Abstract

Though copper-containing zeolites (Cu–zeolites) have shown great potential in the direct conversion of methane to methanol under low temperature, the yields of methanol and the catalytic efficiency remain far behind the necessary level for industrialization. The recent progress in Cu–zeolites catalysts for the direct conversion of methane to methanol by selective oxidation, especially in the investigation on the nature of Cu active species presented in zeolites, was summarized in this mini-review.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zeolites are a series of inorganic aluminosilicate compounds with instinct pore structures [1, 2]. It has been largely used as a substrate for the loading of metal, which has been proved to show excellent catalytic properties [3]. Zeolites show good stabilities in acidic or basic conditions. Furthermore, zeolite catalysts also exhibit good performances even at above 700 °C because of their stabilities toward high temperature. Considering that the regeneration procedure by the calcination is indispensable for many catalysts, zeolites have shown great potential in the chemical reactions at harsh conditions.

Methane as the richest reserved and lowest cost short-chain hydrocarbon [4,5,6] is extremely attractive in hydrocarbons conversion [7], energy carrier for vehicle fuel, as well as direct methanol fuel cells [8]. The conversion of methane is essential in exploring the highly abundant natural gases, especially for scattered oil fields and stranded oil wells which are not suitable for capital-intensive factory facilities. As clean energy, methane can be used to generate energy and heat by directly burning. However, the transport of methane by pipelines remains great cost, and CO2 impurity in methane could cause pipeline corrosion. A high cost would be greatly reduced by the conversion of methane to methanol on site, followed by the transport of liquid methanol or other organic compound transformed from methane. However, the direct conversion of methane to methanol remains a great challenge, as the chemical activity of methane is very low. Indirect conversion methods such as “methane to gasoline” and “Fischer–Tropsch” are extensively used in realities [9,10,11]. Normally, methane is firstly converted to CO and H2 by steam reforming at high temperature [12, 13], followed by the further conversion of syngas to the required compound. For the conversion of methane to methanol (MTM), much higher energy consumption is demanded in the indirect process of MTM than in the direct process of MTM according to Eqs. (1), (2), (3) and (4).

So far, it still remains great challenges in the direct conversion of CH4 to methanol by selective catalytic oxidation with O2 at low temperature [14]. The largest difficulty is that the bond dissociation energy (435 kJ mol−1) of methane restrains the cleavage of C–H in homolytic or heterolytic ways, even the activation of C–H bonds of methane is accessible thermodynamically and kinetically at low temperature [15]. Therefore, it is difficult to suppress the excessive oxidation of methane to CO2. Several substitution strategies have been developed for the activation of methane, such as multi-step oxyfunctionalization in “Periana–Catalytica” system [16] and C–H borylation of methane [17].

CH4 could be selectively converted to methanol by methane monooxygenase enzymes, of which copper and iron active sites play essential roles [18,19,20,21]. Unfortunately, these enzymes are difficult to scale up. Inspired by these natural biological bacterial enzymes, researches in synthetic oxidized catalysts for industrial manufactory of methanol from methane are encouraged, of which the selective oxidation of methane to methanol has been focused on zeolite-based catalysts.

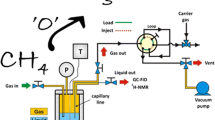

Cu-containing zeolites (Cu–zeolites) have been extensively explored as candidate catalysts for the selective conversion of methane to surface-bound methoxy species through hosting active sites which are similar to methane monooxygenase enzymes. Both continuous-flow reaction system and batch reaction system have been employed for the conversion of MTM on Cu–zeolites. The selectivity toward methanol is high in a batch system, while the yield is limited to the theoretical yield. In addition, both O2 and N2O have been investigated as the oxidants for the conversion of MTM. However, the catalytic active sites, as well as the reaction mechanism, have not been well resolved even through the research for dozens of decades.

Synthesis and characterization of Cu–zeolites

Zeolite structure

Zeolites with particular crystalline structures are constructed from tetrahedron building units, such as [SiO4]4− and [AlO4]5− connected by shared bridged O atoms [22]. To date, 248 kinds of zeolites are discovered in nature or synthesized artificially. In order to clarify their unique structures, all zeolites have been named by three capital letters, such as MFI, FAU and BEA [23].

