Abstract

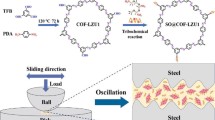

Mechanochemical reactions induced by external stress provide a unique approach for in situ synthesis of carbon tribofilms that can improve friction and wear performance. In this work, we studied how tribofilm formation and tribological performance might be related to the adsorption strength of three additives in polyalphaolefin (PAO4) as base oil, viz., cyclopropanecarboxylic acid (CPCa), cyclopropanemethanol (CPMA), and 1-cyclopropylethanol (CPEA) as characterized by two different surface-active groups –COOH and –OH. Tribo-testing results reveal that addition of 2.5 wt% CPCa to PAO4 gave the lowest friction coefficient and wear volume. FTIR and Raman analysis demonstrate substantial tribofilm formation only in the case when CPCa was used as the oil additive, not CPMA or CPEA, in spite of the fact that all three additives contain the same metastable cyclopropane ring. Thermogravimetric analysis and molecular dynamics simulations indicate the stronger adsorption of CPCa on the iron oxide surface compared with CPMA and CPEA. Weak adsorption of the latter molecules results in their desorption from the surface due to flash heating during tribotesting before they have the chance to participate in mechanochemical reactions required for tribofilm formation. The stronger binding of CPCa to the steel surface is a necessary condition for this type of surface mechanochemistry and appears critical to the efficient formation of carbon-containing tribofilms under our tribo-testing conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Several previous studies demonstrate the important role of mechanical forces in the initiation or acceleration of chemical reactions [1,2,3], possibly by modifying activation energies for different reaction pathways [4]. For example, ultrasound induces the ring opening of trans and cis isomers of 1,2-disubstituted benzocyclobutene, yielding identical products. This is in contrast to the different products obtained from these isomers when induced by heat or light alone [1]. Under full-film elastohydrodynamic lubrication without solid–solid contact, shear stress has been shown to accelerate tribofilm formation from the dissociation of zinc dialkyldithiophosphate (ZDDP) [5]. The applied shear stress effectively decreases the activation energy for the dissociation of ZDDP by half. As noted by Gosvami et al. [6], ZDDP tribofilm growth rate increases exponentially with either applied stress or temperature, consistent with a thermally activated, stress-assisted reaction rate model. This highlights the role of stress on tribofilm formation. In addition, recent studies reveal that molecular structure [7, 8] and substrate materials [9, 10] influence the mechanochemical reaction kinetics during the friction process. These investigations indicate that mechanical energy input provides a new strategy for unique chemical synthesis [11], but the control of specific synthetic pathways via appropriate combination of temperature and mechanical energy input remains non-trivial [12].

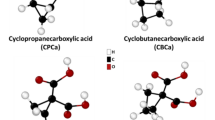

Recent work by Kim et al. [9] have revealed that the tribopolymer yield during vapor phase lubrication using α-pinene is much higher on substrates that can chemisorb α-pinene, as compared with those on which only physisorption occurs. In our previous work [13], we explored the fragmentation of cyclopropanecarboxylic acid (CPCa) as a precursor to carbon tribofilm formation, due to the metastability of the cyclopropane ring. Literature studies [2, 14, 15] have demonstrated that mechanical stress alone is sufficient to open the cyclopropane ring. In the same spirit as Kim et al. [9], we wish to investigate how tribofilm formation based on the fragmentation of CPCa depends on the binding energy of the adsorbate on steel surfaces and hence the effect on tribological properties. We differ in our approach by modifying the surface-active component of adsorbate molecules while keeping the same substrate (steel). Specifically, three adsorbate molecules were explored in this investigation: cyclopropanecarboxylic acid (CPCa), cyclopropanemethanol (CPMA), and 1-cyclopropylethanol (CPEA), as shown in Fig. 1.

