Abstract

With the continuous acceleration of urbanization, traffic congestion, traffic accidents, and urban environmental problems are becoming increasingly serious, which negatively impacts the lives of city residents. With today's urbanization trend, traffic management is a pressing issue, and the safety and smoothness of highways profoundly affect a city's economy and quality of life. As a result, the intelligent inspection robot has entered the public view. It has the advantages of stability and efficiency, can continue to work in a high-intensity state, and helps reduce a lot of human workloads. Firstly, an intelligent transport monitoring system based on the Internet of Things (IoT) is proposed. This system integrates deep learning and artificial intelligence technology, which can quickly query traffic parameters, environmental parameters, and violations that may cause traffic accidents. Secondly, an intelligent inspection robot is introduced to monitor road traffic flow and violation records in real-time, which provides technical support for further scientific management of road traffic. Finally, the intelligent monitoring system's sensitivity and improvement measures are analyzed using the Simultaneous Localization and Mapping (SLAM) algorithm results, making intelligent traffic monitoring more popular. A section of closed safety road is selected for the inspection robot test. The results reveal that (1) the urban transportation model based on the IoT can meet the architecture of intelligent urban transportation. (2) Considering the performance of the inspection robot, the SLAM algorithm is more suitable for road intelligent traffic monitoring. (3) When the number of particles in the improved SLAM algorithm is small, the accuracy and real-time performance of the algorithm can also be guaranteed. The calculation efficiency is improved to 80%, and the modeling accuracy is improved by 23.3%. Traditional traffic monitoring methods typically rely on static sensors and limited data sources. However, the proposed system leverages IoT technology's and inspection robots' real-time data collection capabilities, achieving a more comprehensive, accurate, and flexible acquisition of traffic data. Through this exploration, the overall ideas and objectives of the construction of intelligent highways are clarified, which will lay a solid foundation for the follow-up construction of intelligent highways and provide comprehensive design and practical ideas. The improved SLAM algorithm can more stably complete the positioning and mapping of the tunnel inspection robot in the road environment. In the SLAM algorithm, an Extended Kalman Filter is introduced to ensure the accuracy and real-time of the improved algorithm, which can be applied to the modeling and positioning of unknown environments. Consequently, using the SLAM algorithm in the road detection robot system can stably realize environment awareness and autonomous path planning.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

1.1 Research background and motivations

With the deepening of urbanization, the urban population and vehicles have increased sharply, which causes road congestion, poor traffic, and even frequent traffic accidents. Expressway is an indispensable part of highway transportation, and its construction and development also mark a country's transportation development level and even the overall economic development level [1]. Due to the rapid progress of information and intelligence, the intelligent highway has become an inevitable product of the development of science and technology. Intelligent highway refers to integrating information technology, sensor technology, network technology, automatic control technology, computer processing technology, and artificial intelligence (AI) based on perfect transportation infrastructure to form a road transportation mode with the characteristics of smart informatization and scientific and technological socialization [2]. Intelligent transport event management can reduce the duration of events, shorten the delay caused by events, and reduce the degree of accidental traffic congestion to avoid the occurrence of secondary events effectively. By releasing real-time traffic information, it brings convenience to travelers and avoids unnecessary trouble and consumption [3]. Therefore, studying the intelligent transport monitoring system based on the Internet of Things (IoT) and the new technologies, ideas, and methods of emergency management under new situations can improve the intelligent level of highway traffic management, promote emergency rescue work of road traffic to a new level, and produce significant economic and social benefits [4].

Deep learning (DL) has significantly improved structural damage detection and assessment, road traffic safety monitoring, and other areas of traffic management. It has become one of the crucial research topics for achieving intelligence in future road engineering. In machine learning (ML), the approach of simulating neural networks to learn complex abstract problems is known as neural networks. Neural networks have achieved tremendous success in computer vision and natural language processing, surpassing human-level intelligence on multiple metrics. Deep neural networks are called DL, essentially the same as the principles of neural networks. With the introduction of DL concepts and the rapid development of AI on mobile devices, DL has brought profound changes to research fields in multiple disciplines.

IoT and inspection robots have collaborated closely in designing intelligent transport monitoring systems on highways. IoT technology collects traffic data in real-time through various sensors and transmits it to a central monitoring system. Inspection robots can patrol the road and collect relevant data, which can be integrated and analyzed for real-time monitoring, predicting traffic conditions, and quickly responding to emergencies. This synergistic effect improves roads' safety, smoothness, and sustainability, providing innovative solutions for urban traffic management and planning [5,6,7].

1.2 Research objectives

Through the survey and research, the research objectives can be summarized as follows:

(1) In-depth understanding of intelligent transport monitoring system design in the IoT environment: This exploration aims to delve into the principles and methods of designing intelligent transport monitoring systems grounded on the IoT environment. This includes integrating existing road monitoring systems for improvements and optimizations to meet real-time data requirements better. (2) Establishment of wireless sensor networks (WSNs) for real-time data transmission: One of the research objectives is to establish efficient WSNs to achieve real-time traffic data transmission. This can ensure timely access to information such as road conditions and traffic flow, facilitating immediate responses in traffic management. (3) Establishment of a wide-area network based on mobile communication platforms for remote data interaction: This exploration is to establish a reliable mobile communication platform to construct a wide-area network that supports remote data interaction. This helps to timely and safely investigate road faults and remote monitoring, thus enhancing road safety. (4) Real-time broadcasting of traffic information and traffic environment: One of the research objectives is to realize real-time broadcasting of traffic information and the traffic environment. This can offer timely traffic information to drivers and relevant authorities, contributing to improved traffic efficiency and safety. (5) Research and application of inspection robots: The study and application of inspection robots are emphasized to ensure 360-degree comprehensive monitoring coverage of roads. Inspection robots can also assist in equipment maintenance and gather multidimensional evidence, reducing the workload and intensity of manual inspections. (6) Clarification of the overall concept and goals of intelligent highways: The ultimate goal is to clarify the overall concept and goals of intelligent highway construction, laying the foundation for future intelligent road projects and providing a holistic design and implementation approach. This can contribute to developing an Intelligent Traffic System (ITS) to improve traffic management efficiency and intelligence.

