Abstract

Petroleum hydrocarbons are applied in various energy activities. If accidents happen, they may result in environmental contamination, especially in soil. Petroleum hydrocarbons have low evaporation rates and are adsorbed on the soil surface, making it necessary to treat contaminated soil before the pollutants spread to other areas. Soil washing with surfactant solution is a method used to treat petroleum hydrocarbon contamination. The process relies on surfactant properties which reduce surface tension and desorb diesel from soil particles prior to flushing out with water. The relationship between efficiency of diesel extraction from contaminated soil and factors of both single surfactants (Span20, Tween20, Tween80, Dehydol LS9) and mixed surfactants (Span20+Tween20, Span20+Tween80, Span20+Dehydol LS9) were investigated including hydrophile-lipophile balance (HLB) and interfacial tension (IFT) to select a suitable surfactant. Diesel was analyzed by GC-FID. Findings revealed that extraction efficiency significantly increased when the HLB of the surfactant increased in every solution pair (p = 0.05). Span20+Dehydol LS9 solution with HLB 12 showed the lowest IFT (17.767 ± 0.013 mN/m) and the highest diesel extraction efficiency (66.2%). The water washing process, repeated twice after washing with 1% (w/v) Span20+Dedydol LS9, resulted in less toxicity on germination and growth of tomato, rice, and green bean compared with diesel washing solution and fresh washing solution. Diesel-contaminated soil washing with mixed surfactant is an interesting alternative as an environmentally friendly soil treatment.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Petroleum hydrocarbons are important as fuel for transportation; however, they cause environmental problems as a result of spillage, especially low evaporated oil such as diesel (Safehian et al. 2018). The contamination impacts the ecotoxicity of living organisms such as earthworms, microorganisms (Tang et al. 2011), and plants (Banks and Schultz 2005). Contaminated soil requires remediation to control environmental risk. Soil washing is a popular approach to remove contaminants adsorbed on soil particles (Bai et al. 2019; Peters et al. 1992; Guan et al. 2018). The removal of oil from soil by an aqueous solution involves replacement of soil/oil interfacial tension (IFT) with soil/water IFT and an oil/water IFT.

Surfactants can reduce IFT between different polar phases because their structure consists of both hydrophilic and lipophilic components which are able to cooperate physiochemically with both polar and less polar compounds (Rosen 2004; Peters et al. 1992). In the soil washing process, surfactants decrease IFT between the oil/water interface and soil/water interface. This causes a reduction of soil/oil IFT and enhances soil washing by mechanical extraction (Tadros 2005; Ali et al. 2019). The presence of a nonionic surfactant can enhance IFT lowering and the extent of solubilization of insoluble organic compounds into water (Phasukarratchai et al. 2016; Xiarchos and Doulia 2006; Jafvert et al. 1994; Takeuchi et al. 2014). The hydrophile-lipophile balance (HLB) of a surfactant is a measure of the degree to which it is hydrophilic or lipophilic as a property for rapidly selecting suitable nonionic surfactants in any application. High HLB surfactants are more effective for emulsifying the oil phase in water than low HLB surfactants (Rosen 2004; Tadros 2005). HLB is in the range of 3–6 for water-in-oil emulsions, and 8–18 for oil-in-water emulsions (Tadros 2005). However, there are numerous nonionic surfactants with various hydrophobic and hydrophilic structures. A surfactant with a reasonable HLB is required for diesel soil washing.

In theory, phase behavior appearance is an indication of emulsion type; for example, microemulsion is clear, macroemulsion shows a dispersed turbid phase, and nanoemulsion is blue-white and translucent (Rosen 2004). The most desired emulsion type for oil extracting from solid is microemulsion with Winsor type I (oil in water emulsion) and, especially Winsor type III (the middle phase between surfactant solution and organic phase) (Damrongsiri et al. 2010) because the oil can be desorbed from soil with ultralow IFT (< 10−2 mN/m) (Rosen et al. 2005). Both emulsion types can trap the extracted oil within the micelle which prevents the free oil phase that can re-adsorb on the solid (Rongsayamanont et al. 2017; Rosen 2004). Moreover, this microemulsion enhances the oil extraction efficiency from the solid phase (Arpornpong et al. 2018; Hernandez et al. 2019; Pookboonmee et al. 2018). Microemulsion is not easily formed with only one surfactant type and may require other additives such as salts, co-solvent, or mixed surfactants (Damrongsiri et al. 2013; Rosen 2004).