The two different surface-active groups represented in these adsorbate molecules, viz., –COOH and –OH, are expected to have different adsorption energies on steel surfaces. For example, Jahanmir and Beltzer [16] showed that the Gibbs free energy of adsorption on steel surfaces is more negative for R-COOH than R-OH (R being an alkyl group). Simič et al. [17] demonstrated that hexadecanoic acid adsorbs more strongly on a-CHx surfaces than hexadecanol. These results suggest that –COOH interacts more strongly with the surface than –OH. We would like to find out if this is also true for the additive molecules used in this investigation. To complement our experimental studies, we used molecular dynamics simulations to compare the adsorption geometry and strength of CPCa and CPMA on steel surfaces.

2 Materials and Methods

2.1 Materials and Experiment Procedures

CPCa (purity of 95%), CPMA (purity of ≥ 99.5%), and CPEA (purity of 99%) were obtained from Sigma-Aldrich and used as received. Their boiling point are 456 K, 397 K and 394 K, respectively. Fe3O4 powders, 50–100 nm in diameter and purity of 97%, were purchased from Sigma-Aldrich and used as received. PAO4 oil was provided by Valvoline Inc. The dynamic viscosity of the base oil at 298 K is 0.032 kgm−1 s−1. A unidirectional ball-on-disk tribometer (CETR UMT-2) was used to study the tribological behavior of CPCa, CPMA, and CPEA [13]. Tribological tests were carried out at a load of 10 N and speed of 0.2 m/s at room temperature (295–298 K) and humidity (relative humidity of 22–24%) for these three molecules as lubricant additives (2.5 wt% in PAO4 oil). The ball and disk samples, made of AISI 52,100 bearing steel with a hardness of about 60 HRC, were obtained from McMaster-Carr Company. The balls (Ra = 20 nm, diameter = 9.5 mm) were used as received. Disks were polished using a series of SiC sandpapers to a surface finish Ra of 60.3 ± 2.5 nm, as determined by optical interferometry sampling three randomly chosen areas of each disk specimen measuring 700 μm × 530 μm. Under these conditions, using Young’s modulus of 210 GPa and Poisson ratio of 0.3 for both disk and ball material, we calculated the maximum Hertzian contact stress to be 1.05 GPa. Please note that the value is based on smooth-smooth contact and therefore holds valid for surfaces before the test. Based on the load, speed, materials used, and test geometry, the average lubricant film thickness/composite root-mean-square surface roughness is around 0.74, indicating that the tests were conducted in the deep mixed and boundary lubrication regime. After tribological tests, the ball was rinsed with hexane to remove residual oil, and its profile was measured using Zygo NewView 7300 optical surface profiler to calculate the wear volume. We used Raman spectroscopy (Horiba LabRam HR Evolution Confocal Raman microscope) and micro-FTIR (Bruker LUMOS FTIR Microscope) to study the deposit. Raman spectroscopy studies were carried out using laser wavelength of 473 nm with analyzed area of 10 μm2. Micro-FTIR measurements were performed with a 32 × objective lens and analyzed area of 50 μm2. An LEXT OLS 5000 laser confocal microscope was used to obtain the topography of surfaces.

The adsorption of CPCa and CPMA on Fe3O4 was investigated using thermogravimetric analysis (TGA), combined with differential thermal analysis (DTA) and mass spectrometry (MS), respectively. TGA-DTA-MS tests were performed in a Netzsch STA 449 F3 Jupiter Simultaneous Thermal Analysis (STA) instrument. The experiments were performed in helium from 20 to 500 °C, at a heating rate of 10 °C min−1. MS scans were in the range of 10–500 amu.

2.2 Computational Procedures

The atomistic simulation model to compare the adsorption strength of CPCa and CPMA consists of an iron oxide (Fe3O4) substrate with 25 adsorbate molecules on top of it. Fe3O4 is a common oxide phase present on lightly alloyed steel surfaces due to air exposure [18]. The initial dimensions of the setup are 34.13 Å, 34.13 Å, and 54 Å in the x, y, and z- directions, respectively (Fig. 2). We applied periodic boundary conditions along the x- and y-directions. The Fe3O4 surface was passivated by saturating it with an initial layer of hydrogen atoms and relaxed for 100 ps at 300 K before introducing the adsorbate molecules.

