Abstract

Azadirachta indica is used to insects repellent, control diabetes, and combat with cancer. In this study, the effect of different concentrations of chitosan and sampling times on cell suspension culture and SQS1 and MOF1 genes expression were studied and response surface methodology was used to construct the prediction models for azadirachtin, mevalonic acid and squalene accumulation and production. The highest fresh and dry cell weight and azadirachtin accumulation were 726.21 g/L, 20.76 g/L, and 11.74 mg/g DW obtained 6 days after using 50 mg/L chitosan, respectively. The highest azadirachtin production was 165.50 mg/L achieved by using 50 mg/L chitosan for 8 days. Maximum mevalonic acid accumulation (1.87 mg/g DW) and production (22.50 mg/L) were observed 2 and 4 days after the addition of 50 mg/L chitosan and control condition, respectively. The highest amount of squalene accumulation (0.319 mg/g DW) and production (3.56 mg/L) were obtained 10 days after using 50 mg/L chitosan. Also, the prediction results showed the highest azadirachtin accumulation (10.76 mg/g DW) and production (136.83 mg/L), mevalonic acid accumulation (1.869 mg/g DW) and production (20.576 mg/L) and squalene accumulation (0.217 mg/g DW) and production (2.23 mg/L) by using 71.50 mg/L chitosan for 5.24 days, 66.25 mg/L chitosan for 9.1 days, 2.5 mg/L chitosan for 2 days, without chitosan for 2 days, 98.50 mg/L chitosan for 2 days and 80.25 mg/L chitosan for 6.08 days, respectively. The qRT-PCR analysis indicated the maximum relative expression of SQS1 and MOF1 genes by using 25 and 50 mg/L chitosan for 6 days.

Key message

For the first time, chitosan concentrations and sampling times optimized by response surface methodology for azadirachtin, mevalonic acid and squalene accumulation and production and investigated SQS1 and MOF1 genes expression.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Neem (Azadirachta indica) is a plant of the Meliaceae family and has many medicinal properties. This plant grows in the tropical and subtropical regions of Asia and Africa and used its flowers, leaves, and bark. For example, flowers are used to treat bile disorders, leaves are used to treat ulcers, diabetes, headache, heartburn, and stimulating the appetite, and bark is used to treat central nervous disorders, paralysis, and psychiatric disorders. Also, this plant is used to eliminate malaria (Sujarwo et al. 2016). In 1803 it was discovered that this plant could control mosquitoes. There are various medicinal compounds in this plant including azadirachtin, squalene, mevalonic acid, quercetin, nimbin, nimbidin, etc. (Farjaminezhad and Garoosi 2020; Gupta et al. 2017; Rahmani et al. 2018). Azadirachtin has antimicrobial, antimalarial, and anticancer activities and is produced through the mevalonate pathway (Fernandes et al. 2019). Mevalonic acid and squalene are intermediate compounds located upstream of the azadirachtin and converted to it by several enzyme activities including squalene synthase 1 and squalene epoxidase 1 (Bhambhani et al. 2017). Squalene is an important antioxidant that has several medicinal uses such as reduce serum cholesterol levels, enhance the immune response, and suppress tumor proliferation (Patel et al. 2020).

The cell suspension culture is one of the best strategies for the production of secondary metabolites in in vitro condition because the direct and uniform contact of cells with the culture medium increases the nutrient uptake from the medium and enhances the cell growth (Osman et al. 2018). Despite the low production of secondary metabolites in in vitro culture, applying of elicitors in cell suspension culture stimulates the production of secondary metabolites (Kamalipourazad et al. 2016). Each elicitor (including biotic/abiotic groups and endogenous and exogenous subgroups, including chitosan) has a unique mode of action and stimulates the production of various secondary metabolites depending on the signal transductions (Jaisi and Panichayupakaranant 2020; Alsoufi et al. 2019; Kannan et al. 2020). Chitosan has a positive effect on plant growth under stress conditions and is used as an elicitor to produce secondary metabolites in various plants such as xanthone in root cultures of Hypericum perforatum (Brasili et al. 2014; Zong et al. 2017). Perception of chitosan by the cell causes transient accumulation of signal molecules including Ca2+, NO, and H2O2 and increases the up-regulation of the MAPK signaling cascade pathway, produces defense-related proteins, and activates salicylic acid-related signaling pathways (Poncini et al. 2017; Yang et al. 2017).

The studies show that only optimal levels of elicitors increase the production of secondary metabolites in in vitro culture. There are several methods for this purpose, one of the most important of which is response surface methodology (RSM). This method has different designs, the most common of which is the central composite design (CCD) and the Box-Behnken design (BBD). These two designs give the optimal response of variables from the statistical mathematical model of the RSM. This method investigated the effects of single or multiple response variables and optimize them to get the better possible response (Kaur et al. 2020; Leonard et al. 2018). According to this information the main aim of the present study was the enhancement of cell growth, azadirachtin, mevalonic acid, and squalene accumulation and production by utilizing the chitosan, prediction of their accumulation and production under the effect of chitosan and elicitation time by RSM and investigation of the effect of chitosan on the squalene synthase 1 (SQS1) and squalene epoxidase 1 (MOF1) genes expression. This is the first comprehensive study and so far no study has been done on gene expression and prediction of the effect of chitosan on cell suspension culture of A. indica.

Material and methods

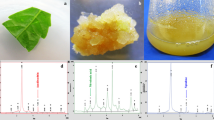

Plant material, callus induction and cell suspension culture establishment

The leaves of A. indica collected from Bandar Abbas city of Iran and surface sterilized with ethanol (70% v/v, for 45 s) and sodium hypochlorite (2.5% w/v, for 13 min) and cultured on MS medium containing 1 mg/L picloram and 2 mg/L kinetin and kept in the growth chamber at 25 ± 2 °C in the dark. The friable calli were transferred to the liquid MS medium with same concentrations of picloram and kinetin and kept on a rotary shaker at 110 rpm with 26 ± 2 °C in the dark and sub-cultured every 12 days (Farjaminezhad and Garoosi 2019).

