Abstract

Aqueous gels such as biopolymer gels, mucus, and high water content hydrogels are often qualitatively described as lubricious. In hydrogels, mesh size, ξ, has been found to be a controlling parameter in friction coefficient. In the tribology of aqueous gels, we suggest that the Weissenberg number (Wi) is a useful parameter to define different regimes, and following the original formulations in rheology, Wi is given by the polymer relaxation time (ηξ3/kBT) multiplied by the shear rate due to fluid shear through a single mesh (V/ξ): Wi = ηVξ2/kBT. At sliding speeds below a Weissenberg number of approximately 0.1, Wi < 0.1, the friction coefficient is velocity-independent and scales with mesh size to the − 1 power, µ ∝ ξ−1. De Gennes’ scaling concepts for elastic modulus, E, give a dependence on polymer mesh size to the − 3 power, E ∝ ξ−3, and following Hertzian contact analysis, the contact area is found to depend on the mesh size squared, A ∝ ξ2. Combining these concepts, the shear stress, τ, and therefore the lubricity of aqueous gels, is predicted to be highly dependent on the mesh size, τ ∝ ξ−3. Studies aimed at elucidating the fundamental mechanism of lubricity in biopolymer gels, mucus, and hydrogels have wrestled with comparisons across mesh size, which can be extremely difficult to accurately quantify. Using scaling concepts relating polymer mesh size to water content reveals that shear stress decreases rapidly with increasing water content, and plots of shear stress as a function of swollen water content are suggested as a useful method to compare aqueous gels of unknown mesh size. As a lower bound, these data are compared against estimates of fluid shear stress for free and bound water flowing through a mesh size estimated by the water content of the gels. The results indicate that the strong dependence on lubricity is likely due to a synergistic combination of a low viscosity solvent (water) coupled to a system that has a decreasing friction coefficient, modulus, and the resulting contact pressure with increasing water content. Although the permeability, K, of aqueous gels increases dramatically with water content (and mesh size), K ≅ ξ2/η, the stronger decrease of the elastic modulus and subsequent decrease in contact pressure due to an increase in the contact length, predicts that the draining time under contact, t, actually increases strongly with increasing water content and mesh size, t ∝ ξ2. Consistent with the finding of extremely high water content aqueous gels on the surfaces of biological tissues, these high water content gels are predicted to be optimal for lubrication as they are both highly lubricious and robust at resisting draining and sustaining hydration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction to Aqueous Gels and Lubricity

Lubricity in biological systems is generally a result of aqueous lubrication [1], and frequently involves mucinous, collagenous, and/or proteinaceous biopolymer gels. Lubricity is more than just low friction—it is a product of both low friction coefficient and low contact pressure (i.e., biological lubricity is related to low shear stress). Biological systems have inspired engineering strategies for aqueous lubrication [2,3,4,5,6,7,8,9,10,11,12], and in this manuscript, we examine scaling models that reveal high water content gels are actually optimal from considerations of friction coefficient, contact pressure, shear stress, and resistance to draining.

The mechanics behind lubricity in aqueous gels have been carefully studied by researchers in biomedicine, chemistry, engineering, and polymer physics [3, 5, 13,14,15,16,17,18,19,20,21,22,23,24]. A generalized framework (in the limit of small deformations and linear elasticity) from which to compare these studies is based on the concept of polymer mesh size, ξ [25]. A major challenge of biological systems and proteinaceous aqueous gels is that it can be extremely difficult (if not impossible) to accurately measure the mesh size. Aqueous biological gels often have complex shear thinning fluids, compositionally graded interfaces, and are soft active evolving materials [26]. Simple aqueous gels made from crosslinked polymers solvated in water have been used extensively in an effort to elucidate the fundamental mechanics of lubricity with the goal of transitioning these data and understanding to more complex biological systems. Although many of the same characterization challenges at the surfaces of hydrogels remain [27, 28], local effects on the surfaces are frequently implicated in the tribology of these gels (e.g., superlubricity of high water content gradients at the surface of polyacrylamide [7]). The degree to which the mold surfaces influence the local water content, mesh size, and gradients across and into the surfaces is unknown and remains an active area of research [9, 27,28,29]. Our best efforts to control this in processing are by molding against low oxygen permeable materials in inert environments and controlled polymerization rates.

