Abstract

Herein, the C60/Cd0.5Zn0.5S (C60/CZS) photocatalysts with excellent photocatalytic performance were prepared using facile one-pot hydrothermal method. The crystal structure, morphology, photoelectric performance and photocatalytic activity of the samples were characterized by XRD, XPS, UV–Vis and electrochemistry. The catalytic degradation of pollutants under the irradiation of visible light was simulated using Rhodamine B (Rh B). The content of C60 was changed from 0.5 to 5 wt%, and the optimal value for the photocatalytic activity was determined to be 2 wt%. The apparent degradation rate and degradation efficiency of Rh B were 0.024 min−1 and 97.5% within 140 min, which is 3.4 times that of pure CZS. C60/CZS exhibited excellent catalytic performance, and its photocatalytic activity was sustained even after three cycles. Moreover, electrochemical test results demonstrated that the separation and transfer of photocarriers on CZS surface were effectively improved by C60, thus enhancing its activity. In this study, we innovatively prepared a novel photocatalyst by combining fullerenes with sulfide solid solution for the first time, which has rarely been studied in the past. The synthetic method is simple, efficient and pollution-free. Subsequently, the catalytic degradation of Rh B experiment confirmed that the catalyst has high catalytic efficiency and stability. This experiment has practical significance not only for the catalytic degradation of Rh B but also for the application of fullerene in photocatalysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid developments in technology have greatly improved people’s lives. However, environmental pollution has emerged as a serious global concern. For decades, numerous efforts have been made on environmental remediation [1, 2]. Several solutions have emerged from scientific efforts, among which photocatalysis is very simple, cheap, with the ability to use solar energy directly [3]. There are many efficient photocatalysts, among which cadmium sulfide (CdS) is widely explored with a suitable band gap of 2.45 eV and coincides with the visible region of sunlight [4,5,6]. There are two critical disadvantages that limit the further application of CdS photocatalysts—a high photogenerated electron–hole pair recombination rate and photocorrosion problem [7,8,9].

The CdZnS solid solutions consisting of narrow-bandgap CdS and wide-bandgap ZnS are effective in solving the aforementioned concerns [10, 11]. As a typical alloy sulfide semiconductor, a CdZnS solid solution photocatalyst reacts to visible light and have a greater negative conduction band (CB) position and corrected valence band (VB) position [12, 13]. In addition, the ratio of Cd to Zn regulates the band structure [14, 15]. Tang et al. [16] used cadmium, zinc, and thiourea as precursors and PVP as a surfactant to obtain CdZnS nanospheres by a hydrothermal method at 150 °C. Numerous experiments have been conducted to confirm that when the proportion of Cd and Zn is equal, Cd0.5Zn0.5S shows the best catalytic performance [17,18,19]. However, the photocatalytic efficiency of ZnxCd1−xS can still be improved. Doping with other substances is generally considered to be an efficient method to achieve the same outcome [20, 21]. The heterojunction structure inhibits the photoinduced electron–hole recombination probability and improves the catalytic efficiency effectively.

Fullerene (C60), composed of 60 carbon atoms, is the third allotrope of carbon. It is a football-like nanomolecule with a 32-hedron structure, 0.7 nm molecular diameter, and 1 nm van der Waals diameter. Its lowest unoccupied molecular orbital energy is low, and it can reversibly accept one to six electrons in the solid and solution [22, 23]. Therefore, C60 can be used as an electron library for absorbing and releasing electrons and has a rich chemical reactivity. In addition, the highly symmetric large π-conjugated bond system and conical arrangement of carbon atoms enable C60 to effectively separate photogenerated charges and recombine charges relatively slowly during electron transport [24,25,26]. Hence, C60, as a potential photosensitive material, can be compounded with semiconductor photocatalytic materials to improve the separation and migration of photogenerated charges, thereby enhancing the photocatalytic activity. Using the Bi2WO6 photocatalyst modified by C60, it was found that the Rhodamine B (Rh B) and MB dyes have high degradation efficiency under visible light and sunlight and focus on the synergistic effect [27]. The synthesized complex using a hydrothermal method showed a greater degradation efficiency than pure TiO2 under visible light, and studied different photocatalytic mechanisms under different light sources [28]. Thus, C60 enhanced Zn–Cd matrix composites have high photocatalytic activity and stability, which has a huge market demand.