The simulations were conducted by using the large-scale atomic/molecular massively parallel simulator (LAMMPS) [19]. The reactive force field (ReaxFF) method, a highly transferable force field used for hydrocarbons, was employed in this study. The complete details of ReaxFF have been described previously by Duin et al. [20]. We derived the iron parameters from the recently developed ReaxFF parameters for Fe/Al/Ni alloys [21] and C/H/O parameters from Obaidur et al. [22].

The simulation was conducted in two stages: (a) the equilibrium stage, in which 25 adsorbate molecules placed on top of the substrate are allowed to adsorb and equilibrate on the surface at 300 K, and (b) the desorption stage, in which the temperature of the system is raised to 400 or 450 K to allow for desorption of these molecules. The equilibrium stage was conducted for 100 ps, long enough for equilibrium to set in. The desorption stage of the simulation was conducted for 300 ps. The procedure used to calculate the number of adsorbed molecules during the simulation will be explained in the Results section. Throughout the simulation, we used a time step of 0.25 fs, and the atoms present in the bottom 10 Å of Fe3O4 were fixed to their initial positions. Molecular visualizations were done by the OVITO software [23].

3 Results

3.1 Tribo-testing

Figure 3 shows the friction and wear of the ball specimens in ball-on-disk tribotesting at a load of 10 N and sliding speed of 0.2 m/s, using pure PAO4, 2.5 wt% CPCa, CPMA, and CPEA dissolved in PAO4 base oil, respectively. CPCa appears to be the most effective additive, resulting in the lowest friction and wear. The other two additives (CPMA and CPEA), though containing the same cyclopropane ring, give friction and wear performance statistically the same as PAO4.

Tribological performance of four lubricants (pure PAO4, 2.5 wt% CPCa, CPMA, and CPEA dissolved in PAO4 respectively) in ball-on-disk tribotesting at 10 N and sliding speed of 0.2 m/s: a friction coefficient; b wear volume obtained from the ball after 1800 s (error bars represent one standard deviation based on three separate tests)

Figure 4 shows the micro-FTIR and Raman spectra obtained from the ball wear scar after tribo-testing and rinsing with hexane to remove PAO4. Both spectra demonstrate the formation of a tribofilm when the tribo-testing was performed with CPCa as the lubricant additive. The characteristic D and G bands (around 1585 cm−1 and 1350 cm−1 respectively) are clearly visible in the Raman spectrum for the tribofilm obtained from CPCa. For FTIR, O–H stretch around 3400 cm−1, C−H stretch between 2800 and 3000 cm−1, and CH2 bending around 1450 cm−1 are observed. The thickness of the tribofilm was measured by laser confocal microscopy to be 2.6 ± 0.08 μm.

We conducted screening experiments using 2.5 wt% butanoic acid and 2.5 wt% cyclohexanecarboxylic acid (CHCa) dissolved in PAO4 respectively. One can think of butanoic acid as CPCa with the cyclopropane ring replaced by a linear propyl chain, while CHCa as CPCa with the cyclopropane ring replaced by cyclohexane. Under the same tribotesting conditions, butanoic acid results in a wear volume of 9500 μm3. As shown in Fig. 3b, this wear volume is similar to that for PAO, CPMA, and CPEA, about ten times that for CPCa. Testing with CHCa results in marked adhesive wear preventing accurate measurement of wear volume. Results of these screening experiments are consistent with the relative inertness of the linear propyl chain and cyclohexane with respect to cyclopropane, preventing their dissociation to form tribofilms.

