Abstract

An efficient protocol was developed for short-term storage and conservation of a woody medicinal climber, Decalepis hamiltonii, using encapsulated nodal segments. The encapsulation of nodal segments was significantly affected by the concentrations of sodium alginate (Na-alginate) and calcium chloride (CaCl2·2H2O). A gelling matrix of 4 % Na-alginate and 100 mM CaCl2·2H2O was found most suitable for the production of ideal Ca-alginate beads. Maximum shoot re-growth (77.00 ± 2.09 %) was recorded on Murashige and Skoog (MS) basal medium supplemented with 5.0 μM 6-benzyladenine (BA), 0.5 μM indole-3-acetic acid (IAA) and 30.0 μM adenine-sulphate (ADS). Microshoots, recovered from encapsulated nodal segments (capsule) were best rooted on half-strength MS medium containing 2.5 μM α-naphthalene acetic acid (NAA). Complete plantlets (with shoot and root) were successfully acclimatized and established in field where they grew well without any detectable variation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Encapsulation technology represents a new and powerful tool in the plant nursery field as well as in approaches to germplasm conservation and exchange of plant materials between laboratories (Standardi and Piccioni 1998; Mallón et al. 2007; Rai et al. 2009; Srivastava et al. 2009; Germanà et al. 2011; Rihan et al. 2011; Mishra et al. 2011; Hung and Trueman 2011, 2012a, b). Previously, synthetic seed or artificial seed (or synseed), described as “artificially encapsulated somatic embryos (bipolar structure) which can be used for sowing under in vitro or ex vitro conditions” (Aitken-Christie et al. 1995). But due to low success and high cost of somatic embryo production, shoot tips, nodes, bulbs or other meristematic tissue (unipolar structures) that can produce a whole plant may also be encapsulated which are also considered as synthetic seeds (Pond and Cameron 2003). A wide range of woody plants has been re-grown from encapsulated shoot tips or nodes (Chand and Singh 2004; Rai et al. 2009; Ahmad and Anis 2010; Germanà et al. 2011; Hung and Trueman 2011, 2012a, b).

Decalepis hamiltonii Wight and Arn., commonly called as ‘swallow root’, is an endangered monogeneric woody medicinal climber of Asclepiadaceae (Anonymous 2003). It is native of the Deccan peninsula and forest areas of Western Ghats of India. The roots of D. hamiltonii are used as a flavoring principle (Murti and Seshadri 1941) and a blood purifier (Jacob 1937). Recently, Naveen and Khanum (2010) suggested that root extract could be used not only as food preservative (to replace for the toxic butylated hydoxy anisole and butylated hydoxy toluene currently under use) but also can be used in the preparation of nutraceuticals and pharmaceutical products. Moreover, antidiabetic, hepatoprotective and antiatherosclerotic properties of root extract of D. hamiltonii have been evaluated in rats (Naveen and Khanum 2010; Harish and Shivanandappa 2010). The highly aromatic roots have been subjected to overexploitation by destructive harvesting that affects the survival of this plant in its wild habitat (see Giridhar et al. 2005). Extended flowering pattern, self-incompatibility, pollinator limitation, absence of seed dormancy, abortion of a considerable percentage of seedlings prior to establishment are contributing factors for the regulation of its population size (Raju 2010). Moreover, the absence of any organized cultivation of this plant calls for immediate conservation measures (Reddy et al. 2002). However, during the past years, considerable efforts have been made for micropropagation of this endangered plant species through direct (Anitha and Pullaiah 2002; Giridhar et al. 2003, 2005) or indirect organogenesis (George et al. 2000) and somatic embryogenesis (Giridhar et al. 2004). So far, there is no report on synthetic seed production and their conversion into plantlets, using either somatic embryos or non-embryogenic vegetative propagules in D. hamiltonii. Encapsulation technology could provide a simpler and more efficient tool for short-term germplasm conservation and distribution of this valuable medicinal climber.

This study aimed to optimize (1) the concentration of Na-alginate and CaCl2·2H2O for ideal bead formation in respect to shape, rigidity and transparency; (2) suitable culture medium for shoot re-growth from Ca-alginate beads; (3) suitable NAA concentration for in vitro root induction of microshoots; (4) possible duration of short-term storage of encapsulated nodal segments (with MS nutrient and DDW gel matrix) and compared it with non-encapsulated nodal segments.

