Abstract

The activity and S-tolerance of monometallic and bimetallic Ir–Pd catalysts with different atomic ratio (Ir/Pd = 0.5, 1 and 2) and the same total metal content (1 wt%) supported on SiO2–Al2O3 were studied in the hydroconversion of decalin. In the absence of sulfur, bimetallic catalysts showed less activity and selectivity to decalin ring opening products compared to the iridium monometallic catalyst. However they exhibited a greater tolerance to thiophene poisoning (S = 10 ppm). The catalysts with Ir/Pd = 1 and 2 (atomic ratio), with similar metal dispersion, had better resistance to sulfur. The optimal ratio found, Ir/Pd = 1, could be related to the formation of bimetallic particles and an adequate acidity. The total acidity of the catalysts decreased with an increasing Ir/Pd atomic ratio. The addition of sulfur did not significantly modify the selectivity to ring opening products but reduced the formation of dehydrogenated (undesirable) and cracking products. The distribution of the cracking products confirmed that in the absence of S the metallic function controls the decalin ring opening mechanism, except with the monometallic Pd catalyst. With the addition of S the acid function predominates because the activity results correlate with the acidity of the catalysts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In last years the study of selective ring opening (SRO), i.e. opening of naphthene rings without loss of reactant molecular weight, was aimed at valuing the Light Cycle Oil (LCO) fraction to increase the production of diesel fuels. Important transformations are required for the conversion of LCO into fuels given its composition: 75–90 wt% aromatics, 0.2–1.5 wt% sulfur and low cetane number (15–25) [1, 2].

The reaction can be carried out on acid or metal catalysts, however bifunctional catalysts are more effective than each of them alone. Catalysts combining a metal with strong hydrogenolysis activity supported on SiO2–Al2O3 with a moderate concentration of Brønsted acid sites present high decalin conversion and selectivity to ring opening products [3,4,5,6].

Ziaei-Azad and Sayari highlight that the majority of the literature on the SRO of decalin focuses on the conventional bifunctional catalysts with noble metals, like Pt and Ir supported on different zeolites, where the catalytic activity is attributed to the strong Brønsted acidity of the support [7]. Noble metal catalysts on acid supports, particularly Ir, have been proven to provide great activity and selectivity to ring opening reactions [8, 9]. Unfortunately the catalysts are deactivated by coke and sulfur [10]. For this reason the feedstock must be hydrodesulfurized which can decrease the sulfur content of the feed to 6.6 ppm [11] or 16 ppm [12].

Thioresistance is related to the nature and structure of the metallic particles formed: bimetallic particles or segregated metal phases, metal dispersion, and the interaction with the support [13]. It is known that the formation of alloys with a noble metal, particularly Pd, favors sulfur resistance [14]. The acidity of amorphous alumina-silica supports promotes the creation of electron-deficient Pd particles due to the interaction with the Brønsted acid sites, improving the sulfur resistance [15]. The SiO2–Al2O3 support can generate moderate or high sulfur resistance [16] due to the transfer of electrons from the metal to the support. This fact weakens the metal-sulfur bond and the strong chemisorption of the sulfur-containing molecules [17].

Most of the publications dedicated to study of thiotolerance in SRO of bifunctional catalysts employ H2S [6, 18, 19] in spite that sulfur compounds in LCO fractions are mainly substituted thiophenes [20, 21].

Recently, we have studied the influence of the Ir content on different SiO2–Al2O3 for decalin ring opening [22]. The objective of this work is to continue to optimize the metal phase composition of Ir–Pd bimetallic catalysts supported on SiO2–Al2O3 for improving its sulfur tolerance in SRO. The reaction tests were performed using decalin poisoned with thiophene as model feedstock.