Thus, only nonionic surfactants were chosen for diesel soil washing in this research. Three mixed surfactants series were investigated including Span20/Dehydol LS9 mixture, Span20/Tween20 mixture, and Span20/Tween80 mixture. Each surfactants series was mixed based on HLB value in the range 9 to 13 (oil-in-water aspect). Phase behavior and IFT measurement were studied to assess the interaction between diesel and mixtures of nonionic surfactant solutions. The nonionic surfactant mixtures were investigated for diesel extraction efficiency from diesel-spiked soil to select a suitable HLB value of surfactants mixture. The diesel-spiked soil concentration of 20,000 mg/kg and 40,000 mg/kg was selected based on the diesel contamination in soil washing study with surfactant in the range of 100 to 40,000 mg/kg (Karthick et al. 2019). Moreover, the potential for reusing surfactant solution was also investigated together with seed germination toxicity with rice, tomato, and green bean for the selected surfactant solution, the diesel-soil washing solution, the 1st and the 2nd cycles of water diesel-soil washing solutions.

2 Materials and Methods

2.1 Materials

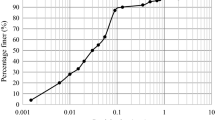

The topsoil used in this study was sampled between 10 and 30 cm depth by the roadside of Phetchakasem Road, Thapraya, Nakornchaisri, Nakhon Pathom Province, Thailand (geographical coordinates: 13° 47′ 55.4″ N, 100° 09′ 59.1″ E). This road is the main transportation route connected between the Bangkok Metropolis and Southern of Thailand; thus, there is a high risk to an oil spill from the logistic accident. Moreover, there is an importance agricultural economic zone around the roadside at this point. The soil sample was collected in December 2017 and immediately measured for moisture content. The soil was air dried 1 month before analysis of soil properties. Soil particle distribution was determined as 17.28% clay, 65.03% sand, and 17.69% silt (hydrometer method) with pH = 8.4, 29.92% moisture (1:1 soil-water ratio), 2.08% soil organic matter (Walkley and Black method), and 1.1 cmol/kg (NH4OAc, pH 7.0).

Commercial diesel as Shell V-Power was bought at a Shell gas station. Absolute ethanol (99.9%) and dichloromethane were obtained from QRëC at analytical grade.

Four nonionic surfactants were used including sorbitan monolaurate or Span 20 (S20), polyoxyethylene sorbitan monolaurate or Tween 20 (T20), polyoxyethylene sorbitan monooleate or Tween 80 (T80), and fatty alcohol C12–14 with 9 mol of ethylene oxide or Dehydol LS9 (LS9). S20 was bought from Sigma-Aldrich. Tween surfactants contained the same structure of hydrophilic polyoxyethylene (20) sorbitan with a different hydrophobic alkyl chain. T20 and T80 were bought from Ajax Finechem. LS9 as commercial grade was supplied by Thai Ethoxylate Co., Ltd. Chemical structures and HLB values of these surfactants are shown in Table 1.

2.2 Diesel-Contaminated Soil Preparation

One hundred grams of dried soil was spiked with 2 g of diesel in a 250-mL Duran glass bottle to achieve the diesel concentration at 20,000 mg/kg. The spiked soil was kept in the closed bottle for 2 days before the soil washing experiment to screen for the suitable surfactant solution. The diesel spiked soil was prepared at 40,000 mg/kg for solution study reuse and seed germination experiments.