2 Mesh Size, the Weissenberg Number, and Friction

The scaling concepts of polymer physics in gels, as pioneered by de Gennes [25], gave the community a number of important formulas, and generally related all mechanical and transport properties back to the polymer mesh size, ξ, thermal energy, kBT, and solvent viscosity, η. Important to this discussion of lubricity are the scaling concepts of elastic modulus, E (Eq. 1), and the permeability, K (Eq. 2).

Polymer fluctuation lubrication [30] and Gemini hydrogel tribology [4, 31, 32] have addressed the low shear sliding observed in self-mated high water content aqueous gels, but no unified mechanistic theory has emerged. Key concepts in the lubricity of these aqueous gels in the speed-independent regime include (1) the contacts remain hydrated (Gemini) and (2) that the polymer chain orientations are unaffected by the sliding speed (polymer fluctuation lubrication). Assuming a viscous shear of the solvent through a single surface mesh sizeFootnote 1 is proportional to the shear rate, V/ξ, the speed at which this shear stress exceeds the polymer chain elasticity is one measure of a critical transition behavior. The concept of a transition behavior as a result of sliding speed has been extensively discussed in publications by Urueña et al. [31], Dunn et al. [4], Pitenis et al. [30], and Shoaib et al. [13, 14].

Borrowing from polymer rheology, we suggest that the Weissenberg number, Wi [33, 34] may be a useful concept to describe the transition behavior observed in several hydrogel sliding systems. For these aqueous gels, the physical interpretation of a low Weissenberg number is that the lower shear stresses (due to lower shear rates) are insufficient to induce significant deformations and dissipation in the polymer chains. As defined by White [35], the Weissenberg number is the product of a characteristic time of the gel and a characteristic rate of deformation. For the tribology of aqueous gels, the Weissenberg number is therefore the product of the polymer relaxation time, ηξ3/kBT, and the shear rate over a single mesh, V/ξ, which gives Wi = Vηξ2/kBT. The resulting formulation is mathematically identical to the Deborah number, De [36], which was offered by Urueña et al. [31], who assumed the characteristic time for the deformation process was ξ/V and plotted normalized friction data versus De (the ratio of the relaxation time to the deformation process time De = Vηξ2/kBT). Interestingly, the same dimensionless formulation can be reached by taking the ratio of the viscous stress over a single mesh, η·V/ξ, divided by the osmotic pressure, kBT/ξ3: Vηξ2/kBT. Although Urueña et al. argued for a transition at Wi ~ 1, subsequent analysis using the viscosity of free water and bulk mesh size, measured by small-angle X-ray scattering (SAXS), suggests that the transition is actually earlier, Wi < 0.1. Dunn et al. [4] and Urueña et al. [31] both found a broad region of speed-independent friction coefficient for a series of self-mated (Gemini) polyacrylamide gels, and the transition at values below Wi = 1 may be the result of differences in the surface mesh size, increases in the solvent viscosity, or both. The collapse of these friction data over an order of magnitude in mesh size and nearly 4 orders of magnitude in sliding speed to the Weissenberg number suggests that it is a useful dimensionless number in aqueous gel friction. Figure 1 shows the normalized friction coefficient (friction coefficient, µ, divided by the speed-independent friction coefficient, µ0) versus the Weissenberg number for three different hydrogels (polyacrylamide, PAAm [31]; poly(N-isopropylacrylamide), PNIPAm [30]; polyethylene glycol, PEG) with similar equilibrium-swollen water content (~ 94%, mesh size ~ 7 nm). All three Gemini hydrogels were tested on a rotary microtribometer using the following conditions: V = 30 µm/s to 100 mm/s, normal load, Fn = 2 mN, and probe radius of curvature, R = 2 mm for PAAm and PNIPAm, and R = 3 mm for PEG.