Preparation of chitosan and treatment

The chitosan was dissolved in 0.1% acetic acid at 50 °C with continuous stirring for 5 h (Ahmad et al. 2019). Then, the chitosan stock solution pH was set to 5.8 and autoclaved at 121 °C for 20 min. Before elicitation with chitosan, cell suspension cultures were transferred to 100 mL Erlenmeyer flasks containing 25 mL liquid MS medium supplemented with 1 mg/L picloram and 2 mg/L kinetin with an initial cell density of 2.6 × 105 (SCV = 8%). According to our previous study growth curve (Farjaminezhad and Garoosi 2019), eight days after culture different concentrations of chitosan including 0, 25, 50, 75, and 100 mg/L were added to cell suspension culture. The cultures were kept on a rotary shaker at 110 rpm with 26 ± 2 °C in the dark and sampling were performed after 2, 4, 6, 8, 10, and 12 days.

Biomass determination

Fresh and dry cell weights were measured by Godoy-Hernández and Vázquez-Flota (2006) method with a little modification. The cells were collected by Whatman No. 1 filter paper using Büchner funnel under vacuum and retained under vacuum for 30 s and weighed immediately. Then the collected cells were transferred to the oven with 50 °C temperature and maintained for 72 h and weighed immediately for dry cell weight.

Mevalonic acid, squalene and azadirachtin extraction and quantification by DAD-HPLC

Azadirachtin, mevalonic acid, and squalene were extracted by Rafiq and Dahot (2010) method with modifications. One milliliter of dichloromethane was added to 100 mg of dried and powdered cells and sonicated for 25 min at room temperature, centrifuged at 7000 rpm for 15 min, and finally the supernatant was collected. The procedure was performed two times. The dichloromethane was evaporated at 50 °C in a water bath and samples were dried. The dried samples were redissolved in 1.5 mL HPLC-grade distilled water and maintained at − 20 °C. The HPLC analysis was performed on a Knauer HPLC–DAD system (DAD detector, Azura, Germany) and Toso C18 column (TSKgel-ODS, 5 µm, 4.6 × 250 mm, Japan) was used. The mobile phase used was acetonitrile: water (10:90) at a flow rate of 0.9 mL/min; the detection wavelength for azadirachtin, mevalonic acid, and squalene were 214, 270 and, 195 nm, respectively. The injection volume of samples was 20 μL (Farjaminezhad and Garoosi 2020). The azadirachtin, mevalonic acid, and squalene production (mg/L) obtained by multiplying the azadirachtin, mevalonic acid, and squalene accumulation (mg/g DW) with dry cell weight (g/L).

RNA extraction, cDNA synthesis and qRT-PCR analysis

For RNA extraction, cDNA synthesis, and qRT-PCR analysis the samples with the highest amount of azadirachtin accumulation at each concentration of chitosan were used. The total RNA was extracted using an RNX-Plus kit (Cinaclon, Iran) based on the producer’s guidance. The quantity of extracted RNA was evaluated by NanoDrop 200C spectrophotometer (Thermo Scientific, USA). Then, extracted total RNAs were treated with Dnase I, RNase-free (Sinaclon, Iran) according to the producer’s guidance to eliminate remaining genomic DNA. For single-strand cDNA synthesis, the mixture of 5 µg of total RNA, 0.5 µg/µL Oligo (dT)18 primer (Cinaclon, Iran) and 12.5 μL DEPC-treated water in the tube maintained at 65 °C for 5 min and immediately transferred on ice. Then, 2 μL 10X reaction buffer (Cinaclon, Iran), 2 μL dNTP Mix 10 mM (Cinaclon, Iran) and 1 µl M-MuLv reverse transcriptase enzyme (200u/µl, Cinaclon, Iran) was added and maintained at 42 °C for 60 min. The reaction was terminated by heating the mixture at 70 °C for 10 min. The reverse transcription reaction product was stored at – 20 °C until qRT-PCR analysis. The qRT-PCR analysis performed by real-time PCR (Applied Biosystems StepOnePlus, USA) with specific primers for squalene synthase 1 (SQS1) gene (forward: 5ʹ-GCTGAAAATGGCTGTGAGGC-3ʹ and reverse: GTCAGTCCCGAGCTGTTGAA-3ʹ), squalene epoxidase 1 (MOF1) gene (forward: 5ʹ-TCAAATCTGCGCCGTTCTCT-3ʹ and reverse: 5ʹ-AGAATGACATGCCCGTGGTT-3ʹ) and housekeeping 18S ribosomal RNA gene (forward: 5ʹ-CACCACACAACTCTCCCCAT-3ʹ and reverse: 5ʹ-ATCAACCACCGTAGTGTCGC-3ʹ). The qRT-PCR mixture contained 1 µl of synthesized cDNA (50 ng), 7.5 µl SYBR Green Premix Ex Taq II (Takara, Japan), 0.5 µl of 10 µmol of gene-specific primer pairs, and 6 µl of nuclease-free water in a final volume of 15 µl. The qRT-PCR conditions included: primary denaturation at 95 °C for 2 min, followed by 35 cycles of denaturation at 95 °C for 30 s, annealing at 57 °C for 30 s and extension at 72 °C for 30 s. Finally, the data were analyzed using the 2−ΔΔCT method (Livak and Schmittgen 2001).

Statistical analysis and experimental design by RSM

The treatment of chitosan was performed in factorial experiments based on a completely randomized design in three replications. The first factor was different concentrations of chitosan and the second factor was different sampling times. The qRT-PCR analysis of SQS1 and MOF1 genes performed with two biological and two technical replications. Data were analyzed by IBM SPSS Statistics software, Version 26.0 (Armonk, NY, USA). The measured indices means compared by using Duncan’s multiple range test at a probability level of 0.01.