Materials and methods

Plant materials and culture conditions

The seeds of D. hamiltonii were collected from Central Food Technological Research Institute (CFTRI), Mysore (Karnataka). They were washed under running tap water for 30 min to remove any adherent particles. The seeds were kept in 1 % (w/v) Bavistin (Carbendazim Powder, BASF India Ltd.), a broad spectrum fungicide, for 20 min and then washed in 5 % (v/v) Teepol (Qualigens, India), a liquid detergent for 15 min. The treated seeds were agitated in sterilized double distilled water (DDW) to remove the chemicals for 10 min. The seeds were surface sterilized with 70 % (v/v) ethanol and 2–3 drops (v/v) of Tween-20 (Qualigens) for 30 s followed by immersion in an aqueous solution of 0.1 % (w/v) HgCl2 (Qualigens) for 3 min under aseptic conditions. Then seeds were washed 5–6 times with sterilized DDW to remove all the traces of sterilants. The surface sterilized seeds were inoculated (two seeds per culture tube) aseptically in the culture tubes (25 × 150 mm, Borosil, India) containing 20 ml of MS medium (Murashige and Skoog 1962) supplemented with 2.5 μM gibberellic acid (GA3). All the culture media used throughout the experiment were gelled with 0.8 % (w/v) bacteriological grade agar (Qualigens) and pH was adjusted to 5.8 before being autoclaved at 1.06 kg cm−2 (121 °C) for 15 min. The cultures were maintained in a culture room at 25 ± 2 °C under a 16-h photoperiod with 50 μmol m−2 s−1 photosynthetic photon flux density (PPFD), provided by cool white fluorescent tubes (40 W, Philips, India) with 55 ± 5 % of relative humidity. Nodal segments (2–3 from the terminal bud, approximately 3–4 mm in size) were excised aseptically from 3 week-old in vitro raised seedlings and used as explant for encapsulation.

Encapsulation

Different concentrations of Na-alginate (Central Drug House, India) viz., 1, 2, 3, 4 and 5 % (w/v) were prepared using either liquid MS medium or DDW, both supplemented with 3 % sucrose. For complexation 25, 50, 75, 100 and 200 mM CaCl2·2H2O (Qualigens) solutions were prepared in liquid MS medium. Both, the gel matrix and complexing agent were sterilized by autoclaving at 1.06 kg cm−2 (121 °C) for 15 min after adjusting the pH to 5.8.

Droplets of Na-alginate, each containing one nodal segment, were then collected using a sterile glass pipette (10 mm diameter) and dropped immediately into autoclaves CaCl2·2H2O solution for 20–25 min for polymerization and formation of capsules. Ca-alginate beads or capsules were then collected, rinsed with sterile liquid MS medium for 10 min and transferred to sterilized filter paper placed in Petri-dishes for 5 min under the laminar airflow hood to absorb the excess of MS medium.

Shoot re-growth from capsules

For shoot re-growth, capsules were cultured in 100 ml wide mouth flask (Borosil) containing 20 ml of semi-solid MS nutrient medium supplemented with or without various concentrations and combinations of different plant growth regulators (PGRs) viz., 5.0 μM 6-benzyladenine (BA), 0.5 μM α-naphthalene acetic acid (NAA), 0.5 μM indole-3-acetic acid (IAA) and growth additive viz., 30 μM adenine-sulphate (ADS). All the PGRs were purchased from Duchefa, the Netherlands. The flasks, each containing six capsules (six replicates) were placed in a well maintained culture room as mentioned above in “Plant materials and culture conditions”, for 6 weeks to determine the percentage with shoot re-growth. Four flasks per treatment were maintained in culture room, thus there were 24 replicates per treatment (6 × 1 × 4 = 24). A separate experiment was performed for in vitro root induction in the microshoots recovered from capsules. The regenerated microshoots (3.0–4.0 cm) with fully expanded leaves were removed from the capsule gel matrix and re-cultured in semi-solid half-strength MS medium supplemented with various concentrations of NAA (1.0, 2.5 and 5.0 μM).