Figures 3 and 4 together give the first indication that having a metastable cyclopropane moiety is not sufficient for efficient production of low-friction, anti-wear tribofilms. As discussed earlier, the two surface-active groups, –OH and –COOH, may give different binding strengths for the corresponding adsorbates, thus affecting the mechanochemical reaction pathways to tribofilm formation for these two precursors.

3.2 Thermogravimetric and Desorption Studies

To explore the point raised in the preceding paragraph about the dependence of tribofilm formation on the nature of surface-active groups, we performed TGA-DTA analysis of a sample containing 15 mg of Fe3O4 powders loaded with 131 mg CPCa. The result is shown in Fig. 5a. Most of the liquid desorbs at 458 K, followed by a smaller loss at about 473 K. The residual product has a mass of 4.5 mg, remaining on the surface until about 623 K. Figure 5b shows the corresponding result when the experiment was repeated using a sample containing 15 mg of Fe3O4 powders loaded with 131 mg CPMA. In this case, the liquid desorbs at 411 K with no measurable residual product. When these experiments were repeated with different CPCa and CPMA loadings while keeping the amount of Fe3O4 approximately constant, we found that the mass of the product varies linearly with CPCa loading. On the other hand, we observed no measurable residual product with CPMA loading from zero to 160 mg (Fig. 5c).

As noted from our recent work [24], the residual thermal product is an oligomer/polymer with molecular weight up to about 1500 and is chemically identical to the tribofilm observed in tribo-testing experiments. The above observations suggest that the binding of adsorbate molecules must be strong enough to remain on the surface at temperatures required for tribofilm formation.

To investigate this issue further, we made three samples: 50 mg Fe3O4 powders mixed with 150 mg CPCa, 50 mg Fe3O4 powders mixed with 150 mg CPMA, and 50 mg Fe3O4 powders mixed with 150 mg CPEA. Each sample was allowed to evaporate at room temperature for 72 h. It is safe to assume that after this procedure, at most one or two monolayers of these adsorbates were left on the surface. We then performed thermal desorption from each sample, detecting the desorbed molecules using MS set at m/e = 39, 41, 85 for CPCa, the primary signals for CPCa; m/e = 31, 43, 44 for CPMA, the primary signals for CPMA; and m/e = 39, 43, 58 for CPEA, the primary signals for CPEA.

Figure 6a shows that all three m/e (= 39, 41, and 85) signals reach their maxima around 543 K. This maximum desorption temperature is markedly higher than 458 K, the vaporization temperature for the bulk CPCa liquid (Fig. 5a), indicating the strong binding of CPCa to the steel surface. In contrast, as shown in Figs. 6b, c, we did not detect signals that could be attributed to the desorption of CPMA and CPEA (m/e = 43 for CPMA and m/e = 58 for CPEA), consistent with the TGA-DTA results in Figs. 5b, c. These results indicate few CPMA or CPEA molecules remaining on the surface after extended drying due to their weaker binding to the surface compared with CPCa. Therefore, during tribo-testing, CPMA or CPEA desorbs from the surface due to frictional flash-heating or the applied shear stress, well before it has the opportunity to dissociate and react to form tribofilms. According to our previous calculations [13], the flash temperature was estimated to be around 400 K for 10 N under 0.2 m/s speed. We should add that the balance between desorption and reaction kinetics is system-dependent. For other surfaces, adsorbates with –OH functional groups may bind to the surface strong enough to initiate reactions required for tribofilm formation. Alternatively, sufficiently high arrival rates of adsorbates to the surface can compensate for weaker binding to maintain reasonable surface coverage for substantial tribofilm formation [25].

