Abstract

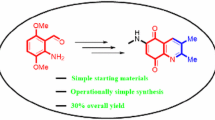

An efficient procedure for the preparation of AB ring core of luotonin A analogues has been achieved with a simple methodology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Luotonins A, 1 (Fig. 1) a novel quinazoline–quinoline alkaloid isolated from the aerial parts of Peganum nigellastrum Bunge [1] is a widely used Chinese traditional medicine to treat rheumatism, abscesses, and inflammation [2]. Similarly, luotonin A, 1a mediates topoisomerase I-dependent cytotoxicity toward Saccharomyces cerevisiae lacking yeast topoisomerase I, but harboring plasmid having the human topoisomerase I gene under the control of a galactose promoter [3]. These alkaloids are cytotoxic against mouse leukemia P-388 cells in vitro and inhibit DNA topoisomerases I and II [1, 3, 4]. This result highlights the importance of the quinoline ring for cytotoxicity. Similarly, a structural feature is also present in the topoisomerase I inhibitor camptothecin, 2 derivatives [5] which are in clinical use for cancer chemotherapy. Nevertheless, up to this point, the development of simple procedures for modified quinazolinone synthesis relied on the use of rather toxic or expensive reagents [6].

The biological activity of luotonin A raises the intriguing possibility of obtaining camptothecin-like analogs where the lactone is replaced by simpler substituted benzene derivatives [3]. Due to the moderate antitumor activity of luotonin A, and the promise of discovering greater biological activity from analogues, there have been a steadily growing number of reported procedures described for total synthesis of luotonin [3]. These considerations, coupled with our interest [7, 8] in quinazoline and quinoline ring, prompted us to embark on a synthesis of luotonin A analogues.

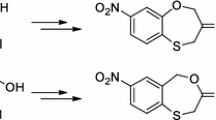

Since the initial report of the isolation of luotonin A [1, 2], different synthetic routes have been reported. Five of these routes have utilized a coupling of the pyrroloquinoline precursor and anthranilic acid derivatives as the final step [6, 9–12]. Various methods [13, 14] have been utilized for the synthesis of 1, but involved complex procedures, harsh reaction conditions, longer reaction times, expensive reagents, anhydrous solvents, and difficult work-up procedures. We developed a new approach for the synthesis of the AB ring core of luotonin A through a simple synthetic intermediate (3) from commercially available potassium phthalimide. A retro-synthetic analysis (Fig. 2) approach has been employed in designing a multistep synthesis of the target molecule such as luotonin A, 1a analogues. The requisite substrate, 3, was easily prepared in two steps as Scheme 1.

In the production of fine chemicals over heterogeneous catalysts, the choice of solvent has a crucial impact; a bad selection of the solvent leads to a complete loss of selectivity and/or activity, thus destroying the possible utilization of a potentially efficient process in practice. Therefore, the choice of a solvent and the understanding of solvent effects is of central importance, and thus requires a careful investigation. In a preliminary reaction, 2-chloro-3-(chloromethyl)7,8-dimethylquinoline, 7a treated with potassium phthalimide, 6 under reflux conditions furnished the alkylated phthalimide, 8a. To study the effect of solvent for this reaction, different solvents were used. The results of this reaction with a various solvents are summarized in Table 1, which suggest that in the presence of low polar and aqueous solvent (Table 1, Entry 1, 3) reaction proceed where as in the presence of high polar solvent the reaction yield is high (Table 1, Entry 7).