Benefitting from the regular atom arrangement, unambiguous pore structures and opened pore channels are generated in zeolites. According to Loewenstein rule [24, 25], the ratio of silicon to aluminum is estimated to be no smaller than 1:1, as two Al tetrahedral atoms cannot share one common oxygen atom. The trivalent nature of Al atom leads to negatively charged frameworks, while two neighboring Al connectors will destroy the stability of zeolite framework. In addition, cations are required to balance the excess negative charges resulting from aluminum connectors. Usually, balanced cations are emerging such as alkali/alkaline earth metal ions, NH4+ and H+. As to Cu–zeolites, copper ions exist as counterions inside the pores or channels of zeolites. The local structure of copper active sites and the generation process of these active sites, which are greatly influenced by the topologies and chemical components of zeolites, are both key factors for the conversion of MTM on Cu–zeolites.

On the other hand, SAPO zeolites are constructed from tetrahedron building units, such as [SiO4]4−, [AlO4]5− and [PO4]3− alternatively. The negatively charged framework of SAPO zeolites is caused by the replacement of the framework of P atoms by Si atoms. In this case, Si–O–P linkage is absent in SAPO zeolites [26,27,28]. Owing to the complex nature of SAPO zeolites, the active sites of copper in Cu–SAPO zeolites have rarely been investigated.

Synthesis of Cu–zeolites

Cu–zeolites can be prepared by three ways: ion exchange, impregnation and direct synthesis. Zeolites are usually calcined to remove organic templates involved in the synthetic process before ion exchange and impregnation.

Ion exchange

Ion exchange procedure can be conducted in both liquid and solid states. Liquid ion exchange methods are the most commonly used methods [29, 30]. In the liquid ion exchange process, zeolites are normally soaked in the solutions of copper at a certain temperature and then stirred for several to dozens of hours. Hydrated copper ions should be accessible to the pore channels of zeolites when copper salts are dissolved in water. Limited by the size of hydration ions, only the pore size larger than 8MR can be accessed [31]. Since copper ions are exchanged to balance the charge in the framework of zeolites, the theoretical maximum ion exchange amount can be decided by the Si/Al ratio of zeolites. The pH values also play an important role in the ion exchange procedure, as Cu2+ ions will precipitate as salts once the pH values are higher than 7. Consequently, the favored pH value of copper solutions is between 4 and 6. Meanwhile, the anions of copper salts should also be considered, and Cu–zeolites prepared by the ion exchange with copper solutions with different anions have shown distinctive performances. For example, Cu–zeolites prepared with Cu(NO3)2 show different catalytic performance with those prepared with CuCl2 [32]. Normally, the ion exchange procedure is often incomplete as only parts of balance ions can be exchanged by copper ions. As a result, some original balance ions are residual in the pore channel of zeolites. An ideal complete ion exchange will enable the molecular content of Cu2+ ions to be half of that of the framework of Al atoms in Cu–zeolites. Therefore, the molecular ratio of Cu/Al is an important index of ion exchange.

The treatment by grinding of zeolites with copper salts in solid states and then heating at high temperature can also produce Cu–zeolites by solid-state ion exchange [33, 34]. The high-temperature treatment is important both for the diffusion of copper ions and for the removal of steam adsorbed and residual impurities in zeolites. The solid-state ion-exchanged Cu/MOR zeolites exhibit a significantly higher activity for the partial oxidation of MTM than those prepared by liquid ion exchange [35]. Furthermore, solid-state ion exchange of copper into zeolites can be facilitated by adding NH3 or NO to the atmosphere during thermal treatments [36].

Impregnation

Cu-containing zeolites can also be prepared by soaking zeolites into the solution of copper salts, followed by the treatment of dryness and calcination. Impregnation methods are normally classified into excessive impregnation, isovolumetric impregnation and multiple impregnation.

- 1.

Excessive impregnation

Larger volume of impregnating solutions than saturated water uptake for zeolites is used for excessive impregnation. Redundant solution can be removed by the filtration after the equilibrium state of the absorption of copper salt solution was reached for zeolites. However, the loading amount of Cu species is unable to be defined before dryness and calcination. The advantages of excessive impregnation are focused on the uniformity of copper species formed in zeolites [37].