Studies of polyacrylamide (PAAm) (white triangles) [31], poly(N-isopropylacrylamide) (PNIPAm) (black squares) [30], and polyethylene glycol (PEG) (gray diamonds) reveal speed-independent friction behavior at low Weissenberg numbers (0.0001 < Wi < 0.1) and increasing friction above Wi > 0.1. All three hydrogels had similar equilibrium-swollen water content (~ 94%, mesh size ~ 7 nm)

Urueña et al. [31] also demonstrated that the friction coefficient in the regime of speed-independent friction, µo, scaled inversely proportional to mesh size, ξ, Eq. 3.

The data used for this relationship were taken from the speed-independent and low Weissenberg number (0.0001 < Wi < 0.1) regime for Gemini polyacrylamide gels (ξ = 1.3–9.4 nm as measured by SAXS): for reference, representative conditions were sliding speed, V = 30–1000 µm/s, normal load, Fn = 2 mN, and probe radius of curvature, R = 2 mm.

3 Mesh Size, Hertzian Contacts, and Lubricity

Studies of these polyacrylamide aqueous gels [37] have also revealed that the contacts behave and follow Hertzian contact mechanics [38], although this has not been exhaustively examined for the highest water-content gels. The defense for the findings of Hertzian contact mechanics and elastic deformation in these gels is based on the concept that contact pressures cannot exceed the osmotic pressure of the gels, unless the gels are thin relative to the contact width (a condition that violates Hertzian analysis). Hertzian mechanics give a contact radius, a, and contact area, A, as described by Eqs. 4 and 5, respectively (the composite modulus is E′ is linearly proportional to E for Gemini contacts).

Substitution of the scaling concept for elastic modulus (Eq. 1) into the Hertzian contact expression for contact area (Eq. 5) gives a scaling concept for contact area that is found to be proportional to the square of the mesh size, Eq. 6.

In biological systems, soft contacts are often used to support large loads, and one of the biological tricks is to keep the contact pressures low through hydrostatic fluid pressures and large areas of contact. Under direct contact, it has been shown that epithelial cells actively respond to shear strains and shear stresses [39, 40], and lubricious contacts are favorable to abating inflammatory signals [41]. The average shear stress in the contact is defined as the friction force, Ff = µ⋅Fn, divided by the contact area, A, and, therefore, the scaling for shear stress as a function of mesh size is given by Eq. 7.

The strong dependence of shear stress on mesh size is difficult to describe from considerations of fluid shear across the entire contact, and many efforts by the authors to mathematically derive this result give a dependence on shear stress that follows a much weaker dependence on mesh size (typically τ ∝ 1/ξ). The strong scaling of shear stress with mesh size, τ ∝ 1/ξ3, is the same as elastic modulus and one possible argument is that the surface strains on the mesh are independent of the mesh size (e.g., deformations of a regular corrugated surface with a roughness amplitude that is roughly the mesh size is always some fraction of the corrugation amplitude) and therefore the resulting shear stresses only depend on the shear modulus [42]. Considerations of asperity level contacts [43], roughness [44], or brushes at the free surface [45] can certainly change these predictions.

4 High Water Content Improves Lubricity

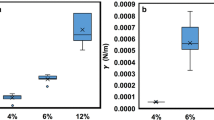

The difficulty and uncertainty associated with measurements of mesh size of aqueous biopolymer gels and mucus often frustrate direct comparisons to synthetic gels made of crosslinked polymers and water [13, 24, 46,47,48]. By comparison, water content is a more straightforward measurement (though not without challenges), and we suggest that this may be a useful method to compare the tribology of these two very different systems. Canal and Peppas [49] performed an extensive set of experiments to correlate the relationship between mesh size, ξ (measured by wide-angle X-ray scattering), polymer volume fraction, ν, and the water content, 1 − ν, in equilibrium-swollen charge-neutral crosslinked gels. Water content increases with increasing mesh size, ξ, and for the lubricious biological gels, the water contents are almost always greater than 90% and well within the range of correlations for high water content aqueous gels, 0.9 < (1 − ν) < 0.99. The data from the synthetic polyacrylamide gels used in Urueña et al. [31], which were originally presented as a function of mesh size, have been replotted in Fig. 2, where the average shear stress (τ, Eq. 7) is plotted versus the swollen water content, 1 − ν.

