Abstract

The anaerobic biodegradability of combined microwave-ultrasonic pretreated thickened excess activated sludge (PTEAS) mixed with raw primary sludge (PS) was investigated in this study. The pretreatment resulted in the enhancement of mesophilic anaerobic digester performance which in turn improved biogas production capacity and quality, total and volatile solid reduction, dewaterability, protein solubilisation and significant reduction of pathogens to produce class A biosolid. This study presented the results of two continuously stirred mesophilic anaerobic digesters charged with various proportions of a mixture of PTEAS and PS similar to the large-scale industrial practice. Digester 1 was charged with 75 % PTEAS and 25 % PS, while digester 2 was fed with 25 % PTEAS and 75 % PS. The methane production was 122 mL CH4/g total chemical oxygen demand for digester 2 after 20 days of anaerobic digestion. This amount further increased for both digesters with digestion time. The biogas quality in terms of methane to carbondioxide ratio (CH4/CO2) was significantly improved for digester 1 compared with digester 2 after 20 days of digestion. Volatile solid reduction of 76 and 57 % was achieved for digester 1 and digester 2 respectively after the same 20 days of digestion. The CH4/CO2 ratio reached 2.2:1 and 1.1:1 after 20 days of digestion for digester 1 and digester 2, respectively. Higher percentage of PTEAS increases the digestion kinetics, the methane production capacity and the biogas quality. Furthermore, total coliform reduction of 84 and 44 % was achieved for digester 1 and digester 2 respectively after 22 days of digestion. Hydrolysis rate and biochemical methane production were improved for both digesters based on the results of Gompertz kinetic model and the hydrolysis rate constants as determined by model fitting of the experimental data.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sewage sludge handling and processing for ultimate disposal is one of the major challenges in the operation of municipal wastewater treatment plants. The production of waste activated sludge has significantly increased as a result of increase in the number and capacity of wastewater treatment plants over time. Sludge disposal is subjected to more stringent environmental policies and regulations and social constraints. Sludge treatment technologies like incineration are also quite expensive (Navaratnam 2007).

Biogas production through anaerobic digestion has recently captured global attention. This is because of various advantages of the anaerobic digestion process. The benefits of anaerobic digestion include eco-friendly energy generation, greenhouse gases emission reduction, high organic removal, high capacity to stabilise large volume of diluted organic slurry at low cost, low biomass production, high decay rate of pathogenic microorganisms, and the capacity of producing solid residue suitable for use as soil conditioner. Anaerobic digestion reduces up to 80 % of the odours in the feedstock (Ghosh et al. 1975). It is rated as one of the most energy-efficient and environmentally beneficial technologies for bioenergy production (Chong et al. 2012; Müller 2001; Weiland 2010). Generally, anaerobic digestion is a favoured stabilisation method compared to aerobic digestion due to its lower cost, lower energy footprint and moderate performance, especially for stabilisation (Appels et al. 2008). Basically, the process involves four major microbiological degradation steps comprising hydrolysis, acidogenesis, acetogenesis and methanogenesis. The hydrolysis step is a slow rate-determining part of the process that lowers the gas yield and retards the kinetics. The slow degradation or hydrolysis of microorganisms also accounts for 70 % of excess sludge which is the primary degradation step in the anaerobic digestion process. The microorganisms in the excess sludge contain extracellular polymeric substances (EPS) that are resistant to biodegradation which in turn limits the rate of the whole anaerobic digestion process (Chong et al. 2012; Tiehm et al. 1997). Therefore, minimisation of the amount of sludge produced coupled with the increased generation of value-added, renewable sources of energy like methane of higher quality is the best strategy for sustainable sludge management. In an effort to improve sludge hydrolysis, biodegradability and dewaterability, many desired experimental studies were documented on the pretreatment of sludge. Such technologies include ultrasonic treatment (Apul and Sanin 2010; Farooq et al. 2009; Saifuddin and Fazlili 2009; Tiehm et al. 2001), chemical treatment (Stuckey and McCarty 1978; Haug et al. 1978; Penaud et al. 2000; Tanaka and Kamiyama 2002), microwave treatment (Eskicioglu et al. 2007b), (Park 2011), ozone oxidation (Yeom et al. 2002; Lin and Lee 2002), mechanical disintegration, supercritical and subcritical water oxidation and high temperature hydrolysis (Carrère et al. 2010). All sludge reduction technologies are working with the principle of disintegration of cell walls and large organic molecules. It was reported that macromolecules with a molar mass of above 40,000 are disrupted by the hydro-mechanical shear forces produced by ultrasonic cavitation (Tiehm et al. 2001). The mechanisms of ultrasonic treatment are influenced by the energy supplied, ultrasonic frequency and the nature of the sludge. Cell disintegration is proportional to energy supplied (Bougrier et al. 2005). High frequencies promote oxidation by radicals, whereas low frequencies promote mechanical and physical phenomena like pressure waves (Portenlanger 1999). Only ultrasonic pretreatment method was applied on large-scale wastewater treatment plants (WWTP) compared to other pretreatment methods (Carrère et al. 2010).