1.3 Research innovation points

The innovation points encompass both theoretical and practical dimensions. Theoretical Innovation: This exploration introduces an entirely new theoretical framework for designing intelligent highway transport monitoring systems, combining IoT technology with the application of inspection robots. Real-time data collection and traffic monitoring are achieved by deploying smart sensor nodes and highway inspection robots. This theoretical innovation seamlessly integrates traditional traffic monitoring methods with IoT technology, offering a more efficient, precise, and sustainable solution for intelligent transport management. Practical Innovation: On the practical front, this exploration innovatively designs a brilliant highway transport monitoring system and tests its application in natural highway environments. It enables real-time collection and analysis of multidimensional data, such as traffic flow, vehicle speed, and accident detection through IoT technology. The introduction of inspection robots adds flexibility and coverage to the monitoring process. This practical innovation validates the feasibility of the theoretical framework and provides a compelling example for the design and deployment of real-world traffic monitoring systems. It offers valuable practical experience for the development of future ITS.

In summary, the research innovation integrates IoT technology and inspection robots, creating a novel intelligent highway transport monitoring system. It demonstrates forward-thinking on a theoretical level and achieves remarkable results in practical applications, offering valuable insights for the future development of ITS.

1.4 Research contributions

This exploration proposes and implements a novel intelligent transport monitoring system that leverages the dual advantages of IoT technology and inspection robots. By deploying smart sensor nodes and highway inspection robots, the system can collect real-time multidimensional traffic data, encompassing vehicle flow, speed, accident detection, and more. The design of this system addresses the limitations of traditional traffic monitoring methods and provides more efficient, accurate, and comprehensive traffic data, offering robust support for traffic management and safety. Furthermore, the research outcomes have been validated and tested in real-world applications. Through deployment and operation in actual highway environments, the research team successfully demonstrates the feasibility and effectiveness of this system. This provides reliable experience for the practical application of intelligent transport monitoring systems and is a valuable reference for research and applications in similar fields.

This exploration promotes integrating IoT technology with traffic management and paves the way for future smart city and ITS development. By introducing IoT technology into transport monitoring, people can better understand and address traffic issues, enhancing road safety and efficiency. This exploration is vital to building more intelligent and sustainable urban traffic systems.

2 Literature review

With the swift progress of modern science and technology, ITS has become a key national construction project. At this stage, the development of intelligent transportation worldwide has been deeply explored. Njoku et al. determined the positioning of China's intelligent highway through comparison and conducted in-depth discussions on the overall construction and framework construction. Ultimately, with the G56 pilot road of Yunnan highway as an example, a highway transportation mode with Yunnan characteristics was formed combined with internet technology, computing and processing technology, sensor technology, and intelligent monitoring system [8]. Khan et al. pointed out that with the vigorous development of the smart city and intelligent transportation design and construction, intelligent highways, one of the vital application scenarios of intelligent transportation advanced technology, had been gradually designed, constructed, and operated in China [9]. Jabbar et al. believed combining intelligent transportation and the IoT could improve current lousy traffic problems. They proposed and designed the architecture of urban ITS based on the IoT, improved the ant colony optimal path algorithm, and verified its superiority [10].

The daily management and maintenance of highway tunnel inspections in China are mainly manual inspections. The overall inspection effect is imperfect, and it is easy to miss the inspection. At this stage, scholars pay more attention to the direction of machine inspection. Zhang et al. pointed out that establishing an intelligent inspection robot’s maintenance automatic detection system in the highway tunnel could increase inspection efficiency, enrich the functions, and strengthen detection coverage. It could also improve the quality and efficiency of the tunnel inspection work as a whole [11]. Zhang et al. took the autonomous mobile platform of a tunnel inspection robot as the research object. Given the problems existing in the tunnel inspection industry, an autonomous mobile platform for the tunnel inspection robot based on laser Simultaneous Localization and Mapping (SLAM) was designed, successfully realizing autonomous perception and autonomous path planning in the tunnel environment [12]. To keep the inspection system in a continuous and high-intensity working state without being disturbed by common external factors, Jia et al. designed a kind of inspection robot based on machine vision, mainly used to help substation staff complete patrol inspections. The robot has two modes, automatic patrol and manual control patrol at the preset station, to help staff complete patrol tasks and save the workforce [13].

To sum up, the construction of intelligent highways in China starts late, develops rapidly, and is currently at the advanced international level. However, there are still some problems. First, at this stage, the system realization of intelligent highway and road detection robots is not perfect regarding environmental awareness. It often occurs that the grasp of environmental conditions is not accurate enough, which leads to the failure to complete the target or damage to itself. Next, the current system implementation effect for robot automation is also not ideal. Some machine systems cannot carry out correct autonomous path planning, or path planning errors may lead to various failures. The ontology proposes to use the SLAM algorithm to optimize the inspection robot to solve these problems. This algorithm can more stably complete the localization and mapping of tunnel inspection robots in the road environment. This exploration also introduces the Extended Kalman Filter (EKF) into the SLAM algorithm to ensure the accuracy and real-time of the improved algorithm. It can be applied to the modeling and positioning of unknown environments to solve the objectives of accurate environmental awareness and autonomous path planning.

