Abstract

A facile synthetic method for benzothiazoles and benzoxazoles comprising the reaction of corresponding 2-aminothiophenol and 2-aminophenol with various substituted aromatic carboxylic acids using Samarium(III) triflate as a catalyst has been described. The advantages of the method are short reaction times and aqueous reaction media and easy work-up. The catalysts can be recovered for the subsequent reactions and reused without any appreciable loss of efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Molecules containing benzothiazole and benzoxazole nucleus attract much interest in diverse areas of chemistry. Benzothiazole derivatives are important for natural products and pharmaceuticals that exhibit remarkable antitumor activities [1–4], and they are also reported to exhibit diverse biological activities [5], with their many derivatives acting as useful intermediates that find applications in medicinal chemistry [6] and material science [7], particularly as sensors [8]. The benzoxazole moiety is a basic structural unit found in a wide class of natural products and synthetic compounds showing biological properties, such as natural antimycobacterials [9], non-nucleoside reserve transcriptase inhibitors [10], cytotoxic natural products [11], anticancer agents [12], and elastase inhibitors [13], and in the agricultural field [14].

A number of methods have been reported for the synthesis of the benzothiazole [15] by condensation of 2-aminophenol with acyl chlorides or aldehydes and also by coupling with carboxylic acid derivatives or by oxidative cyclization of a phenolic imine intermediate [16]. The first route requires strongly acidic conditions, high temperatures, and long reaction times [17], whereas the second route requires strong oxidants [16, 18]. Apart from cyclization reactions, 2-substituted benzoxazoles are synthesized by amination, arylation and alkylation of the benzoxazoles, via metal-catalyzed C–H bond activation [19–21].

Several synthetic methodologies have been developed for the synthesis of 2-substituted benzothiazoles [22]. Most of the synthetic approaches are based on the condensation of 2-aminothiophenol with substituted nitriles [21], carboxylic acids [23–27], acyl chlorides [28, 29] and esters [30], or with aldehydes followed by oxidation by using various oxidative reagents and catalysts [31–43]. Some benzothiazoles and benzoxazoles are also synthesized by cyclocondensation with β-diketones using Bronsted acid [44, 45]. Although these methods are suitable for specific synthetic conditions, most of these methods suffer from one or more disadvantages such as long reaction times, expensive reagents, drastic reaction conditions, low yields, tedious work-up procedures and co-occurrence of several side reactions.

Recently, with the objective of developing new environmentally benign reaction conditions and media for organic reactions with excellent efficiency and selectivity, water has been shown to be a useful solvent for certain Lewis acids [46]. For instance, In(OTf)3, Yb(OTf)3, Bi(OTf)3, Sc(OTf)3, Sm(OTf)3, and other metal triflates have been found to be water-tolerant, reusable Lewis acids catalysts and have received considerable interest for condensation reactions [47] and other organic transformations [48–50].

In continuation of seeking newer synthetic routes for 1,3-azole derivatives [51], we report the use of samarium triflate as a water-tolerant Lewis acid catalyst for the synthesis of 2-substituted benzoxazoles and benzothiazoles by the condensation of 2-aminophenols or 2-aminothiophenols with carboxylic acids in ethanol:water, as shown in Scheme 1.

Experimental

All commercial reagents and solvents were used without further purification. Analytical thin layer chromatography (TLC) was carried out using silica gel 60 F254 pre-coated plates. Column chromatography was carried out using silica gel (60–120 mesh size). Visualization was accomplished with UV lamp, I2 stain. 1H and 13C NMR were recorded on 300 and 75 MHz, respectively, in DMSO-d 6 using TMS as the internal standard. Chemical shifts were reported in parts per million (ppm) downfield from TMS. IR spectra were obtained using a Bruker FT-IR spectrophotometer. Melting points were determined with a capillary apparatus and were not further corrected.

General procedure for the synthesis of benzoxazoles/benzothiazole

To a mixture of o-aminophenol/o-aminothiophenol (1 mmol) and carboxylic acids (1 mmol) in ethanol:water (2:2 mL) under open atmosphere, 10 mol% of samarium triflate catalyst were added. The resulting mixture was stirred at 80 °C. After completion of the reaction, as monitored by TLC, the reaction mixture was diluted with 1:1 mixture of water/ethyl acetate (10 mL) and catalyst recovered by simple filtration. The reaction mixture was extracted with diethyl ether (2 × 10 mL) and dried with anhydrous sodium sulfate. Finally, crude product was recrystallized from ethyl acetate or methanol. All the pure products were confirmed by their 1 HNMR, 13C NMR, IR, and mass spectroscopy data.

Spectral data for selected compounds

-

1.