Results and discussion

Among the solvents screened, including dimethylformamide (DMF), ethanol, and ethanol/water system, the ethanol/water (Table 1, Entry 7) solvent system was the best solvent for getting higher yield. In the case of other solvents such as hexane, toluene, tetrahydrofuran (THF), and water (H2O), the reaction did not proceed (Table 1, Entry 1, 2, and 6). The reaction of potassium phthalimide, 6 and 2-chloro-3-(chloromethyl)-7,8-dimethylquinoline, 7a afford 2-[(2-chloroquinolin-3-yl)methyl]isoindoline-1,3-dione, 8a in 98% yield. The result suggests that ethanol/water (Table 1, Entry 7), i.e., as an effective solvent system for the formation of 2-[(2-chloroquinolin-3-yl)methyl]isoindoline-1,3-dione, 8a. The optimized condition has been established by the compartion of non-polar solvents (hexane, toluene), polar aprotic solvents (THF, DMF), and polar protic solvents (ethanol, H2O) with respect to the dielectric constant value. Mixing an equal ratio of ethanol and water resulted in slightly less than the total volume, which is due to intermolecular hydrogen bonding. The intermolecular hydrogen bonding between different molecules is stronger than that between the same molecules. Based on the result, we chose 1:1 of ethanol/water (Table 1, Entry 7) as an effective solvent system. In view of the recent surge in using ionic liquid as catalyst, we tried N-alkylation of potassium phthalimide, 8 using 1-methyl-3-octylimidazonium chloride ionic liquid. From the results we found that compared to ionic liquid condition, ethanol/water system was giving good yield

With the optimized reaction conditions in hand, the scope of the reaction using a variety of 2-chloro-3-chloromethylquinolines, 7a-d has been explored. The results are summarized in Table 2. Acid hydrolysis of compound, 8a–d gives 3a–d. 1H NMR spectra of the product, 8a (Fig. 3), displayed considerable confirmation exhibiting chemical shifts for -CH2 protons appears as a singlet at δ 4.96 ppm, and quinoline ring protons at C-4 appears at 8.31 ppm. Furthermore, the proton in C-5 appears at 7.75–7.72 and C-6 appears at 7.45–7.47 ppm. The two methyl groups substituted at the quinolines were obtained as a singlet at 2.47, 2.51 ppm. Acid hydrolysis of compound 8a gave 3a.

Conclusions

The AB ring core of luotonin A analogues was synthesized successfully in simple and efficient manner. In our research work, the target AB ring core will be helpful for the construction of luotonin A analogues.

Experimental section

The sources of the reagents used in this study were purchased from Aldrich Chemicals and solvents were purchased from S.D. Fine chemicals. The 2-chloro-3-chloromethylquinolines, 7 required for this study were prepared by the reported procedure (Roopan et al. 2010). The compounds were prepared, analyzed, and compared with data from the literature. Melting points were taken on an Elchem Microprocessor-based DT apparatus in open capillary tubes. IR spectra were obtained on a Nucon infrared spectrophotometer (KBr disc). NMR spectra were recorded on a Bruker 500 spectrometer and chemical shifts are reported in parts per million (δ) relative to tetramethylsilane (TMS) as an internal standard.

General procedure for the synthesis of 2-[(2-chloroquinolin-3-yl)methyl]isoindoline-1,3-diones (8a–d)

A mixture of potassium phthalimide, 6 (1.5 mmol), 2-chloro-3-chloromethylquinolines, 7a–d (1 mmol), and 3 mL of water/ethanol (1:1) mixture were heated at 80 °C for 30 min. After cooling to room temperature, a white potassium chloride residue was formed at the bottom of the flask, which was filtered. The filtrate was poured into 20 mL of water, and filtered to obtain a white crude product, 8a–d. All the products 8 were characterized by FTIR, 1H NMR, 13C NMR, and HRMS analyses.

Synthesis of 3-(aminomethyl)quinolin-2(1H)-one (3a)

To a stirred concentrated hydrochloric acid (5 mL), compound, 8 (1 mmol) was added, and refluxed for 6 h until the mixture became transparent. After cooling to room temperature, the resulting solid was filtered, and the filtrate was concentrated on a rotary evaporator. The resulting yellow residue was dissolved in 10 mL water, then adjusted the solution pH with triethylamine to produce white solid, filtered, dried by calcium chloride under vacuum at room temperature to give compound 3.