Shear stress, τ, is plotted versus water content (1 − ν) for swollen polyacrylamide hydrogels previously measured in Urueña et al. [31] (solid black circles). Error bars represent the standard deviation of the shear stress, determined from combined standard uncertainty analysis [50, 51]. The solid black line shows a power-law fit through these data points. Fluid shear stresses (solid blue lines) were calculated assuming shear across a single mesh size, ξ, which was determined through relationships between mesh size and water content. These shear stresses, τ = ηV/ξ, were calculated for free water viscosity (ηw = 8.9 × 10−4 Pa·s) and bound water viscosity (ηb = 2.7 × 10−3 Pa·s) [52, 53]. Dashed blue lines represent an extension of the Canal and Peppas model [49] above and below the reported range of validity. a Linear–linear, b log-linear. (Color figure online)

The strong dependence of shear stress on water content can be seen in Fig. 2a, where the shear stress drops from over 250 Pa to below 10 Pa with a change in water content of about 10%. The range of water content for various aqueous biological interfaces of mucin [54,55,56] and the superficial layer of cartilage [57] are also indicated. As a reference, the water content of the moon jellyfish (Aurelia aurita) is reported to be ~ 95% [58, 59], which is also consistent with the water content of aqueous mucinated surfaces (e.g., tribological measurements of mucinated rabbit corneas estimated shear stress to be τ ~ 10 Pa) [60].

Shear stress data for aqueous gels as a function of water content are also plotted in a semi-log format in Fig. 2b. The solid blue lines are predictions of fluid shear stress based on the assumption that the shear rate is given by the sliding speed divided by the mesh size as determined through the models of Canal and Peppas [49]. These correlations were reported over a range of water content 0.9 < (1 − ν) < 0.99, and the finely dashed lines represent an extension of these models above and below the reported range of validity. Although the measured shear stresses are generally higher than the simple predictions, at the highest water content they are close. Considerations of bound water, which would have a higher viscosity by a factor of approximately 3 [52, 53], move the predictions closer but fail to capture the general shape of the curve or strength of the predicted and measured dependence of shear stress on water content. It is important to recognize that for aqueous gels, even at polymer concentrations on the order of 10%, nearly the entire solvent fraction is within the criterion for bound water (i.e., strongly influenced by the solvation shell of the polymer and directly interacting with the polymer).

5 Mesh Size, Darcy’s Law, and Draining

Practical experience with high water content aqueous gels supports the notion of a strong dependence of lubricity on water content; in fact, superlubricity (µ < 0.01) [61] has been measured for very high water content Gemini gels [7, 42]. However, a frequent argument against the use of such high water content aqueous gels is that the greatly increased permeability of these gels makes them more susceptible to mechanically drain and exude water under tribological contacts. This prediction persists despite the obvious biological observations that high water content aqueous gels surround all of the biological interfaces involving moist epithelia and the self-mated contacts of cartilage. Revisiting the scaling concepts of Hertzian contacts, the contact pressure, P, and contact half-width, a, are shown to scale inversely and proportionally to mesh size as given in Eqs. 8 and 9, respectively.

Analytical models for flows draining under a contact and through a poroelastic medium generally use Darcy’s Law for the flow dynamics. Assuming that the draining of these aqueous gel contacts is driven by the contact pressure, P, and the flow crosses a peripheral zone around the contact, 2πa, the time to drain, t, a cylindrical volume under the contact can be shown to have the following proportionality, Eq. 10, and a dependence on the mesh size, Eq. 11.

This simple scaling analysis demonstrates an additional, and potentially very important, aspect of these high water content (large mesh size) aqueous gels; the time to drain a Hertzian contact strongly increases with increasing water content and increasing mesh size. The greatly reduced modulus of high water content gels extends the area of contact and contact width while simultaneously decreases the contact pressure—both of which increase the draining time. These high water content aqueous gels are almost ideal at sealing contact and preserving hydration within the contact during sliding. Biological systems use gradients in water content to have highly lubricious surface zones that seal the contact, remain hydrated, and support load under non-Hertzian contact conditions.