3 Research model

3.1 IoT-based intelligent traffic system model

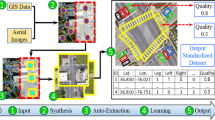

With the rapid progress and in-depth application of IoT technology in modern science and technology, the combination of ITS and IoT technology is increasingly close. The introduction of IoT technology makes ITS functions more perfect and provides more comfortable and convenient travel services [14]. This section implements a service model of ITS based on IoT by analyzing the needs of different travelers in all aspects and the various functions of ITS, combined with the construction of a traffic control and decision support platform. It aims to improve the utilization of transportation facilities with the support of IoT technology. Figure 1 shows the services and functions provided by the ITS control center [15].

At the application level, the real-time collection of traffic information data and the release of information analysis are the core content of the construction. Analyzing road conditions and traffic flow can predict when and where traffic congestion will occur and timely release it to travelers who need information services. In application services, cargo transportation tracking can be realized according to vehicle positioning, and real-time services such as transportation safety services and traffic fault handling can be provided simultaneously. In the construction and maintenance management, the real-time monitoring of traffic facilities is realized, and the static facilities and environmental information involved are regularly collected and processed. Operation control is an essential part of ITS, which is the feedback and control of information to realize the overall control of traffic and route planning [16].

According to IoT’s architecture and functional requirements, a hierarchical model of ITS based on IoT is proposed. It hierarchizes ITS and realizes the analysis and description of the functions and properties of the model. The specific hierarchical model architecture is illustrated in Fig. 2 [17].

In the perception layer, IoT-based intelligent transportation applications are based on vehicles, personnel, environment, and other related infrastructure. The collection of road information is completed through beacons and road sign sensors. More emphasis is placed on sharing and utilizing data in the network layer. The transmission of traffic information in the network layer is completed through satellites, computer networks, wireless mobile communication, and other related technologies. In the application layer, services such as adjusting signal lights according to traffic flow, providing real-time inquiry of traffic information, and corresponding traffic management and control according to different service areas can be realized.

The IoT-based ITS is a network system that realizes traffic information collection, transmission, control, and application. With the continuous advance of IoT technology, the service level of ITS will continue to expand to better serve travelers. The IoT-based ITS module [18] mainly includes the following aspects, as presented in Fig. 3.

According to the decisions made after information collection, transmission, processing, and analysis, it can offer various information security services for traffic travel, fully utilize the collected information, timely release the corresponding traffic congestion situation, dredge the best route information, and provide a reference for travelers. The traffic lights' length should be controlled reasonably according to the main roads' traffic flow information to reduce traffic congestion. It can timely release road condition information for vehicle faults and notify the accident handling agency [19].

3.2 AI inspectin robot

AI is a new technological science that involves studying, developing, and applying theories, methods, techniques, and systems for simulating, extending, and expanding human intelligence. It is a branch of computer science that aims to understand the essence of intelligence and produce intelligent machines capable of reacting in ways similar to human intelligence. Research in this field includes robotics, speech recognition, image recognition, natural language processing, and expert systems. DL is a continuous transformation and deepening process of cognitive and thinking structures, with the transfer being a core feature of DL. Empowering DL with AI can stimulate research interests and motivation, promote compatibility between old and new technologies, facilitate cross-domain technology restructuring and scenario reconstruction, and promote internal correlation transfer and external expansion transfer in DL. It can boost the continuous transformation of scholars' cognitive structures and greatly enhance the efficiency and effectiveness of work and research.

With the rapid progress of AI technology in recent years, the application of robots has become increasingly widespread. Intelligent inspection robots can replace manual inspections and react to the highway environment, hazards, and safety warnings. Alongside this, the DL-based computer vision technologies have also emerged. Neural networks can be reliably used for feature extraction from scene images, thereby assisting inspection robots in making decisions regarding motion instructions. Image information can more comprehensively reflect the surrounding obstacles compared to point cloud data from laser sensors in several aspects. Using DL for decision-making on motion instructions based on image data has been extensively studied and explored in practical applications such as industrial and agricultural drones and unmanned submersibles.

The use of inspection robots to replace workers in complex and hazardous highway tunnel environments is proposed. The inspection robot can conduct long-term, real-time, and continuous inspections and monitoring of the working status of tunnel equipment, vehicle movements, and road conditions. Then, it can promptly detect various anomalies within the tunnel, thus becoming an efficient automated inspection method for tunnels. Through corresponding maintenance, repair, and management measures, tunnel safety hazards can be quickly eliminated, reducing the occurrence of accidents and minimizing loss of life and property. Moreover, when unforeseen situations occur inside the tunnel, the inspection robot can respond promptly to accidents, reducing the losses caused by accidents.

The inspection robot system consists of the body, the local monitoring center's backend, and the remote control center's backend. The inspection robot is installed in the left and right tunnels of the highway tunnel, and the local monitoring center backend is deployed at the toll station that oversees the tunnel. It can remotely control the inspection robot in the tunnel. Workers can access the real-time inspection status of the robot and information about the robot's surroundings through the local monitoring center's backend. The local monitoring center backend can receive instructions from workers and issue inspection commands to the robot. Meanwhile, the remote control center backend is deployed at the regional operations center. The local monitoring center backends of various tunnels will upload inspection results and real-time monitoring image information to the remote control center backend. The remote control center backend can simultaneously control the operation of multiple robot units in numerous sections and tunnels, inspecting the internal conditions of various sections and tunnels. Figure 4 illustrates the architecture of the tunnel inspection robot system.

The software system of the inspection robot is mainly developed using the Ubuntu system. The system is a software platform for robot development that can support many standard operating system services, such as hardware abstraction. It can provide support for code reuse in robot research and development. Various functionalities need to be implemented on Ubuntu, including the following.