2 Experimental

2.1 Catalysts Preparation

A commercial SiO2–Al2O3 supplied by Sasol (SIRAL 80) was used as support [4]. The support is an amorphous solid composed of the 21.0 wt% Al2O3 and 79.0 wt% SiO2 with a specific surface area of 337 m2 g−1. It has the following particle size distribution: < 25 μm 79.9%, < 45 μm 97.1%, < 90 μm 10.0%. First, it was added to the support 1.5 cm3 g−1 of a 0.2 molar solution of HCl (Sigma-Aldrich, 37 wt%) and left to rest for 1 h. Then aqueous solution of H2IrCl6 (4.7 mg Ir cm-3, Strem Chemicals, 99.9%) and PdCl2 (4.8 mg Pd cm-3, Sigma-Aldrich, ≥ 99.9%) were incorporated to obtain a 1 wt% of total metal content. The suspension was gently stirred for 1 h, then dried at 70 °C until a dry powder was obtained. Then it was left overnight in an oven at 120 °C. Finally it was calcined in an air flow (60 cm3 min−1, 300 °C, 4 h) and reduced in H2 (60 cm3 min−1,500 °C, 4 h). Monometallic catalysts were named Pd and Ir, while bimetallic catalysts were named Ir–Pd(x); x is the Ir/Pd atomic ratio.

2.2 Catalyst Characterization

2.2.1 Determination of Metallic and Chlorine Content

The samples were analyzed in an energy dispersive X-ray fluorescence spectrometer, Shimadzu Model EDX-720. The metal and chlorine contents were obtained using Fundamental Parameters. The solid sample was mounted in a sample holder with a polypropylene window and subsequently received a vacuum drying treatment.

2.2.2 Temperature-Programmed Desorption of Pyridine

The experiments were performed in an equipment constructed ad hoc. First the samples were left in the oven at 120 °C for 12 h, then cooled to room temperature in a desiccator. Then 200 mg of the catalyst were impregnated with excess pyridine (Sigma-Aldrich, 99.8%) at room temperature. The excess pyridine was evaporated until a dry powder was obtained. The catalyst was then placed in a quartz reactor under N2 flow (40 ml min−1). The weakly adsorbed pyridine was removed at 110 °C for 1 h. The temperature was then raised to 750 °C (10 °C min−1). The desorbed pyridine was measured by connecting the reactor outlet to a flame ionization detector of the Varian 3400 chromatograph.

2.2.3 Temperature-Programmed Reduction

The reaction were performed in an equipment constructed ad hoc. The catalyst (200 mg) was previously calcined in air for 1 h at 350 °C. It was afterwards allowed to cool down in an air flow to room temperature. The system was then swept with Ar flow and a H2/Ar (5% V/V H2) stream was fed. The temperature was increased linearly (10 °C min−1) from room temperature to 700 °C while measuring the consumption of H2 with a TCD detector controlled by a Gow-Mac apparatus.

2.2.4 Chemisorption of CO

In order to determine the metal dispersion of the catalysts chemisorption of CO were carry out. It was performed in a dynamic adsorption equipment construct ad hoc, injecting 0.6 µmol CO pulses into a stream of inert gas flowing over the sample. The sample was reduced to 500 °C for 1 h. N2 was then circulated for 1 h at 500 °C to remove all the adsorbed H2. Finally, it was cooled down to room temperature in a N2 flow and pulses of CO were injected until saturation was achieved. Non-chemisorbed CO was quantitatively transformed into CH4 over a Ni/Kieselgur catalyst and detected on-line in a flame ionization detector of the Varian 3400 chromatograph.

2.2.5 Cyclopentane Hydrogenolysis

The reaction was performed in a fix bed glass reactor of 60 cm long with an annular section of 0.70 cm2 operated in a continuous flow under isothermal conditions at atmospheric pressure. The reaction temperature was controlled by using a Novus N1100 controller. The products were analyzed on a Thermo Scientific Trace 1300 gas chromatograph equipped with a capillary column Phenomenex ZB-1 connected online. The activity in cyclopentane hydrogenolysis was determined from the conversion extrapolated at zero reaction time. The reaction conditions were: reaction temperature = 250 °C, mass of catalyst = 80 mg, flow of H2 = 36 cm3 min−1 and a flow of cyclopentane (Sigma-Aldrich, 98%) = 0.36 cm3 h−1. The reaction was performed during 2 h. Previously the catalyst was reduced with H2 in situ (36 cm3 min−1, 500 ° C, 1 h).