6 Concluding Remarks

The scaling concepts presented here indicate that increasing water content increases lubricity by decreasing friction coefficient, decreasing the sliding shear stress, decreasing the contact pressures, and increasing the ability of the contacts to remain hydrated during sliding. The high water content aqueous gels indicate that the optimal design direction is to maximize water content.

Notes

Following Milner’s predictions [62], the hydrodynamic penetration depth due to a simple shear flow in a region alongside a semi-dilute polymer network (e.g., hydrogel) would be essentially the mesh size, ξ.

References

Spencer, N.D. (ed.): Aqueous Lubrication. World Scientific (2014)

Seror, J., Zhu, L., Goldberg, R., Day, A.J., Klein, J.: Supramolecular synergy in the boundary lubrication of synovial joints. Nat. Commun. 6, 6497 (2015). https://doi.org/10.1038/ncomms7497

Iuster, N., Tairy, O., Driver, M.J., Armes, S.P., Klein, J.: Cross-linking highly lubricious phosphocholinated polymer brushes: effect on surface interactions and frictional behavior. Macromolecules. 50, 7361–7371 (2017). https://doi.org/10.1021/acs.macromol.7b01423

Dunn, A.C., Sawyer, W.G., Angelini, T.E.: Gemini interfaces in aqueous lubrication with hydrogels. Tribol. Lett. 54, 59–66 (2014). https://doi.org/10.1007/s11249-014-0308-1

Dunn, A.C., Urueña, J.M., Huo, Y., Perry, S.S., Angelini, T.E., Sawyer, W.G.: Lubricity of surface hydrogel layers. Tribol. Lett. 49, 371–378 (2013). https://doi.org/10.1007/s11249-012-0076-8

Perry, S.S., Yan, X., Limpoco, F.T., Lee, S., Müller, M., Spencer, N.D.: Tribological properties of poly(l-lysine)-graft-poly(ethylene glycol) films: influence of polymer architecture and adsorbed conformation. ACS Appl. Mater. Interfaces. 1, 1224–1230 (2009). https://doi.org/10.1021/am900101m

Pitenis, A.A., Manuel Urueña, J., Cooper, A.C., Angelini, T.E., Sawyer, W.G.: Superlubricity in Gemini hydrogels. J. Tribol. 138, 042103 (2016). https://doi.org/10.1115/1.4032890

Li, A., Benetti, E.M., Tranchida, D., Clasohm, J.N., Schönherr, H., Spencer, N.D.: Surface-grafted, covalently cross-linked hydrogel brushes with tunable interfacial and bulk properties. Macromolecules. 44, 5344–5351 (2011). https://doi.org/10.1021/ma2006443

Gong, J.P., Kurokawa, T., Narita, T., Kagata, G., Osada, Y., Nishimura, G., Kinjo, M.: Synthesis of hydrogels with extremely low surface friction. J. Am. Chem. Soc. 123, 5582–5583 (2001). https://doi.org/10.1021/ja003794q

Pitenis, A.A., Manuel Urueña, J., Nixon, R.M., Bhattacharjee, T., Krick, B.A., Dunn, A.C., Angelini, T.E., Sawyer, W.G.: Lubricity from entangled polymer networks on hydrogels. J. Tribol. 138, 042102 (2016). https://doi.org/10.1115/1.4032889

Rudy, A., Kuliasha, C., Uruena, J., Rex, J., Schulze, K.D., Stewart, D., Angelini, T., Sawyer, W.G., Perry, S.S.: Lubricous hydrogel surface coatings on polydimethylsiloxane (PDMS). Tribol. Lett. 65, 3 (2017). https://doi.org/10.1007/s11249-016-0783-7

Klein, J., Kumacheva, E., Mahalu, D., Perahia, D., Fetters, L.J.: Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature. 370, 634–636 (1994). https://doi.org/10.1038/370634a0