- 2.

Isovolumetric impregnation

At first, the amount of saturated water uptake of zeolites must be measured by water absorption measurements. Then, the amount of copper salts solutions should be controlled to ensure a complete absorption of copper solution into zeolites. Distinguishing features of this method are opposite to excessive impregnation method. The active contents are relatively less uniform as sizes of zeolite particles are randomly dispersed, while there is a great advantage that the loading amount of active content could be easily controlled and counted [38].

- 3.

Multiple impregnation

Limited by the saturated concentration of copper salts in solvent, a multiple impregnation procedure is needed for the preparation of Cu–zeolites with high loading of copper. The treatment of dryness and calcination is necessary before the next step of impregnation. Thus, complex procedures brought by multiple impregnations are unavoidable [39].

Direct synthesis

“One-pot” processes have been developed to prepare Cu–zeolite directly by adding copper source into the start gel for zeolite synthesis. Several kinds of Cu-containing zeolites have been synthesized successfully with the gel mixed with copper-containing organic complexes [40,41,42]. This synthesis method is very attractive as the multiple steps required in the procedure of ion exchange or impregnation can be avoided, such as filtration, dryness and calcination. Moreover, Cu–zeolites obtained by these direct synthesis methods have shown unique physicochemical properties comparing with those prepared by the conventional method such as ion exchange and impregnation. After the calcination of as-made Cu–zeolites prepared by direct synthesis method, copper ions can be highly dispersed in the zeolite channel as counterions [43].

Characterization of Cu–zeolites

It is essential to characterize the structure of Cu–zeolites by the following techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). For example, XRD patterns are normally used to verify the structure and crystallinity of zeolites, while SEM and TEM images can be employed for the detection of particle morphology and pore structures. In addition, surface area and volume of pores can be evaluated by gas adsorption/desorption measurements.

The investigation on the local structure of Cu active sites present in zeolites is indispensable for the design and development of Cu–zeolites. Noteworthy, the Rietveld refinement method has been developed to provide the position information of counterions according to the results of XRD measurement [44, 45]. However, spectroscopic techniques, such as X-ray absorption spectroscopy (XAS), UV–Vis, Raman, electron paramagnetic resonance (EPR) and IR, are now universally used for the characterization of Cu species present in Cu–zeolites. Though EPR techniques can give the local geometric information of Cu ions with unpaired electrons, XAS measurements are more effective techniques for the determination of the local geometric and/or electronic structure of copper species [46]. UV–Vis spectroscopy has also been used to analyze the chemical structure of Cu species present in zeolites, while Raman spectroscopy has wildly used for the study on the nature of Cu oxo species recently [47]. In addition, IR vibrations of probe molecules adsorbed on Cu–zeolites are often measured to get indirect information of Cu species present in zeolites [48]. And it is well known that in situ or operando measurements are of great importance to gain more insights of the nature of active sites in Cu–zeolites during the catalytic reactions [49, 50].

Cu–zeolites for the selective oxidation of methane to methanol

Difficulties in the direct conversion of methane to methanol come from the high symmetry of methane. It leads the bond energy of methane to be the highest bond energy in all hydrocarbons, which is also much higher than that of target compound methanol. Therefore, catalysts are preferentially encouraged to successively active methanol with lower bond energy during the direct conversion reaction. As a result, the direct conversion of methane to methanol without any protect tactics will never accomplish the goals for high selectivity and high conversion together. In this respect, multi-step conversion strategy consisting of the protect tactics has been proposed to avoid the over-oxidation of methanol. Normally, multi-step conversion strategy consists of three steps. At first, Cu–zeolites are pretreated in N2O, N2 or O2 atmosphere. Then, methane is introduced to form methoxy species on active sites. Finally, the produced methanol is extracted by solvent or steam. Inert gas is employed in every step to prevent the contact of generated intermediates with oxygen, which may lead to unexpected reactions and by-products. The selectivity of the direct methane conversion will be improved according to this multi-step conversion strategy. Though N2O and H2O2 have been employed as the oxidants initially, O2 and H2O as low-cost oxidants are more attractive for multi-step MTM reactions. Unfortunately, in these multi-step conversion reactions, oxygen of the produced methanol should come from activated Cu–zeolites. Thus, this reaction seems more stoichiometric than catalytic, as two-electron transfer needed for the generation of one molecule of methanol accompanying with the reduction of two Cu2+ ions into two Cu+ ions. The highest theoretical yield of methanol can be estimated to be 0.5 mol CH3OH/mol Cu for one cycle of the multi-step MTM reaction.