Low temperature storage

This experiment compared the shoot re-growth ability of encapsulated (having gel matrix of either MS or DDW) and non-encapsulated nodal segments after short-term storage. After encapsulation, capsules were transferred to sterilized 100 ml beakers moistened with 2 ml of sterile DDW and tightly sealed with two layers of Para Film to prevent desiccation and stored in a laboratory refrigerator at 4 °C for 0, 1, 2, 4, 6 and 8 weeks. After each storage period, encapsulated and non-encapsulated nodal segments were placed on to semi-solid MS medium supplemented with 5.0 μM BA, 0.5 μM IAA and 30.0 μM ADS and maintained for 6 weeks in culture room conditions as mentioned above. Thereafter, recovered microshoots were transferred to rooting medium for 4 weeks, as described above.

Acclimatization

Complete plantlets (with well-developed shoot and roots) were removed from the rooting medium (before and after storage followed by root induction) and after gentle washing of the roots under running tap water, to remove the adhering medium, the plantlets were immersed in 1 % (w/v) Bavistin for half an hour, then transferred to thermocol cups (expanded polystyrene) containing autoclaved Soilrite™ (75 % Irish peat moss and 25 % horticulture grade expanded perlite) (Keltech Energies Ltd., India). The substratum was irrigated with tap water as per requirement. The plantlets were covered with transparent polythene membrane to ensure high humidity (90 %) for initial 2 weeks and then opened gradually in order to acclimatize plantlets to field conditions. After 4 weeks, successfully acclimatized plantlets were transferred to pots filled with normal garden soil and green manure (2:1). The potted plantlets were initially maintained inside the culture room conditions (4 weeks) and then transferred to greenhouse (4 weeks). Afterwards, the plantlets were transferred to field under full sun for further growth and development.

Statistical analysis

The frequency of shoot re-growth was calculated as the percent of encapsulated nodal segments showing well developed shoots of total number of nodal segments encapsulated. For each experiment 24 replicates were used and each experiment was repeated thrice. The data were analyzed by one-way ANOVA using SPSS version 16 (SPSS Inc., Chicago, IL, USA). The significance of differences among means was analyzed using Tukey’s test at 5 % level of significance and data represented as mean ± standard error (SE).

Results and discussion

Encapsulation

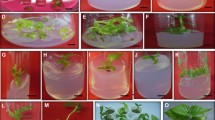

In the present study, only juvenile nodal segments, excised from aseptic seedlings were used for encapsulation (Fig. 1a). The morphology of Ca-alginate beads with respect to shape, texture, transparency and rigidity varied with different concentrations of Na-alginate and CaCl2·2H2O (Tables 1, 2). A 4 % Na-alginate with 100 mM CaCl2·2H2O was found to be the best combination for hydrogel complexion which produced firm, clear and isodiametric beads or capsules (Fig. 1b). Lower concentrations of Na-alginate (1, 2 and 3 %) and CaCl2·2H2O (25, 50 and 75 mM) were not suitable because beads were fragile and difficult to handle during transfer to re-growth media. The reduction in the gelling ability of lower concentrations of Na-alginate after exposure to high temperature during autoclaving has already been reported by Larkin et al. (1998). On the contrary, higher concentrations of both the encapsulating chemicals resulted in too hard beads and showed considerable delay in sprouting. This corroborates with the findings of Kavyashree et al. (2006), Swamy et al. (2009), Sundararaj et al. (2010) who reported 4 % Na-alginate as a critical concentration for bead formation in Morus alba, Pogostemon cablin and Zingiber officinale respectively. However, in most of the reports 3 % sodium alginate with 100 mM calcium chloride was proved as the best combination for an ideal bead formation (Ahmad and Anis 2010; Tabassum et al. 2010; Ozudogru et al. 2011; Mishra et al. 2011; Hung and Trueman 2011, 2012a, b). This variation in Na-alginate concentration for alginate bead formation in different plant species might be due to the variation in commercial source from which the chemicals were purchased as reported earlier by Mandal et al. (2000) in Ocimum species and Sharma et al. (2009b) in Spilanthes acmella.