Microwave (MW) irradiation is also an efficient sludge pretreatment technology that enhances biodegradability, methane production and digester performance (Park 2011). It is a novel pretreatment method for stabilisation of waste activated sludge (WAS). Microwave pretreatment of sludge increases biogas production, reduce sludge viscosity, improve dewaterability and improve pathogen decay as compared to digestion of sludge pretreated through conventional heating and untreated sludge (Eskicioglu et al. 2007a). The use of MWs in the digestion of sludge was found to increase the ratio of soluble chemical oxygen demand (COD) to total chemical oxygen demand (SCOD/TCOD) from 2 to 22 % (Toreci et al. 2010).

Very few researchers reported that the microwave combined with ultrasonic would be a rapid and economical method of sludge pretreatment for enhanced biogas production and quality. Combined microwave-ultrasonic pretreatment resulted in significant improvement in gas production, solid removal and dewaterability of municipal sludge compared to the individual ultrasonic or microwave pretreatment approaches (Saifuddin and Fazlili 2009; Yeneneh et al. 2013a, b). There is a complementary synergy between the two treatment techniques causing improved sludge disintegration, floc destruction, thermal and athermal cell wall disruption and release of organics. Therefore, the objective of this research is to investigate the effect of combined microwave-ultrasonic pretreatment on the anaerobic digestibility of thickened excess activated sludge and mixed sludge. It focuses on intensive investigation of combined microwave-ultrasonic pretreatment when the pretreatment is applied only on the thickened excess activated sludge part before it is mixed with primary sludge. The impacts in terms of biogas production, solid removal, COD reduction and sludge dewaterability were studied. This investigation is motivated by the significant enhancement effect of combined microwave-ultrasonic pretreatment on the digestibility and organic matter removal for thickened excess activated sludge (Yeneneh et al. 2013b).

2 Materials and Methodology

Thickened excess activated sludge and primary sludge samples were collected from Beenyup wastewater treatment plant (BWWTP), Perth, Western Australia for the pretreatment and digestion study. The samples were stored at 4 °C. Digested sludge from previous experiments was utilised to inoculate the digesters. Digester acclimation was done for over 1 month. In this experiment, thickened excess activated sludge (TEAS) was pretreated under optimum combined microwave-ultrasonic pretreatment conditions, and the TEAS was mixed with untreated primary sludge before the mixture was fed into the anaerobic digesters.

Amount of 800 mL TEAS sample was microwave irradiated at a frequency of 2450 MHz and density of 36.92 kJ/L g SCOD. The TEAS sample was then mounted on to Sonics Vibrocell ultrasonication unit for sonication at 48,000 J, 55/5 pulse, 90 % amplitude, and for 8 min. Amount of 200 mL of the sample was transferred to a 250 mL plastic storage bottle, labelled and stored at 4 °C for the digestion test.

The pretreated TEAS was mixed in two ratios by volume with untreated primary sludge: 25 % PS and 75 % pretreated TEAS (digester 1), and 75 % PS and 25 % pretreated TEAS (digester 2). The digester feed samples were characterised as shown in Table 1.

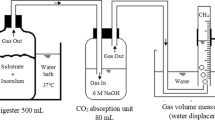

2.1 Experimental Digester Set-Up

Two continuously stirred jacketed digesters were used for the anaerobic digestion test. Jacket heating system was applied to maintain the desired mesophilic digester temperature of 36.5 °C. The digesters were placed on magnetic stirrers to maintain continuous mixing. The sludge samples were fed to the digesters through the sludge charging tube and the biogas produced will exit through another tube to a 1 L buffering bottle, placed outside the water bath heater, for removal of any condensate. Water displacement method was used to measure the gas volume, and the biogas composition was measured using GA plus 2000 biogas analyser. The digested sludge used for inoculation accounts for 20 % of the digester volume.

Digester 1 was fed with 75 % pretreated TEAS and 25 % primary sludge, and digester 2 was charged with mixed sludge with composition of 25 % pretreated TEAS and 75 % primary sludge. This mixing ratio is similar to large-scale wastewater treatment plants. The digesters were continuously purged with N2 at 25–40 mL/min after the charging.

The digesters were operated for a period of 32 days, and the results in the first 20–27 days were used for the analysis. Periodically, the volume and composition of the gas produced were measured and recorded. The gas composition was measured by connecting the gas analyser probe to the inlet tube of the buffering bottle to pump out the biogas from the digesters.