Batch reaction system

For a typical batch reaction system, Cu-exchanged zeolites were activated with O2 at high temperature, followed by the reaction with methane under a temperature about 200 °C. Methanol was then extracted with steam. Repeated cycles were employed to obtain the final compound, methanol.

Bis(μ-oxo)dicopper species have been assumed to be the active species for MTM reaction according to the results of UV–Vis measurements by Groothaert et al. As shown in Fig. 1, the absorption band at 22,700 cm−1 decreases gradually when the reaction of methane with oxygen-activated Cu–ZSM-5 catalysts proceeds [51]. Smeets et al. [52] reported similar results not only on Cu supported on ZSM-5 zeolites but also on that supported on MOR zeolites. Woertink et al. [53] coupled the results of resonance Raman (rR) and absorption spectra with normal coordinate analysis (NCA) and density functional theory (DFT) calculations to define the geometric and electronic structure of the active sites present in oxygen-activated Cu–ZSM-5. The vibrations bands at 456, 870 and 1725 cm−1 have been assigned to mono-(μ-oxo)dicupric core as active species, as shown in Fig. 2. They proposed that one of the low-lying singly occupied orbitals (SOMOs) of the bent mono-(μ-oxo)dicupric core gains oxygen p-character oriented into the zeolite channel and toward the H–CH3 bond. The successive formation of a cupric-oxyl intermediate is highly active for H atom abstraction from methane.

Fiber-optic UV–Vis spectra of O2-activated CZ-12-0.58 during reaction with CH4 at 448 K (left) and 398 K (right) [51]

rR spectra (λex = 457.9 nm) of Cu–ZSM-5 + 16O2 (red), 18O2 (blue). Inset A Absorption spectrum of oxygen-activated Cu–ZSM-5. Inset B “16,18O2” (green), and 1:1 normalized sum of 16O2 and 18O2 (black) [53]. (Color figure online)

Grundner et al. [54] suggested that the topology of MOR can accommodate and stabilize trinuclear copper-oxo clusters, which are responsible for the high activity for MTM reaction on Cu ion-exchanged MOR zeolites. [Cu(II)OH]+ species present in 8MR of Cu ion-exchanged SSZ-13 with low Si/Al ratio were also suggested to be active sites for MTM reaction according to the results of DFT calculations based on the combination of dynamics and thermodynamics parameters [55]. Considering Cu(II) species responsible for active sites have been formed in the presence of oxygen, the amount of these Cu(II) pieces should increase with the activation time. However, Cu(II) species located in 6MR of zeolites with low Si/Al ratio and those present in Cu–SSZ-13 with low loading of Cu exhibit almost no activity. Therefore, Z[Cu(II)OH] species have been considered to be the precursor of active sites for MTM reaction, even it was believed to be inactive [56].

Sushkecich et al. have reported that Cu–MOR zeolites treated in He at 673 K show an improved catalytic activity. 0.204 mol CH3OH/mol Cu can be produced with H2O as an oxidant (Fig. 3) [57]. The distances among copper counterions will be shortened when the Si/Al ratio of Cu–MOR decreases, and dimer Cu species can be formed easily after the heat treatment. On the other hand, monomer Cu species will be reserved in zeolites with high Si/Al ratio because of the high dispersion of copper counterions. Dimer and Cu monomer species are both active in aerobic conditions, while the former contribute to the catalytic activities in anaerobic environment [58].

The mechanism of the partial oxidation of methane using water as oxidant. (Top) Schematic representation of the reaction conditions of the partial oxidation. (Bottom) The DFT-simulated pathway [57]

Recently, Cordon et al. reported that the output of 0.30–0.42 mol CH3OH/mol Cu has been achieved on Cu–H–MOR under methane pressure of 1–35 bar for 4–20 h. Cu K-edge XANES measurement indicates that 83% of Cu sites can be reduced under He at 723 K, while isolated monomeric Cu (II) species which cannot be reduced are inactive for MTM reaction. The results of FT-EXAFS proved that Cu–H–MOR activated by O2 gives a first-shell oxygen coordination number of 2.9, which was in good agreement with the presence of [Cu2O]2+ and [Cu2(trans-μ-1,2-O2)]2+ species [59].