Shoaib, T., Heintz, J., Lopez-Berganza, J.A., Muro-Barrios, R., Egner, S.A., Espinosa-Marzal, R.M.: Stick–slip friction reveals hydrogel lubrication mechanisms. Langmuir. 34, 756–765 (2018). https://doi.org/10.1021/acs.langmuir.7b02834

Shoaib, T., Espinosa-Marzal, R.M.: Insight into the viscous and adhesive contributions to hydrogel friction. Tribol. Lett. 66, 96 (2018). https://doi.org/10.1007/s11249-018-1045-7

Gong, J.P.: Friction and lubrication of hydrogels -its richness and complexity. Soft Matter. 2, 544 (2006). https://doi.org/10.1039/b603209p

Liu, J., Gong, J.: Hydrogel friction and lubrication. In: Spencer, N.D. (ed.) Aqueous Lubrication. World Scientific, Singapore (2014)

Benz, M., Chen, N., Israelachvili, J.: Lubrication and wear properties of grafted polyelectrolytes, hyaluronan and hylan, measured in the surface forces apparatus. J. Biomed. Mater. Res. 71A, 6–15 (2004). https://doi.org/10.1002/jbm.a.30123

de Beer, S., Kutnyanszky, E., Schön, P.M., Vancso, G.J., Müser, M.H.: Solvent-induced immiscibility of polymer brushes eliminates dissipation channels. Nat. Commun. 5, 3781 (2014). https://doi.org/10.1038/ncomms4781

de Beer, S., Kenmoé, G.D., Müser, M.H.: On the friction and adhesion hysteresis between polymer brushes attached to curved surfaces: rate and solvation effects. Friction. 3, 148–160 (2015). https://doi.org/10.1007/s40544-015-0078-2

Li, A., Ramakrishna, S.N., Kooij, E.S., Espinosa-Marzal, R.M., Spencer, N.D.: Poly(acrylamide) films at the solvent-induced glass transition: adhesion, tribology, and the influence of crosslinking. Soft Matter. 8, 9092 (2012). https://doi.org/10.1039/c2sm26222c

Nalam, P.C., Gosvami, N.N., Caporizzo, M.A., Composto, R.J., Carpick, R.W.: Nano-rheology of hydrogels using direct drive force modulation atomic force microscopy. Soft Matter. 11, 8165–8178 (2015). https://doi.org/10.1039/C5SM01143D

Baumberger, T., Caroli, C., Ronsin, O.: Self-healing slip pulses along a gel/glass interface. Phys. Rev. Lett. 88, 075509 (2002). https://doi.org/10.1103/PhysRevLett.88.075509

Kim, J., Dunn, A.C.: Soft hydrated sliding interfaces as complex fluids. Soft Matter. 12, 6536–6546 (2016). https://doi.org/10.1039/C6SM00623J

Reale, E.R., Dunn, A.C.: Poroelasticity-driven lubrication in hydrogel interfaces. Soft Matter. 13, 428–435 (2017). https://doi.org/10.1039/C6SM02111E

De Gennes, P.G.: Scaling Concepts in Polymer Physics. Cornell University Press, Ithaca (1979)

Cone, R.A.: Barrier properties of mucus. Adv. Drug Deliv. Rev. 61, 75–85 (2009). https://doi.org/10.1016/j.addr.2008.09.008

Tominaga, T., Takedomi, N., Biederman, H., Furukawa, H., Osada, Y., Gong, J.P.: Effect of substrate adhesion and hydrophobicity on hydrogel friction. Soft Matter. 4, 1033 (2008). https://doi.org/10.1039/b716465c

Kii, A., Xu, J., Gong, J.P., Osada, Y., Zhang, X.: Heterogeneous polymerization of hydrogels on hydrophobic substrate. J. Phys. Chem. B. 105, 4565–4571 (2001). https://doi.org/10.1021/jp003242u

Sudre, G., Hourdet, D., Cousin, F., Creton, C., Tran, Y.: Structure of surfaces and interfaces of poly(N,N-dimethylacrylamide hydrogels. Langmuir. 28, 12282–12287 (2012). https://doi.org/10.1021/la301417x