Calcium-alginate bead formation and their sprouting. a Aseptic seedlings of D. hamiltonii. b Encapsulated nodal segments placed on MS basal medium, 2 day-old culture. c, d Axillary bud sprouting on MS medium supplemented with 5.0 μM BA, 0.5 μM IAA and 30.0 μM ADS, 2 and 4 week-old cultures. e Root induction in capsule derived microshoot on half-strength MS medium supplemented with 2.5 μM NAA, 4 week-old culture. f An acclimatized plantlet of D. hamiltonii in Soilrite™

Shoot re-growth from capsules

Ca-alginate beads or capsules obtained with 4 % Na-alginate and 100 mM CaCl2·2H2O showed only 68.60 ± 1.86 % sprouting (shoot re-growth) when placed on PGR-free MS basal medium (control) for 6 weeks. Thus, to further enhance sprouting frequency of capsules, PGRs (cytokinin and auxin) and growth additive were added to the MS basal medium (Table 3). On PGR supplemented medium sprouting of capsule was possible within 2 weeks of incubation. Maximum re-growth (77.00 ± 2.09 %) was noticed on MS medium supplemented with 5.0 μM BA, 0.5 μM IAA and 30.0 μM ADS after 6 weeks of culture (Fig. 1c, d). Although capsules failed to induce rooting on re-growth media, therefore an additional experiment was required to induce rooting in microshoots. The best rooting was achieved on half-strength MS medium comprising 2.5 μM NAA where root primordia was visible after 1 week of transfer and a maximum of 4.60 ± 0.50 roots per microshoot with 5.26 ± 0.08 cm root length were induced in 90.20 ± 1.80 % of cultures after 4 weeks of transfer (Table 4; Fig. 1e). Similarly, shoots that developed from encapsulated buds of Morus australis, Morus cathyana and Morus nigra failed to root on any planting media tested. Rooting was induced from the regenerated shoots of M. australis and M. cathyana on half-strength MS medium containing 5.7 μM IAA, 4.9 μM indole-3-butyric acid (IBA) and 5.3 μM IPA (indole-3-propionic acid), while that of M. nigra required only 4.9 μM IBA (Pattnailk and Chand 2000). Gangopadhyay et al. (2005) devised a two step method to achieve maximum recovery of complete plantlets from Ca-alginate beads in Ananus comosus; firstly, shoots were retrieved from capsules and in the second step, microshoots were rooted in liquid medium (supplemented with IBA and Kn) supported with Luffa-sponge. Bekheet (2006) and Lata et al. (2009) achieved rooting in Allium sativum and Cannabis sativa on MS medium containing IAA and IBA respectively. In contrast, Swamy et al. (2009) reported rooting on PGR-free half-strength MS basal medium in microshoots retrieved from encapsulated nodal segments of P. cablin.

Low temperature storage

Encapsulation technology also acts as a tool of germplasm exchange between countries. For this purpose alginate bead storage is a critical factor which determines their successful sprouting (capsule) or conversion (synthetic seed) after transportation abroad. During cold storage, alginate beads require no transfer to fresh medium, thus reduces the cost of maintaining germplasm cultures (West et al. 2006). Therefore, appropriate storage conditions and definite storage period are prerequisites to maintain the viability of capsules or synthetic seeds during transportation that leads to successful commercialization of encapsulation technology.

In the present study, two types of encapsulated (one with MS gel matrix and other with DDW matrix) and non-encapsulated nodal segments were stored at low temperature (4 °C) to see the effect of storage on tissue viability (Table 5). Na-alginate combined with MS nutrients demonstrated significant superiority over DDW with respect to shoot re-growth. With an increase in storage time up to 4 weeks, sprouting frequency decreased gradually, thereafter a drastic loss in sprouting was noticed for capsules having encapsulation matrix of MS medium. Decline in sprouting frequency could be attributed to inhibition of tissue respiration by the alginate matrix or a loss of moisture due to partial desiccation during storage as reported earlier (Danso and Ford-Llyod 2003; Faisal and Anis 2007). After 4 weeks of storage 47.00 ± 1.54 % sprouting was noticed for capsules prepared with MS gel matrix. On the other hand, capsules prepared with DDW failed to store. These findings suggest that the MS nutrients are essential ingredients of Na-alginate matrix for plantlet conversion.

