Abstract

Pump operating as turbine (PAT) is an effective source of reducing the equipment cost in small hydropower plants. However, the manufacturers provide poor information on the PAT performance thus representing a limit for its wider diffusion. Additional implementation difficulties arise under variable operating conditions, characteristic of water distribution networks (WDNs). WDNs allow to obtain widespread and globally significant amount of produced energy by exploiting the head drop due to the network pressure control strategy for leak reductions. Thus a design procedure is proposed that couples a parallel hydraulic circuit with an overall plant efficiency criteria for the market pump selection within a WDN. The proposed design method allows to identify the performance curves of the PAT that maximizes the produced energy for an assigned flow and pressure-head distribution pattern. Finally, computational fluid dynamics (CFD) is shown as a suitable alternative for performance curve assessment covering the limited number of experimental data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Major concerns in the management of water supply networks are water and energy savings (Gonçalves et al. 2011). These two forms of thrift are strictly related to pipeline water leakages: indeed, abnormal water consumption reflects directly in energy wasting. The rate of water losses in a corrupted branch of the network is strictly related to the pressure value (Nazif et al. 2010; Araujo et al. 2006; Vairavamoorthy and Lumbers 1998). Thus, in order to avoid expensive investments in the rehabilitation of older pipelines, a partial reduction of water leakages in urban areas can be achieved by placing control valves to reduce the pipeline water pressure (Almandoz et al. 2005; Tucciarelli et al. 1999; Walsky et al. 2006; Prescott and Ulanicki 2008). The number of pressure reducing valves (PRV) is therefore increasing and, in the framework of a virtuous energetic policy, any attempt should be accomplished by the water network managers in order to convert energy dissipation in energy production (Carravetta and Giugni 2009). Nevertheless, energy production in water supply systems has been realized only in few cases and mainly in the transmission pipelines, where the available hydraulic power is considerable and fairly constant. Conversely, the dissipation nodes in the urban WDNs frequently present a large variability in flow rate and head drop (Karadirek et al. 2012). The power availability in the WDNs is a relevant issue in order to evaluate the economical convenience of dissipation conversion. The theoretical convertible power is considerable and for Germany can be assessed as 4.7 MW (Voitht Hydro, personal communication) and extrapolating these data to the European Union area, a potential power of approximately 28.5 MW can be assessed. Because PRVs replacement with electromechanical equipment for energy production is cost effective, a fashionable challenge for hydraulic and mechanical engineers consists in finding technical solutions combining efficiency and economical convenience. To this aim PAT (pump as turbine) systems are often claimed as the cheapest and most sustainable solution (Nautiyal et al. 2010a) for energy production. Indeed, pumps can be used in turbine mode by reversing flow direction (Chapallaz et al. 1992) with the engine acting as a generator. However, to the authors’ knowledge there is still no standard design criteria available for a pattern of variable flow-rate and pressure head conditions produced by the variability of users demand, and an almost complete lack of technical information on PAT behaviour still stands out. In the present work a design method based on a Variable Operating Strategy (VOS) is proposed to predict the PAT behaviour and to find the optimal solution which maximizes the produced energy in the variable-operating-conditions of an hydro-plant scheme.

2 Energy Dissipation-Production Nodes

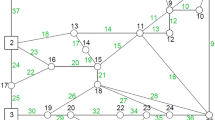

In water supply networks (Fig. 1) several energy dissipation nodes can be found with different characteristics, depending on the water network type (e.g. transmission, distribution) and on other issues such as geodetic quote variations, wear of pipelines and presence of water towers (Liberatore and Sechi 2009).