Herein, we report a facile one-pot hydrothermal preparation method for a C60/Cd0.5Zn0.5S nanocomposite and study its photocatalytic performance under visible light irradiation, where the quantity of C60 varied from 0.5 to 5 wt% (0.5%, 1%, 2%, and 5%), and the optimal value for photocatalytic activity was proved to be 2 wt%. This novel C60/Cd0.5Zn0.5S nanocomposite exhibits immense potential for environmental modification.

Experimental

Materials

Cd(CH3COO)2.2H2O, Zn(CH3COO)2, CH4N2S, and C60 were got from Aladdin Reagent Company (Shanghai, China). Deionized (DI) water used here was obtained from laboratories.

Preparation of C60/Cd0.5Zn0.5S nanocomposites

The first acidizing treatment of C60 was implemented before synthesizing nanocomposites for higher dispersity. First, 100 mg raw C60 was evenly mixed in 40 mL of mixed acid (H2SO4:HNO3 = 3:1) and dispersed for a period of time at room temperature. It was then placed in a three-necked bottle for stirring and acidification at 60 °C for 4 h. Finally, it was diluted and washed by DI water several times until the pH was 7. The product was then placed back into the oven for drying, so as to obtain acidified C60.

C60/Cd0.5Zn0.5S nanocomposites were synthesized via the hydrothermal reaction. Subsequently, 3 mmol of Cd(CH3COO)2.2H2O, 3 mmol of Zn(CH3COO)2, 7 mmol of CH4N2S, and C60 dissolved in 60 mL of deionized water and were vigorously stirred for 30 min. Then, a homogeneous suspension was created and moved to a high-temperature and high-pressure reaction kettle and kept at 180 °C for 12 h. The autoclave was then dropped to indoor temperature. The yellow precipitate was centrifugally many times and then maintained in a 70 °C vacuum oven for 24 h. The weight percentage of C60 was set as 0.5%, 1%, 2%, and 5% to explore its effect on the photocatalytic activity of C60/Cd0.5Zn0.5S nanocomposites. The obtained samples were labelled as 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS.

Characterization

The patterns of X-ray diffraction (XRD) and the UV–Vis absorption spectrum were obtained by a Palmer naco diffractometer (Empyrean, Netherlands) with Cu Kα radiation and a UV–Vis spectrophotometer (Lambda 750S, USA). The Fourier transform infrared (FT-IR) spectra and X-ray photoelectron spectroscopy (XPS) were measured using a Nexus FT-IR spectrometer, and an ESCALAB 250Xi X-ray photoelectron spectrometer. The Brunauer–Emmett–Teller (BET) surface area was determined by a multipoint BET method using adsorption data in the relative pressure (P/P0) range of 0.05–0.3. The CHI 660 B electrochemical system (Shanghai, China) was applied to carry out electrochemical impedance spectroscopy (EIS) and photocurrent measurements with a standard three-electrode cell system.

Photocatalytic degradation of Rh B

Through the Rh B aqueous solution degradation under the irradiation of visible light, the photocatalytic activities of the C60/Cd0.5Zn0.5S nanocomposites (or Cd0.5Zn0.5S reference) were determined. To be specific, the photocatalyst prepared by 30 mg was ultrasonic dispersed in 60 mL of Rh B solution (10 mg/L), which was maintained with a 300 W xenon lamp and a 420 nm cut-off filter offering visible light. The suspension was magnetized and stirred for 30 min in the dark to obtain the adsorption–desorption balance, before the lamp was turned on. After a certain period of irradiation, an appropriate amount of reaction solution was collected, while the photocatalyst and Rh B solution were separated through vacuum suction filtration. Rh B solution concentration was measured using with the 554 nm absorbance UV–Vis spectrometer. The photocatalytic degradation of each sample follows the non-linear least squares fitting equation:

A is the amplitude of the process, C is the concentration of reactant after degradation of Rh B, E is the end point, and k is the degradation rate constant[29].