2-(4-Nitrophenyl)benzo[d]thiazole (Table 2, entry b) Mp 225–227 °C; 1H NMR (300 MHz, DMSO-d 6): δ 7.51–7.62 (d, 2H), 7.60–7.68 (m, 1H), 8.01–8.07 (d, 2H), 8.16–8.76 (m, 1H), 8.36–8.52(m, 2H). 13C NMR (75 MHz, DMSO-d 6): δ 121.9, 123.8, 124.4, 126.1, 126.8, 128.2, 135.6, 139.2, 149.0, 154.1, 165.0., EI MS (m/z): 256.9 (M+).

-

2.

2-(4-Methoxyphenyl)benzo[d]thiazole (Table 2, entry e) Mp 122–124 °C; 1H NMR (300 MHz, DMSO-d 6): δ 3.89 (s, 3H), 7.02–7.13 (d, 2H), 7.39–7.47 (m, 1H), 7.51–7.60 (d, 2H), 7.94–8.15 (d, 1H), 8.06–8.20 (m, 2H). 13C NMR (75 MHz, DMSO-d 6): δ 55.4, 114.3, 121.6, 122.7, 124.8, 126.2, 126.4, 129.0, 135.0, 154.3, 162.0, 167.7., EI MS (m/z): 241.9 (M+).

-

3.

2-(Pyridin-4-yl)benzo[d]thiazole (Table 2, entry h) Mp 130–132 °C; 1H NMR (300 MHz, DMSO-d 6): δ 7.44–7.50 (d, 2H), 7.57–7.68 (m, 1H), 8.01–8.11 (d, 2H), 8.13–8.53 (m, 1H), 8.40–8.56 (m, 2H). 13C NMR (75 MHz, DMSO-d 6): δ 121.8, 123.3, 123.8, 125.6, 126.6, 129.6, 134.4, 135.1, 148.5, 151.6, 154.0, 164.7., EI MS (m/z): 212.9 (M+).

-

4.

2-Phenylbenzo[d]oxazole (Table 2, entry i) Mp 100–102 °C; 1H NMR (300 MHz, DMSO-d 6): δ 7.39-7.43 (m, 5H), 7.57-7.63 (m, 4H). 13C NMR (75 MHz, DMSO-d 6): δ 110.6, 119.9, 124.5, 125.1, 127.3, 127.5, 128.9, 131.5, 142.2, 150.8, 163.0., EI MS (m/z): 195.9 (M+).

-

5.

2-(4-Methylphenyl)benzo[d]oxazole (Table 2, entry j) Mp 114–116 °C; 1H NMR (300 MHz, DMSO-d 6): δ 2.45 (s, 3H), 7.36–7.46 (d, 2H), 7.41–7.49 (m, 1H), 7.51–7.60 (d, 2H), 7.96–8.46 (m, 1H), 8.00–8.16 (m, 2H). 13C NMR (75 MHz, DMSO-d 6): δ 21.2, 121.6, 122.9, 125.0, 126.2, 127.3, 129.7, 131.0, 135.0, 141.6, 154.2, 168.0., EI MS (m/z): 209.9 (M+).

-

6.

2-(4-Chlorophenyl)benzo[d]oxazole (Table 2, entry k) Mp 147–149 °C; 1H NMR (300 MHz, DMSO-d 6): δ 7.44–7.55 (d, 2H), 7.50–7.58 (m, 1H), 7.90–7.97 (d, 2H), 8.05–8.09 (m, 1H), 8.11–8.19 (m, 2H). 13C NMR (75 MHz, DMSO-d 6): δ 121.7, 123.2, 125.4, 126.5, 128.7, 129.2, 132.2, 135.1, 136.8, 154.1, 166.5., EI MS (m/z): 231.9 (M+).

Results and discussion

In order to find the best experimental conditions, the cyclocondensation between equimolar quantities of benzoic acid and 2-aminothiophenol, carried in the presence of samarium triflate, was considered as the standard model reaction. To evaluate the effect of the solvents, the model reaction was run in different solvents, namely ethanol, ethanol:water, 1,4-dioxane, acetonitrile, and toluene. To examine the catalytic efficiency of samarium triflate, the model reaction was then run in ethanol in the absence of a catalyst. There was only 35 % conversion after 8 h (Table 1, entry a). The use of ethanol as solvent gave poor yields in the presence of 5 mol% of catalyst (Table 1, entry b). Solvents like 1,4-dioxane, acetonitrile, and toluene gave moderate yields (Table 1, entries f–i). When the reaction was run in an equimolar amount of ethanol:water, the yield of benzothiazole was found to be relatively better (Table 1, entry e). Therefore, ethanol:water was selected as the solvent for this reaction and, in order to evaluate the reactivities of the different starting materials, the cyclization process was always conducted by heating to 80 °C. We carried out the same reaction using 10 mol% of samarium triflate at room temperature, but it gave a very low yield even with a longer reaction time.