Environmental perception: information about the robot's surrounding environment, such as depth images, image data, and distance information, is collected through environmental perception sensors. AI detection: AI technology is utilized to detect abnormal events inside the tunnel, such as abnormal parking and pedestrian detection. Multi-sensor fusion module: multi-sensor fusion technology is adopted to compensate for the disadvantages of individual sensors, thereby improving the accuracy of environmental perception and tunnel environment awareness. Path planning module: based on received map information, fused localization, and selected destination points, the optimal path is planned, and control information is sent to the motion control module. Motion control module: the movement of the tunnel inspection robot is controlled employing the received control information. Backend monitoring systems are deployed at various toll station control centers. The backend monitoring system mainly consists of modules for human–computer interaction, inspection settings, remote control, and data processing and storage. The human–computer interaction module presents the robot's status, real-time conditions inside the tunnel, and historical data records through a user-friendly visual interface. Inspection settings: it is mainly responsible for controlling the regular inspection process, unique inspection task process, and inspection task resumption functions. Based on the requirements of daily highway tunnel inspections, target inspection points are set, automatic inspection tasks are designated, and instructions are issued to the inspection robot through the monitoring platform. Remote control: it controls the robot's body movement direction and speed, the PTZ camera capturing photographs and videos, related devices, and the navigation system. Data processing and storage: this module is responsible for further processing and analysis of image data from internal tunnel devices collected and transmitted by the inspection robot and temperature image data from temperature measurement devices.

3.3 Ackermann chassis kinematics model

Ackermann chassis is a non-holonomic dynamic constrained chassis. The path planning must consider the robot chassis's dynamic constraints, and the four-wheel forward rotation rear-drive mode is adopted. The steering control of the Ackermann chassis needs to consider the steering characteristics of the Ackermann chassis and adopt corresponding control strategies [20]. This section mainly discusses the linear two-degree-of-freedom model of the Ackermann chassis and the track deduction model based on the Ackermann chassis, deduces the steering control model of the Ackerman chassis, and uses the two-degree-of-freedom model to derive the posture of the Ackermann chassis in motion.

The sum of the resultant force of the external force on the Ackermann chassis along the y-axis direction and the moment around the center of mass is as follows.

FY1 and FY2 represent the lateral reaction force of the front wheel and rear wheel; a and b indicate the distance from the front axle and rear wheel to the center of mass; δ refers to the front wheel sideslip angle. The value of δ is minimal, cosδ≈1, and FY1 = k1α1 + k2α2, FY2 = k2α2. Then, the above equation can be expressed as:

α1 and α2 refer to the front and rear axle sideslip angle.

According to the principle of relative motion, there is the following equation:

u1 indicates the linear speed of the front axle midpoint. ζ refers to the angle between u1 and the axis; u and v represent the velocity component in the x-axis and y-axis directions; ωr means the angular velocity of the Ackermann chassis rotating around the z-axis. Since the sideslip angle of the center of mass β = v/u, there is:

According to the provisions of the coordinate system, the front and rear wheel sideslip angles of the Ackermann chassis are respectively written as:

Equations (3), (4), (7), and (8) are combined to derive the differential equation of motion of the two-degree-of-freedom model of the Ackermann chassis, which is given as follows:

IZ and \({\dot{\omega }}_{r}\) express the rotational inertia and angular acceleration of the Ackermann chassis rotating around the Z axis; m refers to the mass of the Ackermann chassis.

Hence, through the demonstration and analysis of the autonomous mobile chassis of the tunnel inspection robot, the model scheme of using the Ackermann chassis as the mobile chassis of the tunnel inspection robot is obtained.

3.4 Simultaneous Localization and mapping algorithm

The SLAM algorithm is for robot positioning, mapping, and path planning. It was initially used for robot positioning in the Robotics field. The earliest SLAM algorithm did not use the visual camera. Laser Range Finder is generally used for SLAM in the Robotics field.

SLAM, also known as Concurrent Mapping and Localization (CML), refers to real-time positioning and map building, or concurrent mapping and positioning. The problem can be described as putting a robot into an unknown position in an unfamiliar environment to see whether there is a way for the robot to gradually draw a complete map of the environment while deciding which direction the robot should go. For example, the sweeping robot is a typical SLAM problem. The so-called consistent map refers to moving to every corner of the room without obstacles. SLAM was first proposed by Smith, Self, and Cheeseman in 1988. Because of its essential theoretical and application value, it is considered by many scholars to be the key to realizing a genuinely autonomous mobile robot.

When people come to a strange environment, they should do the following: to quickly get familiar with the environment and complete their tasks (such as looking for restaurants and hotels). a. Observing the surrounding landmarks such as buildings, trees, and flower beds with their eyes, and remembering their features (feature extraction). b. Reconstructing the feature landmarks in a three-dimensional map according to the information obtained by their binoculars in their minds (three-dimensional reconstruction). c. When walking, they constantly acquire new feature landmarks and correct the map model in their mind. d. Their trajectories are determined based on the characteristic landmarks they obtain while walking along for some time. e. When they have walked a long way unintentionally, matching with the previous landmarks in their mind to see whether they have returned to the original loop-closure detection. This step is optional. The above five steps are performed simultaneously: simultaneous localization and mapping.

According to the research on the performance of the inspection robot, the SLAM algorithm has been improved for several rounds, taking the joint probability distribution p \(\left({x}_{1:t},\mathrm{m}|{z}_{1:t},{u}_{1:t}\right)\) of map m and the robot's moving trajectory x1:t. The reason is that SLAM obeys a Markov chain. The above probability distribution can be determined by the measured value \({u}_{1:t}\) of the odometer and the observed value \({z}_{1:t}\) of the laser [21]. The joint probability distribution is decomposed as follows:

The decomposition of the above equation makes it possible to obtain the trajectory estimation of the robot first, and then establish a map based on the robot trajectory and the laser observation data. Based on the SIR filter, the odometer and laser’s observation data are used to estimate the robot's pose and update the map. The specific steps are as follows:

-

1.

