 g mycelia (0.1 g mycelial dry weight, 71.4% (w/w) water content), incubated for 24 h at 40 °C, pH 3.6, 200 rev/min

Effect of water depressor

Although we have carefully controlled the water content of the mycelium, a small amount of water produced during the esterification process would affect both the equilibrium and the enzymatic activity. In order to reduce the negative effect of the water produced, after equilibrium, water depressor was added into the reaction medium to reduce the water content. Among various kinds of water depressor, molecular sieve and anhydrous sodium sulfate showed the best results. By using these water depressors the yield increased by 5.1 and 10%, respectively, in the synthesis of propyl gallate by microencapsulated tannase (Yu et al. 2004). Thus, in this research we chose anhydrous sodium sulfate and molecular sieve as the water depressor. With 5% (w/v) anhydrous sodium sulfate added, the yield of propyl gallate was increased from 33.8 to 42.9% after 24 h reaction. However, with the addition of the molecular sieve the equilibrium did not shift to esterification. It may be that although the molecular sieve reduced the water content, it may simultaneously have a negative effect on the mycelium itself. On the other hand, in the microencapsulated tannase reaction system, anhydrous sodium sulfate could react with the immobilization matrix and the vesicles became slightly swollen. Thus, it is important to choose different water depressor at different conditions. Researchers have also used glycerol, sucrose, sorbitol, and NaCl as water depressors to enhance the synthesis of the cephalosporin, cephalexin (Hyun and Kim 1993).

Effect of surfactants and denaturants

Enzyme activity and selectivity can be improved by directly adding denaturants or surfactants into non-aqueous reaction media (Ueji et al. 2001; Guo and Clark 2001). The effects of surfactants and denaturants on tannase were studied by the addition of 0.5% (w/v) of them into the reaction media. The results showed that the yields of propyl gallate were increased significantly with the addition of surfactants, which were 65% for poly (ethylene glycol)-10,000 (PEG-10,000), following 60% for Triton X-100 and 55% for PEG-1,000. However, the enzyme activity was completely lost by the addition of denaturants, such as sodium dodecyl sulfate (SDS) and dimethyl sulphoxide (DMSO). Ueji et al. (2001) found that the addition of SDS increases the E-value from 3.8 to 320 for the Candida rugosa lipase-catalyzed esterification in di-isopropyl ether. The enhanced enantioselectivity may be attributed to the increased conformational flexibility of lipase triggered by the addition of SDS. For mycelium-bound tannase, denaturants may distort the enzyme conformation harshly, and thus may induce the decrease of enzyme activity and stability. On the other hand, surfactants such as Triton X-100 and PEG, may react with enzyme mildly and improve the activity and stability of enzyme.

Synthesis of different gallic acid esters in organic media

As shown in Table 2, the maximum yields were 62% of 1-butyl gallate and 51% of iso-butyl gallate, followed by propyl gallate and pentyl gallate. However yields were almost undetectable with methanol, ethanol, tertiary butanol 1-hexanol, and 1-octanol. Similar enzyme specificity for the alcohol portion of the ester was also observed for immobilized tannase (Yu et al. 2004). The synthesis activity with tertiary butanol was quite low, probably due to steric hindrance. The low conversion with more polar alcohols such as methanol and ethanol is due to their capacity of removing water from the protein hydration shell, leading to enzyme inactivation. When increasing hydrophobicity of the reaction medium, the yields decreased dramatically. Because hydrophobic alcohols with long chains, such as 1-hexanol or 1-octanol, could not solvate gallic acid efficiently and were too big to establish favorable interactions with the active site of enzyme.

Conclusions

The results showed that the direct use of mycelium-bound tannase achieved more promising results than immobilized free tannase (49.4% yield of propyl gallate) (Yu et al. 2004) or microencapsulated mycelium-bound tannase (36.2% yield of propyl gallate) (Yu and Li 2005). It suggests that the mycelia could also protect the mycelium-bound tannase from the harshness of organic solvents in the same way that an immobilization matrix does, moreover the direct use of mycelia could avoid costly and time-consuming purifications. The tannase activity was high in benzene but benzene is expensive and toxic, and could probably be substituted by a more suitable organic solvent with log P of around 2 for application, and the yield (65%) of propyl gallate by mycelium-bound tannase in the present system was lower than that of 86% biosynthesized by purified tannase (Sharma and Gupta 2003), which might be enhanced by improving A. niger tannase activity through biocatalyst engineering, such as rational design, or directed evolution.

References

Barthomeuf C, Regerat F, Pourrat H (1994) Improvement in tannase recovery using enzymatic disruption of mycelium in combination with reverse micellar enzyme extraction. Biotechnol Tech 8:137–142

Bassetti L, Hagendoorn M, Tramper J (1995) Surfactant-induced non-lethal release of anthraquinones from suspension cultures of Morinda citrifolia. J Biotechnol 39:149–155

Chae SK, Yu TJ (1983) Experimental manufacture of acron wine by fungal tannase. Hanguk Sipkum Kwahakhoechi 15:326–332

Coggon P, Sanderson GW (1972) Manufacture of instant tea. Patent Ger. offen 2.304 073

Converti A, Del Borghi A, Gandolfi R, Molinari F, Palazzi E, Perego P, Zilli M (2002) Simplified kinetics and thermodynamics of geraniol acetylation by lyophilized cells of Aspergillus oryzae. Enzyme Microb Technol 30:216–223