Pitenis, A.A., Urueña, J.M., Schulze, K.D., Nixon, R.M., Dunn, A.C., Krick, B.A., Sawyer, W.G., Angelini, T.E., Sawyer, G., Angelini, T.E.: Polymer fluctuation lubrication in hydrogel Gemini interfaces. Soft Matter. 10, 8955–8962 (2014). https://doi.org/10.1039/C4SM01728E

Urueña, J.M., Pitenis, A.A., Nixon, R.M., Schulze, K.D., Angelini, T.E., Sawyer, W.G.: Mesh size control of polymer fluctuation lubrication in Gemini hydrogels. Biotribology. 1–2, 24–29 (2015). https://doi.org/10.1016/j.biotri.2015.03.001

Urueña, J.M., McGhee, E.O., Angelini, T.E., Dowson, D., Sawyer, W.G., Pitenis, A.A.: Normal load scaling of friction in Gemini hydrogels. Biotribology. 13, 30–35 (2018). https://doi.org/10.1016/j.biotri.2018.01.002

Dealy, J.M.: Weissenberg and Deborah numbers—their definition and use. Rheol. Bull. 79, 14–18 (2010)

Poole, R.: The Deborah and Weissenberg numbers. Rheol. Bull. 53, 32–39 (2012)

White, J.L.: Dynamics of viscoelastic fluids, melt fracture and the rheology of fiber spinning. J. Appl. Polym. Sci. 8, 2339–2357 (1964)

Reiner, M.: The Deborah number. Phys. Today. 17, 62 (1964). https://doi.org/10.1063/1.3051374

Schulze, K.D., Hart, S.M., Marshall, S.L., O’Bryan, C.S., Urueña, J.M., Pitenis, A.A., Sawyer, W.G., Angelini, T.E.: Polymer osmotic pressure in hydrogel contact mechanics. Biotribology. 11, 3–7 (2017). https://doi.org/10.1016/j.biotri.2017.03.004

Hertz, H.: Über die Berührung fester elastischer Körper. J. für die reine Angew. Math. 92, 156–171 (1882)

Vogel, V., Sheetz, M.: Local force and geometry sensing regulate cell functions. Nat. Rev. Mol. Cell Biol. 7, 265–275 (2006). https://doi.org/10.1038/nrm1890

Luo, T., Mohan, K., Iglesias, P.A., Robinson, D.N.: Molecular mechanisms of cellular mechanosensing. Nat. Mater. 12, 1064–1071 (2013). https://doi.org/10.1038/nmat3772

Pitenis, A.A., Urueña, J.M., Hart, S.M., O’Bryan, C.S., Marshall, S.L., Levings, P.P., Angelini, T.E., Sawyer, W.G.: Friction-induced inflammation. Tribol. Lett. 66, 81 (2018). https://doi.org/10.1007/s11249-018-1029-7

Bhattacharjee, T., Kabb, C.P., O’Bryan, C.S., Urueña, J.M., Sumerlin, B.S., Sawyer, W.G., Angelini, T.E.: Polyelectrolyte scaling laws for microgel yielding near jamming. Soft Matter. 14, 1559–1570 (2018). https://doi.org/10.1039/C7SM01518F

Beer, S., Müser, M.H., de Beer, S., Müser, M.H.: Alternative dissipation mechanisms and the effect of the solvent in friction between polymer brushes on rough surfaces. Soft Matter. 9, 7234 (2013). https://doi.org/10.1039/c3sm50491c

Yashima, S., Takase, N., Kurokawa, T., Gong, J.P.: Friction of hydrogels with controlled surface roughness on solid flat substrates. Soft Matter. 10, 3192–3199 (2014). https://doi.org/10.1039/C3SM52883A

Lee, S., Spencer, N.D.: Sweet, hairy, soft, and slippery. Science. 319, 575–576 (2008). https://doi.org/10.1126/science.1153273

Bonnevie, E.D., Baro, V.J., Wang, L., Burris, D.L.: In situ studies of cartilage microtribology: roles of speed and contact area. Tribol. Lett. 41, 83–95 (2011). https://doi.org/10.1007/s11249-010-9687-0

