A geometric model is constructed of the complete profile for a cavity cut in Al2O3–TiC ceramic specimens. The effect is established for the main production parameters of a pulsed laser treatment regime on geometric characteristics of cavities cut in ceramic specimens.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The present article is a continuation of work for studying pulsed laser cutting of cavities in Al2O3–TiC ceramic specimens [1] The aim of the present stage of the work is a study of the effect of production parameters of a pulsed laser treatment regime on geometric characteristics of cavities cut in ceramic specimens. The importance of revealing these correlations is determined from conclusions from work in [2,3,4,5].

Research was conducted in two stages. In the first stage a geometric model was constructed of the complete profile of a cut cavity in Al2O3–TiC ceramic specimens on the basis of conclusions formulated previously [1]. According to these conclusions cavities cut in ceramic specimens consist of outer and inner regions, whose sizes are connected with parameters of the pulsed laser action cutting regime. In the second stage with use of results of experimental studies the effect of the main production parameters of the pulsed laser treatment regime on geometric characteristics of cavities cut in ceramic specimens have been established. Regimes for performing these experiments are provided in Table 1.

Measurement of the geometric characteristics of cut cavities was conducted in their central section of a length of 1.5 mm with a pitch of 0.3 mm. A MarSurf LD120 contour-polygraph (tracing force 0.01 N, speed 0.02 mm/min) and a VEGA 3 LMH scanning electron microscope were used. The average value of geometric characteristics for each cavity was calculated from the results of 36 measurements (6 measurements for each side of a cavity ×2 sides in each specimen ×3 of a duplicate specimen).

Results and Discussion

The marked effect of production parameters of pulsed laser treatment cutting regime on the shape and dimensions of cavities, cut in Al2O3–TiC ceramic specimens is shown in Fig. 1. It is seen that the width and depth of cavities varies over a wide range, and during cutting of a cavity with a pitch of laser beam movement exceeding the diameter of its spot in a treated surface there is only formation of a collection of craters.

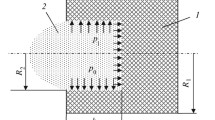

On the basis of studying the general features of the cavity cutting process in specimens of Al2O3–TiC ceramic [1] a geometric model has been constricted for the complete cavity profile (Fig. 2). This model includes the outer and inner regions of a cavity, which are separated by a conditional boundary. The form of the outer region of a cavity fedabcb1a1c1d1e1f1 is determined by the following geometric characteristics: depth of the outer region h1, bead height h3, cavity with l1, bead width l2, and excrescence width l3. The inner region of a cavity bcb1 is specified by channel depth h2. The geometric characteristics of a cavity are connected into a system with use of an original surface 1, excrescence surface 2, bead surface 3, and bottom of the outer region of a cavity and channel bottom.

With use of research procedures developed [1] the effect of production parameters of the pulsed laser treatment regime on geometric characteristics of cavities in Al2O3–TiC ceramic specimens was revealed. The main results of these studies are shown in Fig. 3. It should be noted that in intensive regimes there is an increase in stochastic nature of the process of reaction of pulsed laser radiation with a hard and brittle ceramic, as a result of which there is an increase in scatter of measured values of geometric parameters of cut cavities.

It has been established that the effect of laser pulse power on cavity geometric characteristics is identical, i.e., with an increase in P there is an increase in h1, h2, h3, l1, l2, and l3, although the nature of this effect is different for each dependence (see Fig. 3a). The greatest effect appears on channel depth, forming the inner cavity, and the least on bead height. On P – h1 and P – l1 curves there are two characteristic sections. In the first section (P increases from 2.5 to 5 W) h1 and l1 increase sharply, and in the second section (P increases from 5 to 15 W) h1 and l1 increase smoothly and in the range 12 – 15 W they are almost unchanged. For example, an increase in the value of h1 in the first section of the corresponding curve, obtained during treatment with s = 20 μm, n = 1000, and N = 5 passes, comprises a factor of 3.5, and in the second section a factor of 1.3. Simultaneously with this depth h2 in the first section of the corresponding curve increases from 21 to 66 μm (increase by a factor of 3.1), and in the second section from 66 to 175 μm (increase by a factor of 2.7).

The effect is shown in Fig. 3 of the pitch of a moving laser beam s (P = 5 W, n = 1000, and N = 5 passes) on the dimensions of the cavity profile. It is seen that the effect of movement pitch of a laser beam on geometric characteristics of a cavity is more complex compared with its power. With an increase in s in the range 8 – 20 μm h1 increases from 58 to 81 μm and l1 increases from 41 to 54 μm. A further increase in s from 20 to 50 μm leads to a reduction in h1 and l1. In contrast to this effect, l2 and l3 initially decrease and then increase. The most simple effect of laser beam movement pitch s appears on depth of the inner cavity h2 and excrescence width h3. Curves s – h2 and s – h3 have a linear character and with an increase in s in the range 8 – 50 μm h2 and h3 decrease by 42 and 10%.