2.2.6 Ring Opening of Decalin

The reactions were carried out in a stainless-steel autoclave reactor of 240 cm3 effective volume previously described [23]. Reaction conditions: temperature = 350 °C, hydrogen pressure = 3 MPa, stirring speed = 1360 rpm, weight of decalin = 22.4 g in the absence of sulfur and with the addition of thiophene (S = 10 and 20 ppm), mass of catalyst = 1 g, reaction time = 6 h. A cis/trans decalin mixture from Sigma-Aldrich (≥ 99%) with 37.5% cis isomer was used. A sample was taken at the end of the experiments and it was analyzed using a Shimadzu 2014 gas chromatograph equipped with a capillary column (Phenomenex ZB-5) and a FID. Previous product identification studies were performed in a Saturno 2000 GC–MS.

The conversion, yield (Y) and selectivity (S) are calculated on mass basis [24]. The conversion of decalin was defined as \(\sum wt\%\,{products}_{j}\), j including all reaction products. The yields were calculated as \({Y}_{i}=\sum wt\%\,{products}_{i}\), i representing the reaction products of group i and the selectivity as \({S}_{i}=100\frac{\sum wt\%\,{products}_{i}}{\sum wt\%\,{products}_{j}}\)

3 Results and Discussion

Table 1 shows that the monometallic Pd catalyst had the highest chlorine content, followed by the Ir catalyst. In the case of the bimetallic catalysts, the chlorine content decreased slightly with increasing Ir content. It is worth mentioning that the metallic precursors used contained chlorine. Moreover, in the previous step of catalyst preparation HCl was added to the support. Table 1 shows that the monometallic catalysts had a higher metal content than the bimetallic Ir–Pd(x) catalysts. However the bimetallic catalysts retained the nominal atomic ratio. The metal dispersion results shown in Table 1 were calculated assuming a metal/CO = 1 stoichiometry [25,26,27]. Bimetallic catalysts had a higher metal dispersion than monometallic catalysts.

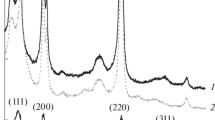

Figure 1 shows the TPR results. Two peaks of hydrogen consumption can be observed in the TPR trace of the Ir catalyst. The main peak at around 260 °C corresponds to well-dispersed iridium oxide species [28] while the second peak of lower intensity between 300–550 °C can be attributed to the adsorption of hydrogen by metals. These would migrate on the support at high temperatures [29]. The reduction peak at 260 °C has a shoulder at higher temperature that could be due to Ir oxides particles with different sizes. Particles of lower size have higher interaction with the support and consequently are reduced at higher temperatures. The existence of large metal Ir particles can be disregarded because the reduction peak at about 60 °C is not observed [30].

The reduction peak at 95 °C in the TPR trace of Pd could be attributed to the reduction of PdO particles, while the wider peak of lower intensity centered about 424 °C could be assigned to PdOxCly species in strong interaction with the support [31]. All palladium-containing catalysts showed a negative peak at above 550 °C. This was attributed to the release of H2 resulting from the breakdown of Pd hydride [32]. Obviously this peak is higher on the Pd monometallic catalyst. It was reported that Pd monometallic catalysts exhibit a reduction peak at room temperature assigned to the reduction of large PdO particles to Pd° [33]. This peak was not observed in the TPR profile of the Pd catalyst.

On bimetallic catalysts the reduction peak at 95 °C due to Pd species is shifted to higher temperatures probably due to their interaction which Ir particles. Moreover the reduction peak at 250 °C due to Ir species was not observed on the bimetallic catalysts. Therefore, it is possible that the reduction of Ir species occurs at lower temperatures due to the catalytic effect of Pd [34]. On the other hand the reduction peak at temperatures higher than 420 °C could be attributed to small particles with high interaction with the support which is bigger on Ir–Pd(0.5) and Ir–Pd(2) in comparison to the Pd monometallic catalyst. This fact indicates that the reduction of PdOxCly species occurs simultaneously with the reduction of Ir oxide particles. The Ir–Pd(1) catalyst shows a reduction peak around 300 °C that is probably due to a simultaneous reduction of Pd and Ir particles in strong interaction, forming Ir–Pd bimetallic particles [35].

From the shape of the TPR trace it can be concluded that on bimetallic catalysts Pd and Ir are in strong interaction because their reduction peaks were shifted to higher temperatures. Moreover, in agreement with the dispersion values, the Ir–Pd(x) catalysts had reduction peaks at higher temperatures than the monometallic catalysts. This can be attributed to small metal particles in strong interaction with the support.