Besides Cu dimer and trimer species, some recent results indicate that larger-sized CuOx species are possibly formed during MTM reactions. Palagin et al. employed global geometric optimization methods based on DFT calculations to evaluate the stabilities of CuOx clusters with different sizes in MOR zeolites. It was found that the ground-state structures for stoichiometric tetramers or pentamers of CunO2+n and CunO2+n−1 incorporated into 8 MR of MORs are relatively more stable than those for smaller clusters. In addition, the content and localization of the framework Al in zeolites also play an important role in the stabilities and structures of CuOx species [60].

Newton et al. have investigated Cu–zeolites with different copper systems based on MOR, MAZ, CHA and MFI zeolites by in situ copper K-edge XANES for both the high-temperature activation route (723 K in flowing oxygen) and the isothermal route (activation at 473 K in oxygen followed by pressurization in methane to between 6 and 15 bar). The results confirm a two-electron mechanism for MTM reaction on Cu–zeolites based on the Cu(I)/Cu(II) redox couple rather than any other mechanism, such as a Cu(II)/Cu(III) couple or one that proceeds via a Cu(II)–O· radical specie [61].

Continuous-flow reaction system

Ipek et al. have conducted continuous-flow reaction using N2O as the oxidant. Methanol has been produced using Cu–SSZ-13 as a catalyst with the yield of 55 mmol CH3OH/g zeolite h−1 at low temperature and ambient pressure. The selectivity toward methanol can be improved by increasing the partial pressures of CH4 and water, while a lower N2O partial pressure should be better for the production of methanol [62].

Continuous MTM reactions using molecular oxygen as the oxidant were also performed by Román-Leshkov and Narsimhan [63]. The catalytic performances for MTM reactions on Cu loaded on different porous materials, such as MFI, FER, MOR, BEA, CHA, FAU and MCM-41, were compared. The highest yield of methanol was found on Cu/Na-SAPO-34 with 7.9 mmol CH3OH/mol Cu h−1. On the contrary, Cu/MCM-41 with the largest pore size exhibited the lowest yield of 0.6 mmol CH3OH/mol Cu h−1. These results indicate that catalytic active sites or important intermediates can be easily formed in porous materials with small pores or cages. However, it is not clear that whether ultra-small CuO clusters or other Cu species present in pores should be responsible for their difference in catalytic activities [64]. In continuous-flow reaction systems, catalytic active sites have been suggested to be uncovered [Cu–O–Cu]2+ sites in SSZ-13. H2O and protons in zeolites were believed to accelerate the desorption of methanol. CuOx nanoparticles, which were suggested to cause low selectivity for methanol, can be easily formed in zeolites with the average loading of Cu above 0.3 atom/cage and in pure silica zeolites with structure defects. More Cu dimer active sites can be produced in these zeolites with lower ratio of Si/Al and lower loading of Cu [65].

CuFe/ZSM-5 catalysts with the loading of both Fe and Cu by chemical vapor impregnation have shown high selectivity to methanol (> 92% selectivity, 0.5% conversion) by using H2O2 as the oxidant under on-flow conditions [66]. The increment in the ion exchange capacity of ZSM-5 will benefit the reaction rate, the selectivity, as well as the catalytic efficiency.

Recent advance in the catalytic activity of Cu–zeolites

Cu supported on ZSM-5 and MOR zeolites are the mostly studied zeolites in the past 15 years, while the yields of methanol have been increased based on the understanding of the nature of Cu active sites present in these zeolites. Though some other zeolites and non-porous materials have also been investigated as supports for the preparation of Cu catalyst, no big breakthrough in the catalytic activity for MTM reactions has been reported until now.