2.3 Surfactant Preparation

Single surfactants (S20, LS9, T20, and T80) solutions and mixed surfactants (S20/LS9, S20/T20, and S20/T80) solutions were prepared at equal 1%(w/v) concentration in tap water. S20 as the lowest HLB was mixed with T20, T80, or LS9 to prepare surfactant solutions with mixed HLB values of 9, 10, 11, 12, and 13. Mixed HLB solutions were prepared by weight basic following Eq. 1 (Griffin 1954; Tadros 2005).

where HLBmix is the HLB value of two surfactants mixtures, X1 and HLB1 are the mass fraction and the HLB value of surfactant 1, and X2 and HLB2 are the mass fraction and the HLB value of surfactant 2. The mass fraction of each surfactant series is shown in Table 2.

2.4 Diesel-Surfactant Phase Behavior Observation

The single and mixed nonionic surfactant solutions were gently mixed with diesel at 1:1 by volume ratio in a screw cap glass tube. Samples were kept at room temperature for 1 month to ensure realization of the equilibrium phase. Phase behavior was visually observed as separation of diesel phase, aqueous phase, and middle phase. The middle phase represented the emulsion of diesel and surfactant with potentially low IFT system between surfactant solution and diesel. The IFT values between each surfactant solution and diesel were measured by a SCAT tensiometer (Dataphysics Instruments GmbH, model DCAT 11) at 25 °C with the Wilhelmy plate which is following ASTM D1331-14: Method D (ASTM 2014).

2.5 Diesel Soil Washing by Surfactant Solution Condition

A total of 1.5 g of diesel-spiked soil with 15 mL of surfactant solutions in the closed centrifuge tube were extracted with a 250 rpm-orbital shaker for 60 min at room temperature (28–30 °C). Then, the samples were centrifuged to separate the washed soil from the solution at relative centrifuge force (RCF) 3000×g for 15 min. The soil was analyzed for remaining diesel to calculate the diesel extraction efficiency. Highest diesel extraction efficiency was selected for further experiments including of the reuse solution test, the water washing, and the seed germination test. The reuse surfactant solution test was performed as the same procedure, using a new spiked soil sample with the used surfactant solution. Water washing was the soil cleaning step after the diesel was extracted from soil by the selected surfactant solution. The extracted soil was washed with tap water in two-cycle with the same extraction condition. Diesel extraction efficiency from the 1st and the 2nd reuse surfactant solution and the 1st and the 2nd cycle of water diesel-soil washing solutions were analyzed.

2.6 Diesel Quantitation

Initial soil and extracted soil by each surfactant solution were analyzed for diesel content. Residual soil and the 1.5 g of spiked soil were extracted with 20 mL of dichloromethane and 5 mL of ethanol in a 40-mL PTFE screw cap glass vial using an orbital shaker at 250 rpm for 4 h. The extracted samples were analyzed by GC-FID (Agilent-6890N) with an Agilent HP-5 5% phenyl methyl siloxane column. Hydrogen gas flow rate was 20 mL/min and sample injection volume was 2 μL. The temperature was controlled at 40 °C for 5 min, then increased to 300 °C at 15 °C/min and kept at 30 °C for 5 min. The external standard of dissolving diesel in dichloromethane was used for preparing the calibration curve. Diesel extraction efficiency was calculated from the diesel mass fraction reduction after extraction by a surfactant solution from the initial spiked soil.

2.7 Seed Germination Toxicity Assay

The seed germination toxicity of the diesel washing solution was assessed on seed germination and root elongation of three seed types including rice (Oryza sativa L.), tomato (Solanum lycopersicum), and green bean (Vigna radiata) following the method described by Pele et al. (2019)). Three types of seeds were selected based on the high population growth in Thailand. The testing solution included the selected surfactant solution after diesel-soil washing, the 1st and the 2nd cycles of water diesel-soil washing solution compared to unwashed selected surfactant solution and tap water as a control. The experiment was determined using sterilized Petri dishes (8 cm × 8 cm) covered with filter paper. All seeds were pretreated with 6% sodium hypochlorite for 10 min and washed with water several times. Ten seeds were placed on the filter paper with 5 mL of the test solution and incubated in the dark at room temperature. Relative seed germination (RSG), relative root elongation (RRE), and germination index (GI) were calculated after 5 days of incubation following Eqs. 2–4, respectively (Luna et al. 2013);

where Ngerm-test and Ngerm-control are no. of seeds germinated in the test and control solution, respectively. Lroot-test and Lroot-control are mean root length in the test and control solution, respectively.