Dolman M, Halling PJ, Moore BD (1997) Functionalized dendritic polybenzylethers as acid/base buffers for biocatalysis in non-polar solvents. Biotechnol Bioeng 55:278–282

Gaathon A, Gross Z, Rozhanski M (1989) Propyl gallate: enzymatic synthesis in a reverse micelle system. Enzyme Microb Tech 11:604–609

Guo Y, Clark DS (2001) Activation of enzymes for non-aqueous biocatalysis by denaturing concentrations of urea. Biochim Biophys Acta 1546:406–411

Gupta MN, Ipsita R (2004) Enzymes in organic media forms, functions and applications. Eur J Biochem 271:2575–2583

Hadi TA, Banerjee R, Bhattacharya BC (1994) Optimization tannase biosynthesis by a newly isolated Rhizopus oryzae. Bioprocess Eng 11:239–243

Harper N, Dolman M, Moore BD, Halling PJ (2000) Acid-base control for biocatalysis in organic media: new solid-state proton cation buffers and an indicator. Chem Eur J 6:1923–1929

Hyun CK, Kim JH (1993) Enhancement effect of water activity on enzymatic synthesis of cephalexin. Biotechnol Bioeng 42:800–806

Inoue A, Horikoshi K (1991) Estimation of solvent-tolerance of bacteria by the solvent paramerer log P. J Ferment Bioeng 71:194–196

Lanne C, Boeren S, Vos K, Veeger C (1987) Rules for optimization of biocatalysis in organic solvents. Biotechnol Bioeng 30:81–87

Lekha PK, Lonsane BK (1997) Production and application of tannin acylhydrolase: state of art. Adv Appl Microbiol 44:215–260

Martinelle M, Hult K (1995) Kinetics of acyl transfer reactions in organic media catalysed by Candida antarctica lipase B. Biochim Biophys Acta 1251:191–197

Maugard T, Remaud-Simeon M, Monsan P (1998) Kinetic study of chemoselective acylation of amino-alditol by immobilized lipase in organic solvent: effect of substrate ionization. Biochim Biophys Acta 1387:177–183

Molinari F, Gandolfi R, Converti A, Zilli M (2000) Mycelium-bound carboxylesterase from Aspergillus oryzae: an efficient catalyst for acetylation in organic solvent. Enzyme Microb Technol 27:626–630

Osborne SJ, Leaver J, Turner MK, Dunnill P (1990) Correlation of biocatalytic activity in an organic-aqueous two-liquid phase system with solvent concentration in the cell-membrane. Enzyme Microb Technol 12:281–291

Schumann G, Dominick HC, Hellmann D, Klauke R, Mockesch M, Stekel H, von Schenck H, Kraft M, Nagel R, Hanseler E (2001) Alkaline phosphatase activity: new assay for the reflotron system. Results of the evaluation in eight clinical laboratories. Clin Chem Lab Med 39:71–78

Sharma S, Gupta MN (2003) Synthesis of antioxidant propyl gallate using tannase from Aspergillus niger van teighem in non-aqueous media. Bioorg Med Chem Lett 13:395–397

Sikkema J, Weber JJ, Heipieper HJ, de Bont JAM (1994) Cellular toxicity of lipophilic compounds: mechanisms, implications, and adaptations. Biocatalysis 10:113–122

Toth G, Hensler D (1952) The enzymatic synthesis of gallic acid derivatives. Acta Chim II 10:209–212

Ueji S, Nishimura M, Kudo R, Matsumi R, Watanabe K, Ebara Y (2001) A dramatic improvement of enantioselectivity of lipase in organic solvents by addition of aqueous SDS: a close correlation between enantioselectivity and conformational flexibility of lipase. Chem Lett 30:912–913

Vermü M, Sikkema J, Verheul A, Bakker R, Tramper J (1993) Toxicity of homologous series of organic solvents for the gram-positive bacteria Arthrobacter and Nocardia sp. and the gram-negative bacteria Acinetobacter and Pseudomonas sp. J Biotechnol Bioeng 42:747–758

Weetal HH (1985) European Patent Application 0137601

Yamada D, Tannaka T (1972) Wine making using tannase in fermentation process. Patent Germ Offen 2.224 100

Yu XW, Li YQ, Wu D (2004) Enzymatic synthesis of gallic acid esters using microencapsulated tannase: effect of organic solvents and enzyme specificity. J Mol Catal B Enzym 30:69–73

Yu XW, Li YQ (2005) Microencapsulated mycelium-bound tannase from Aspergillus niger: an efficient catalyst for esterification of propyl gallate in organic solvents. Appl Biochem Biotechnol 126:177–188

Zacharis E, Moore BD, Halling PJ (1997) Control of enzyme activity in organic media by solid-state acid-base buffers. J Am Chem Soc 119:12396–12397

Acknowledgments

This research work was supported by a grant from Natural Science Fund of China (No. 20,172,046). We would like to thank Dr. Birnie from New Zealand for his editing of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, XW., Li, YQ., Zhou, SM. et al. Synthesis of propyl gallate by mycelium-bound tannase from Aspergillus niger in organic solvent. World J Microbiol Biotechnol 23, 1091–1098 (2007). https://doi.org/10.1007/s11274-006-9338-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-006-9338-7