Initialization: When t = 0, particles are initialized. Each particle contains the current robot pose xt, weight wt, map m, trajectory tree node tree, and other information.

-

2.

Sampling: According to the previous generation particle set \(\left\{{x}_{t-1}^{i}\right\}\), the new species group \(\left\{{x}_{t}^{i}\right\}\) after adding Gaussian noise is calculated through the odometer motion sampling model.

-

3.

Weight estimation: Based on the laser data zt, map m, and particle pose xt, the likelihood field distance’s search model is utilized to search the optimal pose of particles and estimate the weight.

-

4.

Resampling: Resampling is conducted according to the weight of particles. High-quality particles may be sampled many times, and poor-quality particles may be deleted. The resampling evaluation criterion is that the reciprocal of the sum of squares of the normalized weights \(\widetilde{{w}_{i}}\) of all particles is less than a certain threshold \({N}_{\mathrm{res}}\).

$${\mathrm{N}}_{res}=1/{\sum }_{\mathrm{i}=1}^{\mathrm{N}}{(\widetilde{{\mathrm{w}}_{\mathrm{i}}})}^{2}$$(12) -

5.

Map update: one of the best examples has been selected.

According to its optimal trajectory tree x_(1:t) and the corresponding laser data \({z}_{1:t}\), the grid map is updated [22]. The built inspection robot is adopted to establish the odometer motion model. The robot experiences rotation \({\delta }_{rot1}\), translation δ_trans, and rotation δ_rot2 from time t-1 to time t. Gaussian noise exists in both rotation and translation [23]. The odometer motion model is plotted in Fig. 5:

The motion sampling algorithm is based on the probability distribution \(\mathrm{p}\left({x}_{t}|{x}_{t-1},{u}_{t}\right)\), as shown in Eq. (3). Among them, the control quantity \({u}_{t}={({x}_{t-1},{x}_{t})}^{T}\) is the pose estimation of two groups of robots fed back by an odometer. According to the previous generation particle set \(\left\{{x}_{t-1}^{i}\right\}\), the new species group \(\left\{{x}_{t}^{i}\right\}\) after the superposition of Gaussian noise can be calculated.

In the actual operation of the inspection robot, the tire often slips, resulting in an error in the motion model. Small errors can generally be corrected through the SIR filter. However, if it is too large, robot modeling will fail, especially for large map models [24]. Given the above problems, this exploration installs a compass on the robot chassis and uses the data of the Inertial Measurement Unit (IMU) and Compass to dynamically weigh and calculate a more accurate attitude angle through EKF [25]. IMU data are used as the state input \(\overline{{u }_{t}}\), and Compass data are used as the observation value \({z}_{t}\). The calculation process is drawn in Fig. 6:

\({K}_{t}\) represents Kalman gain; \(h(\overline{{u }_{t}})\) refers to the observation equation; \({\mu }_{t}\) means the corrected attitude angle.

The initialization of attitude angle is compass data. The sampling frequency of the gyroscope is up to 50 Hz, and that of the compass is 1 Hz. The state vector prediction of the algorithm is calculated by the angular velocity of the gyroscope every time. If the compass data are not obtained in this cycle, skipping the correction step and entering the next cycle is essential. At this time, the cumulative error of attitude angle will become larger and larger. When the compass data are acquired, the calculated Kalman gain corrects the attitude angle data, and the attitude angle's cumulative error is corrected simultaneously.

4 Experimental design and performance evaluation

4.1 Experimental materials

Inspection robots are typically equipped with various sensors, such as cameras, light detection and ranging, ultrasonic sensors, and more. These sensors gather environmental information, including maps, obstacles, road conditions, etc. Sensor data are collected at appropriate intervals to capture real-time information. Navigation data for the robot are recorded, covering its position, speed, direction, and so on. These data are crucial for analyzing the robot's movement trajectory and path planning. It is essential to guarantee the data are accurately timestamped for time-based correlations during analysis. The robot must ensure time synchronization between the data if it has multiple sensors.

An autonomous mobile platform of road inspection robots is established by constructing the inspection robot platform and designing the algorithm program. This section primarily tests the autonomous mobile platform of the road inspection robot. A section of the road is selected for robot inspection simulation. Staff is arranged to observe and record in the monitoring room and verify the feasibility of the platform software and hardware design. The test data before and after the algorithm improvement are analyzed to verify the improvement effect of the improved algorithm on the stability and driving smoothness of the inspection robot.

4.2 Experimental environment

The main section of a highway is used as a test site to verify the inspection robot's real-time accuracy after using the improved SLAM algorithm. The robot builds a map of the whole road section internally, with a travel speed of 1 m/s, 5 particles, a total length of about 1300 m, 10 Hz laser per second, and 600 laser points scanned each time. In the monitoring room, the monitoring personnel can control the inspection robot from the first perspective of the robot to carry out inspection work. Meanwhile, it has the functions of issuing instructions, presenting data, setting warnings, and assisting the staff in troubleshooting potential safety hazards, reflecting man–machine cooperation.

The central system of the intelligent inspection robot is the main control module. An industrial-grade embedded programmable controller, a control machine named Zhan mei fifth generation I7-5550U, is selected. The controller adopts Intel ATOM Z500 Series CPU (central processing unit) (32-bit), which is equipped with 4 GB (gigabyte) memory, 32 GB flash memory, two RJ45 interfaces, four USB (universal serial bus) 2.0 interfaces, and dual power input to meet the normal patrol operation ability. The data acquisition control board adopts a high-end STM (scanning tunnel microscope) 32F407 chip and CortexM4 core, and the main frequency can reach 160 MHz (megahertz). The new Ethernet interface is adopted for the overall data transmission. The voltage’s withstand voltage of component selection is three times the actual voltage requirements. Most resistors and capacitors are packaged in 0603 to ensure circuit stability and reasonably reduce space occupation. Inspection robot management configuration information is presented in Table 1.