RSM was used to study the effects of independent variables including different concentrations of chitosan and different sampling times and their interaction on accumulation and production of azadirachtin, mevalonic acid, and squalene. The sampling times were selected based on preliminary studies. The CCD with two variables and five different levels (− 2, − 1, 0, + 1, + 2) was used to the optimization of chitosan concentration and sampling time for azadirachtin, mevalonic acid, and squalene accumulation and production. Total of 13 experiments were conducted to test the five levels of chitosan and sampling time with full-factorial CCD. By using coded units, the experimental and predicted values for the azadirachtin, mevalonic acid, and squalene accumulation and production in terms of the different variables of chitosan and sampling time are presented in Tables 2 and 4. The predicted response was calculated using the quadratic polynomial model. The predicted responses were calculated by a second-order polynomial (quadratic) model was shown as follows:

where, Y is the response variable, β0 is the average response obtained during replicated experiments of the CCD, βi, βii, and βij are the linear, quadratic, and cross-product effects, respectively; Xi and Xj are the independent coded variables. Response surface regression coefficient and Analysis of Variance (ANOVA) predicted the effects of independent variables on azadirachtin, mevalonic acid, and squalene accumulation and production from cell suspension culture of A. indica. The data were analyzed using Design Expert (12.0.0 version) software.

Results

Effect of chitosan and sampling time on cell biomass

Different chitosan concentrations, sampling times, and their interactions affected both the fresh and dry cell weight (Table 1). An increase in the concentrations of chitosan decreased the fresh and dry cell weight. The most suitable condition for biomass production was control without chitosan. This condition maximized the fresh and dry cell weight, which was 413.41 and 14.47 g/L, respectively. According to the results, by adding 25, 50, 75, and 100 mg/L chitosan the fresh cell weight reduced 10.97, 6.22, 11.68, and 26.03% and dry cell weight reduced 36.56, 24.29, 24.10, and 52.55% compared to the control, respectively. The sampling time of 6 days also gave the highest fresh and dry cell weight of 473.46 and 15.19 g/L. The fresh and dry cell weight were increased from the 2nd day to the 6th day of sampling time but decreased from the 6th day to the 12th day. Therefore, the fresh cell weight on the 6th day of sampling was 105.40, 59.67, 4.86, 26.90, and 23.61% and the dry cell weight was 75.26, 38.17, 4.53, 46.79, and 56.74% higher than the 2nd, 4th, 8th, 10th and 12th days of sampling. By simultaneously, in studing the effect of different concentrations of chitosan and sampling times, it was found that the highest fresh and dry cell weight were 726.21 and 20.76 g/L obtained 6 days after addition 50 mg/L of chitosan. In this treatment, the fresh cell weight increased 36.42, 68.99, 21.76, and 77.55% and the dry cell weight increased 7.67, 69.88, 6.62, and 55.62% compared to the control, 25, 75, and 100 mg/L chitosan at same sampling time (Table S1).

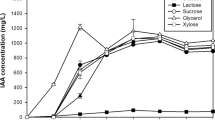

Effect of chitosan and sampling time on azadirachtin accumulation and production

The HPLC–DAD analysis demonstrated that the applied concentrations of chitosan, sampling times, and their interaction significantly stimulated the azadirachtin accumulation and production in treated cells compared to the control (Table 1). Accumulation and production of azadirachtin showed a dose-dependent response to the chitosan and increasing its accumulation and production at 25 mg/L and 50 mg/L, respectively. Chitosan with moderate concentrations including 25 and 50 mg/L showed the highest azadirachtin accumulation and production which was 7.62 mg/g DW and 87.16 mg/L, respectively. The amount of azadirachtin accumulation from the control treatment to 25 mg/L increased and decreased with increasing chitosan concentration from 25 to 100 mg/L. Also, the azadirachtin production increased from the control to 50 mg/L and decreased from 25 to 100 mg/L. At 25 mg/L chitosan the azadirachtin accumulation was 106.50, 8.08, 16.87, and 17.59% more than the control, 50, 75, and 100 mg/L (Fig. 1a). In terms of sampling time, the highest azadirachtin accumulation and production were 7.79 mg/g DW and 110.54 mg/L observed at 6 days after treatment. On the 6th day of sampling, the azadirachtin accumulation increased 193.96, 24.64, 71.58, 33.16, 10.81, and 26.05% and azadirachtin production increased 1114.84, 120.07, 23.21, 55.62, and 101.20% compared to the 2nd, 4th, 8th, 10th and 12th days, respectively (Fig. 1b). The effect of different concentrations of chitosan along with different sampling times is shown in Table S1. The best conditions for induction of azadirachtin accumulation and production were the application of 50 mg/L for 6 days (11.74 mg/g DW) and 50 mg/L for 8 days (165.50 mg/L). In these conditions, the azadirachtin accumulation increased 149.79, 13.65, 92.14, and 45.30% compared to the control, 25, 75, and 100 mg/L chitosan at 6th day of sampling and the azadirachtin production increased 325.52, 97.56, 55.78 and 205.41% compared to the control, 25, 75 and 100 mg/L at same day, respectively (Table S1).

A suitable model for predicting the effect of chitosan and sampling time on azadirachtin accumulation and production

According to the results, the sampling times of 2, 4, 6, 8, and 10 days were selected for RSM analysis and prediction of azadirachtin accumulation and production. The combined effects of different concentrations of chitosan and sampling times were investigated by the RSM using a CCD. The specific interaction of different concentrations of chitosan and sampling times with the measured and predicted response values of azadirachtin accumulation and production is shown in Table 2. Experiment No. 10 in 50 mg/L chitosan and sampling on the 6th day had the highest amount of azadirachtin accumulation (11.74 mg/g DW) and experiment No. 13 in the control condition and sampling on the 6th day had the lowest azadirachtin accumulation (3.15 mg/g DW). Also, experiment No. 8 with the application of 50 mg/L chitosan and sampling time of 6 days had the highest azadirachtin production (136.83 mg/L), and experiment No. 13 with no use of chitosan and sampling time of 6 days had the lowest azadirachtin production (47.88 mg/L). ANOVA results of the response surface model are presented in Table 3. In the ANOVA of the CCD, the coefficient of determination of the model for azadirachtin accumulation and production were 91.36% and 86.04%, respectively; which indicates that 91.36% and 86.04% of the actual levels can correspond to the predicted levels. Also, the p-value of the models was significant and the proposed models were appropriate. Therefore, the following formulas were obtained to predict the azadirachtin accumulation and production using chitosan and sampling times:

Optimization of the response surface of the effect of chitosan and sampling time on azadirachtin accumulation and production