The effect of number of pulses in a package n (P = 5 W, s = 20 μm, and N = 1 pass) on geometric parameters of a cavity is shown in Fig. 3a. It has been established that with an increase in the number of pulses is a package in the range from 100 to 1000 the values of h1, h2, h3, l1, l2, and l3 increase linearly, and the greatest effect of n appears in a change in h2 and least in h3.With an increase in n from 100 to 1000 values of h1, h3, l1, l2, and l3 increase from 33 to 53, from 4.4 to 5.9, 34 to 40, from 6 to 9, and from 19 to 27 μm respectively. It should be noted that in cutting cavities with a number of pulses in a package of 1000, channels forming the inner surface of a cavity are not formed. Formation of these channels is recorded during treatment in a regime with a number of pulses in a package of 500 or more.

Dependences specifying the effect of number of passes in a cycle N (P = 5 W, n = 1000 pul, s = 20 μm) on the dimensions of the cavity profile are shown in Fig. 3d. It has been established that with a change in N from 2 to 100 passes the cavity profile dimensions increase, and the degree of the effect varies. The greatest effect of number of pulses during laser cutting of cavities appears in l2 and l3, and the least in h3. On curves N – h1, N – l1, N – h2, N – l2, N – l3, specifying cavity dimensions, there are two characteristic sections. In the first section (N increases from 2 to 10 passes) h1, l1, h2, l2, and l3, increase sharply. In the second section h1 increases from 68 to 86 (increase by a factor of 1.3), h2 from 59 to 74 (increase by a factor of 1.3), h3 from 6.4 to 8.3 (increase by a factor of 1.3), l1 from 48 to 60 (increase by a factor of 1.3), l2 from 31 – 38 (increase by a factor of 1.2), and l3 from 49 to 83 (increase by a factor of 1.7). In the second section (N from 10 to 1000 passes) h1, h2, h3, l1, l2 increase on average by 10%, and l3 increases by a factor of 1.5.

Conclusion

As a result of these studies a correlation has been revealed for production parameters of a pulsed laser treatment regime with geometric characteristics of cavities cut in Al2O3–TiC-ceramic specimens. It has been established that intensification of a pulsed laser action regime increases instability of the process and in the majority of cases leads to an increase in cavity profile dimensions. An exception is a change in the pitch of laser beam movement: an increase in this production parameter in the range from 8 to 50 μm leads to a reduction in channel depth h2, and in the range from 20 to 50 μm a reduction is recorded in the depth of outer region h1 and cavity width l1. The depth of the inner region of cut cavities may exceed the depth of their outer region in more intensive treatment regimes. In the case of a low number of pulses in a laser radiation package a cut cavity is only specified by the outer region with absence of an inner region.

Change history

25 May 2019

The Acknowledgement on page 289 should read

25 May 2019

The Acknowledgement on page 289 should read

References

V. V. Kuzin, S. N. Grigor’ev, M. Yu. Fedrorov, and E. A. Ostrikov, “Physicotechnological aspects of pulsed laser cutting of cavities in ceramic. General process characteristics,” Novye Ogneupory, No. 3, 64 – 68 (2018).

L. Rihakova and H. Chmelickova, “Laser micromachining of glass, silicon and ceramics. A review,” Eur. Int. J. Sci. Technol., 4(7), 41 – 49 (2015).

V. V. Kuzin, S. N. Grigor’ev, M. Yu. Fedorov, M. R. Portnoi, et al., “Effect of pulsed laser radiation on the surface of ceramic VOK71,” Refract. Indust. Ceram., 56(4), 390 – 393 (2015).

E. D. Vaks, M. N. Milen’kii, and L. G. Saprykin, Precision Laser Treatment Practice [in Russian, Tekhnosfera, Moscow (2013)

X. Chen, L. Ji, Y. Bao, and Y. Jiang, “Improving cutting quality by analysis of microstructure characteristics and solidification behaviour of recast layer formation on laser cut ceramic,” J. Eur. Ceram. Soc., 32(10), 2203 – 2211 (2012).

Work was conducted with financial support of the RF Ministry of Education and Science within the scope of fulfilling a state assignment within the sphere of scientific activity (task No. 2014/105, project No. 1908).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 5, pp. 66 – 68, May, 2018.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N., Fedorov, M.Y. et al. Physical and Technological Aspects of Precision Laser Treatment of Ceramic Materials. Effect of Treatment Regime. Refract Ind Ceram 59, 287–289 (2018). https://doi.org/10.1007/s11148-018-0222-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0222-4