Abstract

The synthesis of 5-ethoxymethylfurfural (EMF) from glucose using metal chlorides or combined metal–surfactant catalysts as Lewis acids in a solution of ethanol/dimethyl sulfoxide was investigated. Metal chlorides such as aluminum chloride and chromium(III) chloride mainly produced 5-hydroxymethylfurfural and ethyl glucoside in reactions at 140 °C for 180 min. However, the combined metal–surfactant catalysts aluminum tridodecyl sulfate (Al(DS)3) and chromium(III) tridodecyl sulfate efficiently improved the yield of EMF from glucose. The maximum yield of EMF using Al(DS)3 was 37.9% at 160 °C for 60 min. Moreover, the EMF yields from other saccharides (fructose, mannose, sucrose, cellobiose, and inulin) in the presence of Al(DS)3 as a catalyst ranged from 31.2 to 59.3%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Because of diminishing fossil fuel resources and increasing environmental concerns, renewable biomass resources have been attracting broad attention as a feedstock for the sustainable production of energy and raw materials [1, 2]. 5-Hydroxymethylfurfural (HMF) can be produced from biomass resources by simple reactions of hexoses such as fructose and glucose [3]. HMF and its derivatives are expected to become valuable chemical intermediates for fine chemicals, bio-based plastics, and bio-liquid fuels because of the two functional groups (hydroxyl and formyl groups) of their furan ring [4,5,6,7,8,9]. Thus, HMF is a promising green building block for bio-based raw materials [10].

5-Ethoxymethylfurfural (EMF), an alkylated derivative of HMF, is a promising liquid fuel and fuel additive because its energy density (8.7 kWh/L) is higher than that of ethanol (6.1 kWh/L) and similar to that of regular gasoline (8.8 kWh/L) and diesel fuel (9.7 kWh/L) [11,12,13]. EMF has previously been synthesized from HMF or its derivative, 5-chloromethylfurfural, via etherification with ethanol [12,13,14,15]. The synthesis of EMF from fructose and fructose-based carbohydrates such as sucrose and inulin has also been reported, where high yields of EMF were obtained using various acid catalysts, e.g., mineral acids [16, 17] or solid acids [18,19,20,21] as Brønsted acids, various metal halides [22,23,24,25] or heteropolyacids [26, 27] as Lewis acid catalysts, or a combination of solid acid (Amberlyst-15) and solid base (dealuminated beta zeolites) [28]. Although high EMF yields from fructose have been reported in earlier papers, the EMF yields from glucose were relatively low because of the inefficient prerequisite isomerization from glucose to fructose for HMF synthesis [25]. To obtain a higher EMF yield from glucose, further investigations using various catalysts and reaction conditions are required.

The objective of this study was to investigate whether Lewis acid catalysts combined with a surfactant can effectively catalyze the synthesis of EMF from glucose via isomerization, dehydration, and etherification. Kobayashi et al. previously reported that surfactant-combined Lewis acid catalysts could promote certain chemical reactions such as aldol condensation in aqueous media [29, 30]. In addition, as Lewis acids, these surfactant-combined catalysts catalyzed the transesterification of the ester group in various alcohols without severe degradation of the Lewis acid to a Brønsted acid [29,30,31,32]. With regard to the production of furan derivatives from carbohydrates, Zhao et al. [33] reported that a Brønsted–Lewis acid surfactant-combined heteropolyacid catalyzed the conversion of cellulose to HMF in relatively high yield. Moreover, we previously used several metal–surfactant-combined catalysts such as tin(II) dodecyl sulfate to convert glucose to HMF in an aqueous solvent [34].

In the present study, we used metal halides or combined metal–surfactant catalysts to investigate the synthesis of EMF from glucose in an ethanol/dimethyl sulfoxide (DMSO) solvent mixture. First, we tested various metal species that could promote the creation of furan derivatives via several reactions, including isomerization, dehydration, and etherification. Next, we used selected combined metal–surfactant catalysts to study the influence of temperature, reaction time, catalyst amount, and DMSO content in the reaction solvent.