2.8 Statistical Testing

All experiments were performed in triplicate and average and standard deviation were calculated for each set. One-way analysis of variance (ANOVA) was applied to compare the significance of different conditions at p < 0.05 using the SPSS (Statistical Product and Service Solutions) software package, version17.0.

3 Results and Discussion

3.1 Diesel-Surfactant Phase Behavior and Interfacial Tension

Phase behavior observation between diesel and surfactant in water solution as the preliminary method was followed to determine the potential surfactant system as shown in Fig. 1. The results showed that the same HLB in different mixture series showed different phase behavior. The aqueous solution (denser phase) appeared turbid in all mixtures at HLB ranging 9–10 (demonstrating macroemulsion), and a translucent solution was shown when HLB was higher than 11 (demonstrating microemulsion). For single surfactants LS9, T80, and T20, the aqueous phases were clear as shown in Fig. 1a–c, respectively. The mixed S20 with LS9 solution at HLB equal to 11 and 12 were observed as the middle phase between diesel and the aqueous phase (Fig. 1a). By contrast, the mixed S20 with T20 and with T80 demonstrated an unclear zone of middle phase in the HLB range 10–12 (Fig. 1b, c).

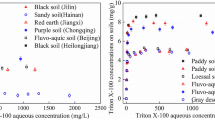

When considering the diesel-surfactant IFT at 25 °C, 1% (w/v) single nonionic surfactant solutions of S20, LS9, T20, and T80 gave IFT with diesel equal to 30.11 mN/m, 30.73 mN/m, 31.67 mN/m, and 31.55mN/m, respectively, while IFT between water and diesel was 38.33 mN/m. The mixed S20 with LS9 clearly demonstrated the synergism effect of IFT lowering, whereas the mixed S20 with T20 or T80 did not (Fig. 2a). The lowest IFT of this series was 17.767 mN/m at HLB = 12 for mixed S20/LS9 solution (Fig. 2a), similar to phase observation.

Only S20/LS9 at HLB = 11 and 12 showed a layer between diesel and the solution (middle phase). The middle phase of S20/LS9 possibly occurred because of the lowest IFT between the surfactant solution and diesel phase, considered as the higher potential of washing diesel from contaminated soil. However, the IFT was still higher than ultralow IFT (< 10−2 mN/m) and the aqueous phase in phase observation was not a clear solution. These results demonstrated that the mixture between diesel and surfactant without any additive in water was not a microemulsion in this study.

3.2 Diesel-Soil Washing by Surfactant Solution

When considering diesel extraction from soil, water alone can extract diesel from contaminated soil at about 6.0%. Surfactant solutions enhanced diesel extraction from soil, especially LS9 solution (Fig. 2b). For single nonionic surfactant solutions, LS9 (HLB = 13.4) was the highest, followed by T80 (HLB = 15) and T20 (HLB = 16.7), respectively. Although mixed surfactants at HLB range 9 to 13 in this study were in the range of oil-in-water emulsion as a guideline for surfactant application, the different nonionic surfactant types at similar HLB showed disparate efficiency on diesel extraction from soil (Fig. 2b). The single T20 and T80 surfactant solutions extracted diesel better than when mixed with S20, similar to the IFT results that the mixed solution cannot reduce IFT in significant. For the S20/LS9 mixture, even though the IFT between diesel and S20/LS9 solution at HLB = 12 was the lowest, diesel extraction efficiency increased when HLB of mixed surfactants increased until HLB = 12. These results were not significantly different from HLB = 13 and single LS9 solution (p = 0.05).