Cyclopentane hydrogenolysis (HCP) is useful for evaluating the metallic properties of the catalyst. This reaction requires large ensembles of metal particles [36]. Table 1 shows the number of molecules reacting per active site per second, i.e., the turn over frequency (TOF) of the HCP reaction. It can be seen that the iridium monometallic catalyst had greater hydrogenolytic activity than the monometallic palladium catalyst. It is known that Ir has a stronger hydrogenolytic activity than Pd [37]. Gao and Schmidt reported that Ir/SiO2 is 100 times more active than Pd/SiO2 on C2H6 hydrogenolysis [37]. The higher hydrogenolytic activity on n-heptane and ethane of Ir than Pd catalysts was also reported by Sinfelt [38].

Ir–Pd(x) bimetallic catalysts exhibited an intermediate behavior compared to monometallic catalysts. This may be due to the fact that Pd modifies the electronic structure of Ir, by a geometric or by an inductive effect. In any case both metals would be in strong interaction as found by TPR.

Table 2 shows the total acidity and acid sites distribution of the catalysts as obtained by the TPD of pyridine. The total acidity increases with the chlorine content of the catalyst regardless of the kind of metal supported or whether they are mono or bimetallic catalysts. It has been reported that the acidity of an OH group is strengthened by the inductive effect exerted by a Cl− ion adjacent to the OH group [39]. The promotion of acidity by chlorine has been reported for catalysts supported on SiO2 and on Al2O3 [40]. In a previous work, we also reported that the impregnation of different SIRAL with chlorine increased the total acidity by 20–30% as compared to the nonchlorinated supports [4].

Monometallic catalysts have the highest values of total acidity in agreement with the highest chlorine content. The Ir monometallic catalyst exhibited mostly strong acidic sites whereas the Pd catalyst mainly had mild acidic sites. In the case of the bimetallic catalysts a decrease in the total acidity is found as the Ir/Pd atomic ratio increases, following the trend found with Cl content reported on Table 1. Moreover each of these catalysts has similar amounts of strong and moderate acid sites.

The decalin reaction was carried out in the absence of S and with the addition of 10 and 20 ppm of sulfur to study the thiotolerance of the catalysts. According to the criteria adopted in a previous work [41] the reaction products were grouped into a few lumps: cracking (CR, C1-C9) products, ring opening (RO, C10) products, ring contraction (RC) products and dehydrogenation products (PD).

Figure 2 shows the influence of the metal function activity of the catalysts on the yields to different reaction products of the decalin reaction in absence of sulfur. It is observed that the increase in the hydrogenolytic activity produces an increase in the yield to the cracking products, in contrast to what occurs with the yield to dehydrogenated products. The cracking reactions are catalyzed by the strong acid sites of the support and also by hydrogenolysis on the metallic function [3]. According to the evolution of CR products reported in Fig. 2, it can be concluded that the formation of cracking products is controlled by the hydrogenolysis reaction. However, cracking reaction at acid sites should not be ruled out. Pd has low hydrogenolysis activity but high de/hydrogenation activity. Consequently the Pd catalyst produces dehydrogenated products and a lower yield to RO products [5].

The yield to RC products has not a definite trend with the increase of the hydrogenolytic activity since the formation of these products is promoted by the acid function. RC products are considered intermediates that lead to RO products [6].

As was mentioned in the the introduction section, the objective of the SRO reaction is opening of naphthene rings without loss of reactant molecular weight. Figure 3 shows the yield to RO products as a function of the metal activity (conversion of cyclopentane relative to catalyst Ir) and the acid activity (concentration of strong acid sites relative to Ir catalyst). It is observed that the yield to RO products obtained with the Ir catalyst is higher than that obtained with other catalysts. This is attributed to their higher hydrogenolytic activity and the higher acidity. The bimetallic catalysts outperform the Pd monometallic catalyst when considering the RO yield. Again, higher strong acid sites and higher hydrogenolysis activity lead to higher yields to RO products. This is in agreement with the bifunctional reaction mechanism proposed by several research groups; i.e. the opening of decalin starts with the ring contraction promoted on the acid sites and then is followed by the ring opening on the metal sites [6, 42,43,44,45].