Experimental

Materials

The monosaccharides glucose (98%), fructose (99%), mannose (98%), and ethyl glucoside (98%, EGL) were purchased from Wako Pure Chemical Industry Co. (Osaka, Japan). HMF (99%) and EMF (97%) were obtained from Sigma-Aldrich Chemical Co. (St. Louis, USA) and were used as received. Sodium dodecyl sulfate (97%, SDS), sucrose, and inulin were purchased from Tokyo Chemical Industry Co. (Tokyo, Japan). All the other reagents, including metal halides, were purchased from Wako Pure Chemical Industry Co. (Osaka, Japan). The reagents and solvents were used as received.

Analytical methods

The yield of HMF and EMF was determined by high-performance liquid chromatography (HPLC) on a Shimadzu LC-10AT (Shimadzu, Kyoto, Japan) equipped with a GF-210 HQ column (Shodex, Tokyo, Japan) and a Shimadzu SPD-10A UV detector (280 nm; Shimadzu, Kyoto, Japan). The mobile phase, H2O/acetonitrile (70/30, v/v) including 0.1% formic acid, was eluted at a rate of 0.6 mL/min; vanillin was used as an internal standard. The contents of glucose, mannose, fructose, and EGL were determined by HPLC with a JASCO Pump 2080 (JASCO, Tokyo, Japan) and a JASCO Refractive Index Detector 2031 Plus (JASCO, Tokyo, Japan) equipped with an NH2P-50 4E column (Shodex, Tokyo, Japan). The mobile phase, acetonitrile/H2O (80/20, v/v), was eluted at a rate of 0.6 mL/min; we used maltose as an internal standard. The metal content was determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES; Kyoto, Shimadzu, Japan). The elemental analysis for C, H, and N was carried out with a CHN Corder (Yanaco, Kyoto, Japan).

Preparation of combined metal–surfactant catalysts

The combined metal–surfactant catalysts were prepared according to previously published methods [35,36,37]. To a solution of SDS (9 mmol, 2.6 g) in deionized water (75 mL), a solution of AlCl3·6H2O (3 mmol, 1.1 g) in deionized water (25 mL) was added at room temperature. A white precipitate appeared, and the mixture was stirred for 20 min. The white precipitate was separated by filtration and was washed with deionized water (30 mL). Drying of the isolated solid under reduced pressure at 40 °C gave the target compound as a white powder in 67% yield.

The sulfur content of the product was measured via an oxygen-flask combustion method. The carbon and hydrogen contents were analyzed with a CHN Corder. The metal content was determined by ICP-AES analysis. Fe(DS)3, Cr(DS)3, and La(DS)3 were prepared from SDS by similar operations. The yield was 67% for Al(DS)3. The analysis calculated for Al(DS)3·3H2O (= C24H56O11S3Al): C, 52.6%; H, 9.1%; S, 11.6%; Al, 3.3%. The following were found: C, 44.7%; H, 8.9%; S, 12.0%; Al, 2.5%. The analysis calculated for Fe(DS)3 (= C24H50O8S3Fe): C, 41.0%; H, 8.0%; S, 10.8%; Fe, 11.0%. The following were found: C, 41.0%; H, 8.0%; S, 10.5%; Fe, 6.5%. The analysis calculated for Cr(DS)3 (= C C24H50O8S3Cr): C, 50.9%; H, 8.8%; S, 11.3%; Cr, 6.1%. The following were found: C, 40.4%; H, 8.6%; S, 13.8%; Cr, 4.4%. The analysis calculated for La(DS)3 (= C24H50O8S3La): C, 46.2%; H, 8.0%; S, 10.3%; La, 14.9%. The following were found: C, 39.9%; H, 5.6%; S, 11.1%; La, 13.2%.

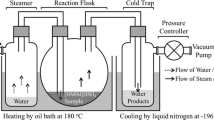

Procedures to produce EMF from glucose and to perform quantitative analysis of the products

Glucose (180 mg, 1 mmol) and the previously described catalyst (0.1 mmol) were added, along with a stirring bar, to a solution of ethanol/DMSO (6 mL, 7/3, v/v) in a 10-mL stainless-steel microtube in which a smaller glass tube was placed. The reaction was carried out at a predetermined temperature and duration with stirring in an oil bath.