4.3 Parameters setting

To validate the effectiveness of the proposed method, this exploration evaluates its performance in dynamic environments using the publicly available TUM RGB-D dataset. The TUM RGB-D dataset provides multiple frames of images in dynamic environments. To better simulate real-world scenarios, human subjects are primarily used as dynamic objects to observe how moving individuals can destroy the robustness and accuracy of the SLAM system. This is challenging. The designed method is analyzed through comparative experiments. Specifically, Table 2 lists some dataset category parameters used:

4.4 Performance evaluation

First, the SLAM algorithm is applied to compare the theoretical attitude angle of the robot, the attitude angle calculated by the gyroscope, and the numerical change of attitude angle obtained by EKF filtering of the gyroscope and compass. Figure 7 outlines the data.

To compare the two algorithms’ accuracy before and after optimization more intuitively, the position tracking errors of the robot in the x and y directions are defined, respectively, and the Euclidean distance error between the robot’s real and estimated positions is calculated. Figure 8 depicts the relationship between the robot's x direction, y direction, and distance error before optimizing the SLAM algorithm and its running time.

Through the analysis of Fig. 8, it can be found that the error value of the traditional robot algorithm in the x direction is about 0.06 m, and the maximum error value is about 0.06 m. The error value in the y direction is around 0.005 m, and the maximum error value, distance error, and maximum error are approximately -0.005 m, 0.06 m, and 0.06 m. Before optimization, the amplitude of error fluctuation in the X and Y directions reaches the maximum at 115 s and then fluctuates up and down after reaching a peak of fluctuation, which indicates that there is still a certain gap in the accuracy of tracking and positioning. Figure 9 shows the relationship between the robot's x direction, y direction, and distance error after optimization of the SLAM algorithm and its running time.

Figure 9 suggests that the error value of the improved SLAM algorithm in the x direction is approximately -0.03 m, and the maximum error value is about -0.04 m. The error value in the y direction is -0.03 m, and the maximum error value is about -0.04 m. The distance error and maximum error are around 0.04 m and 0.06 m. The comparison between the position error in x and y directions and the distance error of the robot before and after optimization shows that the positioning error of the improved SLAM algorithm is significantly smaller than that of the traditional robot algorithm, and the positioning error can be reduced to 20% of the original.

The data reveal that the robot attitude angle calculated by the gyroscope is more similar to that obtained by EKF filtering, and the value has been fluctuating around 0. It means that EKF filtering can eliminate the accumulated error of gyroscope data and improve the accuracy of the attitude angle. The data can verify that the improved SLAM algorithm has higher real-time performance and can be conducive to using fewer particles to establish a more accurate map.

Based on the statistical analysis of the obtained data, the position and pose variance data under different algorithms are exhibited in Table 3.

Data comparison signifies that the position and pose variance is greatly reduced after using EKF filtering correction, and the effect of machine modeling is good. Meanwhile, when the number of particles is small, the accuracy and real-time performance of the improved SLAM algorithm can also be guaranteed. The calculation efficiency is increased to 80%, and the modeling accuracy is increased by 23.3%. This illustrates that the SLAM algorithm can be effectively applied to the modeling and positioning of unknown environments. Various road environments are injected into the inspection robot system, so the robot can also give feedback when encountering complex environments.

The Python drawing tool is employed to draw the global path and the real-time collected robot position and posture. The global path and the following graph of the global path of the IoT-based inspection robot are obtained. The maximum linear and maximum angular accelerations before the optimization are 1.5 m/s2 and 1.8 m/s2, respectively, with frequent and violent changes in the process. Figure 10 displays the specific situation:

Figure 10 reveals that the unoptimized local path planning can drive the tunnel inspection robot to follow the global path to reach the target position and pose, and the overall speed is relatively stable. Nevertheless, the acceleration change is too frequent and violent, which will cause the tunnel inspection robot to stumble and impact the driving motor too much. Figure 11 portrays the test data after optimization based on IoT and SLAM algorithms.

Figure 11 suggests the optimized local path planning algorithm can follow the global path to reach the target point. It starts decelerating after reaching the target point, and the speed change is relatively stable. The acceleration variations in the whole process have been better improved than without optimization. The ride comfort of the inspection robot has been improved, and the impact on the drive motor has also been reduced.

4.5 Discussion

In the Design and Practice of Intelligent Highway, it is concluded that although the construction of the intelligent highway in China started late, it has developed rapidly and is now at the advanced international level. Expressway is the transportation field with the highest development degree and the most prominent economic proportion in the transportation industry. Its gradual trend toward informatization, intelligence, and socialization is the inevitable trend of scientific and technological development [26]. First, the development of intelligent highways worldwide has been combed and compared, the overall design of highways in China has been studied, and the future development of intelligent highways is prospected and expected. By analyzing the needs of different travelers in all aspects and the various functions of ITS, combined with the construction of a traffic control and decision support platform, a service model of ITS based on IoT is proposed to improve the utilization of transportation facilities with the support of IoT technology.