Control valves are placed within the water transmission network in order to face large variations of the geodetic quotes or to dissipate any residual head at the end of the pipeline. Furthermore, PRV are used to dissipate the surplus energy head resulting from the lower head losses of smoother new pipes during the earlier stage of their life cycle. Filion et al. (2004) showed that the conversion of this energy excess, together with the premature replacement of pipes, could be convenient. In all these cases the seasonal variability of flow rates and available head drop is very low and traditional turbines—Pelton, Francis, Kaplan or propeller—can be conveniently used (Afshar et al. 1990). On the other hand, the hydraulic regime in the water distribution network is much more variable, because flow rate and pressure head depend on the user demand (Fontana et al. 2012). Energy production nodes are located at the base of the reservoir-service tank (elevated or ground tank), or between the elevated and the ground tank, or inline (Afshar et al. 1990). The large variability of the hydraulic characteristics is shown in Fig. 2, where the flow rates (Q) and upstream pressure head (PH) values, measured in a PRV station of an urban water distribution system of Pompei in the Campania region (I), are shown for a daily demand pattern. The head drop of the PAT system and consequently the installed power of the energy production plant may vary depending on the value of the backpressure (BP), namely the preset head value downstream the pressure-reducing valve ensuring the optimal pressure distribution in all the branches. In Fig. 2 the available head is the difference between the pressures head (PH) and the required backpressure (BP). In all these cases, due to the low installed power and the need to reduce both the purchasing and maintenance costs, the use of PATs could be the best solution. Several applications can be found in technical literature on reversible electromechanical devices, used in stand-alone and grid-off power plants (Arriaga 2010), but in the last years the use of PAT is suggested for energy production even in the water supply systems (Ramos et al. 2005, 2010).

3 PAT Characteristic Curves

PATs are generally used in combination with asynchronous electric generator, having constant rotation speed. In such conditions the performances of the machines are described by the characteristic curves, which relates the flow rate and head drop. The device efficiency curve, depending on the discharge, presents a maximum: the corresponding values of discharge and head drop (\(Q_B^T\), \(H_B^T\)) is called Best Efficiency Point (BEP). Both characteristic and efficiency curves can be obtained in three ways: experimentally (Gantar 1988; Fernandez et al. 2004; Derakhshan and Nourbakhsh 2008a), by computational fluid dynamics (CFD) (Rodrigues et al. 2003; Natanasabapathi and Kshirsagar 2004) and by any one-dimensional method (Stepanoff 1957; Childs 1962; Hanckock 1963; Grover 1980; Sharma 1985; Schmiedl 1988; Alatorre-Frenk and Thomas 1990). The first choice is the most reliable, but a large number of experiments is necessary for the whole range of flow conditions and generator rotation speed. These results are generally available for classical turbines but not for PATs. CFD could be considered a valid alternative to experiments. A good agreement was found by several authors between experimental and numerical characteristic curves (Kerschberger and Gehrer 2010; Nautiyal et al. 2010b). Such opportunity is even more feasible by an optimal design of the computational grid leading to a computation time reduction without a sensible lack of precision (Fecarotta et al. 2011). For pumped storage power plants, a large number of one-dimensional methods for PAT performance prediction (Williams 1994) and machine selection (Singh and Nestmann 2010) have been proposed. Derakhshan and Nourbakhsh (2008a) developed a semi-empirical method tested on a 250 mm diameter shaft PAT. This algebraic method relates the BEP (\(Q_B^P, H_B^P\)) in pump mode to the BEP (\(Q_B^T, H_B^T\)) in turbine mode, and the latter to the turbine performance curves. The procedure could be also reverted in order to select a pump from the pump manufacturers catalogues, once the point (\(Q_B^T, H_B^T\)) is assigned.

Once the prototype characteristic and efficiency curves are available, the results may be extended to obtain the characteristic curves of other similar devices of different runner diameter and rotation speed, by using the Suter (Suter 1966; Wylie et al. 1993) parameters (see Appendix). Two machines of the same type (e.g. centrifugal, semiaxial) can be considered similar if they have either the same turbine specific speed (\(N_S^T\)) or the same pump specific speed (\(N_S^P\)):

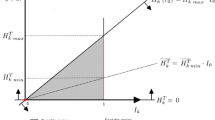

where N B , Q B , P B e H B are rotational speed, flow rate, power and head drop at the best efficiency point (BEP), respectively, and the superscript T and P refers to turbine and pump mode, respectively. There are two ways to regulate the behavior of a PAT. The first is the PAT installation in a series-parallel combination (Nautiyal et al. 2010b) as represented in Fig. 3. The characteristic curve of a PAT together with the available head, measured in Fig. 2, are plotted in Fig. 4. Herein, for an available head higher than the head-drop deliverable by the machine (left points) the series valve dissipates the excess pressure. Instead, when the discharge is larger, the PAT produces a head-drop higher than the available head: in this case the bypass is opened to reduce the discharge flowing in the PAT. This form of regulation implies an effective energy production lower than the maximum based on both available discharges and heads.