The products in the reaction mixture were extracted with ethyl acetate (50 mL × 3 times) after being filtered to remove the insoluble substances. The ethyl acetate was then removed by evaporation, and vanillin (50 mg) was added as an internal standard. The syrup was diluted with deionized water (970 mL) and acetonitrile (30 mL) so that the 1-L volumetric flask was filled. The yields of HMF and EMF were determined by an HPLC system equipped with a GF-210 HQ column. The content of residual glucose in the reaction mixture which was not extracted with ethyl acetate was determined by an HPLC system equipped with an NH2P-50 4E column.

Calculation of the product yields, glucose conversion, and selectivity

The yields, conversion, and selectivity were calculated on the basis of the results of HPLC analysis using the following formula:

Results and discussion

Synthesis of EMF from glucose in a solvent mixture of ethanol/DMSO

Because glucose is the most abundant hexose in biomass resources, the synthesis of furan derivatives from glucose appears to be a favorable pathway for biomass conversion (Fig. 1). First, we examined the effect of metal halides on the formation of furan derivatives (HMF and EMF) in the mixture of ethanol/DMSO at 140 °C for 180 min (Table 1, entries 2–13). The yields of furan derivatives, the glucose conversion, and the selectivity are listed in Table 1. With regard to the glucose conversion, high conversion (almost 100%) was accomplished except for lithium chloride (LiCl) and sodium chloride (NaCl). However, almost no EMF was detected with these catalysts, with the exception of AlCl3·6H2O and SnCl4·5H2O, which produced a minor yield of EMF. Instead, EGL was one of the major products under these conditions. The chemical shift and coupling constants (J-values) of EGL in the 1H NMR spectrum indicated that both α- and β-anomers of EGL were formed in this reaction (4.73 ppm and J = 4.12 Hz for the α-anomer; 4.23 ppm and J = 8.22 Hz for the β-anomer [38, 39]). HMF was produced in the second-highest yields (lower than the EGL yields) in most cases; however, fairly high yields of HMF were obtained with the catalysts AlCl3·6H2O (31.4%), CrCl3·6H2O (28.0%), and SnCl4·5H2O (24.8%); the yields of HMF with these catalysts were higher than any other product yields.

The results suggest that the many catalysts tested here did not catalyze the reactions toward HMF or EMF (e.g., the isomerization of glucose to fructose and dehydration of fructose to HMF) more effectively than the reactions toward EGL, with the exception of AlCl3·6H2O, CrCl3·6H2O, and SnCl4·5H2O [40, 41]. Furthermore, the etherification step of HMF to EMF was not catalyzed effectively even with these catalysts. The results suggest that the reaction of glucose toward HMF or EMF and the reaction toward EGL compete with each other.

Second, we examined the effect of the combination of metal halides and surfactant on the formation of furan derivatives in the aforementioned solvent mixture (Table 1, entries 14–18). When Al(DS)3 or Cr(DS)3 was used as the combined metal(III)–surfactant catalyst, the EMF yields obtained were 34.2% for Al(DS)3 and 22.1% for Cr(DS)3, showing substantial increases from the yields attained with the corresponding simple metal halides. By contrast, the HMF yields severely decreased to 5.5% for Al(DS)3 from 31.4% for AlCl3·6H2O and to 5.4% for Cr(DS)3 from 28.0% for CrCl3·6H2O. Because the sum of the yields of HMF and EMF appears to be similar regardless of whether a simple metal halide or a combined metal–surfactant was used as the catalyst, the formation of EMF from HMF was promoted under the effect of surfactants combined with a metal. These results suggest that the long alkyl chains of Al(DS)3 or Cr(DS)3 may enhance the hydrophobic environment that leads to the promotion of etherification: An interaction (or “contact”) between the catalyst and the HMF may be enhanced by the incorporation of the surfactant into these catalysts [31, 32]. Because Al(DS)3 was the most promising catalyst examined here, we used this catalyst in subsequent experiments in which the parameters were varied to favor the formation of EMF.