The sulfur influence on the metal activity was widely studied being the poisoning of the noble metal a major challenge for decades [46]. Barbier et al. [47] in their pioneering work reviews the thermodynamic of the sulfur adsorption on different metals, the metal-sulfur interaction, the chemical state of adsorbed sulfur and influence of the sulfur on the hydrogen adsorption, and sulfur effect on the catalyst activity. They concluded that the toxicity of S depends on the sort of metal, the S/metal ratio and the reaction [47]. Basically, S is adsorbed onto the metal blocking their hydrogenation and hydrogenolytic activity.

Table 3 shows the values of the decalin conversion and the selectivity to RO products obtained after 6 h of reaction with S = 0, 10 and 20 ppm. In the absence of sulfur the highest conversion of decalin and selectivity to RO products is achieved using the Ir catalyst. The addition of 10 ppm S produces a decrease of the decalin conversion on the monometallic catalysts (about 35%) and on the Ir–Pd(0.5) catalyst (close to 26%). In the case of the Ir–Pd(1) and Ir–Pd(2) catalysts the conversion slightly decreases. The strong decrease of the monometallic catalyst activity is due to the metal blockage by sulfur [46, 47]. The bimetallic catalysts suffer lower deactivation due to part of sulfur is adsorbed on the Pd particles which are less actives than Ir particles. Probably the greater thiotolerance of the IrPd(1) and IrPd(2) catalysts is due to their strong Ir–Pd interaction as found by TPR. This interaction would lead to the formation of electrodeficient metal particles, which in interaction with the Brønsted acid sites of the support decrease the S-Metal bond strength [15] and hence the thiophene adsorption.

The results of Table 3 show that the addition of 20 ppm of sulfur causes a great deactivation of the bimetallic catalysts. In all cases the addition of S practically does not modify the selectivity to RO products which is 60–73%.

The distribution of decalin reaction products with S = 0, 10 and 20 ppm is shown in Fig. 4. Sulfur addition decreases the amount of dehydrogenated products, as a consequence of the poisoning of the metal function. Regarding the performance of RO products, in the presence of 10 ppm of S, bimetallic catalysts maintain the same trend found in the absence of S. The yield to cracking products decreases progressively with the increase in the amount of sulfur in the reaction medium. The sulfur adsorbed on the metal decreases its hydrogenation and its hydrogenolytic activity. Therefore, fewer cracking products are formed by hydrogenolysis [3].

The Ir–Pd(1) and Ir–Pd(2) catalysts show a slight increase in yield to RO and RC products using decalin with 10 ppm S, as compared to pure decalin. Pd has a lower hydrogenolitic activity than Ir (Table 1) and sulfur is preferably adsorbed on Pd. Therefore sulfur poison the atoms of Pd in a greater proportion, leading to a decrease of the yield to PD products. Ir is less affected by sulfur on the bimetallic catalysts being their hydrogenolytic activity less diminished. The ring contraction products are then transformed into ring opening products by hydrogenolysis on iridium, which is less affected by sulfur on the bimetallic catalysts.

It is important to analyze the yield to CR and RO products as a function of the amount remanent at the end of the reaction of trans-decalin and cis-decalin, respectively.

The yield to cracking products obtained in the absence of S and using decalin dopped with 10 ppm of sulfur are consistent with the trans-decalin results shown in Fig. 5a. The lower percentages of trans decalin at the end of the reaction correspond to the highest yields to cracking products [48]. On the other hand, the yields to RO products (decalin with 10 ppm and without of sulfur) are compatible with the final percentages of cis-decalin (Fig. 5b), given the greater reactivity of cis-decalin for forming RO products [48]. Moreover Fig. 5 indicates that in the absence of sulfur practically all the cis-decalin isomer is reacted. It is also remarkable from the Fig. 5 that cis isomer is more reactive than trans isomer. Santikunaporn et al. [48] argues that the cis isomer can produce the reaction intermediate more easily than the trans isomer due to steric hindrance and that the activation energy for the formation of the reaction intermediate would be higher for trans-decalin.