The second way consists in an electrical regulation of the rotational speed. The angular velocity of the runner can be changed by varying the frequency of the electric signal by using an inverter.

4 Variable Operating Strategy

Two main problems must be addressed for the design of a small hydro power plant in a water distribution network. The first is the lack of complete series of characteristic curves for industrial PAT. Indeed, such curves are needed for multistage mode, shaft geometry and rotation speed. The second is the absence of a strategy for turbine selection and overall efficiency computation. In Fig. 4 all the working conditions of the PRV Campania station of Fig. 2 are shown in a discharge, Q, and head-drop, H, plot. A PAT operating region wich includes all working conditions is defined. In the same plot the characteristic curve of an hypothetical PAT is also shown. The series-parallel combination system (Fig. 3) allows to convert the available operating points in PAT operating points. The proposed method is based on the preliminary introduction of an overall plant efficiency defined as

being η p the overall plant efficiency, namely the fraction of the stream hydraulic energy that can be transformed in electric energy by the power plant, n the number of available operating points, \(H_i^T\) and \(Q_i^T\) the head drop and the discharge delivered by the PAT, \(\eta_i^T\) the PAT efficiency, H i and Q i the available head drop and discharge and Δt i the time-interval discretization of discharge-head drop pattern, i.e. the operating points (Fig. 5).

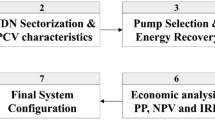

Then the following PAT design variable operating strategy (VOS) is suggested:

-

1.

A measured pattern of flow-rate and pressure-head conditions is assigned and available head is determined based on required backpressure (BP);

-

2.

PAT type is considered (e.g. centrifugal, semiaxial.);

-

3.

A wide set of PAT characteristic curves is considered in the PAT operating region;

-

4.

For each curve the overall plant efficiency is calculated by Eq. 2;

-

5.

The PAT that maximize the produced energy, i.e. the PAT having the largest η p , is considered the optimal design solution;

-

6.

The near-optimal machine is selected from the market and its turbine mode curves are calculated by Eq. 2 to verify the actual efficiency.

In order to perform step 3 and 4, the characteristic and efficiency curves for a whole set of PATs, having their BEPs in the operating region, are necessary. Such trail curves are obviously not available to technicians and a new approach is proposed herein: once a machine type (e.g. centrifugal, semiaxial) is considered and a single reference prototype machine (superscript I) curve is known, by using the turbomachine affinity law,

BEPs (\(Q_B^{II}, H_B^{II}\)) and produced power at the BEP (\(P_B^{II}\)) can be determined for any PAT, having D II diameter and N II rotational speed, similiar (superscript II) to the prototype one. Furthermore, since the Suter parameters can be calculated from the prototype data by Eq. 4 (see Appendix and Fig. 9), thus the performances curves of the similar PATs (Ramos and Almeida 2001, 2002) can be assessed. This procedure was used to obtain Fig. 6, where the BEP variations with the diameter and the rotational speed, together with some characteristic curves of seven similar turbines, are plotted. Finally, by the application of VOS on the PATs whose BEPs lye in the operating region, the diameter and the rotational speed of the PAT that gives the largest overall efficiency, together with its BEP and characteristic curve, can be identified and step 4 to 5 can be performed.