An average of 14.00 ± 1.37 % capsules prepared with MS nutrients remained viable even after 8 weeks of cold-dark storage while only 14.40 ± 1.69 % sprouting was noticed for non-encapsulated nodal segments just within 2 weeks of storage, thereafter none of the naked nodal segments survived. The observation with cold stored capsules of this endangered species is in accordance with the previous reports on other species (Tsvetkov et al. 2006; Faisal and Anis 2007; Ahmad and Anis 2010). However, the temperature requirement for optimum viability varies from plant to plant. Generally, 4 °C temperature is found to be most suitable for alginate bead storage (Faisal and Anis 2007; Sharma et al. 2009a, b; Tabassum et al. 2010; Ahmad and Anis 2010). Few investigations revealed the requirement of higher temperature (25 °C) rather than low temperature for amenable storage of alginate beads in certain tropical and sub-tropical crops. Sundararaj et al. (2010) observed 100 % re-growth ability for Z. officinale encapsulated microshoots incubated at 25 °C while no re-growth was observed for encapsulated microshoots stored at 4 °C in dark. Encapsulated microshoots of Cineraria maritima and Picrorhiza kurrooa could be stored for 6 and 3 months, respectively at 25 ± 2 °C (Srivastava et al. 2009; Mishra et al. 2011). While, Hung and Trueman (2012a, b) successfully stored encapsulated shoot tips of Corymbia torelliana × Corymbia citriodora and Khaya senegalensis up to 12 months storage under 14 °C and zero-irradiance.

Acclimatization

During acclimatization plantlets have to adapt to the new environment of greenhouse or field. The plantlets usually need some weeks of acclimatization in shade with the gradual lowering of air humidity (Pospíšilová et al. 1998). Fully developed D. hamiltonii plantlets with proper shoots and roots were removed from rooting media, transferred to thermocol cups containing sterile Soilrite™ and acclimatized by adopting the standard procedure (Fig. 1f). Acclimatized plants showed more than 80 % survival rate when transferred to field and grew well.

Conclusion

In conclusion, the present study developed a simple and preliminary experimentation for capsule formation, shoot re-growth and short-term storage of encapsulated nodal segments. Encapsulated nodal segments of D. hamiltonii resumed growth immediately upon transfer to culture medium. Preservation of encapsulated explants is also simpler than cryopreservation and less labor-intensive than conventional storage of non-encapsulated propagules under minimal growth conditions (Rai et al. 2009). In the present study, capsules of D. hamiltonii could be stored up to 8 weeks at low temperature (4 °C). Being small in size the capsules, therefore, provide an effective tool for storage and exchange of this endemic and endangered plant species, potentially overcoming many of the difficulties associated with long-distance transport of plant germplasm. However, in the present study rooting was not possible in a single step on re-growth media which calls for further refinement in the established protocol in such a way that rooting would be possible in a single step (on re-growth medium).

Abbreviations

- ADS:

-

Adenine-sulphate

- BA:

-

6-Benzyladenine

- IAA:

-

Indole-3-acetic acid

- GA3 :

-

Gibberellic acid

- MS:

-

Murashige and Skoog’s medium (1962)

- NAA:

-

α-Naphthalene acetic acid

References

Ahmad N, Anis M (2010) Direct plant regeneration from encapsulated nodal segments of Vitex negundo. Biol Plant 54:748–752

Aitken-Christie J, Kozai T, Smith MAL (1995) Glossary. In: Aitken-Christie J, Kozai T, Smith MAL (eds) Automation and environmental control in plant tissue culture. Kluwer, Dordrecht, pp 9–12

Anitha S, Pullaiah T (2002) In vitro propagation of Decalepis hamiltonii. J Trop Med Plants 3:227–232

Anonymous (2003) The wealth of India: a dictionary of indian raw materials and industrial products, vol 3. CSIR, New Delhi, p 24

Bekheet SA (2006) A synthetic seed method through encapsulation of in vitro proliferated bulblets of garlic (Allium sativum L.). Arab J Biotech 9:415–426

Chand S, Singh AK (2004) Plant regeneration from encapsulated nodal segments of Dalbergia sissoo Roxb.—a timber yielding leguminous tree. J Plant Physiol 161:237–243

Danso KE, Ford-Llyod BV (2003) Encapsulation of nodal cuttings and shoot tips for storage and exchange of cassava germplasm. Plant Cell Rep 21:718–725

Faisal M, Anis M (2007) Regeneration of plants from alginate-encapsulated shoots of Tylophora indica (Burm. F.) Merrill., an endangered medicinal plant. J Hort Sci Biotech 82:351–354

Gangopadhyay G, Bandyopadhyay T, Ramit P, Gangopadhyay SB, Mukherjee KK (2005) Encapsulation of pineapple microshoots in alginate beads for temporary storage. Curr Sci 88:972–977

George J, Bais HP, Ravishankar GA (2000) Optimization of media constituents for shoot regeneration from leaf callus cultures of Decalepis hamiltonii Wight and Arn. HortSci 35:296–299

