Abstract

Typical lubricants for magnetic hard disks comprise the central perfluoropolyether section and the short hydrocarbon end groups bearing hydroxyl unit(s). It had been shown earlier that chemical bonding of these lubricants to the carbon overcoat of disks involves (1) dangling bonds shielded inside the carbon, (2) transfer of the hydrogen atom of the hydroxyl unit to a dangling bond site, and (3) attachment of the remaining alkoxy system, R–CF2–CH2–O·, to the carbon surface as a pendant ether unit. Dangling bonds at or near the surface react immediately with H2O or O2 in the atmosphere. It follows that, in order to bond, the hydrocarbon end group must move into crevices of the carbon film. It was postulated that the bonding rate would depend on the length of the hydrocarbon end-group, –(CH2) n –OH. The longer the hydrocarbon sector is, the faster and the more extensively the bonding would proceed. Bonding rates were examined for a set of samples differing only in the dimension of the hydrocarbon end-group. Results clearly in accordance with the postulate were obtained. The sample set included two novel lubricants, D-2TX2 and D-2TX4, with the following end-groups, –O–CF2–CH2–O–(CH2) n=2,4–OH. Excellent bonding rate, coverage, and potential anticorrosion property were revealed for these lubricants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The magnetic layer of hard disks is coated with a layer (3–5 nm) of sputter-deposited carbon and then with a thin layer (1–2 nm) of lubricant in order to protect the magnetic layer from corrosion and to abate the tribological impact of the head flying nominally 5–10 nm above the disk surface. Perfluoropolyethers (PFPE) with a variety of end-groups are used as disk lubricants. Examples of most topically used and studied are Z-dol and Z-tetraol with the following formulae

where, for Z-dol: R = –CF2–CH2–OH and, for Z-tetraol: R = –CF2–CH2–O–CH2–CH(OH)–CH2–OH. For both lubricants the main backbone is a linear, random copolymer of tetrafluoroethylene-oxide and difluoromethylene-oxide units with a roughly equimolar ratio. The molecular weight of the lubricant is in the range of 2,000–4,000 corresponding to m (or n) ≈ 10–20. Coating of disks with a given lubricant is accomplished by dipping disks into a dilute solution (~0.1 wt%) of the lubricant and pulling out of the solution at a controlled rate (e.g., 1 mm/s). The solvent quickly evaporates leaving the lubricant molecules atop the disk surface.

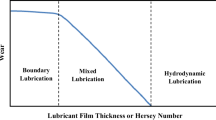

The excellent lubricity of these materials is due to the low surface energy of the fluorocarbon backbone. Corrosion protection is also rendered by the hydrophobicity of the backbone. The hydrocarbon sectors with hydroxyl units are attached at the termini in order to achieve adhesion to the disk surface. The adhesion is attained (1) by hydrogen bonding or (2) by formation of a bona fide chemical bond. The hydrogen bonding occurs between hydroxyl units in the end-group and hydroxyl units on the carbon surface. The interaction occurs rapidly, and the disposition of the lubricant molecules atop the disk surface based on the hydrogen bonding is established immediately after application of the lubricant. The hydrogen bonding, however, is weak (~5 kcal/mol), and is easily disrupted by ambient thermal energy. The hydrogen bonding thus does not contribute to formation of the bonded fraction, the fraction of the lubricant that cannot be removed by solvent rinsing. The bonded fraction is due to those molecules attached to the carbon overcoat via a bona fide chemical bond. It develops slowly (taking several weeks at ambient temperature). It has been shown that the process involves: (1) dangling bonds (free radicals) shielded within the sputter-deposited carbon, (2) transfer of the hydrogen atom of the hydroxyl unit of the lubricant end-group to the dangling bond site, and (3) attachment of the remaining alkoxy system, R–O–CF2–CH2–O·, to the carbon surface as a pendant ether unit. See ref. [1] and references cited therein. Figure 1 illustrates the depicted sequence.