The interaction between different chitosan concentrations and different sampling times is presented in Fig. 1. The results revealed that chitosan concentration is the most important factor and with increasing its concentration, the amount of azadirachtin accumulation first increases and then decreases. According to Fig. 1c and d, increasing the concentration of chitosan along with increasing the time of exposure does not have a significant effect on the accumulation of azadirachtin. The best chitosan concentrations and sampling times for maximum azadirachtin accumulation were between 25 and 100 mg/L and 4–6 days, respectively. The highest amount of azadirachtin accumulation was obtained with the application of 50 mg/L chitosan for 6 days. However, the optimal conditions for maximizing the azadirachtin accumulation (10.76 mg/g DW) were predicted 71.5 mg/L chitosan for 5.24 days. The results also indicated that the azadirachtin production depends on chitosan concentration and sampling time. According to Fig. 1e an f, increasing the chitosan concentration from 0 to 50 mg/L with increasing the duration of exposure, increases the amount of azadirachtin production, but then with increasing the chitosan concentration the azadirachtin production decreases. Based on Fig. 1, the highest amount of azadirachtin production is achieved by applying 50–75 mg/L of chitosan and increases the amount of production by the most exposing of cell suspension culture to this range. In the present study, the highest azadirachtin production was achieved 6 days after applying 50 mg/L chitosan, but it is predicted that the highest azadirachtin production with 136.83 mg/L is obtained by culturing of the cells for 9.1 days at medium containing 66.25 mg/L chitosan.

Effect of chitosan and sampling time on mevalonic acid accumulation and production

The mevalonic acid accumulation and production were significantly changed under different chitosan concentrations, sampling times, and their interactions (Table 1). In comparison with control, mevalonic acid accumulation and production increased by the addition of 25 mg/L chitosan. Among the studied chitosan concentrations, 25 and 50 mg/L increased the mevalonic acid accumulation compared to the control, and 75 and 100 mg/L decreased it. With increasing the chitosan concentration in the culture medium from 0 to 25 mg/L, the mevalonic acid accumulation increased and then decreased. The highest amount of mevalonic acid accumulation was 0.815 mg/g DW obtained at 25 mg/L chitosan, which was 51.20% higher than the control and 19.50, 113.91, and 186.98% higher than the 50, 75, and 100 mg/L, respectively. Also, increasing the concentration of chitosan in the culture medium inhibited mevalonic acid production. With increasing the chitosan concentration from 0 to 25 mg/L, the production of mevalonic acid increased but it was not statistically significant compared to control. The highest mevalonic acid production (7.927 mg/L) was obtained at 25 mg/L chitosan. By adding 25 mg/L chitosan, the mevalonic acid production increased 2.15, 5.93, 105.41, and 340.15% compared to the control and concentrations of 50, 75, and 100 mg/L, respectively (Fig. 2a). Therefore, the utilization of low concentrations of chitosan had a positive effect on the production of mevalonic acid. By investigating of the effect of sampling times, we founded that prolonged exposure of neem cell suspension culture with chitosan reduces the mevalonic acid accumulation. The highest amount of mevalonic acid accumulation with an average of 0.916 mg/g DW was observed on the second day of sampling. In general, two days after the treatment amount of mevalonic acid accumulation was 15.22, 203.31, 288.13, 60.98, and 116.5% higher than the 4th, 6th, 8th, 10th, and 12th days, respectively. Between different sampling times, the highest mevalonic acid production (9.689 mg/L) was observed on the 4th day of sampling. By culturing neem cell suspension for 4 days, the mevalonic acid production was increased 10.82, 112.62, 137.88, 83.71, and 187.68% compared to days 2, 6, 8, 10, and 12, respectively (Fig. 2b). The interaction of chitosan and sampling time showed that the highest mevalonic acid accumulation (1.87 mg/g DW) obtained two days after using 50 mg/L chitosan, which was 11.48, 377.81, 366.92, and 340.15% higher compared to the control, 25, 75, and 100 mg/L chitosan on the same day. Also, the control condition produced the highest amount of mevalonic acid (22.50 mg/L) on the 4th day of sampling. Therefore, in the control condition on the 4th day, the amount of mevalonic acid production was 91.98, 186.62, 532.02, and 700.71% higher than the 25, 50, 75, and 100 mg/L chitosan on the same day (Table S1).

A suitable model for predicting the effect of chitosan and sampling time on mevalonic acid accumulation and production

Based on the results the sampling times of 2, 4, 6, 8, and 10 days were selected for RSM analysis and prediction of mevalonic acid accumulation and production. The specific interaction of different concentrations of chitosan and sampling times with the measured and predicted response values of mevalonic acid accumulation and production is shown in Table 2. Experiment No. 12 (two days after addition of 50 mg/L chitosan) had the highest amount of mevalonic acid accumulation (1.78 mg/g DW) and production (15.08 mg/L) and experiment No. 4 (eight days after application of 75 mg/L chitosan) was free of mevalonic acid. ANOVA results showed that the coefficient of determination (R2) of the model for mevalonic acid accumulation and production were 89.79% and 91.96%, respectively; which indicates that 89.79% and 91.96% of the actual levels can correspond to the predicted levels. Also, the p-value of the models was significant and the proposed models were appropriate (Table 3). Therefore, the following formulas were obtained to predict the mevalonic acid accumulation and production using chitosan and sampling times:

Optimization of the response surface of the effect of chitosan and sampling time on mevalonic acid accumulation and production

The interaction between different chitosan concentrations and sampling times is shown in Fig. 2. The results showed that chitosan concentration and sampling time are the most important factors. An increase in the chitosan concentration and sampling time leads to a decrease in the mevalonic acid accumulation in the A. indica cell suspension culture. Therefore, by using the different concentrations of chitosan and sampling times, the highest amount of mevalonic acid accumulation was observed in their highest and lowest levels. According to Fig. 2c and d, the highest amount of mevalonic acid accumulation was obtained by applying 0–50 mg/L of chitosan, which is reduced by exposing the most time of cell suspension culture to this range. The highest amount of mevalonic acid accumulation was obtained two days after application of 50 mg/L chitosan, but it is predicted that the highest amount of mevalonic acid accumulation with the amount of 1.869 mg/g DW was obtained by culture the cells for 2 days in a medium containing 2.5 mg/L chitosan. Also, increasing the concentration of chitosan along with increasing the time of exposure reduced the production of mevalonic acid. In this study, the highest mevalonic acid production was obtained by exposing the cell suspension culture with 50 mg/L chitosan for 2 days. Optimal conditions for maximizing the mevalonic acid production predicted at cell suspension culture without chitosan after 2 days, which can produce 20.576 mg/L mevalonic acid.