2.2 Analytical Methods

All the analyses required for the experimental work in this section including determination of TS, VS, SCOD, TCOD, pH, dewaterability (CST), elemental analysis, particle size analysis, protein analysis and microbial analysis were conducted. pH was measured with WP-90 and WP-81 conductivity/TDS-pH/temperature meter equipped with a glass electrode according to Standard Methods of APHA 2005 (APHA et al. 2000). The total and soluble chemical oxygen demands were determined using oxidation method with HACH COD reagent and colorimetric analysis on ORION UV/vis spectrophotometer from Cole Palmer, USA. The soluble chemical oxygen demand was determined by centrifuging the sample at 5000 rpm for 10 min to separate the supernatant from the solid sludge and filtering the supernatant in Whatman (45 μm) filter paper. The COD measurement was then conducted on the filtrate exactly in the same way as total COD.

Standard Method 4500 NH3-F of APHA 2005 was employed to measure the dissolved ammonia (NH3(aq) and N–H) concentration. The equipment used for the measurement was an ammonia electrode model 95-12 and WP-90 and WP-81 conductivity/TDS-pH/temperature meter (TPS, Australia).

The total and volatile solids contents were determined according to the Standard Methods for the Examination of Water and Wastewater, APHA 2005 (APHA et al. 2000). Bicarbonate alkalinity was measured as alkalinity according to Standard Method APHA 2005 (APHA et al. 2000)

The biogas composition was measured using Geotech GA 2000 plus (Keison Products, UK). The gas meter is designed to measure the volume percentage of methane, carbon dioxide, oxygen and other gases. Temperature measurement was conducted using WP-90 and WP-81 conductivity/TDS-pH/temperature meter (TPS, Australia) for all analytical measurements to ensure consistency of the results. Temperature during the digestion process was maintained constant using the water bath heater which pumps the water flowing in the jacket of the digesters.

The particle size distribution of the feed, intermediate and digested sludge samples was determined using Mastersizer 2000® laser diffraction particle size analyser (Malvern Instruments Ltd, UK).

The microbial content was measured using Coliscan Kit (Micrology Laboratories, USA). The Coliscan kit incorporates two special chromogenic substrates which interact with the enzymes galactosidase and glucuronidase to produce pigments of contrasting colours. Bio-Rad assay was used for the determination of total protein concentration in the hydrolysis and methanogenesis stages. One part of the Bio-Rad reagent was mixed with four parts of ultra-pure water. Protein standard solution of gamma bovine serum (IgG) was prepared in the range of 0.2 to 1.5 mg/mL. Sludge samples withdrawn at different solids retention times (SRT) from digesters were diluted 50 times. Amount of 200 μL of four standard protein samples and the unknown diluted sludge samples were mixed with 5 mL of the Bio-Rad reagent. The samples were analysed on UV/vis spectrophotometer, after thorough mixing. The calibration curve was first developed using the known standards of IgG.

The dewaterability of the different sludge samples was measured using capillary suction timer (type 304M CST from Triton Electronics Ltd, England).

3 Results and Discussion

The samples from the two continuously stirred anaerobic digesters were collected and analysed. The results from the analyses are presented as follows.

3.1 Effect of Combined Microwave-Ultrasonic Pretreatment on Biochemical Methane Potential and Biogas Composition

The results obtained from the biochemical methane potential test conducted during the 32 days of digestion are presented. Figure 1 shows the specific methane yield for both digesters where the yield from digester 1 was significantly greater than that of digester 2 after the lag phase of the hydrolysis stage of the digestion process is completed. The slow lag phase at the start is the result of the rate-limiting hydrolysis process where sludge disintegration and solubilisation of complex organic molecules take place followed by the rapid acidogenesis and acetogenesis stages. Substantial amount of methane with a maximum of 205 mL CH4/g TCOD was produced in digester 1 after 8 days in the lag phase. The maximum methane yield of digester 2 was 157 mL CH4/g TCOD which was produced after a lag phase of 13 days. The difference in sludge yield is attributed to the percentage composition of pretreated TEAS in the two digesters which determines the rate of sludge disintegration. Digester 1 contains significantly greater amount of pretreated TEAS, which has more readily degradable organics. On the other hand, the higher percentage of the primary sludge in digester 2 prolongs the period of hydrolysis to disintegration unlike the case in digester 1.

The results of this study confirm that combined microwave and ultrasonic pretreatment of TEAS is better than microwave pretreatment or other pretreatment methods on waste activated sludge. Saha et al. (2011) pretreated mixed sludge sample composed of 40 % WAS and 60 % PS using microwave only (2450 MHz, 0–1250 W, 25–260 °C) and ultrasonic only (20 kHz, 1 W/mL, 15–90 min) pretreatment techniques. The maximum specific methane yield achieved at a digestion time of 20 days was 80 mL CH4/g TCOD for microwave and ultrasonic pretreatment which was lower than the specific methane yield obtained from this study where digester 2 in this study produced 100 mL CH4/g TCOD for SRT of 20 days. This clearly shows the effectiveness of the combined microwave-ultrasonic pretreatment method in terms of enhancing the performance of anaerobic digestion process.