It has also been shown that the carbon overcoat is a composite stack of diamond- and graphite-like granules and a large number of dangling bonds (1020–21 spins/cm3) are generated and trapped within the diamond-like granules. See ref. [2] and references cited therein. Dangling bonds (free radicals) at or near the very surface of the carbon layer would react with oxygen or water molecules in the atmosphere the moment the freshly processed disk has been taken out of the sputtering system. Thus for disks ready to be lubricated, dangling bonds needed for chemical bonding are present only at a deeper level of the granule composite. Figure 2 shows the depicted structural features of the carbon overcoat.

It has been known that Z-tetraol bonds to the carbon surface better than Z-dol [3]. The difference has been tacitly attributed to the difference in the number of hydroxyl unit(s) in the respective end-groups. The mechanism leading to formation of bonded Z-tetraol must be similar to that of Z-dol, involving the primary hydroxyl unit of the end-group and dangling bonds in the carbon. In order for the reaction to occur, the hydrocarbon sector of the lubricant must move into crevices between granules and reach the vicinity of a dangling bond. The cross-sectional diameter of the fluorocarbon sector, –CF2–, is ~4.4 Å, whereas that of the hydrocarbon sector, –CH2–, is ~2.7 A. One may thus envisage that Z-tetraol achieves more extensive bonding owing to its longer length of the hydrocarbon sector.

It would be most elucidative if we could compare the bonding rates of lubricants differing only in the dimension of the hydrocarbon end-group, –(CH2) n –, all possessing a hydroxyl unit at the terminus. To this end we managed to obtain a set of samples shown in Fig. 3. All the lubricants here are based on the Demnum type PFPE backbone and have the same hydrocarbon end-groups at both termini. In the following text, notations D-1, D-4, D-5*, and D-6 will be used to indicate the respective lubricants. Here the numeral following D- indicates the number of C and O atoms contiguously present in the hydrocarbon segment, hence its relative length. The lubricant D-5* has the end group identical to that of Z-tetraol; the superscript * is placed to indicate the presence of the secondary OH at C-2.

2 Experimental Sections

Lubricant D-2OH was obtained by chromatography from Demnum-SA purchased from Daikin Corp. The major component of Demnum-SA is of mono-functional form, CF3CF2CF2O–(CF2CF2CF2O–)

n

–CF2CF2CH2–OH. It typically contains 10–20 wt% bifunctional D-2OH. D-4OH was prepared from D-2OH using glycidol (I). D-2TX2 and D-2TX4 were prepared from D-2OH using respective 2-(ω-bromoalkoxy)tetrahydro2Hpyran (II).

The chemical structures of all the lubricants were confirmed by the F-19 and proton NMR spectra. The number averaged molecular weights determined from the F-19 spectra were all 2,000 ± 100. The lubricant thickness was measured by the IR spectroscopy method (glazing angle) and the water contact angle was measured using a Kyowa DM500 unit.

3 Results

Before proceeding to present and discuss the current results we will briefly review a result obtained earlier in order to facilitate understanding of the current result. It has been shown that the spin concentration (the number of dangling bonds) in a sputtered carbon can be determined by the ESR (electron spin resonance) spectroscopy [2]. If the hydroxyl proton in the end group of Z-dol reacts with dangling bonds in the carbon overcoat as depicted in Fig. 1, any molecule bearing a hydroxyl unit is expected to react similarly. The temporal decay of the ESR signal (due to dangling bonds) when freshly sputtered carbon films were immersed in Z-dol, hexanol, ethanol, and water, respectively, at ambient temperature, had been measured. The result reported earlier is reproduced in Fig. 4. It is clearly revealed that any OH-bearing molecule does indeed react with the dangling bonds and the reaction rate is extremely size-dependent. The smaller the molecule is, the faster and more extensively it reacts. The larger the molecule is, the higher the asymptotic value (the amount of remaining radicals) reached after several days. The process entailing diffusion of the OH-bearing end of the molecule into inter-granular gaps, and blocking of openings by the already reacted molecules would account for the observed results.