Cu-exchanged omega (MAZ) zeolite was reported to be one of the most promising copper–zeolite materials by Knorpp et al. in 2018. They reported the highest yield for Cu catalysts supported on highly crystalline and uniform zeolite omega (150 μmol methanol/g zeolite under 1 bar methane; 200 μmol methanol/g zeolite under 30 bar methane). Cu–MAZ zeolites with the high loading of Cu shows much higher selectivity than that of widely studied Cu–MOR zeolites, as shown in Fig. 4 [67]. The local structure of Cu species present in omega zeolites and the relationship between these species with the activities for MTM reactions need to be further investigated.

Methanol yield as a function of copper loading for Cu-omega and Cu-mordenite. Only active copper loadings were used to establish the trendline. For zeolite omega, the x-intercept indicates the minimum copper loading required for conversion [67]

Conclusions

In this mini-review, we have summarized the recent progress in Cu–zeolites catalysts for the direct conversion of methane to methanol by selective oxidation, especially in the investigation on the nature of Cu active species present in zeolites. Though batch reaction system shows a great advantage in the selectivity toward methanol, the yields and catalytic efficiency remain far behind the necessary level for industrialization. Moreover, the activation at high temperature and the reaction under low temperature are both involved in the stepwise conversion of methane to methanol. Obviously, it will take much time consumption for heating and cooling, which also restrict the applicability for this route. The development of a continuous-flow reaction system with high efficiency is a pressing need due to the enormous economic value for methane conversion.

There are also several substantial divergences of opinions both on the active species and on the mechanism for MTM reactions yet. The presence of a mixture of Cu species in zeolites and their actual roles dependent on the reaction conditions make it difficult to explore the nature of active sites. Operando characterization techniques should be further developed to monitor the oxidation state and the local structure transformation of Cu active sites during the reaction. It can promote the fundamental understanding of the reaction mechanism and the structure–catalysis relationship, which provides insight into the rational design of Cu–zeolites catalysts with a unique topology to accommodate and stabilize Cu active sites.

References

C.E. Gounaris, E.L. First, J. Wei, C.A. Floudas, R. Ranjan, M. Tsapatsis, ZEOMICS: Zeolites and Microporous Structures Characterization

H.H. Kung, Res. Chem. Intermed. 26, 121 (2000)

N. Li, F. Jiao, X.L. Pan, Y.X. Chen, J.Y. Feng, G. Li, X.H. Bao, Angew. Chem. Int. Ed. 58, 7400 (2019)

R.A. Kerr, Science 328, 1624 (2010)

T.A. Moore, Int. J. Coal Geol. 101, 36 (2012)

Y. Konno, T. Fujii, A. Sato, K. Akamine, M. Naiki, Y. Masuda, K. Yamaoto, J. Nagao, Energy Fuels 31, 2607 (2017)

Y. Shen, Y. Zhan, S. Li, F. Ning, Y. Du, Y. Huang, T. He, X. Zhou, Chem. Sci. 8, 7498 (2017)

Z. Zakaria, S.K. Kamarudin, Renew. Sustain. Energy Rev. 65, 250 (2016)

M.C. Alvarez-Galvan, N. Mota, M. Ojeda, S. Rojas, R.M. Navarro, J.L.G. Fierro, Catal. Today 171(1), 15 (2011)

M. Ravi, M. Ranocchiari, J.A. van Bokhoven, Angew. Chem. Int. Ed. 56, 16464 (2017)

J. Van de Loosdrecht, F.G. Botes, I.M. Ciobica, A.C. Ferreira, P. Gibson, D.J. Moodley, A.M. Saib, J.L. Visagie, C.J. Weststrate, J.W. Niemantsverdriet, Comprehensive Inorganic Chemistry II: from Elements to Applications (Elsevier, 2013), p. 525

M.A. Pen, J.P. Gómez, J.L.G. Fierro, Appl. Catal. A 144, 7 (1996)

H.D. Gesser, N.R. Hunter, C.B. Prakash, Chem. Rev. 85, 235 (1985)

J. Shan, M. Li, L.F. Allard, S. Lee, M. Flytzani-Stephanopoulos, Nature 551, 7682 (2017)

S.J. Blanksby, G.B. Ellison, Acc. Chem. Res. 36, 255 (2003)

N.J. Gunsalus, M.M. Konnick, B.G. Hashiguchi, R.A. Periana, Isr. J. Chem. 54, 1467 (2014)