Effect of chitosan and sampling time on squalene accumulation and production

The results showed that different concentrations of chitosan, sampling times, and their interactions had a significant effect on squalene accumulation and production (Table 1). A significant increase in squalene accumulation and production was observed in chitosan treated cells as compared with the control. The study of squalene accumulation in the presence of chitosan indicated that low to moderate concentrations of chitosan stimulates squalene accumulation and higher concentrations reduced its accumulation. With increasing the chitosan concentration from 0 to 50 mg/L, the squalene accumulation increased and then decreased. The highest squalene accumulation between different concentrations of chitosan was obtained (0.166 mg/g DW) at 50 mg/L and compared to the control and 25, 75, and 100 mg/L concentrations it was 148.13, 111.73, 48.88, and 34.30% higher, respectively. Application of 50, 75, and 100 mg/L chitosan increased squalene production compared to the control and use of 25 mg/L decreased it. Among different concentrations of chitosan, the highest production of squalene (1.851 mg/L) was obtained at 50 mg/L, which was 87.73, 128.52, 31.84, and 47.84% higher compared to the control and 25, 75, and 100 mg/L, respectively (Fig. 3a). Between different sampling times, the highest amount of squalene accumulation was 0.187 mg/g DW obtained on the 10th day of sampling. In general, 10 days after treatment the amount of squalene accumulation compared to 2, 4, 6, 8, and 12 days was 129.81, 69.35, 119.06, 81.84, and 113.32% higher, respectively. Also, over time the production of squalene in the neem cell suspension culture increases; thus, the highest amount of squalene production (1.984 mg/L) was observed on the 10th day of sampling. So, on the 10th day of sampling, the amount of squalene production compared to the 2nd, 4th, 6th, 8th, and 12th days was 197.01, 83.19, 44.08, 28.83, and 118.02% higher, respectively (Fig. 3b). Further study of squalene accumulation and production was performed using the simultaneous examination of different concentrations of chitosan and different sampling times. The results showed that 10 days after application of 50 mg/L chitosan the highest amount of squalene accumulation (0.319 mg/g DW) and production (3.56 mg/L) obtained which were 179.83, 390.77, 120, and 8.87% and 143.77, 474.03, 266.91, and 7.52% higher compared to the control, 25, 75, and 100 mg/L, respectively (Table S1).

A suitable model for predicting the effect of chitosan and sampling time on squalene accumulation and production

The sampling times of 4, 6, 8, 10, and 12 days were selected for RSM analysis and prediction of squalene accumulation and production. The experimental and predicted values of chitosan-induced squalene accumulation are shown in Table 4. Experiment No. 12 (4 days after using 50 mg/L chitosan) had the highest squalene accumulation (0.214 mg/g DW) and experiment No. 3 (control condition after 8 days) had the lowest squalene production (0.063 mg/g DW). Experiment No. 11 with the application of 75 mg /L chitosan and sampling time of 6 days had maximum squalene production (3.63 mg/L) and experiment No. 8 with the application of 25 mg/L chitosan and sample time of 10 days had the lowest squalene production. The results of ANOVA of CCD showed that the coefficient of determination (R2) of the model is 98.44% for squalene accumulation and 80.63% for squalene production. This indicates that 98.44% and 80.63% of the actual levels of squalene accumulation and production correspond to the predicted levels. Also, the p-value of the models was significant for squalene accumulation and production, which indicates the suitability of the models (Table 3). Therefore, mathematical models were obtained to predict the squalene accumulation and production under chitosan elicitation:

Optimization of the response surface of the effect of chitosan and sampling time on squalene accumulation and production

According to RSM results, chitosan concentration was the most important parameter; so that with its increase, the accumulation of squalene reached a maximum. In contrast, with increasing sampling time the amount of squalene accumulation decreased at different concentrations of chitosan. The highest amount of squalene accumulation was obtained 4 days after the application of 50 mg/L chitosan. In general, the optimal predicted condition for maximizing squalene accumulation is the application of 98.5 mg/L chitosan for 2 days, which can accumulate 0.217 mg/g DW of squalene. Also, increasing the chitosan concentration during low exposure periods increased squalene production, but increasing chitosan concentration at high exposure times did not affect squalene production. According to Fig. 3e and f, it can be said that using 50–100 mg/L chitosan for 4–8 days can produce an acceptable amount of squalene. The highest amount of squalene production was obtained with an application of 75 mg/L chitosan for 6 days, but it is predicted that the use of 80.25 mg/L chitosan for 6.08 days can produce 2.23 mg/L squalene.

qRT-PCR analysis of SQS1 and MOF1 genes expression

The qRT-PCR analysis showed that relative expression of the SQS1 gene was increased 48.90% at 6 days after application of 25 mg/L chitosan compared with the control cells after 12 days. But, after the addition of 50 mg/L chitosan for 6 days, 75 mg/L chitosan for 4 days, and 100 mg/L chitosan for 12 days, the relative expression of the SQS1 gene decreased 48.90, 43.91, and 69.72% compared to the control after 12 days. Also, the use of chitosan significantly up-regulated the MOF1 gene. The highest relative expression of MOF1 gene obtained by addition of 50 mg/L chitosan for 6 days, which was 37.60, 8.21, 19.69, and 16.33% higher than the control at 12 days, 25 mg/L chitosan at 6 days, 50 mg/L chitosan at 6 days, 75 mg/L chitosan at 4 days and 100 mg/L chitosan at 12 days (Fig. 4).

Discussion

The use of elicitor is one of the effective strategies to increase the production of secondary metabolites through plant cell culture (Kamalipourazad et al. 2016), in which many parameters including elicitor specificity and dose, elicitor exposure time, culture conditions and cell growth stage can have a great impact on the extraction process (Jaisi and Panichayupakaranant 2017; Murthy et al. 2014). Also, in this context, signal transduction network and biosynthesis pathway regulate transcription factors for the expression of biosynthesis genes and catalytic enzymes involved in plant secondary metabolism (Sivanandhan et al. 2014).