In the Research on An Autonomous Mobile Platform of the Intelligent Tunnel Inspection Robot Based on Laser Slam, the overall design requirements of the tunnel inspection robot are obtained through scenario analysis. The design scheme of each subsystem is demonstrated according to the general design requirements, and the tunnel inspection robot’s overall design scheme is obtained. Ultimately, according to the overall design scheme, the comprehensive software and hardware scheme design and hardware selection are carried out, and the hardware platform of the tunnel inspection robot is built. The results show that the improved SLAM algorithm can more stably complete the positioning and mapping of the tunnel inspection robot in the road environment [27]. EKF filter is introduced into the SLAM algorithm, and the accuracy and real-time performance of the improved algorithm are guaranteed, which can be applied to the modeling and positioning of an unknown environment. Therefore, applying the SLAM algorithm to the road inspection robot system can stably achieve environmental awareness and autonomous path planning.

The analysis results of the research data indicate that the robot attitude angle calculated by the gyroscope is more similar to that obtained by EKF, and the value fluctuates around 0. It demonstrates that EKF can eliminate the accumulated error of gyroscope data and enhance the accuracy of the attitude angle. The data can verify that the improved SLAM algorithm has higher real-time performance and is conducive to building more accurate maps with fewer particles. Moreover, after EKF correction, the variance of position and attitude is significantly reduced, and the machine modeling effect is good. Meanwhile, when the number of particles is small, the accuracy and real-time of the improved SLAM algorithm can also be guaranteed. The calculation efficiency is increased to 80%, and the modeling accuracy is increased by 23.3%. It depicts that the SLAM algorithm can be effectively applied to the modeling and location of unknown environments. Various road environments are injected into the detection robot system, so the detection robot can also give feedback when encountering complex environments.

This exploration's main discovery and research contribution is the successful design of an intelligent highway transport monitoring system based on IoT and inspection robots. Combining IoT technology and autonomous inspection robots enables real-time traffic data acquisition, road condition monitoring, and the ability to respond quickly to traffic accidents. This exploration provides scientific data support for urban traffic management and improves traffic efficiency, safety, and sustainability, contributing to smart city development and innovation in transportation infrastructure. In future, the automation and intelligence capabilities of the monitoring system will be continuously improved to enhance the efficiency and accuracy of data acquisition. More advanced inspection robot technologies, including autonomous navigation and ML, are studied to make robots more adaptable to various road and environmental conditions. In addition, data analysis and real-time monitoring algorithms are further optimized to better cope with complex traffic scenarios and predict future traffic demand. Strengthening cooperation with urban planning authorities and transport management agencies can ensure the feasibility and effectiveness of the system, and implement the intelligent transport monitoring system in more cities. These explorations will help improve the safety and efficiency of road traffic to meet the growing challenges of urban transportation..

5 Conclusion

5.1 Research contribution

Here, the accuracy of the two algorithms before and after optimization is compared, the position tracking error of the robot in the x direction and the y direction is defined, respectively, and the Euclidean distance error between the actual and estimated position is calculated. Figures 8 and 9 denote the relationship between the robot’s x direction, y direction, and distance error before and after optimizing the SLAM algorithm and its running time. The results manifest that the maximum error values of the traditional robot algorithm in the x and y directions are approximately 0.06 and −0.005 m, and the maximum distance error is about 0.06 m. The maximum error values of the improved SLAM algorithm in both the x and y directions are around -0.04 m, and the maximum distance error is approximately 0.06 m. It can be observed that the position error of the improved SLAM algorithm is significantly less than that of the traditional robot algorithm, and the position error can be reduced to 20% of the original. Then, the global path and real-time collected robot pose are drawn by a Python drawing tool to obtain the global path of IoT-based inspection robots and the following diagram of the global path. The results demonstrate that the maximum linear and maximum angular accelerations before the optimization are 1.5 and 1.8 m/s2, respectively, and the changes are frequent and drastic. After optimization, the local path planning algorithm can follow the global path to the target point, and start to slow down after reaching the target point, and the speed change is relatively stable. Moreover, the transformation of the whole acceleration is better than the non-optimization. The inspection robots’ ride comfort is improved, and the impact on the drive motor is reduced. All these tests show that the proposed intelligent transport monitoring system has achieved certain optimization efficiency, and can provide technical support for highway inspection in the future.

This exploration has successfully designed and implemented an intelligent highway transport monitoring system based on the IoT and inspection robots. In the process, multiple research objectives have been achieved and significant discoveries and findings have been made. First, this exploration demonstrates the potential of IoT technology in the field of traffic monitoring. It has successfully realized real-time data collection and remote interaction for traffic data by combining WSNs and mobile communication platforms. This opens up new possibilities for enhancing the safety and efficiency of highways. Then, the research and application of inspection robots have proven their value in road monitoring and equipment maintenance. The system proposed ensures 360-degree monitoring coverage without blind spots. Moreover, the involvement of inspection robots significantly improves work efficiency and reduces the workload associated with manual inspections during equipment maintenance and fault troubleshooting. Most importantly, this exploration has outlined intelligent highways' overall concept and goals. The system proposed provides a feasible framework for building smarter, safer, and more efficient traffic management systems. This is significant for road management authorities and improves all traffic participants' travel experience and safety.

In conclusion, achieving research objectives strongly supports developing the intelligent traffic field. This exploration has made theoretical breakthroughs, and the system proposed has also been validated in practical applications. These discoveries and results can offer valuable experience and guidance for future intelligent highway construction, positively contributing to improving traffic management and advancing ITS.

5.2 Future works and research limitations

With the rapid progress of science and technology, the future development trend of intelligent highways can be considered from two aspects. From the perspective of information management, it is essential to fully control the traffic condition, engineering conditions, road service life, and other road condition monitoring and engineering monitoring of highways from the national level, provincial level to the city and county level, and truly achieve "real-time response" and "intelligent control." From the perspective of technological breakthroughs, wireless charging technology and 5G network driverless technology can be realized in stages. Meanwhile, it can provide customized information services to travelers, such as in-car holographic projection technology, active safety early warning, photovoltaic energy storage, and charging technology. It can fully realize the intelligent coordination of people, vehicles, roads, and the environment, and comprehensively achieve a new way of intelligent, safe, flexible, and convenient green travel.