Other research results found that the lowest IFT showed the highest effectiveness of surfactant on oil dispersion (Rongsayamanont et al. 2017) and oil extraction from solid phase (Arpornpong et al. 2018). However, our results demonstrated that the lowest IFT surfactant solution might not be the highest effective solution for diesel removal from soil. The IFT presented the relationship between only target compounds and selected surfactants. Many complexes in the soil matrix possibly affect soil extraction mechanisms and also affect emulsion formation (Karthick et al. 2019). Lower IFTs between surfactant solution and the extracted target are preferred over high IFT values for oil extraction application (Rosen et al. 2005). Some surfactants with same HLB value show the difference in IFT (Griffin 1954; Tadros 2005). HLB is a function that is estimated with potency of hydrophilicity of surfactant, but IFT is the function that demonstrates the interaction between surfactant and target compounds depending on the chemical structure (Rosen 2004; Tadros 2005). Therefore, the selection of surfactants for organic-contaminated soil washing should consider the surfactant structure and lower IFT rather than only HLB selection.

Thus, 1% (w/v) in the mixture between S20 and LS9 at HLB = 12 solution was selected for diesel extraction because this showed the lowest IFT with diesel and high extraction efficiency (66.2% ± 4.1%) from 20,000 mg/kg of diesel in spiked soil. When doubling the initial diesel contamination in the soil to 40,000 mg/kg, the extraction efficiency slightly decreased (60.7% ± 3.0%).

3.3 Diesel-Soil Washing by Used Surfactant Solution

Reuse of solvent or solution for the extraction process is one important factor to determine solvent effectiveness (Wennersten 2004). Here, we found that surfactants in the solution could be used more than once with new diesel-contaminated soil; however, the efficiency slightly dropped from the fresh solution about 9% and 6% for the 1st time and the 2nd time reuse, respectively as shown in Fig. 3. However, the reusing the solution for the first time gave extraction efficiency of less than the fresh solution but not significantly different from the second time of reuse (p = 0.05).

3.4 Washed Soil Cleaning and Seed Germination Testing

After diesel-contaminated soil was washed with 1% (w/v) of S20/LS9 surfactant solution, the decontaminated soil was cleaned with water to remove the remaining surfactant solution and residual diesel extracted. Soil were washed with water twice times and this process showed a slightly significant increase in diesel removal about 5% and 7% from the 1st cycle and the 2nd cycle, respectively (p = 0.05) (Fig. 4). Furthermore, some evidence showed that toxic compounds and surfactant also impacted on inhibition of seed germination and root growth of the plant (Besalatpour et al. 2008; Gálvez et al. 2019; Visioli et al. 2014). For this reason, the effect of 1% (w/v) S20/LS9 diesel washing solution, 1st/2nd cycle of water washing solution and fresh 1% (w/v) S20/LS9 were investigated on relative seed germination and root elongation of local vegetable seeds including tomato, rice, and green bean. Surprisingly, surfactant solution after diesel washing process and fresh surfactant solution showed no growth in tomato and rice, while the germination and root elongation in water washing solution in the 1st and 2nd cycle significantly increased (p < 0.05) (Fig. 5a, b). The 2nd cycle of water washing solution showed the highest seed germination and root elongation in all types of seed.

Percentage of a relative seed germination (RSG), b relative root elongation and (RRE), c germination index of tomato, rice, and green bean in day 5 with 1% (w/v) of S20/LS9 diesel washing solution, 1st and 2nd cycle of water washing solution comparing with fresh 1% (w/v) S20/LS9; a, b, c, d, and e represent the statistic testing (p < 0.05)

The germination index (GI) (Fig. 5c) that reflex to the relationship between relative seed germination and relative root elongation had no significantly affected (p > 0.05) by the 1st cycle of water washing solution compared with the 2nd cycle in green bean seed. By contrast, the GI in tomato and rice were significantly (p > 0.05) different in the two water washing cycles. The GI index of green bean showed significantly higher than those of the tomato and rice seeds (p < 0.05).