K.T. Smith, S. Berritt, M. González-Moreiras, S. Ahn, M.R. Smith, M.H. Baik, D.J. Mindiola, Science 351, 1424 (2016)

M.O. Ross, F. MacMillan, J.Z. Wang, A. Nisthal, T.J. Lawton, B.D. Olafson, S.L. Mayo, A.C. Rosenzweig, B.M. Hoffman, Science 364, 566 (2019)

A.C. Rosenzweig, C.A. Frederick, S.J. Lippard, P. Nordlund, Nature 366, 537 (1993)

R.L. Lieberman, A.C. Rosenzweig, Nature 434, 177 (2005)

S.I. Chan, K.H.C. Chen, S.S.F. Yu, C.L. Chen, S.S.J. Kuo, Biochemistry 43, 4421 (2004)

R.M. Barrer, Hydrothermal Chemistry of Zeolites (Academic Press, Cambridge, 1982)

International Zeolite Association. IZA Structure database

W. Loewenstein, Am. Mineral. 39, 92 (1954)

M.H. Mahyuddin, Y. Shiota, K. Yoshizawa, Catal. Sci. Technol. 9, 1744 (2019)

L. Yang, Y. Aizhen, X. Qinhua, Appl. Catal. 67, 169 (1991)

Y. Xu, P. Maddox, J.W. Couves, J. Chem. Soc. Faraday Trans. 86, 425 (1990)

S. Moulai, R. Ghezini, A. Hasnaoui, A. Bengueddach, P.G. Weidler, Res. Chem. Intermed. 45, 1653 (2019)

S. Sato, Y. Yu-u, H. Yahiro, N. Mizuno, M. Iwamoto, Appl. Catal. 70, L1 (1991)

H. Yamaura, T. Akamatsu, Y. Abe, S. Yamaguchi, H. Yahiro, Res. Chem. Intermed. 37, 1157 (2011)

S.T. King, Catal. Today 33, 173 (1997)

F.S. Xiao, S. Zheng, J. Sun, R. Yu, S. Qiu, R. Xu, J. Catal. 176, 474 (1998)

A.V. Kucherov, A.A. Slinkin, Zeolites 6, 175 (1986)

S.T. King, Catal. Today 33, 173 (1997)

H.V. Le, S. Parishan, A. Sagaltchik, C. Göbel, C. Schlesiger, W. Malzer, A. Trunschke, R. Schomäcker, A. Thomas, ACS Catal. 7, 1403 (2017)

S. Shwan, M. Skoglundh, L.F. Lundegaard, R.R. Tiruvalam, T.V.W. Janssens, A. Carlsson, P.N.R. Vennestrøm, ACS Catal. 5, 16 (2015)

J.L. d’ltri, W.M. Sachtler, Catal. Lett. 15, 289 (1992)

D. Li, L. Zeng, X. Li, X. Wang, H. Ma, S. Assabumrungrat, J. Gong, Appl. Catal. B 176, 532 (2015)

J.S. Beck, S.B. McCullen, D.H. Olson, U.S. Patent 5403800 (1995)

L. Ren, L. Zhu, C. Yang, Y. Chen, Q. Sun, H. Zhang, C. Li, F. Nawaz, X. Meng, F.S. Xiao, Chem. Commun. 47, 9789 (2011)

R. Martínez-Franco, M. Moliner, C. Franch, A. Kustov, A. Corma, Appl. Catal. B 127, 273 (2012)

R. Martínez-Franco, M. Moliner, A. Corma, J. Catal. 319, 36 (2014)

R. Martinez-Franco, M. Moliner, P. Concepcion, J.R. Thogersen, A. Corma, J. Catal. 314, 73 (2014)

D.W. Fickel, F.L. Raul, J. Phys. Chem. C 114, 1633 (2009)

G.L. Marra, A.N. Fitch, A. Zecchina, G. Ricchiardi, M. Salvalaggio, S. Bordiga, C. Lamberti, J. Phys. Chem. B 101, 10653 (1997)

G.T. Palomino, S. Bordiga, A. Zecchina, G.L. Marra, C. Lamberti, J. Phys. Chem. B 104, 8641 (2000)

P.K. Dutta, E.Z. Robert, Zeolites 8, 179 (1988)