Spectral data of the newly synthesized compounds 3a–d and 8a–d are given below

3a: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,428, 2,928, 2,924, 1,651; 1H NMR (400 MHz, CDCl3):δ = 7.86 (s, 1 H), 7.4 (d, 1 H), 7.04 (d, 1 H), 5.30 (s, 1H, OH), 3.70 (s, 2H, -CH2), 2.33 (s, 3H, -CH3), 2.32 (s, 3H, -CH3); 13C NMR(100 MHz, CDCl3) δ = 162.7, 139.1, 138.1, 137.0, 125.6, 2 × 124.7, 121.7, 117.9, 52.5, 20.9, 13.1. HRMS: m/z calcd for C12H14N2O, 202.1106; found 202.1104 M+.

3a: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,428, 2,928, 2,924, 1,651; 1H NMR (400 MHz, CDCl3):δ = 7.86 (s, 1 H), 7.4 (d, 1 H), 7.04 (d, 1 H), 5.30 (s, 1H, OH), 3.70 (s, 2H, -CH2), 2.33 (s, 3H, -CH3), 2.32 (s, 3H, -CH3); 13C NMR(100 MHz, CDCl3) δ = 162.7, 139.1, 138.1, 137.0, 125.6, 2 × 124.7, 121.7, 117.9, 52.5, 20.9, 13.1. HRMS: m/z calcd for C12H14N2O, 202.1106; found 202.1104 M+.

3b: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,459, 2,921, 1,659; 1H NMR (400 MHz, DMSO-d6): δ = 7.86 (s, 1 H), 7.49–7.48 (d, 1H, J 7.5 Hz), 7.32–7.30(d, 1H, J 7.2 Hz), 7.11-7.07 (t, 1H), 5.3(s, 1H, -OH), 3.64(s, 2H, -CH2), 2.43 (s, 3H, -CH3); 13C NMR (100 MHz, CDCl3) δ = 162.2, 136.1, 135.3, 133.6, 130.6, 125.5, 123.0, 121.5, 119.2, 51.9, 17.1. LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

3b: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,459, 2,921, 1,659; 1H NMR (400 MHz, DMSO-d6): δ = 7.86 (s, 1 H), 7.49–7.48 (d, 1H, J 7.5 Hz), 7.32–7.30(d, 1H, J 7.2 Hz), 7.11-7.07 (t, 1H), 5.3(s, 1H, -OH), 3.64(s, 2H, -CH2), 2.43 (s, 3H, -CH3); 13C NMR (100 MHz, CDCl3) δ = 162.2, 136.1, 135.3, 133.6, 130.6, 125.5, 123.0, 121.5, 119.2, 51.9, 17.1. LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

3c: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,445, 2,922, 1,650; 1H NMR (400 MHz, CDCl3): δ = 7.71 (s, 1H), 7.41 (d, 1H), 7.03–7.00 (d, 2H, J 8.8 Hz), 5.70 (s, 1H, -OH), 3.88 (s, 2H, -CH2), 2.44 (s, 3H). LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

3c: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,445, 2,922, 1,650; 1H NMR (400 MHz, CDCl3): δ = 7.71 (s, 1H), 7.41 (d, 1H), 7.03–7.00 (d, 2H, J 8.8 Hz), 5.70 (s, 1H, -OH), 3.88 (s, 2H, -CH2), 2.44 (s, 3H). LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

3d: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,420, 2,914, 1,628; 1H NMR (400 MHz, CDCl3): δ = 7.84 (s, 1H), 7.52–7.50 (d, 1H, J 8 Hz), 7.09 (s, 1H), 7.01–6.99 (q, 1H), 5.3 (s, 1H, -OH), 3.65 (s, 2H, -CH2), 2.48 (s, 3H, -CH3); 13C NMR(400 MHz, CDCl3): δ = 161.8, 139.6, 138.0, 135.5, 131.2, 127.3, 123.2, 116.9, 114.6, 51.9, 21.3. LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

3d: White solid: IR, \( \tilde{\nu } \)/cm−1: 3,420, 2,914, 1,628; 1H NMR (400 MHz, CDCl3): δ = 7.84 (s, 1H), 7.52–7.50 (d, 1H, J 8 Hz), 7.09 (s, 1H), 7.01–6.99 (q, 1H), 5.3 (s, 1H, -OH), 3.65 (s, 2H, -CH2), 2.48 (s, 3H, -CH3); 13C NMR(400 MHz, CDCl3): δ = 161.8, 139.6, 138.0, 135.5, 131.2, 127.3, 123.2, 116.9, 114.6, 51.9, 21.3. LCMS: m/z calcd for C11H12N2O, 188.0949; found 188 M+.