Our results showed that in response to treatment with different concentrations of chitosan, the cell growth and azadirachtin, mevalonic acid, and squalene accumulation increased. For the maximum cell growth, azadirachtin, and mevalonic acid accumulation and production the suitable conditions were the application of 50 mg/L chitosan for 6 days, 50 mg/L chitosan for 6 and 8 days, applying 50 mg/L chitosan for 2 days, and not using chitosan for 4 days, respectively. Also, the best condition for the accumulation and production of squalene was 50 mg/L chitosan for 10 days. In various studies have been reported the effect of chitosan on the increase of secondary metabolites (Sivanandhan et al. 2012). Chitosan activates methyl jasmonate, a signal molecule associated with the defense gene and phospholipase C and protein kinase C cascades (Doares et al. 1995; Vasconsuelo et al. 2004, 2003). In the study of the effect of chitosan on neem hairy root culture, it was reported that the use of 50, 100, 250, and 500 mg/L chitosan gives 7.6, 3.6, 2.8, and 2.8 g/L biomass, 3.60, 2.52, 2.03 and 1.36 mg/g DW azadirachtin accumulation and 27.36, 9.07, 5.68, and 3.81 mg/L azadirachtin production (Srivastava and Srivastava 2014). In this study, cell suspension cultures exposed to high concentrations of chitosan showed some browning. Similar results were observed after adding fungal elicitors to Catharanthus roseus cell culture (Zhao et al. 2001), chitosan-treated Calendula officinalis L. (Wiktorowska et al. 2010), and ginseng suspension culture treated with yeast extract or methyl jasmonate (Lu et al. 2001). Studies have shown that the use of chitosan in plant cell culture induces or stimulates the production of many secondary metabolites. However, it seems that the response of cells depends on the chitosan concentration used for stimulation and determining the optimal concentration is very important. Treatment of C. officinalis L. suspension cultures with relatively high concentrations of chitosan resulted cell permeability, increased culture medium conductivity, reduced cell viability, and alkaloid production (Wiktorowska et al., 2010). The ability of chitosan to increase the production of secondary metabolites may be due to elicit a natural defense response or activate enzymes involved in their biosynthesis (Baque et al. 2012; Chakraborty et al. 2009). Also, inducing cell permeability can release secondary metabolites such as plumbagin (Jaisi and Panichayupakaranant 2017). The signal transduction of chitosan during the synthesis of secondary metabolites is unknown. Excessive treatment may lead to metabolic or physiological damage. The 150 mg/L chitosan has been reported in Plumbago indica root culture as the best concentration (Jaisi and Panichayupakaranant 2016). Determining the optimal exposure period and the age of culture is also very important to stimulate the neem cell suspension culture to produce maximum azadirachtin, mevalonic acid, and squalene. The cells at different stages of growth show changes in mRNA and protein production; so, treatment at different stages of growth may increase cell growth and secondary metabolite production (Chong et al. 2005). In the P. indica root culture, treatment of cultures with 150 mg/L chitosan for 72 h produced 13.08 mg/g DW plumbagin (Jaisi and Panichayupakaranant 2017). In winter cherry cell suspension culture, the highest amount of total vitaminolysis obtained by application of 100 mg/L chitosan and 6 mM squalene with 1 mg/L picloram, 0.5 mg/L kinetin, 200 mg/L L-glutamine and 5% sucrose and 48 h of exposure time (Sivanandhan et al. 2014).

The different concentrations of chitosan and sampling times were optimized using RMS. The RSM consists of three CCD, BBD, and D-optimal designs. The CCD and BBD are used for sequential and non-sequential experiments, respectively. The BBD has a lower accuracy than CCD (Singh and Chaturvedi 2012). In this study, CCD was used to optimize the levels of variables, which will be useful for the mathematical model. The various combinations of two factors and the corresponding measured and predicted azadirachtin, mevalonic acid, and squalene accumulation and production showed that the highest azadirachtin accumulation and production, mevalonic acid accumulation and production and squalene accumulation and production obtained 5.24 days after addition of 71.50 mg/L chitosan, 9.1 days after using 66.25 mg/L chitosan, 2 days after the application of 2.5 mg/L chitosan, 2 days after no use of chitosan, 98.50 mg/L chitosan for 2 days and 80.25 mg/L chitosan for 6.08 days, respectively. Farjaminezhad and Garoosi (2021) applied CCD for the prediction of the effect of yeast extract and sampling time on azadirachtin, mevalonic acid, and squalene accumulation and production. Prakash and Srivastava (2005) used CCD for media optimization for cell growth and azadirachtin production in neem cell suspension cultures. Prakash and Srivastava (2008) used CCD for optimization of elicitors to the enhancement of azadirachtin production.

Conclusion

This is the first study on the optimization of chitosan and sampling time for the production of azadirachtin, mevalonic acid, and squalene in the cell suspension cultures of A. indica and investigation of SQS1 and MOF1 genes expression. CCD of RSM optimizes the linear, quadratic, and interaction effects of chitosan and sampling time for maximum azadirachtin, mevalonic acid, and squalene accumulation and production. The cell suspension culture growth and secondary metabolites synthesis can be enhanced by the optimal level of chitosan and sampling time. These results showed that advancement in techniques and prediction methods could be applied for secondary metabolites production. The cell suspension culture is a great platform for the production of secondary metabolites in in vitro conditions. In the future, methods of predicting optimal conditions for secondary metabolites production by cell suspension can reduce the production time of new medicinal compounds.