Influence of reaction temperature

We examined the effect of reaction temperature on the transformation of glucose to HMF and EMF. Figure 2 shows the yields of HMF, EMF, and EGL, together with the glucose conversion for reaction temperatures of 120, 140, and 160 °C for 60 min. At 120 °C, the yields of HMF and EMF were 23.7% and 2.9%, respectively. The glucose conversion was almost 100%, and EGL was the major product at this temperature. In the case of 140 °C, the HMF yield decreased to 12.8% and the EMF yield increased substantially to 19.0%. The yield of EGL also obviously decreased from 28.8 to 16.5%. At the highest temperature of 160 °C, the EMF yield showed a remarkable increase and reached a maximum of 37.9%, whereas the yields of HMF and EGL decreased slightly. The amount of insoluble humic substance in the reaction mixture was less than 1.4% (data not shown). Because the maximum yield of EMF was obtained at 160 °C and a further increase in temperature (> 160 °C) led to an obvious increase in the amount of polymeric humic substance (6.6% at 180 °C), we adopted 160 °C as the reaction temperature in subsequent investigations.

Influence of reaction time

Third, we investigated the influence of the duration of the reaction involving Al(DS)3. As shown in Fig. 3, 100% of the glucose was converted at the initial stage of the reaction. The EMF yield increased and reached a maximum of 37.9% within 60 min; it then decreased gradually as the reaction proceeded. The maximum yield obtained here is comparable with the yields reported in previous works; however, the reaction time necessary to obtain the maximum yield in our study is substantially shorter than those reported previously (~ 10 h) [21, 28]. The HMF yield reached 17.3% within 15 min and gradually decreased thereafter. The EGL yield reached 28.1% within 30 min and then decreased gradually with increasing reaction time. The gradual decrease in the EMF yield after reaching a maximum is presumed to be a result of the degradation of EMF into smaller molecules (e.g., levulinic acid and formic acid) or its conversion into larger polymeric substances soluble in the solvent.

Influence of the ratio of DMSO in the ethanol/DMSO solvent mixture

Next, we examined the influence of the ratio of DMSO in the solvent mixture on the yield of EMF from glucose (Fig. 4). The incorporation of DMSO as a co-solvent in an alcoholic solvent has been reported to substantially increase the yield of furan derivatives and to reduce by-product formation from carbohydrates [27, 42, 43]. When only ethanol was used as the solvent, the main product was EGL in 30.2% yield; the yields of furan derivatives (HMF and EMF) were much lower (0.5%). The EMF yield increased from 21.1 to 37.9% (maximum yield) when the DMSO content was increased from 10 to 30%. By contrast, the EGL yield gradually decreased with increasing DMSO content in the solvent mixture. When the ratio of DMSO in the solvent was 50%, the highest yield product changed from EMF (16.7%) to HMF (26.2%). These results suggest that the addition of DMSO to the solvent promotes the formation of EMF from HMF and suppresses the formation of by-products such as EGL and humic substances [3, 27, 42, 43] as long as sufficient ethanol remains in the solvent mixture for the etherification of HMF. Similar trends were observed in the yields of EMF and HMF when Amberlyst-15 or Al(OTf)3 was used as a catalyst for the transformation of glucose or fructose in an EtOH/DMSO mixed solvent [43].

Influence of catalyst amount

We investigated the influence of catalyst amount on the reaction (Fig. 5). At a small catalyst amount of 0.01 mmol, the main product was EGL with a high yield of 40.6%; the yields of HMF and EMF were 15.6% and 11.2%, respectively. When the catalyst amount was increased to 0.1 mmol, the maximum yield of EMF was obtained (37.9%). A further increase in the amount of catalyst (2.5 mmol) led to a decrease in the EMF yield from 37.9 to 24.2%. An excess amount of the catalyst may lead to the formation of the aforementioned by-products.