Results and discussion

XRD characterization

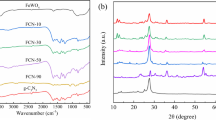

The XRD pattern of the C60/CZS nanocomposites with different C60 composition ratios were shown in Fig. 1a. The diffraction peaks at 24.8°, 26.5°, 28.2°, 36.6°, 43.7°, 47.8°, and 52.8° correspond to the (100), (002), (101), (102), (110), (103), and (201) crystal surfaces of Cd0.5Zn0.5S. This is consistent with the standard card (JCPDS No. 49-1302), indicating that the synthesis of hexagonal Cd0.5Zn0.5S is successful. In addition, the pattern showed no change after the introduction of C60, indicating that its introduction did not change the crystal structure of CZS. Fig. 1b presents a partially enlarged view of the XRD patterns from 10° to 22°. The content of C60 is low (≤ 1 wt%), and the diffraction peak is not obvious. However, three peaks at 10.8° (111), 17.7° (200), and 20.8° (311) were obtained with 2 wt% C60. It can be labeled as the cubic phase of C60 (JCPDS No. 44-0558), confirming that C60/CZS was synthesized.

a X-ray diffractometer pattern of CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS(XRD condition: Empyrean, 10°–60°, 10°/min) b local X-ray diffractometer pattern of CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS from 10° to 22° (1) Cd0.5Zn0.5S; (2) 0.5C60/CZS; (3) 1C60/CZS; (4) 2C60/CZS; (5) 5C60/CZS

XPS profiles

X-ray photoelectron spectroscopy profiles were recorded to explore the chemical properties of C60/CZS nanocomposites. XPS measurements were used to research the chemical state of the constituent elements and chemical composition of 2C60/CZS nanocomposites (Fig. 2). The XPS survey spectrum results demonstrated that the sample contained C, S, Cd, and Zn (Fig. 2a). The peaks of C1s appeared at 284.3 eV, 286.0 eV and 289.3 eV, among which the peak at 284.3 eV belongs to the adventitious carbon and C60 (Fig. 2b). The peak at 286.0 eV is portioned to the oxidized C–O, as produced by oxidizing the defective sp2− hybridized C60. Furthermore, the peak at 289.3 eV was supposed to be caused from carboxyl carbon (C = C–O) [30]. Fig. 2c and d show the XPS profiles of the Cd 3d and Zn 2p orbitals, respectively, with the binding energies of the Cd 3d orbital are at 406.0 eV, 411.3 eV and the Zn 2p at 1021.8 eV, 1044.9 eV, distinctly different from those for pure ZnS and CdS combination on the corresponding orbit. Therefore, it was concluded that the prepared catalyst was a metal complex sulfide, not pure ZnS and CdS mixture. Additionally, the interaction between metals caused differences in the binding energy. As suggested by the S 2p peaks at 161.0 eV and 162.2 eV, the common form of existing S in Cd0.5Zn0.5S is S2− (Fig. 2e).

UV–Vis diffuse reflectance spectrum

The UV–Vis spectra for different ratios in the C60/CZS composite were determined (Fig. 3a). The absorption band edge of CZS is at 490 nm, which is consistent with its direct bandgap (2.4 eV). Consequently, visible light can be directly used for the catalytic reaction. Compared with pure CZS, the absorption band edge of each C60/CZS sample shows barely any change, indicating that the carbon atoms in C60 do not enter the lattice of CZS and are bonded only by physical adsorption. In addition, the bandgap width of each C60/CdS sample as calculated using the Kubelka–Munk [31] method is almost equal to that of pure CZS (Fig. 3b), indicating that the introduction of C60 will not affect the bandgap width of CZS but only slightly enhance the light absorption ability.