One of the considerations when selecting a surfactant to enhance contaminant removal is the toxicity of the surfactant system. Even though the diesel remains in the soil after surfactant solution washing and after the 1st and 2nd cycle water washing process is not significantly different in this study. The toxicity assay with local vegetables showed a significant difference in seed germination and root elongation. This phenomenon resulted from the toxicity of the surfactant itself at higher concentrations which affected seed germination. The concentration of our selected surfactant washing solution was above the critical micelle concentration (CMC). When concentration achieved the CMC, surfactant monomers naturally combined in complex micelle form. The increasing of micelle size could enhance the pollutant solubilization of pollutant and increase the bioavailability for seed tissues (de Bruin et al. 2016; de Bruin et al. 2017; Pele et al. 2019). Therefore, the water washing process after washing with 1% (w/v) S20/LS9 can enhance diesel extraction, mobilize the residual diesel, and also reduce toxicity to seed plants. Therefore, the recommendation of using washed soil for plantation after the surfactant solution process is following with the water washing process at least twice times.

4 Conclusions

In this study, a fatty alcohol ethoxylate surfactant as Dehydol LS which has lower IFT with diesel showed higher ability to extract diesel from soil than a polyethoxylated sorbitan surfactant or Tween on the basis of mass weight concentration. The combination of a polyethoxylated sorbitan surfactant with a fatty alcohol ethoxylate surfactant at hydrophilic-lipophilic balance (HLB) equal to 12 enhanced the reduction of IFT and increased diesel removal from soil better than individual surfactants and other formulations (S20 + Tween) at different HLB. The reuse performance of 1% S20/LS9 surfactant solutions at two times showed reduction of diesel extraction efficiency but efficiency was higher than 40%. It was necessary to conduct the process of water washing after the surfactant washing process to ensure removal of residual diesel concentration and surfactant molecules that might be toxic to plants.

References

Ali, N., Bilal, M., Khan, A., Ali, F., & Iqbal, H. M. N. (2019). Effective exploitation of anionic, nonionic, and nanoparticle-stabilized surfactant foams for petroleum hydrocarbon contaminated soil remediation. Science of the Total Environment, 135391. https://doi.org/10.1016/j.scitotenv.2019.135391.

Arpornpong, N., Charoensaeng, A., Khaodhiar, S., & Sabatini, D. A. (2018). Formulation of microemulsion-based washing agent for oil recovery from spent bleaching earth-hydrophilic lipophilic deviation concept. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 541, 87–96. https://doi.org/10.1016/j.colsurfa.2018.01.026.

ASTM. (2014). ASTM D1331-14: Standard test methods for surface and interfacial tension of solutions of paints, solvents, solutions of surface-active agents, and related materials. West Conshohocken, PA: ASTM International.

Bai, X., Wang, Y., Zheng, X., Zhu, K., Long, A., Wu, X., et al. (2019). Remediation of phenanthrene contaminated soil by coupling soil washing with Tween 80, oxidation using the UV/S2O82− process and recycling of the surfactant. Chemical Engineering Journal, 369, 1014–1023. https://doi.org/10.1016/j.cej.2019.03.116.

Banks, M. K., & Schultz, K. E. (2005). Comparison of plants for germination toxicity tests in petroleum-contaminated soils. [journal article]. Water, Air, and Soil Pollution, 167(1), 211–219. https://doi.org/10.1007/s11270-005-8553-4.

Besalatpour, A., Khoshgoftarmanesh, A. H., Hajabbasi, M. A., & Afyuni, M. (2008). Germination and growth of selected plants in a petroleum contaminated calcareous soil. Soil and Sediment Contamination, 17(6), 665–676. https://doi.org/10.1080/15320380802425113.