The analysis of cracking products provides valuable information on the decalin ring opening reaction mechanism. It was reported that a hammock-type distribution (i.e., high selectivity to C9 and C1 and low selectivity to C3 to C7) indicates that the ring opening occurs primarily through hydrogenolysis on the metal sites, whereas a “M”-type distribution (maximum selectivities for C4 and C6 and low selectivities to C1 y C9) shows that ring opening is catalyzed by the acid function (involving carbocations) [49]. Therefore C9 products are considered indicators of hydrogenolysis on metal sites, while C5-C8 products are representative of cracking on the acid function.

Table 4 shows yield and distribution of cracking products obtained upon decalin ring opening (S = 0, 10 and 20 ppm). In the absence of S it can be seen that the metal function has a greater importance than the acid function (with the exception of the Pd catalyst) and with the addition of S this behavior is reversed. This is consistent with S poisoning of the metal function. When a sulfur-free decalin is used, the ring opening of decalin occurs through a bifunctional mechanism. For all catalysts the increase in S content on decalin caused a marked decrease in the percentage of C9 products and an increase of the C5-C9 fraction (cracking products). These results clearly show that at higher S contents the metallic phase is poisoned and the reaction proceeds by an acid mechanism. The percentages of C5-C9 products obtained with the bimetallic catalysts follow the acidity trend measured by TPD of pyridine.

4 Conclusions

It was found that in the absence of S, Ir monometallic catalyst had the highest activity and selectivity to decalin ring opening products. However bimetallic catalysts had a greater tolerance to thiophene poisoning. The S-tolerance of Ir–Pd catalysts can be attributed to modifications of the electronic properties of metal atoms, mainly resulting from the strong Ir–Pd interaction and their interaction with the Brønsted acid sites of the support. The optimal ratio, Ir/Pd = 1, was possibly due to the formation of bimetallic particles and an optimal acidity. Sulfur reduces the yield to cracking and dehydrogenated products and slightly modifies the selectivity to decalin ring opening products. The distribution of the cracking products confirmed that in the absence of S the metallic function controls the decalin ring opening mechanism, except in the case of the monometallic Pd catalyst. With the addition of S the acid function dominates and the activity results correlate with the catalyst acidity.

5. References

Palos R, Gutiérrez A, Arandes J, Bilbao J (2018) Fuel 216:142–152

Yun GN, Lee YK (2014) Appl Catal B Environ 150–151:647–655

D’Ippolito SA, Especel C, Epron F, Pieck CL (2015) Fuel Process Technol 140:180–187

D’Ippolito S, Ballarini A, Pieck C (2017) Energy Fuel 31:5461–5471

D’Ippolito SA, Pirault-Roy L, Especel C, Epron F, Pieck CL (2018) Fuel Process Technol 177:6–15

Nassreddine S, Massin L, Aouine M, Geantet C, Piccolo L (2011) J Catal 278:253–265

Ziaei-Azad H, Sayari A (2016) J Catal 344:729–740

McVicker G, Touvelle M, Hudson C, Vaughan D, Daage M, Hantzer S, Klein D, Ellis E, Cook B, Feeley O, Baumgartner J (1998) US Patent 5,763,731

Finashina ED, Avaev VI, Tkachenko OP, Greish AA, Davshan NA, Kuperman A, Caro J, Kustov LM (2021) Ind Eng Chem Res 60:7802–7815

Castaño P, Gutiérrez A, Hita I, Arandes J, Aguayo A, Bilbao J (2012) Energy Fuels 26:1509–1519

Calemma V, Ferrari M, Rabl S, Weitkamp J (2013) Fuel 111:763–770

Calemma V, Giardino R, Ferrari M (2010) Fuel Process Technol 91:770–776

Fujikawa T, Idei K, Ebihara T, Mizuguchi H, Usui K (2000) Appl Catal A 192:253–261

Yasuda H, Yoshimura Y (1997) Catal Lett 46:43–48

Niquille-Röthlisberger A, Prins R (2007) Catal Today 123:198–207

Navarro R, Pawelec B, Trejo J, Mariscal R, Fierro J (2000) J Catal 189:184–194

Do PTM, Crossley S, Santikunaporn M, Resasco D (2007) Catalysis 20:33–64

Blanco E, Piccolo L, Laurenti D, di Felice L, Catherin N, Lorentz C, Geantet C, Calemma V (2018) Appl Catal A Gen 550:274–283