References

Ahmad W, Zahir A, Nadeem M, Garros L, Drouet S, Renouard S, Doussot J, Giglioli-Guivarc’h N, Hano C, Abbasi BH (2019) Enhanced production of lignans and neolignans in chitosan-treated flax (Linum usitatissimum L.) cell cultures. Process Biochem 79:155–165. https://doi.org/10.1016/j.procbio.2018.12.025

Alsoufi ASM, Pączkowski C, Szakiel A, Długosz M (2019) Effect of jasmonic acid and chitosan on triterpenoid production in Calendula officinalis hairy root cultures. Phytochem Lett 31:5–11. https://doi.org/10.1016/j.phytol.2019.02.030

Baque MA, Shiragi MHK, Lee EJ, Paek KY (2012) Elicitor effect of chitosan and pectin on the biosynthesis of anthraquinones, phenolics and flavonoids in adventitious root suspension cultures of Morinda citrifolia (L.). Aust J Crop Sci 6(9):1349

Bhambhani S, Lakhwani D, Gupta P, Pandey A, Dhar YV, Kumar Bag S, Asif MH, Kumar Trivedi P (2017) Transcriptome and metabolite analyses in Azadirachta indica: identification of genes involved in biosynthesis of bioactive triterpenoids. Sci Rep 7(1):5043. https://doi.org/10.1038/s41598-017-05291-3

Brasili E, Praticò G, Marini F, Valletta A, Capuani G, Sciubba F, Miccheli A, Pasqua G (2014) A non-targeted metabolomics approach to evaluate the effects of biomass growth and chitosan elicitation on primary and secondary metabolism of Hypericum perforatum in vitro roots. Metabolomics 10(6):1186–1196. https://doi.org/10.1007/s11306-014-0660-z

Chakraborty M, Karun A, Mitra A (2009) Accumulation of phenylpropanoid derivatives in chitosan-induced cell suspension culture of Cocos nucifera. J Plant Physiol 166(1):63–71. https://doi.org/10.1016/j.jplph.2008.02.004

Chong TM, Abdullah MA, Lai OM, Nor’Aini FM, Lajis NH (2005) Effective elicitation factors in Morinda elliptica cell suspension culture. Process Biochem 40(11):3397–3405. https://doi.org/10.1016/j.procbio.2004.12.028

Doares S, Syrovets T, Weiler W, Ryan C (1995) Oligouronides and chitosan utilize the octadecanoid pathway to activate plant defensive genes. Proc Natl Acad Sci USA 92:4095–4098. https://doi.org/10.1073/pnas.92.10.4095

Farjaminezhad R, Garoosi GA (2019) New biological trends on cell and callus growth and azadirachtin production in Azadirachta indica. 3 Biotech 9(8):309. https://doi.org/10.1007/s13205-019-1836-z

Farjaminezhad R, Garoosi G-a (2020) Establishment of green analytical method for ultrasound-assisted extraction of azadirachtin, mevalonic acid and squalene from cell suspension culture of Azadirachta indica using response surface methodology. Ind Crops Prod 144:111946. https://doi.org/10.1016/j.indcrop.2019.111946

Farjaminezhad R, Garoosi G (2021) Improvement and prediction of secondary metabolites production under yeast extract elicitation of Azadirachta indica cell suspension culture using response surface methodology. AMB Express 11(1):43. https://doi.org/10.1186/s13568-021-01203-x

Fernandes SR, Barreiros L, Oliveira RF, Cruz A, Prudêncio C, Oliveira AI, Pinho C, Santos N, Morgado J (2019) Chemistry, bioactivities, extraction and analysis of azadirachtin: State-of-the-art. Fitoterapia 134:141–150. https://doi.org/10.1016/j.fitote.2019.02.006

Godoy-Hernández G, Vázquez-Flota FA (2006) Growth Measurements. In: Loyola-Vargas VM, Vázquez-Flota F (eds) Plant Cell Culture Protocols. Humana Press, Totowa, NJ, pp 51–58

Gupta SC, Prasad S, Tyagi AK, Kunnumakkara AB, Aggarwal BB (2017) Neem (Azadirachta indica): An indian traditional panacea with modern molecular basis. Phytomedicine 34:14–20. https://doi.org/10.1016/j.phymed.2017.07.001

Jaisi A, Panichayupakaranant P (2016) Increased production of plumbagin in Plumbago indica root cultures by biotic and abiotic elicitors. Biotechnol Lett 38(2):351–355. https://doi.org/10.1007/s10529-015-1969-z

Jaisi A, Panichayupakaranant P (2017) Chitosan elicitation and sequential Diaion® HP-20 addition a powerful approach for enhanced plumbagin production in Plumbago indica root cultures. Process Biochem 53:210–215. https://doi.org/10.1016/j.procbio.2016.11.027

Jaisi A, Panichayupakaranant P (2020) Enhanced plumbagin production in Plumbago indica root culture by simultaneous and sequential dual elicitations using chitosan with ʟ-alanine and methyl-β-cyclodextrin. Bioresour Bioprocess 7(1):10. https://doi.org/10.1186/s40643-020-0298-9

Kamalipourazad M, Sharifi M, Maivan HZ, Behmanesh M, Chashmi NA (2016) Induction of aromatic amino acids and phenylpropanoid compounds in Scrophularia striata Boiss. cell culture in response to chitosan-induced oxidative stress. Plant Physiol Biochem 107:374–384. https://doi.org/10.1016/j.plaphy.2016.06.034

Kannan N, Manokari M, Shekhawat MS (2020) Enhanced production of anthraquinones and phenolic compounds using chitosan from the adventitious roots of Morinda coreia Buck and Ham. Ind Crops Prod 148:112321. https://doi.org/10.1016/j.indcrop.2020.112321

Kaur P, Gupta R, Dey A, Malik T, Pandey DK (2020) Optimization of salicylic acid and chitosan treatment for bitter secoiridoid and xanthone glycosides production in shoot cultures of Swertia paniculata using response surface methodology and artificial neural network. BMC Plant Biol 20:1–13. https://doi.org/10.1186/s12870-020-02410-7

Leonard J, Seth B, Sahu BB, Singh VR, Patra N (2018) Statistical optimization for enhanced bacoside A production in plant cell cultures of Bacopa monnieri. Plant Cell, Tissue Organ Cult 133(2):203–214. https://doi.org/10.1007/s11240-017-1373-6

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2− ΔΔCT method. Methods 25(4):402–408. https://doi.org/10.1006/meth.2001.1262

Lu M, Wong H, Teng W (2001) Effects of elicitation on the production of saponin in cell culture of Panax ginseng. Plant Cell Rep 20(7):674–677. https://doi.org/10.1007/s002990100378

Murthy HN, Lee E-J, Paek K-Y (2014) Production of secondary metabolites from cell and organ cultures: strategies and approaches for biomass improvement and metabolite accumulation. Plant Cell, Tissue Organ Cult 118(1):1–16. https://doi.org/10.1007/s11240-014-0467-7