3.3 Molecular Dynamics Simulations

To interpret experimental findings in terms of the relative adsorption strengths of different additive molecules, we conducted MD simulations to study the adsorption of CPCa and CPMA on the Fe3O4 surface at 400 and 450 K. These temperatures are based on flash temperature estimates from our previous work [13]. We started with 25 molecules on the surface in each case and monitored the center of mass (CoM) for each molecule during the simulation. Our objective is to determine the number of molecules adsorbed on the surface as a function of time. An important detail that needs to be resolved is the critical distance between the CoM of a given molecule and the surface beyond which we can identify that molecule as not being adsorbed. Here, we define the radius of a molecule as the distance between the CoM and the furthest atom of the molecule. Using this definition, we found this radius to be 2.86 Å for CPCa and 2.16 Å for CPMA respectively as shown in Fig. 7. Based on this definition, we set the critical distance to be three times the radius of the molecule in question. This distance corresponds to approximately the location of the second monolayer. The critical distance so defined provides a useful demarcation between adsorbed and desorbed molecules.

Using the demarcation criterion described in the preceding paragraph, we plot the number of adsorbed molecules as a function of time in Fig. 8. Note that the initial 100 ps time block in the plots corresponds to the equilibrium stage of the simulation at 300 K. At 100 ps, the temperature of the system is raised while maintaining the system volume constant. At 400 ps, all 25 CPCa molecules remain on the surface at 400 and 450 K. On the other hand, at 400 ps, only 16 CPMA molecules remain on the surface at 400 K, decreasing to 3 at 450 K. These results indicate that CPCa adsorbs more strongly on the iron oxide surface than CPMA. This conclusion is not affected when we modify the demarcation criterion as discussed earlier, e.g., changing the critical distance to four times the radius of the molecule instead of three. Consistent with experimental data, these simulation results suggest that unlike CPCa, most CPMA molecules are desorbed from the surface due to temperature increase, equivalent to frictional flash-heating under applied shear stress during tribotesting, thus reducing the amount of source material needed for tribofilm formation and hence resulting in poorer tribological performance.

In the course of our MD studies, we discovered a somewhat surprising result regarding the orientation of adsorbed CPCa and CPMA molecules. Molecular adsorption of aliphatic alcohols and carboxylic acids on metal and oxide surfaces, as widely reported in the surface science literature, leads to an approximate vertical orientation due to the –COOH and –OH groups interacting the surface respectively. However, in the case of CPCa and CPMA, they are strongly tilted, as demonstrated in Fig. 9, which shows two of the most common adsorption orientations for CPCa and CPMA obtained from our simulation studies. By “tilted”, we mean that the cyclopropane ring in CPCa and CPMA tilts towards the surface. Previous studies of cyclopropane adsorption on metal and metal oxide surfaces [26, 27] found that cyclopropane tends to achieve a tilted orientation with one C–C bond parallel to the surface. Hoffman et al. [28] suggested that this is due to the participation of the σC–C orbital, which possesses some delocalized charge due to the ring strain, in interacting with the surface. Our observed tilted orientation of CPCa and CPMA appears consistent with such an interaction. This result also indicates that in spite of the cyclopropane moiety contributing to adsorption, this contribution is not sufficient for CPMA to maintain substantial surface coverage at 400 K. Therefore, our overall finding is that while the ring strain would facilitate tribochemical reactions [7], it is not a sufficient condition. Without strong binding to the surface, there is insufficient coverage of these precursor molecules to form tribofilms under our tribo-testing conditions.

4 Conclusions

In this study, we investigated how the tribological behavior and tribofilm formation might be related to the adsorption behavior of cyclopropanecarboxylic acid (CPCa), cyclopropanemethanol (CPMA), and 1-cyclopropylethanol (CPEA) as additives to PAO4 base oil. The major conclusion is that tribofilm formation is favored by strong adsorption of additive molecules on the friction surface, which in turn affects the tribological performance. Specific results are summarized as follows:

- (a)

Addition of 2.5 wt% CPCa (a metastable carbon ring with a surface-active –COOH group) to PAO4 gives rise to low friction and low wear in ball-on-disk tribotesting under boundary lubrication conditions, along with substantial carbon tribofilm formation. On the other hand, addition of 2.5 wt% CPMA or CPEA (both with a metastable carbon ring and a surface-active –OH group) to PAO4 results in friction and wear similar to the base oil, with little tribofilm formation.