Synthesis of EMF from various carbohydrates

Lastly, we investigated the effect of the type of saccharide as a starting material on the behavior of EMF formation in the presence of Al(DS)3 in an ethanol/DMSO solution mixture. Various saccharides, including monosaccharides (fructose, glucose, and mannose), disaccharides (cellobiose and sucrose), and polysaccharides (inulin and cellulose), were used as substrates; the results are compiled in Fig. 6. The EMF yield from fructose was 59.7%, whereas those from glucose and mannose as another hexose were 31.2% and 37.8%, respectively. In the case of disaccharides, the EMF yields obtained for cellobiose and sucrose were 13.8% and 30.8%, respectively. When polysaccharides were used as a feedstock, the EMF yield for inulin was 51.0% and that for cellulose was less than 4.7%; this difference in yields may reflect the difference in fructose or fructose-residue content. The aforementioned results indicate that the combined metal–surfactant catalyst, Al(DS)3, effectively catalyzed the formation of EMF from various saccharides other than cellulose. The cleavage of β-glycoside and the breakage of the crystalline structure of cellulose appear to be difficult under these conditions, consistent with previous reports [44, 45].

Formation of HMF and EMF from various saccharides (A, fructose; B, glucose; C, mannose; D, cellobiose; E, sucrose; F, inulin; and G, cellulose). The reaction was carried out at 160 °C for 60 min in an ethanol/DMSO solution (6 mL, 7/3, v/v) containing a monosaccharide or monosaccharide residue (1 mmol) and Al(DS)3 (0.1 mmol)

Conclusions

The conversion of glucose into EMF was successfully carried out in the presence of combined metal–surfactant catalysts as Lewis acids in a solvent mixture of ethanol/DMSO. Al(DS)3 exhibited the best catalytic performance among the prepared metal–surfactant catalysts. Almost complete conversion of glucose was achieved, and the maximum yield of EMF (37.9%) was obtained at 160 °C for 60 min. Moreover, the introduction of DMSO as a co-solvent could change the yield of EMF. The EMF yield from other saccharides (fructose, mannose, cellobiose, sucrose, inulin, and cellulose) was also investigated and showed good results except for cellulose.

References

R.A. Sheldon, Green Chem. 16, 950 (2014)

A. Corma, S. Iborra, A. Velty, Chem. Rev. 107, 2411 (2007)

A.S. Amarasekara, L.D. Williams, C.C. Ebede, Carbohydr. Res. 343, 3021 (2008)

J.A. Moore, J.E. Kelly, Macromolecules 11, 568 (1978)

A. Gandini, A.J.D. Silvestre, C.P. Neto, A.F. Sousa, M. Gomes, J. Polym. Sci. Polym. Chem. 47, 295 (2009)

S. Gharbi, A. Gandini, Acta Polym. 50, 293 (1999)

S. Boufi, A. Gandini, M.N. Belgacem, Polymer 36, 1689 (1995)

N. Yoshida, N. Kasuya, N. Haga, K. Fukuda, Polym. J. 40, 1164 (2008)

Y. Román-Leshkov, J.N. Chheda, J.A. Dumesic, Science 312, 1933 (2006)

B.R. Caes, R.E. Teixeira, K.G. Knapp, R.T. Raines, ACS Sustain. Chem. Eng. 3, 2591 (2015)

G.J.M. Gruter, L.E. Manzer, U.S. 20100058650 (2010)

M. Mascal, B.E. Nikitin, Angew. Chem. 120, 8042 (2008)

S. Alipour, H. Omidvarborna, D.-S. Kim, Renew. Sust. Energy Rev. 71, 908 (2019)

P. Lanzafame, D.M. Temi, S. Perathoner, G. Centi, A. Macario, A. Aloise, G. Giordano, Catal. Today 175, 435 (2011)

M. Balakrishnan, R.E. Saciaa, T.A. Bell, Green Chem. 14, 1626 (2012)

F. Thomas, D. Stephen, J.J. Leahy, Energy Fuels 29, 7554 (2015)

J. Liu, Y. Tang, X. Fua, Starch/Stärke 67, 765 (2015)

P.A. Russo, M.M. Antunes, P. Neves, P.V. Wiper, E. Fazio, F. Neri, F. Barreca, L. Mafra, M. Pillinger, N. Pinna, A.A. Valente, J. Mater. Chem. A 2, 11813 (2014)