Figure 2 represents the biogas quality of each digester in the form of methane to carbon dioxide ratio. The methane/carbon dioxide ratio (biogas quality) indicated the level of methanogenic activity in the digesters. High CH4/CO2 ratio justifies how healthy the digesters are to convert all VFA into acetate and ultimately to methane (acetogenic methanogenesis) or CO2 and H2 to methane (hydrogenotrophic methanogenesis). It was observed that digester 1 achieved significantly higher methane to carbon dioxide ratio in a short duration of time, whereas digester 2 produced more carbon dioxide than methane up until 20 days. Methanogenesis in digester 1 happened faster and more readily due to the higher degree of degradation and availability of soluble organics and due to the pretreatment which makes the hydrolysis and acidogenesis stages much shorter, whereas digester 2 which contains more primary sludge showed slow degradation rate. The primary sludge contains a large fraction of lignin and cellulose, with polysaccharides present in the cell walls of organic structures (Saha et al. 2011). The reduction of such compounds to the soluble phase requires a large amount of energy; this can explain the slow hydrolysis step in digester 2. In terms of environmental sustainability of the process, reducing the carbon dioxide produced is very beneficial as greenhouse gas emissions is a nuisance to the environment. The carbon dioxide generated in digester 1 is reduced after 5 days to the value digester 2 achieved after 20 days. This is a substantial difference, which demonstrates the benefits of combined microwave-ultrasonic pretreatment of the TEAS portion of the mixture.

Figures 3 and 4 demonstrate the biogas compositions for both digesters separately. It can be observed that the methane/carbon dioxide ratio became 1:1 in less than 10 days for digester 1. This shows high methanogenic activity in digester 1 at a reasonably short retention time as discussed earlier. The most important feature of this graph is the maximum methane production of 71 %, which was achieved after 15 days. Other studies, applying alternative pretreatment methods to mixed sludge feed achieved significantly lower methane percentages. For microwave pretreatment of a 1:1 ratio of primary to secondary sludge mixture, a methane composition of 59 % was achieved after 20 days (Park and Ahn 2011). Applying ultrasonic pretreatment on the secondary sludge (activated sludge) feed methane percentage of 65.9 % was achieved a for an ultrasonication pretreatment duration of 30 min (Tiehm et al. 2001). This further indicates the benefits of combined microwave-ultrasonic pretreatment in terms of enhancing organic solubilisation that are more readily available for reduction, hence increasing methane production.

Figure 4 shows that for digester 2, the steps discussed above take significantly longer time due to the large percentage of primary untreated sludge available in the digester. Methane production reached a steady percentage composition of 55 % CH4 after 15 days of digestion. As 75 % of the digester feed is raw primary sludge in digester 2, 55 % methane production in 15 days is an interesting result compared to the results from other studies by Tiehm et al. 2001.

It is also important to note the oxygen content recorded in both digesters was very low at all stages of digestion indicating that appropriate anaerobic condition was maintained throughout the process. Exposing anaerobic bacteria to oxygen can result in the formation of toxic radicals, which result in the destruction of the anaerobic environment, causing digester inhibition (Rolfe et al. 1978).

3.2 Effect of Pretreatment on Solids Removal and Sludge Disintegration

Total and volatile solids reductions are used to directly measure the degree of biodegradation that has occurred in the sludge through the anaerobic digestion process. Figure 5 shows the total solid content of the sludge at different times in the 32 days digestion time. Digester 1 achieved a 43 % total solids reduction over 20 days digestion, while digester 2 experienced a 46 % reduction in the same amount of time. The most important feature to note from the percentage reductions is the rate of solid removal in the first 5 days of the digestion process. The total solids percentage in digester 1 was reduced more significantly in the first 5 days of digestion as compared to digester 2. This is due to the larger percentage of pretreated TEAS present in digester 1 where pretreatment helps to degrade the sludge, making it more susceptible to reduction by hydrolysis. Hence, the organic complexes originally available in the solids phase will be solubilised faster, and the availability of soluble organics facilitate the acidogenic and methanogenic stages of anaerobic digestion.

Interestingly, as shown in Fig. 5, the total solid content in both digesters did not shown much change after 20 days of digestion. This justifies that anaerobic digestion for duration longer than 20 days is not required especially for large-scale anaerobic digestion applications. Sufficient sludge degradation and methane production achieved in shorter digester time significantly reduce the sludge treatment cost (Lee et al. 2011).

The total solids reduction achieved in this research was found to be much greater than what is reported by other researchers. This confirms the effectiveness of combined microwave-ultrasonic pretreatment for efficient sludge solubilisation. For two digesters charged with a 40:60 WAS to PS feed, the maximum total solids reductions of 25 and 20 % were achieved using microwave (2450 MHz, 0–1250 W, 25–260 °C) and ultrasonic (20 kHz, 1 W/mL, 15–90 min) pretreatment options, respectively (Saha et al. 2011). Significantly higher solids reduction was achieved for similar mixed feed sludge composition in this study confirming that combined microwave-ultrasonic pretreatment results in better solids removal than the individual pretreatment options.