The possibility of using a reference characteristic curve of a PAT based on CFD rather than the experimental procedure (Fecarotta et al. 2011; Carravetta et al. 2011) produces great advantages. Indeed, shaft geometry and stage numbers (for multi-stage machines) can be easily modified in numerical simulations. In the following the VOS method has been tested both with CFD and experimental curves. The proposed design procedure has been applied on two different machine types, A (centrifugal, single stage, \(N_s^T = 44.0 \ [\mathrm{rpm} \ \mathrm{kW}^{\frac{1}{2}} \ \mathrm{m}^{-\frac{4}{3}}]\)) and B (semi-axial, 4 stages, \(N_s^T = 35.9 \ [\mathrm{rpm} \ \mathrm{kW}^{\frac{1}{2}} \ \mathrm{m}^{-\frac{4}{3}}]\)), whose prototypes specifications are given in Table 1. Semi-axial machines usually have \(N_s^T\) values greater than centrifugal machines, but the number of stages (s n ) yields a specific speed reduction related to s n 3/4 (Ramos 2000). For both prototypes the experimental characteristic and efficiency curves were available, together with the 3D geometrical models, thus also the CFD curves were calculated. For each CFD calculation, a great effort has been made in order to minimize the number of elements and the computational resources request, as suggested by Fecarotta et al. (2011). The single stage configuration of the machine A has been simulated dividing the fluid domain into 2,121,688 elements, while the 4 stages of the machine B have been divided into 2,083,965 elements. The massflow value at the inlet section and the average static pressure value at the outlet of the two machines have been considered as boundary conditions. The CFX software has been used and an upwind first order numerical scheme has been used for advection, as well as a high resolution second order numerical scheme for the turbulence and a second order backward eulerian scheme for the transient calculations. The agreement of the CFD results with the experimental data, as shown in Figs. 7 and 8, is very high and these results have been used to perform the VOS turbine selection method.

VOS has been applied to six hypothetical power plants (A1, A2, A3, B1, B2, B3) generated by modifying the backpressure value for the set of data of Fig. 4, as reported in the second column of Table 2. For each of the six plants, the optimal PAT has been found by the application of the VOS. The CFD prototypes curves have been used as reference, in order to find the optimal design rotational speeds and diameters of the machine type A—for cases A1, A2 and A3—and of machine type B—for cases B1, B2 and B3, as reported in the third and fourth columns of Table 2. The overall efficiencies η p of the six plants, resulting from the application of the VOS, are reported in the fifth column. According to the available pressure head and discharge measurements, η p calculations have been performed on 15 min sampling, assuming constant (Q i , H i ) values foe each time interval. VOS results show that in all cases more than 50 % of the available energy can be converted by a PAT installed in a series-parallel combination. The average daily energy production (ADEP) is shown in the seventh column of Table 2. It is interesting to observe that the choice of a runner diameter or a runner speed different from the VOS optimal one will produce a high performance reduction. For example, for case A1 the use of D = 230 mm instead of D = 194 mm will prduce an efficiency η p = 0.34, while a runner speed n = 1,500 instead of n = 3,000 will produce an efficiency η p = 0.21.

Furthermore, in order to verify the real efficiency of such designed plants, the characteristic and the efficiency curves of the six PATs have been simulated by Eq. 7 using the experimental prototypes curves. Such values of efficiency \(\eta_p^{EXP}\) are reported in the sixth column of Table 2. The results show that more than the half of the available energy can be reconverted by PATs. The comparison between the design and experimental efficiencies shows that the CFD technique could be a valid tool for the calculation of the PAT performance curves, since the average and maximum errors, \((\eta_p - \eta_p^{EXP})/\eta_p^{EXP}\) , are, respectively, 4.46 and 10.4 %.

The last step of VOS consists in selecting the PAT from the market, once the machine type (e.g. centrifugal, semi-axial) and the runner diameter have been selected. The near-optimal PAT, similar to the prototype one, can be identified by the comparison of \(N_S^P\), since it is known for the prototype and can be easily calculated from the pump performances reported on the pump catalogues.

5 Conclusions

The main result of the paper is the Variable Operating Strategy (VOS) for PAT design in WDNs. A number of straightforward item rules are stated that allow PAT’s geometry selection for a given flow-head distribution pattern and optimal network back pressure. VOS design allows maximum efficiency of the power plant and a continuous pressure regulation for a PAT installed in a series-parallel configuration. The PAT characteristic curve, expressing the relation between flow rate and head drop, and the related efficiency curve, could be determined, alternatively, experimentally, based on CFD - computational fluid dynamics, or calculated analytically by one-dimensional methods. Furthermore VOS, used in combination with a CFD based characteristic curves, furnishes very accurate design solutions. In absence of a complete pump producers’ characterization of PAT performance, CFD is a valid alternative to experiments. Computational fluid dynamics is an ideal tool for simulating pump geometries in PAT reverse working conditions. The effect of any change in runner configuration, or of pump stage increase, can be simulated and used in VOS comparisons.