a Ultraviolet visible diffuse reflectance spectra of CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS b band gap width of CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS(UV–Vis diffusion spectroscopy condition: Lambda 750 S, Wavelength range: 200–750 nm, Absorption ratio reference: BaSO4; Eg calculation formula: [(αhν)1/n = A(hν−Eg)], n = 1/2)

Photocatalytic activity and stability

The photocatalytic degradation of Rh B under visible light irradiation was explored and the photocatalytic reaction of the as-obtained samples was determined. Degradation efficiency of the C60/CZS photocatalysts with various C60 mass ratios were shown in Fig. 4a presents. In the adsorption stage, the decolorization rates of Cd0.5Zn0.5S, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS to Rh B are 15.4%, 17.2%, 23.2%, 24%, and 22%. The adsorption rate of C60/CZS is slightly higher than that of CZS. This may be because C60/CZS has a slightly larger surface area than CZS. During the photocatalysis, the degradation rates of all C60/CZS catalysts for Rh B were much higher compared with pure Cd0.5Zn0.5S. Additionally, the photocatalytic degradation rate of 2C60/CZS for Rh B was the highest, reaching 97.5%. In comparison, it was 61% for pure Cd0.5Zn0.5S, 86.3% for 0.5C60/CZS, 89.5% for 1C60/CZS, and 93% for 5C60/CZS. Thus, it can be confirmed that 2 wt% was the optimum.

a Photocatalytic degradation of RhB by CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS. b Recycling experiments of visible-light photocatalytic degradation of RhB over the 2C60/CZS(experimental conditions: [Rh B]0 = 10 mg/L, catalyst dose = 30 mg, vsolution = 60 mL, 300 W xenon lamp, λ > 420 nm, illumination time: 100 min)

The entire photocatalytic degradation process conforms to non-linear least squares fitting equation [32]. The rate constant (k), standard deviation (σ) and correlation coefficient value (R2) of CZS, 0.5C60/CZS, 1C60/CZS, 2C60/CZS, and 5C60/CZS are shown in Table 1. Obviously, 2C60/CZS composite has the highest rate constant. The introduction of C60 increases k. The apparent reaction rate of 2C60/CZS photocatalyst was the highest, which is 3.4 times than that of pure Cd0.5Zn0.5S (0.024 min−1 vs. 0.007 min−1) (Fig. 4a). It indicated that medicated C60 had the ability to efficiently increase the photocatalytic activity of Cd0.5Zn0.5S photocatalysts. Subsequently, the photocatalytic stability of the 2C60/CZS photocatalysts was determined for comparison. The catalytic efficiency of the catalyst toward Rh B was essentially unchanged after three cycles, suggesting that the catalyst owned a good cyclic stability (Fig. 4b). In addition, some similar studies on the catalytic degradation of Rh B were sorted out and compared with this study (Table 2).

Mechanisms of the increase of photocatalytic activity and stability

In general, luminous surface absorptivity, surface property, and the efficiency of photo charge separation are the determining factors for the photocatalytic activity. Surface properties are usually expressed in terms of specific surface area. The larger the specific surface area, the better the general catalytic effect. The catalytic efficiency of pure CZS nanocrystals can be improved via C60 decoration. As shown in Fig. 3a, the absorption of visible light by C60/CZS nanocomposites saw a small increase. The specific surface area of 2C60/CZS is only slightly higher than that of CZS (41.3 m2/g vs. 38.4 m2/g) (Fig. 5). The specific surface areas of other samples are 38.6 m2/g (0.5C60/CZS), 39.6 m2/g (1C60/CZS) and 41.6 m2/g (5C60/CZS). Thus, it can be deduced that the effective charge separation and transfer is the leading factor for the high activity, and that the other two factors have little effect.