Damrongsiri, S., Tongcumpou, C., Weschayanwiwat, P., & Sabatini, D. A. (2010). Solubilization of dibutyltin dichloride with surfactant solutions in single and mixed oil systems. Journal of Hazardous Materials, 181(1–3), 1109–1114. https://doi.org/10.1016/j.jhazmat.2010.05.129.

Damrongsiri, S., Tongcumpou, C., & Sabatini, D. A. (2013). Partition behavior of surfactants, butanol, and salt during application of density-modified displacement of dense non-aqueous phase liquids. Journal of Hazardous Materials, 248–249(0), 261–267, doi: https://doi.org/10.1016/j.jhazmat.2012.12.059.

de Bruin, W., Kritzinger, Q., Bornman, M. S., & Korsten, L. (2016). Nonylphenol, an industrial endocrine disrupter chemical, affects root hair growth, shoot length and root length of germinating cos lettuce (Lactuca sativa). Seed Science and Technology, 44(1), 43–52. https://doi.org/10.15258/sst.2016.44.1.12.

de Bruin, W., van der Merwe, C., Kritzinger, Q., Bornman, R., & Korsten, L. (2017). Ultrastructural and developmental evidence of phytotoxicity on cos lettuce (Lactuca sativa) associated with nonylphenol exposure. Chemosphere, 169, 428–436. https://doi.org/10.1016/j.chemosphere.2016.11.020.

Gálvez, A., López-Galindo, A., & Peña, A. (2019). Effect of different surfactants on germination and root elongation of two horticultural crops: Implications for seed coating. New Zealand Journal of Crop and Horticultural Science, 47(2), 83–98. https://doi.org/10.1080/01140671.2018.1538051.

Griffin, W. C. (1954). Calculation of HLB values of non-ionic surfactants. Journal of the Society of Cosmetic Chemists, 5, 249–256.

Guan, Z., Tang, X.-Y., Nishimura, T., Katou, H., Liu, H.-Y., & Qing, J. (2018). Surfactant-enhanced flushing enhances colloid transport and alters macroporosity in diesel-contaminated soil. Journal of Environmental Sciences, 64, 197–206. https://doi.org/10.1016/j.jes.2017.06.006.

Hernandez, H. W., Ehlert, W., & Trabelsi, S. (2019). Removal of crude oil residue from solid surfaces using microemulsions. Fuel, 237, 398–404. https://doi.org/10.1016/j.fuel.2018.10.035.

Jafvert, C. T., Patricia, L. V. H., & Heath, J. K. (1994). Solubilization of non-polar compounds by non-ionic surfactant micelles. Water Research, 28(5), 1009–1017. https://doi.org/10.1016/0043-1354(94)90185-6.

Karthick, A., Roy, B., & Chattopadhyay, P. (2019). A review on the application of chemical surfactant and surfactant foam for remediation of petroleum oil contaminated soil. Journal of Environmental Management, 243, 187–205. https://doi.org/10.1016/j.jenvman.2019.04.092.

Luna, J. M., Rufino, R. D., Sarubbo, L. A., & Campos-Takaki, G. M. (2013). Characterisation, surface properties and biological activity of a biosurfactant produced from industrial waste by Candida sphaerica UCP0995 for application in the petroleum industry. Colloids and Surfaces B: Biointerfaces, 102, 202–209. https://doi.org/10.1016/j.colsurfb.2012.08.008.

Pele, M. A., Ribeaux, D. R., Vieira, E. R., Souza, A. F., Luna, M. A. C., Rodríguez, D. M., et al. (2019). Conversion of renewable substrates for biosurfactant production by Rhizopus arrhizus UCP 1607 and enhancing the removal of diesel oil from marine soil. Electronic Journal of Biotechnology, 38, 40–48. https://doi.org/10.1016/j.ejbt.2018.12.003.

Peters, R. W., Montemagno, C. D., Shem, L., & Lewis, B.-A. (1992). Surfactant screening of diesel-contaminated soil. Hazardous Waste and Hazardous Materials, 9(2), 113–136. https://doi.org/10.1089/hwm.1992.9.113.