Volatile solids as a percentage of the total solids in the sludge are shown graphically in Fig. 6. The graph depicts the volatile solids reduction achieved in the system. Volatile solids reduction of 57.8 and 76 % was achieved for digesters 1 and 2 respectively after 20 days of digestion. Volatile solid measures the amount of biodegradable and non-biodegradable organic components present in the sludge and therefore, it can be inferred from Fig. 6 that digester 2 contains significantly larger percentage of reducible organics. This is due to higher percentage of primary sludge in the digester feed stock. It is well known that primary sludge digestion results in higher volatile solids reduction (Grönroos et al. 2005). Figure 6 shows that digester 1 has volatile solids percentage almost equal to that of digester 2, but the reducible organic fraction is more predominant in the digester with more primary sludge.

TCOD and soluble chemical oxygen demand (SCOD) are other indicators of the degree of sludge biodegradability. These parameters show the amount of organic and inorganic species and organisms that can be chemically oxidised in the sludge. Figures 7 and 8 show that the TCOD fraction decreased more significantly in digester 1 than digester 2. A 37.5 % reduction in TCOD was observed in the first 6 days of digestion for digester 1, whereas a 16.8 % reduction is achieved in digester 2 for the same duration of digestion. This justifies the advantage of applying combined microwave-ultrasonic pretreatment on the activated sludge portion of the mixture before digestion. It also shows that the higher the percentage of pretreated TEAS, the greater will be the solid disintegration and biodegradation. Microorganisms required for sludge oxidisation can be disrupted to a greater extent by pretreatment.

The SCOD trend shown in Figs. 7 and 8 displays slight change in SCOD fraction over the total sludge retention time for digester 1, whereas digester 2 shows an increase up to 6 days of digestion and then decreases progressively until 27 days. The fact that the SCOD fraction in digester 1 does not change can be explained by the faster mixing and solubilisation of SCOD after mixing of the feed that no discernible decrease in the SCOD was observed over the digestion period. This can be supported by the rapid rate of TCOD reduction observed in the digester containing more pretreated TEAS. The results shown in digester 2 for the SCOD removal are more typical of anaerobic digestion process, as the SCOD fraction increases in the original phase of digestion due to increased solubilisation of organics in the hydrolysis stage, and then a decrease is observed due to the consumption of organics with increasing sludge retention time. SCOD reduction in digester 2 took place at a slower rate because of the lower fraction of pretreated TEAS in the feed. Pretreating the sludge increases the fraction of soluble organics available for oxidisation which will, in turn, increases the percentage reduction in SCOD and enhances biogas production and solid removal. Furthermore, the maximum reduction achieved in the first 6 days of operation confirms advantage of pretreatment for the reduction.

3.3 Effect of Pretreatment on Bacterial Reduction

The total coliform content of sludge after digestion is one important factor determining effluent quality. Coliforms are bacteria that are associated with faecal matter, and the degree of coliform and Escherichia coli (pathogen) removal is an important target of the anaerobic digestion process (Lafitte-Trouqué and Forster 2002) to produce class A biosolids ultimately. The bacterial analysis of the two digesters at the beginning and end of a 20-day digestion process was completed, and the results are displayed in Table 2.

The results portray an 84 % reduction in the total coliform count for digester 1, while digester 2 resulted in a lesser reduction of 44 %. This is again attributed to the larger percentage of pretreated TEAS in digester 1, as the pretreatment disturbs the cell membranes of the bacteria prior to digestion, which results in improved destruction of microbial bacteria through the anaerobic digestion process. It can also be noted that complete destruction of the E. coli bacteria was observed in both digesters, which is very beneficial as these pathogens and the major nuisances which should not be present in the biosolids or the liquid effluent after the digestion process.

3.4 Effect on Protein Solubilisation

Protein is an organic compound that occupies approximately 50 % of the total organics present in waste activated sludge (Shao et al. 2013). The reduction of protein can be used to measure sludge degradation in terms of the total organics removal achieved throughout the anaerobic digestion process. Figure 9 displays the amount of total protein available in 500 mL of sludge at different stages of the digestion process both in digester 1 and digester 2, respectively.

Figure 9 shows that the protein content decreased continuously in digester 2 over the total digestion and sludge retention time considered in the study. However, the rate of reduction in the first 5 days is faster in digester 1, which is attributed to greater percentage of pretreated TEAS in the digester feed. Greater proportion of PTEAS increases the availability of proteins for reduction by hydrolysis in the early stage of digestion. However, an increase in the protein content was observed in digester 1 following the initial period of faster protein reduction. This can be explained by the original biomass in the sludge being reduced in the first stage of digestion and due to the solubilisation of more proteins from the original sludge and growth of new microorganisms (methanogens) in the later stages of the anaerobic digestion process.