A photocatalytic mechanism for the composite photocatalyst was made out according to the above experimental results and considering the properties of C60. The VB electrons of CZS semiconductors can be stirred up to the CB after absorbing enough photon energy under visible light irradiation, which makes the VB generate holes (h+). However, it is inevitable that some photocarriers will recombine quickly and cannot participate in the catalytic reaction. When C60 is introduced into the composite system, it can attract photogenerated electrons from the CB of CZS to migrate to the surface, as the CB position of CZS is more negative than that of C60 [23]. Thus, the separation of photogenerated electrons and holes on the CZS surface can be effectively enhanced, resulting in more catalytically active species being involved in the catalytic reaction. Besides, the photogenerated holes in the VB of CZS transferred to C60 spontaneously, thus preventing the oxidation of CZS by holes. In this experiment, when C60/CZS was used for Rh B photocatalytic degradation, the photogenerated electrons converted the adsorbed O2 into O2− active species, which decomposing Rh B into small molecules. Rh B was also oxidized by photogenerated holes in the VB of CZS [39]. Hence, the C60/CZS composite photocatalyst showed excellent photocatalytic activity and stability.

To further verify the mechanism of enhanced photocatalytic activity and stability, the transient photocurrent response (i−t test) and EIS profiles of Cd0.5Zn0.5S and 2C60/CZS were recorded. It is known that the photocurrent reflects the separation properties of light-generated electrons and holes. When the photocurrent is high, the separation efficiency would be high. Fig. 6 shows the transient photocurrent response of pure CZS and 2C60/CZS. The photocurrent density of Cd0.5Zn0.5S was higher compared to 2C60/CZS, even though the photocurrent of both samples is relatively stable. This suggests that the photogenerated electron–hole separation efficiency is higher in C60/CZS, and more electrons and holes will join the catalytic reaction, thus improving the catalytic efficiency. Besides, the EIS results (Fig. 7) also suggested that the C60/CZS system performed better interfacial charge separation and transfer [40]. Accordingly, it was expected that the photocatalytic performance of C60/CZS was better.

Transient photocurrent responses of the Cd0.5Zn0.5S and 2C60/CZS samples (instrument: CHI 660B electrochemical system, test system: standard three-electrode cell system, working electrode: C60/CZS, counter electrode: platinum wire, reference electrode: Ag/AgCl (saturated KCl), electrolyte: 0.1 M Na2SO4, radiation

Nyquist plots of the Cd0.5Zn0.5S and 2C60/CZS samples (instrument: CHI 660B electrochemical system, test system: standard three-electrode cell system, working electrode: C60/CZS, counter electrode: platinum wire, reference electrode: Ag/AgCl (saturated KCl), electrolyte: 0.1 M Na2SO4, radiation

Conclusion

In this study, we synthesized C60/Cd0.5Zn0.5S nanocomposites by a facile one-pot hydrothermal preparation method. The degradation efficiency of Rh B was evaluated under visible light irradiation, and the results showed that the catalytic efficiency of C60/CZS was better than that of pure CZS. The optimum content of C60 was determined to be 2% when the catalytic efficiency was the highest; the optimal apparent degradation rate of Rh B was 0.024 min−1 (degradation efficiency of 97.5%), which is 3.4 times that of the pure CZS reference. Moreover, the cyclic stability of the composites was excellent, and their photocatalytic activity was well maintained after three cycles. The photocurrent measurement and EIS results showed that the introduction of C60 can efficiently promote the separation and transfer of photoexcited charge carriers, which in turn can improve the catalytic efficiency. Herein, we innovatively synthesized a novel photocatalyst by combining C60 with sulfide solid solution for the first time, which has rarely been studied. Subsequently, the catalytic degradation of Rh B experiment suggested that the catalyst has good catalytic efficiency and stability. This experiment is of great help to the catalytic degradation of Rh B and the application of fullerenes in photocatalysis.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Feng X, Maier S, Salmeron M (2012) Water splits epitaxial graphene and intercalates. J Am Chem Soc 134:5662–5668. https://doi.org/10.1021/ja3003809

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. J Chem Rev 95:69–96. https://doi.org/10.1021/CR00033A004

Chen X, Mao SS (2007) Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem Rev 107:2891–2959. https://doi.org/10.1021/cr0500535

Ke D, Liu S, Dai K, Zhou J, Na N, Peng T (2009) CdS/regenerated cellulose nanocomposite films for highly efficient photocatalytic H2 production under visible light irradiation. J Phys Chem C. https://doi.org/10.1021/jp903378q