We shall now present the current results. For the set of lubricants given in Fig. 3, the bonding rates were examined as follows. A set of 5 disks was dip-coated in each lubricant with an initial thickness of 18 ± 2 Å. The thickness of the bonded layer was then measured after rinsing away the non-bonded fraction with solvent VM (2:1 mixture of Vertrel X and methanol) at week’s interval. The results are shown in Fig. 5. The contact angle of a water-droplet of each disk after the VM rinse was also measured. The results are shown in Fig. 6. The bonding rates of D-1, D-4, and D-6 are clearly in the predicted order; the longer the hydrocarbon sector is, the faster the bonding rate is. The bonding rate of D-5* is inferior to that of D-4; it is attributed to the steric hindrance by the secondary OH unit. Also noted is a good correlation between the coverage of the carbon overcoat (reflected on the water contact angle) and the thickness of the bonded lubricant.

The bonding process envisaged above entailing infusion of end-groups into inter-granular gaps of the carbon overcoat should be accelerated if heated. It is known that the bonding fraction achieved after standing at room temperature for several weeks can be attained by thermal treatment of 30 min at 150 °C. Figure 7 shows the results obtained when disks were coated with the same set of lubricants (Fig. 3) and treated thermally (150 °C/30 min). The lubricant thicknesses measured (a) immediately after the dip-coating, (b) after the thermal treatment, and (c) after VM rinsing are shown. The water contact angles measured after the VM rinsing are also shown.

It is apparent that, under the thermal treatment, disks coated with D-5*, D-4, and D-6 all attained ~11 Å of bonded lubricant with good coverage (as indicated by a high water contact angle, 107°). In contrast, in the case of D-1, the bonded layer obtained was only 6 Å thick with a lower water contact angle of 93°. The paucity of dangling bonds within the region accessible by the short end-group of D-1 is indicated.

4 Summary and Discussion

The results presented above clearly substantiate the postulated process leading to bonding of PFPE lubricant bearing a hydroxyl unit at its terminus. The process entails migration of the OH-bearing end group into intra-granular crevices of the carbon overcoat. It is extremely size-dependent; the longer the hydrocarbon end-group is, the faster and the more extensively the reaction proceeds. The sputter-deposited carbon overcoat is a mixture of diamond- and graphite-like granules. An ESR study showed that the dimension of the granules in a typical sputter-deposited carbon film is ~3 nm [1]. It accords with observation that the pinhole density of sputtered carbon and the corrosion rate (of the magnetic layer) increase precipitously when the film thickness is reduced below ~3 nm (Tang and Dai, IBM, “Unpublished result”). If three spheres of 3 nm across are in the closest contact (as they would be in the closest packing arrangement), the dimension of the opening is ~5 Å. The experimental result obtained for D-1 in the thermal study (Fig. 7) indicates that the fluorocarbon section, –CF2–, is where the infusion into the carbon layer is blocked. The proximity of the openings inferred for the carbon layer (5 Å) and the estimated cross-sectional dimension of the fluorocarbon sector (4.4 Å) is intriguing.

It also follows that, when lubricants such as D-4 and D-6 bond to the carbon film deep inside the crevices, they are effectively plugging the pinholes. It should be emphasized that these efficacies of D-4 and D-6 are realized only under thermal curing. Under UV curing where photo-electrons emanating from the carbon overcoat generate PFPE molecular chains bearing a free radical center, the bonding occurs at the surface of the overcoat.

References

Kasai, P.H.: Z-Dol and carbon overcoat: the bonding mechanism. Tribol. Lett. 26, 93–101 (2007)

Kasai, P.H.: Carbon overcoat: structure and bonding of Z-Dol. Tribol. Lett. 13, 155–166 (2002)

Wakabayashi, A.: Lubricant spin-off and oxidation phenomenon on hard disk media. Tribol. Online 4, 42–45 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasai, P.H., Shimizu, T. Bonding of Hard Disk Lubricants with OH-Bearing End Groups. Tribol Lett 46, 43–47 (2012). https://doi.org/10.1007/s11249-012-9916-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9916-9