3.5 Particle Size Distribution of Sludge During Anaerobic Digestion

The particle size distributions for the two digesters are shown in Tables 3 and 4. The average particle size of the feed sludge is different from the average particle size of digested sludge at different days during the anaerobic digestion process. The particle size distribution of the two digesters generally shows similar trend, yet there is a difference in the average particle size and specific surface area at different days. This is because of the differences in biodegradability of the different types of feed sludge. The d(0.1), d(0.5) and d(0.9) values indicate that 10, 50 and 90 % of the particles measured were less than or equal to the size stated. According to the distributions shown in Tables 3 and 4, the particle size distribution of digester 1 appeared to have smaller particles as compared to the distribution of particles in digester 2 in the first 13 days. This is related to increased disintegration of the TEAS particles which accounts for 75 % of feed in digester 1 than the case in digester 2 after the combined microwave-ultrasonic pretreatment. The sludge specific surface area was derived from the particle size distribution. The specific surface area data quoted in Tables 3 and 4 illustrate that the smaller particles contributed more in terms of specific surface area than the larger size fractions, and specific surface area increases with increasing number of days of digestion. Table 4 shows greater specific surface area of particles for digester 2 after long digestion time. The smaller particle sizes are indicative of the disintegration and floc disruption that happened because of pretreatment which has ultimately assisted the release of organic matter for biogas production and digester performance.

3.6 Modelling of Anaerobic Digestion Kinetics and Sludge Hydrolysis Rate

The hydrolysis rate constant can be calculated using biochemical methane potential data from the digesters. The methane yield is a function of the reduction of organic material achieved during anaerobic digestion, which reflects on the hydrolysis rate. The hydrolysis rate constant is an indicator of the speed of hydrolysis achieved in the digesters. Enhancing the hydrolysis rate constant is an important factor.

The model developed by Gompertz was used to determine the hydrolysis rate constant. This model represents cumulative methane production as a function of the methane production potential, maximum methane production rate and duration of the lag phase (Gadhamshetty et al. 2010). The equation is given as follows:

where M is the cumulative methane production (mL), P is the methane production potential (mL), R m the maximum methane production rate (mL/day), λ is the duration of the lag phase (day), and t is the duration of the assay in which cumulative methane production M is calculated (day).

Using the nonlinear regression technique, the Gompertz equation was used to develop the predictive model curves based on the experimental results achieved for the cumulative methane production in both digesters 1 and 2. These results are shown in Figs. 10 and 11.

Subsequent to fitting the equation to the experimental results, the values of the methane production potential (P), maximum methane production rate (R m ), and the duration of the lag phase (λ) can be calculated by applying a least squares regression fit to the experimental data obtained. The various kinetic parameters calculated from the analysis are presented in Table 5.

Table 6 displays the values for these parameters determined for each digester and the correlation coefficient (R 2), which indicated the fitting between the experimental and theoretical models. Furthermore, Table 5 depicts the experimental and predicted values of the cumulative methane production after 20 days of digestion.

From the data presented in Tables 5 and 6, it can be observed that the Gompertz equation is suitable for estimating the methane production trend observed in the experiment. High daily methane production potential and shorter lag time calculated for digester 1 as compared to digester 2 correlate well to the experimental results. Higher daily methane production rate and shorter lag time in digester 1 are attributed to the higher proportion of combined microwave-ultrasonic pretreated sludge in the digester feedstock, which reduces the time taken to reach the methanogenesis stage of digestion.

The hydrolysis rate constant k can be determined from this data using first-order rate Eq. 2 as shown. The value for this constant helps to understand the kinetics of the digestion process and evaluate the effect that the combined microwave-ultrasonic pretreatment method and mixing ratio has on the performance of the anaerobic digestion of sludge.

where M is the cumulative methane production (mL) at time, t (day), P is the methane production potential (mL) which was assumed to be equal to the final cumulative methane volume.

By linearising the results calculated from the above equation, the relationship between the cumulative methane production and time is determined. Figure 12 displays these results graphically, and Table 7 shows the values for the hydrolysis rate constant for each digester.

Table 7 shows that the rate of hydrolysis observed in digester 1, containing a larger portion of pretreated TEAS, is faster than that of digester 2. This perfectly agrees with the experimental results discussed throughout this section about the effects of the combined microwave-ultrasonic pretreatment method in reducing the time required for the completion of the hydrolysis stage of digestion. Moreover, the higher percentage of PTEAS (greater PTEAS mixing ratio) resulted in greater enhancement in the kinetics of the anaerobic digestion process.