References

Afshar A, Jemaa F, Marino M (1990) Optimization of hydropower plant integration in water supply system. J Water Res Pl-ASCE 116(5):665–675

Alatorre-Frenk C, Thomas T (1990) The pumps as turbines approach to small hydropower. In: World congress on renewable energy, Reading

Almandoz J, Cabrera E, Arregui F, Cabrera E, Cobacho R (2005) Leakage assessment through water distribution network simulation. J Water Res Pl-ASCE 131(6):458–466

Araujo L, Ramos H, Coelho S (2006) Pressure control for leakage minimisation in water distribution systems management. Water Resour Manage 20(1):133–149

Arriaga M (2010) Pump as turbine—a pico-hydro alternative in Lao people’s democratic republic. Renew Energy 35:1109–1115

Carravetta A, Giugni M (2009) Functionality factors in the management and rehabilitation of water networks. In: Management of water networks, proc conf efficient management of water networks. Design and Rehabilitation Techniques, Franco Angeli Ed. Milano

Carravetta A, Fecarotta O, Ramos H (2011) Numerical simulation on pump as turbine: mesh reliability and performance concerns. In: IEEE (ed) international conference on clean electrical power. Ischia, Franco Angeli Ed. Milano

Chapallaz J, Eichenberger P, Fischer G (1992) Manual on pumps used as turbines. DeutschesZentru fur Entwicklungstechnologien, GATE, Eschborn

Childs S (1962) Convert pumps to turbines and recover HP. Hydrocarbon Processing and Petroleum Refiner 41(10):173–174

Derakhshan S, Nourbakhsh A (2008a) Experimental study of characteristic curves of centrifugal pumps working as turbines in different specific speeds. Exp Therm Fluid Sci 32:800–807

Fecarotta O, Carravetta A, Ramos H (2011) CFD and comparisons for a pump as turbine: mesh reliability and performance concerns. Int J Energy Environ 2(1):39–48

Fernandez J, Blanco E, Parrondo J, Stickland M, Scanlon T (2004) Performance of a centrifugal pump running in inverse mode. Proc Inst Mech Eng A J power energy 218(4):265–271

Filion Y, MacLean H, Karney B (2004) Life cycle energy analysis of a water distribution system. J Infrastruct Syst 10(3):120–130

Fontana N, Giugni M, Portolano D (2012) Losses reduction and energy production in water-distribution networks. J Water Res Pl-ASCE 138(3):237–244

Gantar M (1988) Propeller, pump running as turbines. In: Conference on hydraulic machinery

Gonçalves F, Costa L, Ramos H (2011) ANN for hybrid energy system evaluation: methodology and WSS case study. Water Resour Manage 25:2295–2317

Grover K (1980) Conversion of pumps to turbines. In: GSA Inter corp. Katonah, New York

Hanckock J (1963) Centrifugal pump or water turbine. Pipe Line News, 25–27

Karadirek I, Kara S, Yilmaz G, Muhammetoglu A, Muhammetoglu H (2011) Implementation of hydraulic modelling for water-loss reduction through pressure management. Water Resour Manage. doi:10.1007/s11269-012-0032-2

Kerschberger P, Gehrer A (2010) Hydraulic development of high specific-speed Pump-turbines by means of an inverse design method, numerical flowsimulation (CFD) and model testing. In: 25th IAHR symposium on hydraulic machinery and systems. IOP Conf. Series: Earth and Environmental Science, vol 12

Liberatore s, Sechi G (2009) Location and calibration of valves in water distribution networks using a scatter-search meta-heuristic approach. Water Resour Manage 23:1479–1495