F. Giordanino, P.N. Vennestrøm, L.F. Lundegaard, F.N. Stappen, S. Mossin, P. Beato, S. Bordiga, C. Lamberti, Dalton Trans. 42, 12741 (2013)

H. Yamashita, M. Matsuoka, K. Tsuji, Y. Shioya, M. Anpo, M. Che, J. Phys. Chem. 100, 397 (1996)

J.H. Kwak, T. Varga, C.H.F. Peden, F. Gao, J.C. Hanson, J. Szanyi, J. Catal. 314, 83 (2014)

M.H. Groothaert, P.J. Smeets, B.F. Sels, P.A. Jacobs, R.A. Schoonheydt, J. Am. Chem. Soc. 127, 1394 (2005)

P.J. Smeets, M.H. Groothaert, R.A. Schoonheydt, Catal. Today 110, 303 (2005)

J.S. Woertink, P.J. Smeets, M.H. Groothaert, M.A. Vance, B.F. Sels, R.A. Schoonheydt, E.I. Solomon, Proc. Natl. Acad. Sci. USA 106, 18908 (2009)

S. Grundner, M.A.C. Markovits, G. Li, M. Tromp, E.A. Pidko, E.J.M. Hensen, A. Jentys, M. Sanchez-Sanchez, J.A. Lercher, Nat. Commun. 6, 7546 (2015)

A.R. Kulkarni, Z.J. Zhao, S. Siahrostami, J.K. Nørskov, F. Studt, ACS Catal. 6, 6531 (2016)

D.K. Pappas, E. Borfecchia, M. Dyballa, I.A. Pankin, K.A. Lomachenko, A. Martini, M. Signorile, S. Teketel, B. Arstad, G. Berlier, C. Lamberti, S. Bordiga, U. Olsbye, K.P. Lillerud, S. Svelle, P. Beato, J. Am. Soc. Chem. 139, 14961 (2017)

V.L. Sushkevich, D. Palagin, M. Ranocchiari, J.A. van Bokhoven, Science 356, 523 (2017)

V.L. Sushkevich, D. Palagin, J.A. van Bokhoven, Angew. Chem. Int. Ed. 57, 8906 (2018)

G. Brezicki, J.D. Kammert, T.B. Gunnoe, C. Paolucci, R.J. Davis, ACS Catal. 9, 5308 (2019)

D. Palagin, A.J. Knorpp, A.B. Pinar, M. Ranocchiari, J.A. van Bokhoven, Nanoscale 9, 1144 (2017)

M.A. Newton, A.J. Knorpp, A.B. Pinar, V.L. Sushkevich, D. Palagin, J.A. van Bokhoven, J. Am. Chem. Soc. 140, 10090 (2018)

B. Ipek, R.F. Lobo, Chem. Commun. 52, 13401 (2016)

Y. Román-Leshkov, K. Narsimhan, US Patent 0267616A1 (2017)

K. Narsimhan, K. Iyoki, K. Dinh, Román-Leshkov Y. ACS Cent. Sci. 2, 424 (2016)

K.T. Dinh, M.M. Sullivan, K. Narsimhan, P. Serna, R.J. Meyer, M. Dinca, Y. Roman-Leshkov, J. Am. Chem. Soc. 141, 11641 (2019)

J. Xu, R.D. Armstrong, G. Shaw, N.F. Dummer, S.J. Freakley, S.H. Taylor, G.J. Hutchings, Catal. Today 270, 93 (2016)

A.J. Knorpp, A.B. Pinar, M.A. Newton, V.L. Sushkevich, J.A. van Bokhoven, ChemCatChem 10, 5593 (2018)

Acknowledgements

This work is supported by The National Key Research and Development Program of China (2017YFE0129000), Tianjin Municipal Science and Technology Bureau (18ZXSZSF00070, 18ZXSZSF00210) and National Engineering Laboratory for Mobile Source Emission Control Technology (NELMS2018A14).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, H., Liu, C. & Chen, H. Nature of Cu active sites in zeolite-based catalysts for selective catalytic oxidation of methane. Res Chem Intermed 45, 5849–5861 (2019). https://doi.org/10.1007/s11164-019-04005-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-04005-w