4 Conclusions

This study showed that combined microwave and ultrasonic pretreatment of activated sludge resulted in better anaerobic digester performance in terms of biogas production, total and volatile solid reductions, protein degradation and destruction of pathogens. More importantly, pretreatment of thickened excess activated sludge only before mixing with primary sludge resulted in substantial improvement in biodegradability, solid reduction, methane production kinetics and overall performance of anaerobic digestion process. Furthermore, increasing the percentage of pretreated thickened excess activated sludge in the mixed digester feed sludge increases the rate of hydrolysis, the methane production capacity and the biogas quality, whereas greater volatile and total solid removal were achieved for the digester with greater percentage of primary sludge. Great percentage of primary sludge mixed with pretreated excess activated sludge can be easily digested unlike the slow hydrolysis step and digestion kinetics of raw primary sludge. The significance of the findings of this study in large-scale wastewater treatment plants is enormous in terms of reducing the sludge treatment and handling costs. It will also help to enhance anaerobic digestion kinetics and overall performance and popularise the technology.

References

APHA, AWWA and WEF. (2000). Standard methods for the examination of water and wastewater (21st ed.). Washington DC: American Public Health Association, American Water Works Association and Water Environment Federation.

Appels, L., Baeyens, J., Degreve, J., & Dewil, R. (2008). Principles and potential of the anaerobic digestion of waste-activated sludge. Progress in Energy and Combustion Science, 34(6), 755–781.

Apul, O. G., & Sanin, F. D. (2010). Ultrasonic pretreatment and subsequent anaerobic digestion under different operational conditions. Bioresource Technology, 101, 8984–8992.

Bougrier, C., Carrère, H., & Delgenès, J. P. (2005). Solubilisation of waste-activated sludge by ultrasonic treatment. Chemical Engineering Journal, 106(2), 163–169. doi:10.1016/j.cej.2004.11.013.

Carrère, H., Dumas, C., Battimelli, A., Batstone, D. J., Delgenès, J. P., Steyer, J. P., et al. (2010). Pretreatment methods to improve sludge anaerobic degradability: a review. Journal of Hazardous Materials, 183(1–3), 1–15. doi:10.1016/j.jhazmat.2010.06.129.

Chong, S., Sen, T. K., Kayaalp, A., & Ang, H. M. (2012). The performance enhancements of upflow anaerobic sludge blanket (UASB) reactors for domestic sludge treatment–a state-of-the-art review. Water Research, 46(11), 3434–3470. doi:10.1016/j.watres.2012.03.066.

Eskicioglu, C., Kennedy, K. J., & Droste, R. L. (2007a). Enhancement of batch waste activated sludge digestion by microwave pretreatment. Water Environment Research, 79(11), 2304–2317.

Eskicioglu, C., Terzian, N., Kennedy, K. J., Droste, R. L., & Hamoda, M. (2007b). Athermal microwave effects for enhancing digestibility of waste activated sludge. Water Research, 41(11), 2457–2466.

Farooq, R., Rehman, F., Baig, S., Sadique, M., Khan, S., & Farooq, U. (2009). The effect of ultrasonic irradiation on the anaerobic digestion of activated sludge. World Applied Sciences Journal, 6(2), 234–237.

Gadhamshetty, V., Arudchelvam, Y., Nirmalakhandan, N., & Johnson, D. C. (2010). Modeling dark fermentation for biohydrogen production: ADM1-based model vs. Gompertz model. International Journal of Hydrogen Energy, 35(2), 479–490. doi:10.1016/j.ijhydene.2009.11.007.

Ghosh, S., Conrad, J., & Klass, D. (1975). Anaerobic acidogenesis of wastewater sludge. Journal Water Pollution Control Federation, 47(1), 30–45.

Grönroos, A., Kyllönen, H., Korpijärvi, K., Pirkonen, P., Paavola, T., & Jokela, J. (2005). Ultrasound assisted method to increase soluble chemical oxygen demand (SCOD) of sewage sludge for digestion. Ultrasonics Sonochemistry, 12(1–2), 115–120. doi:10.1016/j.ultsonch.2004.05.012.

Haug, R., Stuckey, D., Gossett, J., & McCarty, P. (1978). Effect of thermal pretreatment on digestibility and dewaterability of organic sludges. Journal Water Pollution Control Federation, 50(1), 73–85.

Lafitte-Trouqué, S., & Forster, C. F. (2002). The use of ultrasound and γ-irradiation as pre-treatments for the anaerobic digestion of waste activated sludge at mesophilic and thermophilic temperatures. Bioresource Technology, 84(2), 113–118. doi:10.1016/S0960-8524(02)00038-X.

Lee, I.-S., Parameswaran, P., & Rittmann, B. E. (2011). Effects of solids retention time on methanogenesis in anaerobic digestion of thickened mixed sludge. Bioresource Technology, 102(22), 10266–10272. doi:10.1016/j.biortech.2011.08.079.

Lin, C.-Y., & Lee, Y.-S. (2002). Effect of thermal and chemical pretreatments on anaerobic ammonium removal in treating septage using the UASB system. Bioresource Technology, 83(3), 259–261. doi:10.1016/S0960-8524(01)00223-1.