Natanasabapathi S, Kshirsagar J (2004) Pump as turbine: an experience with CFX-5.6. In: Corporate research and engineering division. Pune, India, Kirloskar Bros. Ltd

Nautiyal H, Varun, Kumar A (2010a) CFD analysis on pumps working as turbines. Hydro Nepal, vol 6, 35–37

Nautiyal H, Varun, Kumar A (2010b) Reverse running pumps analytical, experimental and computational study: a review. Renew Sustain Energy Rev 14:2059–2067

Nazif S, Karamouz M, Tabesh M, Moridi A (2011) Pressure management model for urban water distribution networks. Water Resour Manage 24:437–458

Prescott S, Ulanicki B (2008) Improved control of pressure reducing valves in water distribution networks. J Hydraul Eng-ASCE 134(1):56–65

Ramos H, Almeida A (2001) Dynamic orifice model on waterhammer analysis of high or medium heads of small hydropower plants. J Hydraul Res 39(4):429–436

Ramos H, Almeida A (2002) Parametric analysis of water-hammer effects in small hydro schemes. J Hydraul Eng-ASCE 128(7):1–8

Ramos H (2000) Guidelines for design of small hydropower plants. WREAN and DED, Belfast, North Ireland

Ramos H, Covas D, Araujo L, Mello M (2005) Available energy assessment in water supply systems. In: XXXI IAHR congress. Seoul, Korea

Ramos H, Mello M, De P (2010) Clean power in water supply systems as a sustainable solution: from planning to practical implementation. Water Sci Technol 10(1):39–49

Rodrigues A, Singh P, Williams A, Nestmann F, Lai E (2003) Hydraulic analysis of a pump as a turbine with CFD and experimental data. In: IMechE seminar computational fluid dynamics for fluid machinery

Schmiedl E (1988) Serien-Kreiselpumpentagung. Karlsruhe

Sharma K (1985) Small hydroelectric projects—use of centrifugal pumps as turbines. In: Kirloskar Electric o. Bangalore, India

Singh P, Nestmann F (2010) An optimization routine on a prediction and selection model for the turbine operation of centrifugal pumps. Exp Therm Fluid Sci 34(2):152–164

Stepanoff A (1957) Centrifugal and axial flow pumps. John Wiley, New York

Suter P (1966) Representation of pump characteristics for calculation of water hammer. Sulzer Tech Rev 4:45–48

Tucciarelli T, Criminisi A, Termini D (1999) Leak analysis in pipeline systems by means of optimal valve regulation. J Hydraul Eng-ASCE 125(3):277–285

Vairavamoorthy K, Lumbers J (1998) Leakage reduction in water distribution systems: optimal valve control. J Hydraul Eng-ASCE 124(11):1146–1154

Walsky T, Bezts W, Posluzny E, Weir M, Withman B (2006) Modeling leakage reduction through pressure control. J Am Water Works Ass, pp 148–155

Williams A (1994) The turbine performance of centrifugal pumps: a comparison of predictione methods. Proc Inst Mech Eng A J power energy 208(1):59–66

Wylie E, Streeter V and Suo L (1993) Fluid transient in systems. Prentice Hall, Englewood Cliffs, NJ 7632

Acknowledgements

The authors would like to thank Caprari s.p.a. and Eng. Lauro Antipodi for having provided both the experimental performance curves and the 3D-geometry of the two machines.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

In 1966 Suter introduced two parameters (see also Wylie et al. 1993):

where

represents the operating condition of the machine and

Being T the torque applied to the runner. The two functions WH(θ) and WT(θ) are unique for similar machines. Thus, once they are available for a prototype machine, they can be used to calculate the head drop H T and the efficiency η T of similar PATs in any operating condition θ

where \(\eta_B^T\) is the efficiency of the machine at the BEP. In Fig. 9 the Suter parameters of the machines A and B are shown for the turbine operating mode.

Rights and permissions

About this article

Cite this article

Carravetta, A., Del Giudice, G., Fecarotta, O. et al. Energy Production in Water Distribution Networks: A PAT Design Strategy. Water Resour Manage 26, 3947–3959 (2012). https://doi.org/10.1007/s11269-012-0114-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-012-0114-1