Catherin N, Blanco E, Piccolo L, Laurenti D, Simonet F, Lorentz C, Leclerc E, Calemma V, Geantet C (2019) Catal Today 323:105–111

Girgis MJ, Gates BC (1991) Ind Eng Chem Res 30:2021–2058

Whitehurst DD, Farag H, Nagamatsu T, Sakanishi I, Mochida I (1998) Catal Today 45:299–305

D’Ippolito SA, Ballarini AD, Rosas SM, Pirault-Roy L, Especel C, Epron F, Pieck CL (2020) Can J Chem Eng 99:1146–1157

D’Ippolito S, Especel C, Vivier L, Epron F, Pieck C (2014) Appl Catal A Gen 469:541–549

Nylén U, Sassu L, Melis S, Jäås S, Boutonnet M (2006) Appl Catal A Gen 299:1–13

Haneda M, Fujitani T, Hamada H (2006) J Mol Catal A Chem 256:143–148

Bourane A, Nawdali M, Bianchi D (2002) J Phys Chem B 106:2665–2671

Mahata N (2016) Surf Interfaces 4:51–54

Subramanian S, Schwarz JA (1991) Appl Catal 74:65–81

Carnevillier C, Epron F, Marecot P (2004) Appl Catal A Gen 275:25–33

Huang Y, Xue J, Gates W, Schwarz J (1988) J Catal 111:59–66

Rodríguez-Castellón E, Mérida-Robles J, Díaz L, Maireles-Torres P, Jones DJ, Rozière J, Jiménez-López A (2004) Appl Catal A Gen 260:9–18

Gusovius AF, Watling TC (1999) Appl Catal A 188:187–199

Lieske H, Völter J (1985) J Phys Chem 89:1841–1842

Nakagawa Y, Takada K, Tamura M, Tomishige K (2014) ACS Catal 4:2718–2726

Rocha A, Moreno E, da Silva G, Zotin J, Faro A Jr (2008) Catal Today 133–135:394–399

Biloen B, Helle J, Verbeek H, Dautzembverg F, Sachtler W (1980) J Catal 63:112–118

Gao S, Schmidt LD (1989) J Catal 115:356–364

Sinfelt JH (1973) Adv Catal 23:91–119

Regalbuto JR, Antos GJ (2004). In: Antos GJ, Aitani AM (eds) Preparation of reforming catalysts, 2nd edn. Marcel Dekker, New York

Carvalho L, Pieck C, Rangel M, Fígoli N, Vera C, Parera J (2004) Appl Catal A Gen 269:105–116

D’Ippolito S, Gutierrez L, Pieck C (2012) Appl Catal A Gen 445–446:195–203

Chandra Mouli K, Sundaramurthy V, Dalai AK, Ring Z (2007) Appl Catal A Gen 321:17–26

McVicker G, Daage M, Touvelle M, Hudson C, Klein D, Baird W, Cook B, Chen J, Hantzer S, Vaughan D, Ellis E, Feeley O (2002) J Catal 210:137–148

Galadina A, Muraza O (2016) Fuel 18:618–629

Arribas MA, Corma A, Díaz-Cabañas M, Martinez A (2004) Appl Catal A Gen 273:277–286

Kim HJ, Song C (2021) J Catal 403:203–214

Barbier J, Lamy-Pitara E, Marécot P, Boitiaux JP, Cosyns J, Verna F (1990) Adv Catal 37:279–318

Santikunaporn M, Herrera J, Jongpatiwut S, Resasco D, Alvarez W (2004) J Catal 228:100–113

Santi D, Holl T, Calemma V, Weitkamp J (2013) Appl Catal A Gen 455:46–57

Acknowledgements

The authors thank CONICET (PIP 2021-2023 Grant 11220200100786 CO) and UNL (CAI + D-2020 Grants 50620190100073LI) for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

D’Ippolito, S.A., Rosas, S.M., Ballarini, A.D. et al. Optimization of the Metal Phase Composition of Ir–Pd/SiO2–Al2O3 Catalysts to Increase Thiotolerance in Selective Ring Opening of Decalin. Top Catal 65, 1209–1217 (2022). https://doi.org/10.1007/s11244-022-01608-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-022-01608-3