After optimization, we extended the study to various 2-aminothiophenol and 2-aminophenol with aliphatic, aromatic and heteroaromatic carboxylic acids. In general, most of the reactions proceed very smoothly to give the corresponding 2-substituted benzothiazoles and benzoxazoles in moderate to excellent yields. We have also studied the electronic factor, and we assumed that electron-deficient carboxylic acids gave better yields in shorter reaction times as compared to electron-rich acids. The results are summarized in Table 2.

Here, for the first time, samarium triflate has been successfully employed to catalyze the condensation of 2-aminothiophenol/2-aminophenol and carboxylic acids in ethanol:water (2:2 mL) to yield 2-substituted benzothiazoles/benzoxazoles in moderate to good yields under mild reaction conditions. This protocol is user friendly and could be an attractive tool for the synthesis of highly functionalized bioactive benzothiazoles and benzoxazoles.

Another advantage of this method is catalytic reusability or recovery: the catalyst was removed by simple filtration, treated with ethanol and filtered. The catalyst was then dried at 100 °C for 1 h and could be reused for a second reaction. It was found that the catalytic activities of the recovered catalyst were almost the same as that of the fresh catalyst (Table 3).

Conclusion

In conclusion, a one-pot methodology has been developed for the synthesis of benzothiazole and benzoxazoles catalyzed by samarium triflate. Compared to previously reported methods, this method as mild reaction conditions, clean reaction, cost efficiency, easy work-up, easy recovery and reusability of the catalyst.

References

I. Hutchinson, M.S. Chua, H.L. Browne, V. Trapani, T.D. Bradshaw, A.D. Westwell, M.F. Stevens, J. Med. Chem. 44, 1446 (2001)

S. Aiello, G. Wells, E.L. Stone, H. Kadri, R. Bazzi, D.R. Bell, M.F. Stevens, C.S. Matthews, T.D. Bradshaw, A.D. Westwell, J. Med. Chem. 51, 5135 (2008)

B.S. Tan, K.H. Tiong, A. Muruhadas, N. Randhawa, H.L. Hoo, T.D. Bradshaw, M.F. Stevens, O. Leong, Mol. Cancer Ther. 10, 1982 (2011)

K. Wang, F.P. Guengerich, Chem. Res. Toxicol. 25, 1740 (2012)

K. Serdons, C. Terwinghe, P. Vermaelen, K. Van Laere, H. Kung, L. Mortelmans, G. Bormans, A. Verbruggen, J. Med. Chem. 52, 1428 (2009)

P.S. Yadav, D. Devprakash, G.P. Senthilkumar, Int. J. Pharm. Sci. Drug. Res. 1, 01 (2011)

D. Li, H. Zhang, C. Wang, S. Huang, J. Guo, Y. Wang, J. Mater. Chem. 22, 4319 (2012)

R. Hu, J. Feng, D. Hu, S. Wang, S. Li, Y. Li, G. Yang, Angew. Chem. Int. Ed. 49, 4915 (2010)

J.P. Davidson, E.J. Corey, J. Am. Chem. Soc. 125, 13486 (2003)

J.A. Glober, G. Dornadula, M.R. Rice, A.L. Simcoe, D.J. Hazuda, M.D.J. Miller, J. Biol. Chem. 282, 8005 (2007)

M. Ueki, K. Ueno, S. Miyadoh, K. Abe, K. Shibata, M. Taniguchi, S. Oi, J. Antibiot. 46, 1089 (1993)

J. Jiang, X. Tang, W. Dou, H. Zhang, W. Liu, C. Wang, J. Zheng, J. Inorg. Biochem. 104, 583 (2010)

P.D. Edwards, M.A. Zottola, M. Davis, J. Williams, P.A. Tuthill, J. Med. Chem. 38, 3972 (1995)

A.B. Naidu, G. Sekar, Synthesis, 579 (2010)

I. Hutchinson, S.A. Jennings, B.R. Vishnuvajjala, A.D. West well, M.F.G. Stevens, J. Med. Chem. 45, 744 (2002)

A.R. Katritzky, C.A. Ramsden, E.F.V. Scriven, R.J.K. Taylor, Comprehensive Heterocyclic Chemistry III, (Elsevier, Oxford, 2008), Vol. 4, pp. 487–543

Y.H. So, J.P. Heeschen, J. Org. Chem. 62, 3552 (1997)

D.S. Bose, M. Idrees, Synthesis, 398 (2010)

M. Lamani, K.R. Prabhu, J. Org. Chem. 76, 7938 (2011)

A.J. Blacker, M.F. Mohamed, S.P. Marsden, O. Saidi, J.M.J. Williams, Tetrahedron Lett. 50, 6106 (2009)

R.-G. Xing, Y.-N. Li, Q. Liu, Q.-Y. Meng, J. Li, X.-X. Shen, Z. Liu, B. Zhou, X. Yao, Z.-L. Liu, Eur. J. Org. Chem. 6627 (2010)