Moore, A.C., Burris, D.L.: An analytical model to predict interstitial lubrication of cartilage in migrating contact areas. J. Biomech. 47, 148–153 (2014). https://doi.org/10.1016/j.jbiomech.2013.09.020

Moore, A.C., Burris, D.L.: Tribological rehydration of cartilage and its potential role in preserving joint health. Osteoarthr. Cartil. 25, 99–107 (2017). https://doi.org/10.1016/j.joca.2016.09.018

Canal, T., Peppas, N.A.: Correlation between mesh size and equilibrium degree of swelling of polymeric networks. J. Biomed. Mater. Res. 23, 1183–1193 (1989). https://doi.org/10.1002/jbm.820231007

Schmitz, T.L., Action, J.E., Ziegert, J.C., Sawyer, W.G.: The difficulty of measuring low friction: uncertainty analysis for friction coefficient measurements. J. Tribol. 127, 673 (2005). https://doi.org/10.1115/1.1843853

Burris, D.L., Sawyer, W.G.: Addressing practical challenges of low friction coefficient measurements. Tribol. Lett. 35, 17–23 (2009). https://doi.org/10.1007/s11249-009-9438-2

Raviv, U., Laurat, P., Klein, J.: Fluidity of water confined to subnanometre films. Nature. 413, 51–54 (2001). https://doi.org/10.1038/35092523

Raviv, U.: Fluidity of bound hydration layers. Science. 297, 1540–1543 (2002). https://doi.org/10.1126/science.1074481

Lieleg, O., Vladescu, I., Ribbeck, K.: Characterization of particle translocation through mucin hydrogels. Biophys. J. 98, 1782–1789 (2010). https://doi.org/10.1016/j.bpj.2010.01.012

Datta, S.S., Preska Steinberg, A., Ismagilov, R.F.: Polymers in the gut compress the colonic mucus hydrogel. Proc. Natl. Acad. Sci. 113, 7041–7046 (2016). https://doi.org/10.1073/pnas.1602789113

Lai, S.K., Wang, Y.-Y., Wirtz, D., Hanes, J.: Micro- and macrorheology of mucus. Adv. Drug Deliv. Rev. 61, 86–100 (2009). https://doi.org/10.1016/j.addr.2008.09.012

Crockett, R., Grubelnik, A., Roos, S., Dora, C., Born, W., Troxler, H.: Biochemical composition of the superficial layer of articular cartilage. J. Biomed. Mater. Res. Part A. 82A, 958–964 (2007). https://doi.org/10.1002/jbm.a.31248

Larson, R.J.: Water content, organic content, and carbon and nitrogen composition of medusae from the northeast Pacific. J. Exp. Mar. Bio. Ecol. 99, 107–120 (1986). https://doi.org/10.1016/0022-0981(86)90231-5

Lucas, C.H.: Biochemical composition of Aurelia aurita in relation to age and sexual maturity. J. Exp. Mar. Biol. Ecol. 183, 179–192 (1994). https://doi.org/10.1016/0022-0981(94)90086-8

Sterner, O., Aeschlimann, R., Zürcher, S., Scales, C., Riederer, D., Spencer, N.D., Tosatti, S.G.P.: Tribological classification of contact lenses: from coefficient of friction to sliding work. Tribol. Lett. 63, 9 (2016). https://doi.org/10.1007/s11249-016-0696-5

Erdemir, A., Martin, J.-M.: Superlubricity. Elsevier, Amsterdam (2007)

Milner, S.T.: Hydrodynamic penetration into parabolic brushes. Macromolecules. 24, 3704–3705 (1991). https://doi.org/10.1021/ma00012a036

Acknowledgements

The authors acknowledge research funding from Alcon Laboratories, and appreciate the many scholarly discussions on lubrication and scaling concepts in gels with Profs. Thomas Angelini, David Burris, Alison Dunn, and Cyrus Safinya.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pitenis, A.A., Sawyer, W.G. Lubricity of High Water Content Aqueous Gels. Tribol Lett 66, 113 (2018). https://doi.org/10.1007/s11249-018-1063-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1063-5