Osman NI, Jaafar Sidik N, Awal A (2018) Efficient enhancement of gallic acid accumulation in cell suspension cultures of Barringtonia racemosa L. by elicitation. Plant Cell, Tissue Organ Cult 135(2):203–212. https://doi.org/10.1007/s11240-018-1456-z

Patel A, Liefeldt S, Rova U, Christakopoulos P, Matsakas L (2020) Co-production of DHA and squalene by thraustochytrid from forest biomass. Sci Rep 10(1):1992. https://doi.org/10.1038/s41598-020-58728-7

Poncini L, Wyrsch I, Dénervaud Tendon V, Vorley T, Boller T, Geldner N, Métraux J-P, Lehmann S (2017) In roots of Arabidopsis thaliana, the damage-associated molecular pattern AtPep1 is a stronger elicitor of immune signalling than flg22 or the chitin heptamer. PLoS ONE 12(10):e0185808. https://doi.org/10.1371/journal.pone.0185808

Prakash G, Srivastava AK (2005) Statistical media optimization for cell growth and azadirachtin production in Azadirachta indica (A Juss) suspension cultures. Process Biochem 40(12):3795–3800. https://doi.org/10.1016/j.procbio.2005.05.010

Prakash G, Srivastava AK (2008) Statistical elicitor optimization studies for the enhancement of azadirachtin production in bioreactor Azadirachta indica cell cultivation. Biochem Eng J 40(2):218–226. https://doi.org/10.1016/j.bej.2007.12.017

Rafiq M, Dahot MU (2010) Callus and azadirachtin related limonoids production through in vitro culture of neem (Azadirachta indica A Juss). Afr J Biotechnol 9(4):449–453

Rahmani A, Almatroudi A, Alrumaihi F, Khan A (2018) Pharmacological and therapeutic potential of neem (Azadirachta indica). Pharmacogn Rev 12(24):250–255. https://doi.org/10.4103/phrev.phrev_8_18

Singh M, Chaturvedi R (2012) Statistical optimization of media for enhanced azadirachtin production from redifferentiated zygotic embryo cultures of neem (Azadirachta indica A. Juss.). Vitro Cell Dev Biol Plant 48(1):92–98. https://doi.org/10.1007/s11627-011-9394-z

Sivanandhan G, Arun M, Mayavan S, Rajesh M, Mariashibu TS, Manickavasagam M, Selvaraj N, Ganapathi A (2012) Chitosan enhances withanolides production in adventitious root cultures of Withania somnifera (L) Dunal. Ind Crops Prod 37(1):124–129. https://doi.org/10.1016/j.indcrop.2011.11.022

Sivanandhan G, Selvaraj N, Ganapathi A, Manickavasagam M (2014) Enhanced biosynthesis of withanolides by elicitation and precursor feeding in cell suspension culture of Withania somnifera (L) dunal in shake-flask culture and bioreactor. PLoS ONE 9(8):e104005. https://doi.org/10.1371/journal.pone.0104005

Srivastava S, Srivastava AK (2014) Effect of elicitors and precursors on azadirachtin production in hairy root culture of Azadirachta indica. Appl Biochem Biotech 172(4):2286–2297. https://doi.org/10.1007/s12010-013-0664-6

Sujarwo W, Keim AP, Caneva G, Toniolo C, Nicoletti M (2016) Ethnobotanical uses of neem (Azadirachta indica A.Juss.; Meliaceae) leaves in Bali (Indonesia) and the Indian subcontinent in relation with historical background and phytochemical properties. J Ethnopharmacol 189:186–193. https://doi.org/10.1016/j.jep.2016.05.014

Vasconsuelo A, Mari XA, Giuletti A, Picotto G, Rodriguez-Talou J, Boland R (2003) Involvement of the PLC/PKC pathway in Chitosan-induced anthraquinone production by Rubia tinctorum L. cell cultures. Plant Sci 165(2):429–436. https://doi.org/10.1016/S0168-9452(03)00208-5

Vasconsuelo A, Giulietti AM, Boland R (2004) Signal transduction events mediating chitosan stimulation of anthraquinone synthesis in Rubia tinctorum. Plant Sci 166(2):405–413. https://doi.org/10.1016/j.plantsci.2003.10.007

Wiktorowska E, Długosz M, Janiszowska W (2010) Significant enhancement of oleanolic acid accumulation by biotic elicitors in cell suspension cultures of Calendula officinalis L. Enzyme Microb Technol 46(1):14–20. https://doi.org/10.1016/j.enzmictec.2009.09.002

Yang A, Yu L, Chen Z, Zhang S, Shi J, Zhao X, Yang Y, Hu D, Song B (2017) Label-free quantitative proteomic analysis of chitosan oligosaccharide-treated rice infected with southern rice black-streaked dwarf virus. Viruses 9(5):115. https://doi.org/10.3390/v9050115

Zhao J, Zhu W-H, Hu Q (2001) Selection of fungal elicitors to increase indole alkaloid accumulation in Catharanthus roseus suspension cell culture. Enzyme Microb Technol 28(7):666–672. https://doi.org/10.1016/S0141-0229(01)00309-X

Zong H, Liu S, Xing R, Chen X, Li P (2017) Protective effect of chitosan on photosynthesis and antioxidative defense system in edible rape Brassica rapa L in the presence of cadmium. Ecotoxicol Environ Saf 138:271–278. https://doi.org/10.1016/j.ecoenv.2017.01.009

Acknowledgements

This work was supported by Imam Khomeini International University (IKIU). Special thanks to Dr. Jafar Ahmadi for the technical support.

Funding

The work was supported by the Imam Khomeini International University (IKIU).

Author information

Authors and Affiliations

Contributions

RF wrote the manuscript and carried out experiments and data analysis. GG supervised the experiment and conducted an English revision. Both authors approved its final version.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no confict of interest.

Additional information

Communicated by Silvia Moreno.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Farjaminezhad, R., Garoosi, G. Prediction of the effect of chitosan on cell suspension culture of Azadirachta indica by response surface methodology. Plant Cell Tiss Organ Cult 146, 323–337 (2021). https://doi.org/10.1007/s11240-021-02072-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-021-02072-9