P. Maneechakr, S. Karnjanakom, Res. Chem. Int. 45, 743 (2019)

T. Chen, L. Peng, X. Yu, L. He, Fuel 219, 344 (2018)

M. Zuo, K. Le, Y. Feng, C. Xiong, Z. Li, X. Zeng, X. Tang, Y. Sun, L. Lin, Ind. Crop Prod. 112, 18 (2018)

B. Li, Z. Zhang, K. Huang, Z. Fang, Fuel 113, 625 (2013)

J. Liu, Y. Tang, K. Wu, C. Bi, Q. Cui, Carbohydr. Res. 350, 20 (2012)

Y. Yang, C. Hu, M.M. Abu-Omar, Biores. Technol. 116, 190 (2012)

X. Yu, X. Gao, R. Tao, L. Peng, Catalysts 7, 182 (2017)

Y. Yang, M.M. Abu-Omar, C. Hu, Appl. Energy 99, 80 (2012)

H. Wang, T. Deng, Y. Wang, Y. Qi, X. Hou, Y. Zhu, Biores. Technol. 136, 394 (2013)

H. Li, S. Saravanamurugan, S. Yang, A. Riisager, Green Chem. 18, 726 (2016)

S. Kobayashi, T. Wakabayashi, S. Nagayama, H. Oyamada, Tetrahedron Lett. 38, 4559 (1997)

S. Kobayashi, K. Manabe, Acc. Chem. Res. 35, 209 (2002)

G.F. Ghesti, J.L.D. Macedo, V. Cavalcanti, I. Parente, J.A. Dias, S.C.L. Dias, Appl. Catal. A Gen. 355, 139 (2009)

Y. Qiu, H. Sun, Z. Ma, W. Xia, J. Mol. Catal. A Chem. 392, 76 (2014)

S. Zhao, M. Cheng, J. Li, J. Tian, X. Wang, Chem. Commun. 47, 2176 (2011)

H. Hota, Y. Mori, N. Kasuya, BioResources 13, 2775 (2018)

H. Firouzabadi, N. Iranpoor, F. Nowrouzi, Chem. Commun. 5, 789 (2005)

K. Deleersnyder, D. Shi, K. Binnemans, T.N. Parac-Vogt, J. Alloys Compd. 451, 418 (2008)

C.B. Rasrendra, S. Adisasmito, I.G.B.N. Makertihartha, H.J. Heeres, Top. Catal. 53, 1241 (2010)

W. Lu, G. Lin, H. Yu, A. Tong, J. Xu, J. Mol. Catal. B Enzym. 44, 72 (2007)

C. Li, H. Dong, C. Cui, Molecules 20, 2034 (2015)

I. Delidovich, R. Palkovits, Chemsuschem 9, 547 (2016)

J. Tang, X. Guo, L. Zhu, C. Hu, ACS Catal. 5, 5097 (2015)

G. Morales, M. Paniagua, J.A. Melero, J. Iglesias, Catal. Today 279, 305 (2016)

X. Yu, X. Gao, L. Peng, L. He, J. Zhang, ChemistrySelect 3, 13391 (2018)

S. De, S. Dutta, B. Saha, Green Chem. 13, 2859 (2011)

Y. Yang, C. Hu, M.M. Abu-Omar, Green Chem. 14, 509 (2012)

Acknowledgements

The authors thank Professor Izumi Watanabe at Tokyo University of Agriculture and Technology for the determination of metal contents using ICP-AES. The authors also thank the staff of the center for the elemental analyses of organic compounds at Kyushu University and Enago (www.enago.jp) for some of the elemental analyses and for the English language review, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mori, Y., Katayama, Y., Shikata, T. et al. Synthesis of 5-ethoxymethylfurfural from saccharides using combined metal–surfactant catalyst in ethanol/dimethyl sulfoxide. Res Chem Intermed 46, 609–620 (2020). https://doi.org/10.1007/s11164-019-03980-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-03980-4