- (b)

CPCa binds to the Fe3O4 surface stronger than CPMA or CPEA, as shown by TGA coupled with MS. This stronger binding allows a sufficiently high concentration of CPCa precursor molecules to remain on the surface to undergo mechanochemical reactions for substantial carbon tribofilm formation.

- (c)

Based on molecular dynamics simulation, CPMA molecules desorb rapidly from the Fe3O4 surface at 400 K, while CPCa remains adsorbed at 400 and 450 K. At 300 K, both molecules adsorb on the Fe3O4 surface in a strongly tilted orientation, indicating interaction of the metastable carbon ring with the surface.

References

Hickenboth, C.R., Moore, J.S., White, S.R., Sottos, N.R., Baudry, J., Wilson, S.R.: Biasing reaction pathways with mechanical force. Nature 446(7134), 423 (2007)

Ribas-Arino, J., Marx, D.: Covalent mechanochemistry: theoretical concepts and computational tools with applications to molecular nanomechanics. Chem. Rev. 112(10), 5412–5487 (2012)

Yeon, J., He, X., Martini, A., Kim, S.H.: Mechanochemistry at solid surfaces: polymerization of adsorbed molecules by mechanical shear at tribological interfaces. ACS Appl. Mater. Interfaces 9(3), 3142–3148 (2017)

Tysoe, W.: On stress-induced tribochemical reaction rates. Tribol. Lett. 65(2), 48 (2017)

Zhang, J., Spikes, H.: On the mechanism of ZDDP antiwear film formation. Tribol. Lett. 63(2), 24 (2016)

Gosvami, N., Bares, J., Mangolini, F., Konicek, A., Yablon, D., Carpick, R.: Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 348(6230), 102–106 (2015)

He, X., Kim, S.H.: Mechanochemistry of physisorbed molecules at tribological interfaces: molecular structure dependence of tribochemical polymerization. Langmuir 33(11), 2717–2724 (2017)

He, X., Barthel, A.J., Kim, S.H.: Tribochemical synthesis of nano-lubricant films from adsorbed molecules at sliding solid interface: tribo-polymers from α-pinene, pinane, and n-decane. Surf. Sci. 648, 352–359 (2016)

He, X., Kim, S.H.: Surface chemistry dependence of mechanochemical reaction of adsorbed molecules-an experimental study on tribopolymerization of α-pinene on metal, metal oxide, and carbon surfaces. Langmuir 34(7), 2432–2440 (2018)

Khajeh, A., He, X., Yeon, J., Kim, S.H., Martini, A.: Mechanochemical association reaction of interfacial molecules driven by shear. Langmuir 34(21), 5971–5977 (2018)

Do, J.-L., Friščić, T.: Mechanochemistry: a force of synthesis. ACS Central Sci. 3(1), 13–19 (2016).

Andersen, J.M., Mack, J.: Decoupling the Arrhenius equation via mechanochemistry. Chem. Sci. 8(8), 5447–5453 (2017)

Johnson, B., Wu, H., Desanker, M., Pickens, D., Chung, Y.-W., Wang, Q.J.: Direct formation of lubricious and wear-protective carbon films from phosphorus-and sulfur-free oil-soluble additives. Tribol. Lett. 66(1), 2 (2018)

Lenhardt, J.M., Ong, M.T., Choe, R., Evenhuis, C.R., Martinez, T.J., Craig, S.L.: Trapping a diradical transition state by mechanochemical polymer extension. Science 329(5995), 1057–1060 (2010)

Wang, J., Kouznetsova, T.B., Craig, S.L.: Single-molecule observation of a mechanically activated cis-to-trans cyclopropane isomerization. J. Am. Chem. Soc. 138(33), 10410–10412 (2016)