Germanà MA, Micheli M, Chiancone B, Macaluso L, Standardi A (2011) Organogenesis and encapsulation of in vitro-derived propagules of Carrizo citrange [Citrus sinesis (L.) Osb. × Poncirius trifoliata (L.) Raf.]. Plant Cell Tissue Organ Cult 106:299–307

Giridhar P, Vijaya Ramu D, Reddy BO, Rajasekharan T, Ravishankar GA (2003) Influence of phenylacetic acid on clonal propagation of Decalepis hamiltonii Wight and Arn; an endangered shrub. In Vitro Cell Dev Biol Plant 39:463–467

Giridhar P, Kumar V, Ravishankar GA (2004) Somatic embryogenesis, organogenesis and regeneration from leaf callus culture of Decalepis hamiltonii Wight and Arn., an endangered shrub. In Vitro Cell Dev Biol Plant 40:567–571

Giridhar P, Gururaj HB, Ravishankar GA (2005) In vitro shoot multiplication through shoot tip cultures of Decalepis hamiltonii Wight and Arn, a threatened plant endemic to southern India. In Vitro Cell Dev Biol Plant 41:77–80

Harish R, Shivanandappa T (2010) Hepatoprotective potential of Decalepis hamiltonii (Wight and Arn) against carbon tetrachloride-induced hepatic damage in rats. J Pharm Bioallied Sci 2:341–345

Hung CD, Trueman SJ (2011) Encapsulation technology for short-term preservation and germplasm distribution of the African mahogany Khaya senegalensis. Plant Cell Tissue Organ Cult 107:397–405

Hung CD, Trueman SJ (2012a) Alginate encapsulation of shoot tips and nodal segments for short-term storage and distribution of the eucalypt Corymbia torelliana × Corymbia citriodora. Acta Physiol Plant 34:117–128

Hung CD, Trueman SJ (2012b) Preservation of encapsulated shoot tips and nodes of the tropical hardwoods Corymbia torelliana × Corymbia citriodora and Khaya senegalensis. Plant Cell Tiss Organ Cult 109:341–352

Jacob KC (1937) An unrecorded economic product Decalepis hamiltonii W. and Arn., family Asclepidaceae. Madras Agric J 25:176

Kavyashree R, Gayatri MC, Revanasiddaiah HM (2006) Propagation of mulberry variety-S54 by synseeds of axillary bud. Plant Cell Tissue Organ Cult 84:245–249

Larkin PJ, Davies PA, Tanner GJ (1998) Nurse culture of low number of Medicago and Nicotiana protoplasts using calcium alginate beads. Plant Sci 58:203–210

Lata H, Chandra S, Khan IA, Elsohly MA (2009) Propagation through alginate encapsulation of axillary buds of Cannabis sativa L.—an important medicinal plant. Physiol Mol Biol Plants 15:79–86

Mallón R, Barros P, Luzardo A, González ML (2007) Encapsulation of moss buds: an efficient method for the in vitro conservation and regeneration of the endangered moss Splachnum ampullaceum. Plant Cell Tissue Organ Cult 88:41–49

Mandal J, Pattnaik S, Chand PK (2000) Alginate encapsulation of axillary buds of Ocimum americanum L. (Hoary Basil), O. basilicum (Sweet Basil), O. gratissium (Shrubby Basil) and O. sanctum (Sacred Basil). In Vitro Cell Dev Biol Plant 36:287–292

Mishra J, Singh M, Palni LMS, Nandi SK (2011) Assessment of genetic fidelity of encapsulated microshoots of Picrorhiza kurrooa. Plant Cell Tissue Organ Cult 104:181–186

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiol Plant 15:473–494

Murti PB, Seshadri TR (1941) A study of the chemical components of the roots of Decalepis hamiltonii (Makali veru), Part IV- Resinol of Decalepis hamiltonii and Hemidesmus indicus. Proc Ind Acad Sci 14:93–99

Naveen S, Khanum F (2010) Antidiabetic, antiatherosclerotic and hepatoprotective properties of Decalepis hamiltonii in streptozotocin-induced diabetic rats. J Food Biochem 34:1231–1248