Phasukarratchai, N., Damrongsiri, S., & Tongcumpou, C. (2016). Solubilization behavior of Phorbol esters from Jatropha oil in surfactant micellar solutions. Journal of Surfactants and Detergents, 19(1), 29–37. https://doi.org/10.1007/s11743-015-1758-7.

Pookboonmee, P., Tongcumpou, C., & Phasukarratchai, N. (2018). Application of surfactant aqueous-based solution for oil and phorbol esters extraction from Jatropha curcas L. seed-kernel in one step. Chiang Mai Journal of Science, 45(7), 2757–2767.

Rongsayamanont, W., Soonglerdsongpha, S., Khondee, N., Pinyakong, O., Tongcumpou, C., Sabatini, D. A., et al. (2017). Formulation of crude oil spill dispersants based on the HLD concept and using a lipopeptide biosurfactant. Journal of Hazardous Materials, 334, 168–177. https://doi.org/10.1016/j.jhazmat.2017.04.005.

Rosen, M. J. (2004). Surfactants and interfacial phenomena (3rd ed.). New Jersey: John Wiley & Sons, Inc..

Rosen, M. J., Wang, H., Shen, P., & Zhu, Y. (2005). Ultralow interfacial tension for enhanced oil recovery at very low surfactant concentrations. Langmuir, 21(9), 3749–3756.

Safehian, H., Rajabi, A. M., & Ghasemzadeh, H. (2018). Effect of diesel-contamination on geotechnical properties of illite soil. Engineering Geology, 241, 55–63. https://doi.org/10.1016/j.enggeo.2018.04.020.

Tadros, F. (2005). Applied surfactants: Principles and applications. Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA.

Takeuchi, E., Matsuoka, K., Ishii, S., Ishikawa, S., Honda, C., & Endo, K. (2014). Solubilization of polycyclic aromatic hydrocarbons in C16E7 nonionic surfactant solutions. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 441, 133–139. https://doi.org/10.1016/j.colsurfa.2013.09.011.

Tang, J., Wang, M., Wang, F., Sun, Q., & Zhou, Q. (2011). Eco-toxicity of petroleum hydrocarbon contaminated soil. Journal of Environmental Sciences, 23(5), 845–851. https://doi.org/10.1016/S1001-0742(10)60517-7.

Visioli, G., Conti, F. D., Gardi, C., & Menta, C. (2014). Germination and root elongation bioassays in six different plant species for testing Ni contamination in soil. Bulletin of Environmental Contamination and Toxicology, 92(4), 490–496. https://doi.org/10.1007/s00128-013-1166-5.

Wennersten, R. (2004). Extraction of organic compounds. In J. Rydberg, M. Cox, C. Musikas, & G. R. Choppin (Eds.), Solvent extraction principles and practice (2nd ed.). New York: Marcel Dekker, Inc..

Xiarchos, I., & Doulia, D. (2006). Effect of nonionic surfactants on the solubilization of alachlor. Journal of Hazardous Materials, 136(3), 882–888. https://doi.org/10.1016/j.jhazmat.2006.01.027.

Acknowledgments

This work was supported by the Remediation Technologies for Petroleum Contamination Research Program, Center of Excellence on Hazardous Substance Management (HSM), Chulalongkorn University. The authors appreciatively acknowledge Faculty of Environment and Resource Studies, Mahidol University and the HSM, Chulalongkorn University for the laboratory instrument support.

Funding

This work was supported by the Remediation Technologies for Petroleum Contamination Research Program, Center of Excellence on Hazardous Substance Management (HSM), Chulalongkorn University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rongsayamanont, W., Tongcumpou, C. & Phasukarratchai, N. Diesel-Contaminated Soil Washing by Mixed Nonionic Surfactant Emulsion and Seed Germination Test. Water Air Soil Pollut 231, 267 (2020). https://doi.org/10.1007/s11270-020-04649-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-04649-0