Jahanmir, S., Beltzer, M.: Effect of additive molecular structure on friction coefficient and adsorption. J. Tribol. 108(1), 109–116 (1986)

Simič, R., Kalin, M., Kovač, J., Jakša, G.: Adsorption of alcohols and fatty acids onto hydrogenated (aC: H) DLC coatings. Appl. Surf. Sci. 363, 466–476 (2016)

Fursey, A.: Oxide films on mild steel. Nature 207(4998), 747 (1965)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. JCoPh 117(1), 1–19 (1995)

Van Duin, A.C., Dasgupta, S., Lorant, F., Goddard, W.A.: ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105(41), 9396–9409 (2001)

Kyung, S.Y., Hyunwook, K., Chenyu, Z., Vasenkov, A.V., Van Duin, A.C.T.: Development and validation of a ReaxFF reactive force field for Fe/Al/Ni alloys: molecular dynamics study of elastic constants, diffusion, and segregation. J. Phys. Chem. A 116(49), 12163–12174 (2012).

Obaidur, R., Van Duin, A.C.T., Goddard, W.A., Doren, D.J.: Development of a ReaxFF reactive force field for glycine and application to solvent effect and tautomerization. J. Phys. Chem. B 115(2), 249–261 (2011)

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18(1), 015012 (2009)

Wu, H., Khan, A.M., Johnson, B.A., Sasikumar, K., Chung, Y.-W., Wang, Q.J.: Formation and nature of carbon-containing tribofilms. ACS Appl. Mater. Interfaces 11(17), 16139–16146 (2019)

Barthel, A.J., Combs, D.R., Kim, S.H.: Synthesis of polymeric lubricating films directly at the sliding interface via mechanochemical reactions of allyl alcohols adsorbed from the vapor phase. RSC Adv. 4(50), 26081–26086 (2014)

Martin, R., Kim, M., Franklin, A., Bian, Y., Weaver, J.F. Adsorption and oxidation of propane and cyclopropane on IrO 2 (110). PCCP 20(46), 29264–29273 (2018).

Javahery, G., Petrie, S., Wang, J., Bohme, D.K.: A theoretical study on the cyclopropane adsorption onto the copper surfaces by density functional theory and quantum chemical molecular dynamics methods. J. Mol. Catal. A 220(2), 189–198 (2004)

Hoffmann, F.M., Felter, T.E., Weinberg, W.H.: The orientation and symmetry of adsorbed cyclopropane on Ru(001) measured by off specular high resolution electron energy loss spectroscopy and angular resolved photoelectron spectroscopy. J. Chem. Phys. 76(7), 3799–3808 (1982)

Acknowledgements

The authors would like to thank the support from the US National Science Foundation (Grant No. CMMI-1662606). We thank Valvoline for providing PAO lubricants and Prof. Seong H. Kim for critical reading of this manuscript. This work made use of the Keck-II Facility of Northwestern University’s NUANCE Center, which has received support from the Keck Foundation, the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205), the Materials Research Center (NSF DMR-1121262), the McCormick Research Catalyst Awards Fund, Grant No. 10038293, and the International Institute for Nanotechnology (IIN) at Northwestern University. We would like to thank Dr. Xinqi Chen for his help in conducting FTIR spectroscopy. Hongxing Wu and Qiang Ma would also like to acknowledge the scholarship support from China Scholarship Council (CSC, Nos. 201606280181 and 201806280152 respectively). This research was supported in part through the computational resources and staff contributions provided for the Quest high performance computing facility at Northwestern University, which is jointly supported by the Office of the Provost, the Office for Research, and Northwestern University Information Technology.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, A.M., Wu, H., Ma, Q. et al. Relating Tribological Performance and Tribofilm Formation to the Adsorption Strength of Surface-Active Precursors. Tribol Lett 68, 6 (2020). https://doi.org/10.1007/s11249-019-1249-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-019-1249-5