R.S. Pottorf, N.K. Chadha, M. Katkevics, V. Ozola, E. Suna, H. Ghane, T. Regberg, M.R. Player, Tetrahedron Lett. 44, 175 (2003)

R.H. Tale, Org. Lett. 4, 1641 (2002)

S. Mourtas, D. Gatos, K. Barlos, Tetrahedron Lett. 42, 2201 (2001)

A.K. Chakraborti, C. Selvam, G. Kaur, S. Bhagat, Synlett, 851 (2004)

C.P. Chen, Y.J. Chen, Tetrahedron Lett. 45, 113 (2004)

J.A. Seijas, M.P. Vazquez-Tato, M.R. Carballido-Reboredo, J. Crecente-Campo, L. Romar-Lopez, Synlett, 313 (2007)

I.R. Laskar, T.M. Chen, Chem. Mater. 16, 111 (2004)

R.N. Nadaf, S.A. Siddiqui, T. Daniel, R.J. Lahoti, K.V. Srinivasan, J. Mol. Catal. A: Chem. 214, 155 (2004)

H. Matsushita, S.H. Lee, M. Joung, B. Clapham, K.D. Janda, Tetrahedron Lett. 45, 313 (2004)

X.L. Yang, C.M. Xu, S.M. Lin, J.X. Chen, J.C. Ding, H.Y. Wu, W.K. Su, J. Braz. Chem. Soc. 21, 37 (2010)

K. Bahrami, M.M. Khodaei, F. Naali, J. Org. Chem. 73, 6835 (2008)

H.Y. Guo, J.C. Li, Y.L. Shang, Chin. Chem. Lett. 20, 1408 (2009)

M. Okimoto, T. Yoshida, M. Hoshi, K. Hattori, M. Komata, K. Tomozawa, T. Chiba, Heterocycles 75, 35 (2008)

A. Kumar, R.A. Maurya, P. Ahmad, J. Comb. Chem. 11, 198 (2009)

H.L. Xiao, J.X. Chen, M.C. Liu, D.J. Zhu, J.C. Ding, H.Y. Wu, Chem. Lett. 38, 170 (2009)

M. Abdollahi-Alibeik, S. Poorirani, Phosphorus, Sulfur Silicon Relat. Elem. 184, 3182 (2009)

M. Kodomari, Y. Tamaru, T. Aoyama, Synth. Commun. 34, 3029 (2004)

U.R. Pratap, J.R. Mali, D.V. Jawale, R.A. Mane, Tetrahedron Lett. 50, 1352 (2009)

K. Bahrami, M.M. Khodaei, A. Nejatia, Green Chem. 12, 1237 (2010)

A. Kumar, S. Sharma, R.A. Maurya, Tetrahedron Lett. 51, 6224 (2010)

S.V. Nalage, S.V. Bhosale, D.S. Bhosale, W.N. Jadhav, Chin. Chem. Lett. 21, 790 (2010)

H. Eshghi, M. Rahimizadeh, A. Shiri, P. Sedaghat, Bull. Korean Chem. Soc. 33, 515 (2012)

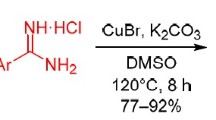

M.S. Mayo, X. Yu, X. Zhou, X. Feng, Y. Yamamoto, M. Bao, J. Org. Chem. 79, 6310 (2014)

M.S. Mayo, X. Yu, X. Zhou, X. Feng, Y. Yamamoto, M. Bao, Org. Lett. 16, 764 (2014)

C.-J. Li, B.M. Trost, Proc. Natl. Acad. Sci. USA 105, 13197 (2008)

A.V. Narsaiah, A.R. Reddy, J.S. Yadav, Synth. Commun. 41, 262 (2011)

S. Kobayashi, K. Manabe, Acc. Chem. Res. 35, 209 (2002)

A. Dzudza, T.J. Marks, J. Org. Chem. 73, 4004 (2008)

A.V. Narsaiah, A.R. Reddy, J.S. Yadav, Synth. Commun. 41, 2794 (2011)

P.B. Gorepatil, Y.D. Mane, V.S. Ingle, Synlett 24, 2241 (2013)

Acknowledgment

One of the authors, Mr. P.B. Gorepatil, is grateful to the Council of Scientific and Industrial Research (CSIR), New Delhi for a Junior Research Fellowship (JRF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gorepatil, P.B., Mane, Y.D., Gorepatil, A.B. et al. Samarium(III) triflate: a new catalyst for facile synthesis of benzothiazoles and benzoxazoles from carboxylic acids in aqueous media. Res Chem Intermed 41, 8355–8362 (2015). https://doi.org/10.1007/s11164-014-1897-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-014-1897-x