Ozudogru EA, Krdok E, Kaya E, Capuna M, Carlo AD, Engelmann F (2011) Medium-term conservation of redwood [Sequoia sempervirens (D. Don) Endl.] in vitro shoot cultures and encapsulated buds. Sci Hort 127:431–435

Pattnaik S, Chand PK (2000) Morphogenic response of the alginate-encapsulated axillary buds from in vitro shoot cultures of six mulberries. Plant Cell Tissue Organ Cult 60:177–185

Pond S, Cameron S (2003) Tissue culture: artificial seeds. In: Thomas B, Murphy DJ, Murray BG (eds) Encyclopedia of applied plant sciences. Elsevier Academic Press, Amsterdam Boston, pp 1379–1388

Pospíšilová J, Wilhelmová N, Synková H, Čatský J, Krebs D, Tichá I, Hanáčková B, Snopek J (1998) Acclimation of tobacco plantlets to ex vitro conditions as affected by application of abscisic acid. J Exp Bot 49:863–869

Rai MK, Asthana P, Singh SK, Jaiswal VS, Jaiswal U (2009) The encapsulation technology in fruit plants-a review. Biotech Adv 27:671–679

Raju AJS (2010) Pollination biology of Decalepis hamiltonii and Shorea tumbuggai, Lambert Academic Publishing, Germany, p 64

Reddy OB, Giridhar P, Ravishankar GA (2002) The effect of triacontanol on micropropagation of Capsicum frutescens and Decalepis hamiltonii W and A. Plant Cell Tissue Organ Cult 71:253–258

Rihan HZ, Al-Issawi M, Burchett S, Fuller MP (2011) Encapsulation of cauliflower (Brassica oleracea var botrytis) microshoots as artificial seeds and their conversion and growth in commercial substrates. Plant Cell Tiss Organ Cult 107:243–250

Sharma S, Shahzad A, Jan N, Sahai A (2009a) In vitro studies on shoot regeneration through various explants and alginate-encapsulated nodal segments of Spilanthes mauritiana DC., an endangered medicinal herb. Int J Plant Dev Biol 3:62–64

Sharma S, Shahzad A, Sahai A (2009b) Artificial seeds for propagation and preservation of Spilanthes acmella (L.) Murr., a threatened pesticidal plant species. Int J Plant Dev Biol 3:56–61

Srivastava V, Khan SA, Banerjee S (2009) An evaluation of genetic fidelity of encapsulated microshoots of the medicinal plant: Cineraria maritima following 6 months of storage. Plant Cell Tissue Organ Cult 99:193–198

Standardi A, Piccioni E (1998) Recent perspectives of synthetic seed technology using non-embryogenic in vitro-derived explants. Int J Plant Sci 159:968–978

Sundararaj SG, Agrawal A, Tyagi RK (2010) Encapsulation for in vitro short-term storage and exchange of ginger (Zingiber officinale Rosc.) germplasm. Sci Hortic 125:761–766

Swamy MK, Balasubramanya S, Anuradha M (2009) Germplasm conservation of patchouli (Pogostemon cablin Benth.) by encapsulation of in vitro derived nodal segments. Int J Bio Con 1:224–230

Tabassum B, Nasir IA, Farooq AM, Rehman Z, Latif Z, Husnain T (2010) Viability assessment of in vitro produced synthetic seeds of cucumber. Afr J Biotech 9:7026–7032

Tsvetkov I, Jouve L, Hausman JF (2006) Effect of alginate matrix composition on re-growth of in vitro-derived encapsulated apical microcuttings of hybrid aspen. Biol Plant 50:722–724

West TP, Ravindra MB, Preece JP (2006) Encapsulation, cold storage and growth of Hibiscus moscheutos nodal segments. Plant Cell Tissue Organ Cult 87:223–231

Acknowledgments

Anwar Shahzad gratefully acknowledges the financial support provided by the Council of Science and Technology, Uttar Pradesh (Project No. CST/D3836), UGC (Project No. 39-369/2010) and DST-FIST Programme 2005 (Project No. SR/FST/LSI-085/2005). Shiwali Sharma is thankful to UGC, for the award of BSR Fellowship in Science (1st April 2010) for providing research assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, S., Shahzad, A. Encapsulation technology for short-term storage and conservation of a woody climber, Decalepis hamiltonii Wight and Arn.. Plant Cell Tiss Organ Cult 111, 191–198 (2012). https://doi.org/10.1007/s11240-012-0183-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-012-0183-0