Müller, J. (2001). Prospects and problems of sludge pre-treatment processes. Water Science and Technology: a Journal of the International Association on Water Pollution Research, 44(10), 121.

Navaratnam (2007). Anaerobic digestion of waste activated sludge with ultrasonic pretreatment. Master of engineering in environmental engineering and management, Asian Institute of Technology, Thailand.

Park, W. J. (2011). Effects of microwave pretreatment on mesophilic anaerobic digestion for mixture of primary and secondary sludges compared with thermal pretreatment. Environmental Engineering Research, 16(2), 103–109.

Park, W. J., & Ahn, J.-H. (2011). Effects of microwave pretreatment on mesophilic anaerobic digestion for mixture of primary and secondary sludges compared with thermal pretreatment. Environmental Engineering Research (EER), 16(2), 103–109.

Penaud, V., Delgenes, J., & Moletta, R. (2000). Influence of thermo-chemical pre-treatment conditions on solubilization and anaerobic biodegradability of a microbial biomass. Environmental Technology, 21, 87–96.

Portenlanger, G. (1999). Mechanical and radical effects of ultrasound. Ultrasound in Environmental Engineering, TU Hamburg-Harburg Reports on Sanitary Engineering, 25, 139–151.

Rolfe, R. D., Hentges, D. J., Campbell, B. J., & Barrett, J. T. (1978). Factors related to the oxygen tolerance of anaerobic bacteria. Applied and Environmental Microbiology, 36(2), 306–313.

Saha, M., Eskicioglu, C., & Marin, J. (2011). Microwave, ultrasonic and chemo-mechanical pretreatments for enhancing methane potential of pulp mill wastewater treatment sludge. Bioresource Technology, 102(17), 7815–7826. doi:10.1016/j.biortech.2011.06.053.

Saifuddin, N., & Fazlili, S. A. (2009). Effect of microwave and ultrasonic pretreatments on biogas production from anaerobic digestion of palm oil mill effluent. American Journal of Engineering and Applied Sciences, 2, 139–146.

Shao, L., Wang, T., Li, T., Lü, F., & He, P. (2013). Comparison of sludge digestion under aerobic and anaerobic conditions with a focus on the degradation of proteins at mesophilic temperature. Bioresource Technology, 140, 131–137. doi:10.1016/j.biortech.2013.04.081.

Stuckey, D., & McCarty, P. (1978). Thermo-chemical pre-treatment of nitrogeneous to increase methane yield. Biotech Eng, 8, 219–233.

Tanaka, S., & Kamiyama, K. (2002). Thermo-chemical pre-treatment in the anaerobic digestion of waste activated sludge. Water Science and Technology, 46, 173–179.

Tiehm, A., Nickel, K., & Neis, U. (1997). The use of ultrasound to accelerate the anaerobic digestion of sewage sludge. Water Science and technology, 36(11), 121–128.

Tiehm, A., Nickel, K., Zellhorn, M., & Neis, U. (2001). Ultrasonic waste activated sludge disintegration for improving anaerobic stabilization. Water Research, 35(8), 2003–2009.

Toreci, I., Kennedy, K. J., & Droste, R. L. (2010). Effect of high-temperature microwave irradiation on municipal thickened waste activated sludge solubilization. Heat Transfer Engineering, 31(9), 766–773.

Weiland, P. (2010). Biogas production: current state and perspectives. Applied Microbiology and Biotechnology, 85(4), 849–860.

Yeneneh, A. M., Chong, S., Sen, T. K., Ang, H. M., & Kayaalp, A. (2013a). Effect of ultrasonic, microwave and combined microwave–ultrasonic pretreatment of municipal sludge on anaerobic digester performance. Water, Air, & Soil Pollution, 224(5), 1–9.

Yeneneh, A. M., Sen, T. K., Chong, S., Ang, H. M., & Kayaalp, A. (2013b). Effect of combined microwave-ultrasonic pretreatment on anaerobic biodegradability of primary, excess activated and mixed sludge. Computational water, Energy and Envrionmental Engineering, 2(Number 3B), 7–11. doi:10.4236/cweee.2013.23B002.

Yeom, I. T., Lee, K. R., Lee, Y. H., Ahn, K. H., & Lee, S. H. (2002). Effects of ozone treatment on the biodegradability of sludge from municipal wastewater treatment plants. Water Science and Technology, 46(4–5), 421–425.

Acknowledgments

The authors would like to acknowledge Water Corporation, Perth WA and Chemical Engineering department of Curtin University, Perth for proving funding and laboratory space for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeneneh, A.M., Kayaalp, A., Sen, T.K. et al. Effect of Combined Microwave-Ultrasonic Pretreatment of Real Mixed Sludge on the Enhancement of Anaerobic Digester Performance. Water Air Soil Pollut 226, 314 (2015). https://doi.org/10.1007/s11270-015-2586-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-015-2586-0