This exploration only theoretically constructs the architecture of urban ITS based on IoT and does not develop the system. Therefore, the next step is to develop the system according to the system model. The inspection robot is used to conduct experimental research on the main road section of a highway. Still, the specific route has limitations, and the road situation is not comprehensive enough. The subsequent practical research on multiple road sections is still needed. SLAM algorithm is introduced to test the built-in hardware of the device. There is no comparison with the operation data of other algorithms, and there is still a lack of specific comparison and optimization stages. As the actual traffic situation is changeable, the inspection robot system needs to expand more traffic scenes, enrich the detection system, improve the communication and early warning module, and improve the quality and efficiency of inspection work.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

References

Liu C, Du Y, Ge Y, Wu D, Zhao C, Li Y (2021) New generation of smart highway: framework and insights. J Adv Transp

Finogeev A, Finogeev A, Fionova L, Lyapin A, Lychagin KA (2019) Intelligent monitoring system for smart road environment. J Ind Inf Integr 15(2):15–20

Ata A, Khan MA, Abbas S, Ahmad G, Fatima A (2019) Modelling smart road traffic congestion control system using machine learning techniques. Neural Network World 29(2):99–110

Zhang R, Ishikawa A, Wang W, Striner B, Tonguz OK (2019) Using reinforcement learning with partial vehicle detection for intelligent traffic signal control. IEEE Trans Intell Transp Syst 22(1):404–415

Tang C, Zhou G, Gao Z, Shu X, Chen P (2019) A novel rail inspection robot and fault detection method for the coal mine hoisting system. IEEE Intell Transp Syst Mag 11(2):110–121

Jo BW, Lee YS, Kim JH, Yoon KW (2018) A review of advanced bridge inspection technologies based on robotic systems and image processing. Int J Contents 14(3):45

Islas-García E, Ceccarelli M, Tapia-Herrera R, Torres-SanMiguel CR (2021) Pipeline inspection tests using a biomimetic robot. Biomimetics 6(no1):17

Njoku JN et al (2023) Prospects and challenges of Metaverse application in data-driven intelligent transportation systems. IET Intel Transp Syst 17(1):1–21

Khan AR et al (2022) DSRC technology in vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) IoT system for intelligent transportation system (ITS): a review. Recent trends in mechatronics towards industry 4.0: selected articles from iM3F 2020, Malaysia, pp 97–106

Jabbar R et al (2022) Blockchain technology for intelligent transportation systems: a systematic literature review. IEEE Access 10:20995–21031

Zhang J et al (2023) Automated guided vehicles and autonomous mobile robots for recognition and tracking in civil engineering. Automat Construct 146. Article ID. 104699

Zhang X et al (2023) Key technology for the construction and inspection of long-distance underwater tunnel for 1000 kV gas-insulated transmission line. Bull Eng Geol Env 82(1):7

Jia Z et al (2022) Condition assessment of the cable trench based on an intelligent inspection robot. Front. Adv Digital Technol Digital Smart Grid, 10. Article ID. 880825089

Babar M, Arif F (2019) Real-time data processing scheme using big data analytics in internet of things based smart transportation environment. J Ambient Intell Humaniz Comput 10(10):4167–4177

Rudskoy A, Ilin I, Prokhorov A (2021) Digital twins in the intelligent transport systems. Transp Res Proc 54:927–935

Awad AY, Mohan S (2019) Internet of things for a smart transportation system. Int J Interdiscip Telecommun Netw (IJITN) 11(1):57–70

Li W et al (2020) Design and implementation of intelligent traffic and big data mining system based on internet of things. J Intell Fuzzy Syst 38(2):1967–1975

Zhang H, Lu X (2020) Vehicle communication network in intelligent transportation system based on Internet of Things. Comput Commun 160:799–806

Lei G, Zheng Y (2021) Research on cooperative trajectory planning algorithm based on tractor-trailer wheeled robot. IEEE Access 10:64209–64221

Shi Y et al (2020) Integrated navigation by a greenhouse robot based on an odometer/lidar. Instrument Mesures Métrol, 19(2)

Lan C, Chang CY (2020) Development of a low cost and path-free autonomous patrol system based on stereo vision system and checking flags. Appl Sci 10(3):974

Liu T, Kuang J, Ge W, Zhang P, Niu X (2019) A simple positioning system for large-scale indoor patrol inspection using foot-mounted INS, QR code control points, and smartphone. IEEE Sens J 21(4):4938–4948

Szrek J, Jakubiak J, Zimroz R (2022) A mobile robot-based system for automatic inspection of belt conveyors in mining industry. Energies 15(1):327

Pathmakumar T, Kalimuthu M, Elara MR, Ramalingam B (2021) An autonomous robot-aided auditing scheme for floor cleaning. Sensors 21(13):4332

Hollinger NB (2022) Examining autonomous inspection of geologic repositories. ESARDA

Oad P, Kajewski S, Kumar A (2020) Innovation in road construction industry: an analysis of different case studies

Rea P, Ottaviano E (2019) Design and development of an Inspection Robotic System for indoor applications. Robot Comput Integrated Manuf 49(1):143–151

Acknowledgements

The authors acknowledge the help from the university colleagues.

Funding

This work was supported by Major Project of Fujian Social Science Fund Base (No.FJ2020JDZ020).

Author information

Authors and Affiliations

Contributions

The author confirms being the sole contributor of this work and has approved it for publication.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y. Constructing the intelligent expressway traffic monitoring system using the internet of things and inspection robot. J Supercomput 80, 8742–8766 (2024). https://doi.org/10.1007/s11227-023-05794-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11227-023-05794-z