8a: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,927, 1,771, 1,707; 1H NMR (500 MHz, DMSO-d6):δ = 8.31 (s, 1H), 7.96–7.94 (m, 2H), 7.91–7.88 (m, 2H), 7.75–7.72 (d, J = 8.3 Hz, 1H), 7.47–7.45 (d, J = 8.3 Hz, 1H), 4.96 (s, 2H, -CH2), 2.61 (s, 3H), 2.47 (s, 3H); 13C NMR(125 MHz, DMSO-d6) δ 167.6, 147.2, 145.3, 138.3, 137.3, 134.5, 4 × 132.6, 131.8, 130.1, 2 × 126.2, 125.3, 124.7, 123.3, 63.9, 20.2, 12.9. HRMS: m/z calcd for C20H15ClN2O2, 350.0820; found 350.0822 M+.

8a: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,927, 1,771, 1,707; 1H NMR (500 MHz, DMSO-d6):δ = 8.31 (s, 1H), 7.96–7.94 (m, 2H), 7.91–7.88 (m, 2H), 7.75–7.72 (d, J = 8.3 Hz, 1H), 7.47–7.45 (d, J = 8.3 Hz, 1H), 4.96 (s, 2H, -CH2), 2.61 (s, 3H), 2.47 (s, 3H); 13C NMR(125 MHz, DMSO-d6) δ 167.6, 147.2, 145.3, 138.3, 137.3, 134.5, 4 × 132.6, 131.8, 130.1, 2 × 126.2, 125.3, 124.7, 123.3, 63.9, 20.2, 12.9. HRMS: m/z calcd for C20H15ClN2O2, 350.0820; found 350.0822 M+.

8b: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,923, 1,710, 1,649; 1H NMR (500 MHz, DMSO-d6):δ = 7.94–7.91 (dd, 3 H), 7.80–7.77 (dd, 2H), 7.56 (t, 2 H), 7.43–7.41 (d, 1 H), 5.13 (s, 2 H, -CH2), 2.76 (s, 3H). HRMS: m/z calcd for C19H13ClN2O2, 336.0656; found 336.0666 M+.

8b: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,923, 1,710, 1,649; 1H NMR (500 MHz, DMSO-d6):δ = 7.94–7.91 (dd, 3 H), 7.80–7.77 (dd, 2H), 7.56 (t, 2 H), 7.43–7.41 (d, 1 H), 5.13 (s, 2 H, -CH2), 2.76 (s, 3H). HRMS: m/z calcd for C19H13ClN2O2, 336.0656; found 336.0666 M+.

8c: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,917, 1,770, 1,710; 1H NMR (500 MHz, DMSO-d6):δ = 7.94–7.92 (dd, 3 H), 7.81–7.78 (dd, 3H), 7.65–7.62 (d, 1H, J 8.3 Hz), 7.38–7.35 (d, 1H, J 8.5 Hz), 5.11 (s, 2H, -CH2), 2.54 (s, 3H). HRMS: m/z calcd for C19H13ClN2O2, 336.0648; found 336.0656 M+.

8c: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,917, 1,770, 1,710; 1H NMR (500 MHz, DMSO-d6):δ = 7.94–7.92 (dd, 3 H), 7.81–7.78 (dd, 3H), 7.65–7.62 (d, 1H, J 8.3 Hz), 7.38–7.35 (d, 1H, J 8.5 Hz), 5.11 (s, 2H, -CH2), 2.54 (s, 3H). HRMS: m/z calcd for C19H13ClN2O2, 336.0648; found 336.0656 M+.

8d: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,923, 2,856, 1,771, 1,712; 1H NMR (500 MHz, DMSO-d6): δ = 7.94–7.87 (m, 4H), 7.81–7.78 (dd, 2H), 7.52 (d, 2H), 5.12 (s, 2H, -CH2), 2.49 (s, 3H); 13C NMR(125 MHz, DMSO-d6): δ = 168.1, 147.8, 145.2, 137.6, 136.9, 135.0, 133.3, 4 × 132.3, 128.0, 2 × 127.6, 127.4, 127.1, 123.8, 63.1 21.5. HRMS: m/z calcd for C19H13ClN2O2, 336.0653; found 336.0656 M+.

8d: White solid: IR, \( \tilde{\nu } \)/cm−1: 2,923, 2,856, 1,771, 1,712; 1H NMR (500 MHz, DMSO-d6): δ = 7.94–7.87 (m, 4H), 7.81–7.78 (dd, 2H), 7.52 (d, 2H), 5.12 (s, 2H, -CH2), 2.49 (s, 3H); 13C NMR(125 MHz, DMSO-d6): δ = 168.1, 147.8, 145.2, 137.6, 136.9, 135.0, 133.3, 4 × 132.3, 128.0, 2 × 127.6, 127.4, 127.1, 123.8, 63.1 21.5. HRMS: m/z calcd for C19H13ClN2O2, 336.0653; found 336.0656 M+.

References

Z.-Z. Ma, Y. Hano, T. Nomura, Y.-J. Chen, Heterocycles 46, 541 (1997)

X.-H. Xiao, G.-L. Qou, H.-L. Wang, L.-S. Lui, Y.-L. Zheng, Z.-J. Jia, Z.-B. Dreng, Zhongguo Yaolixue Yu Dulixue Zazhi 2, 232 (1998)

A. Cagir, S.H. Jones, R. Gao, B.M. Eisenhauer, S.M. Hecht, J. Am. Chem. Soc. 125, 13628 (2003)

Z. Ma, Y. Hano, T. Nomura, Y. Chen, Bioorg. Med. Chem. Lett. 14, 1193 (2004)

W.J. Stichenmyer, E.K. Rowinsky, R.C. Donehower, S.H. Kautmann, J. Nat. Caner Inst. 85, 271 (1993)

E.S. Lee, J.-G. Park, Y. Jahng, Tetrahedron Lett. 44, 1883 (2003)

S.M. Roopan, T. Maiyalagan, F.N. Khan, Can. J. Chem. 86, 1019 (2008)

S.M. Roopan, F.N. Khan, ARKIVOC xiii, 161 (2009)

D. Osborne, P.J. Stevenson, Tetrahedron Lett. 43, 5469 (2002)

S. Dallavalle, L. Merlini, Tetrahedron Lett. 43, 1835 (2002)

J.S. Yadav, B.V.S. Reddy, Tetrahedron Lett. 43, 1905 (2002)

H. Wang, A. Ganesan, Tetrahedron Lett. 39, 9097 (1998)

T.R. Kelly, S. Chamberland, R.A. Silva, Tetrahedron Lett. 40, 2723 (1999)

Z.-Z. Ma, Y. Hano, T. Nomura, Y.-J. Chen, ChemInform 30 (1999)

Acknowledgements

This work was supported by the Department of Science & Technology Government of India (Grant No. SR/FTP/CS-99/2006). We also acknowledge SAIF, IIT Madras, Chennai, for providing NMR and MS facility. The authors are thankful to the VIT University management for their generous support and facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roopan, S.M., Nawaz Khan, F. & Jin, J.S. Efficient synthesis of AB ring core of luotonin A derivatives: (2-chloroquinolin-3-yl)methanamine. Res Chem Intermed 38, 443–451 (2012). https://doi.org/10.1007/s11164-011-0361-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-011-0361-4