Kudo A, Miseki Y (2009) Heterogeneous photocatalyst materials for water splitting. Chem Soc Rev 38:253–278. https://doi.org/10.1039/b800489g

Iqbal S, Pan Z, Zhou K (2017) Enhanced photocatalytic hydrogen evolution from in situ formation of few-layered MoS2/CdS nanosheet-based van der Waals heterostructures. Nanoscale 9:6638–6642. https://doi.org/10.1039/c7nr01705g

Shi R, Ye HF, Liang F, Wang Z, Li K, Weng Y, Lin Z, Fu WF, Che CM, Chen Y (2018) Interstitial P-doped CdS with long-lived photogenerated electrons for photocatalytic water splitting without sacrificial agents. Adv Mater. https://doi.org/10.1002/adma.201705941

Wu J-C, Zheng J, Wu P, Xu R (2011) Study of native defects and transition-metal (Mn, Fe Co, and Ni) doping in a zinc-blende CdS photocatalyst by DFT and hybrid DFT calculations. J Phys Chem C. https://doi.org/10.1021/jp109567c

Luo M, Liu Y, Hu J, Liu H, Li J (2012) One-pot synthesis of CdS and Ni-doped CdS hollow spheres with enhanced photocatalytic activity and durability. ACS Appl Mater Interfaces 4:1813–1821. https://doi.org/10.1021/am3000903

Zhong W, Huang X, Xu Y, Yu H (2018) One-step facile synthesis and high H2-evolution activity of suspensible CdxZn1-xS nanocrystal photocatalysts in a S2-/SO32- system. Nanoscale 10:19418–19426. https://doi.org/10.1039/c8nr06883f

Li Q, Meng H-H, Zhou P, Zheng Y, Wang J, Yu J, Gong JR (2013) ZnO1-xCdxS solid solutions with controlled bandgap and enhanced visible-light photocatalytic H2-production activity. J ACS Catal 3:882–889. https://doi.org/10.1021/CS4000975

Chen J, Chen J, Li Y (2017) Hollow ZnCdS dodecahedral cages for highly efficient visible-light-driven hydrogen generation. J Mater Chem A. https://doi.org/10.1039/C7TA07587A

Yu G, Zhang W, Sun Y, Xie T, Ren A-M, Zhou X, Liu G (2016) A highly active cocatalyst-free semiconductor photocatalyst for visible-light-driven hydrogen evolution: synergistic effect of surface defects and spatial bandgap engineering. J Mater Chem A. https://doi.org/10.1039/C6TA03803D

Shen C-C, Liu Y-N, Zhou X, Guo H-L, Zhao Z, Liang K, Xu A-W (2017) High improvement of visible-light photocatalytic H2-evolution based on cocatalyst-free Zn0.5Cd0.5S synthesized by a two-step process. Catal Sci Technol. https://doi.org/10.1039/C6CY02382G

Wu L, Gong J, Ge L, Han C, Fang S, Xin Y, Li Y, Lu Y (2016) AuPd bimetallic nanoparticles decorated Cd0.5Zn0.5S photocatalysts with enhanced visible-light photocatalytic H2 production activity. Int J Hydrog Energy 41:14704–14712. https://doi.org/10.1016/j.ijhydene.2016.04.157

Tang L, Kuai L, Li Y, Li H, Zhou Y, Zou Z (2018) ZnxCd1-xS tunable band structure-directing photocatalytic activity and selectivity of visible-light reduction of CO2 into liquid solar fuels. Nanotechnology 29:064003. https://doi.org/10.1088/1361-6528/aaa272

Xue W, Chang W, Hu X, Fan J, Liu E (2021) 2D mesoporous ultrathin Cd0.5Zn0.5S nanosheet: fabrication mechanism and application potential for photocatalytic H2 evolution. Chin J Catal 42:152–163. https://doi.org/10.1016/S1872-2067(20)63593-8

Liu T, Li Q, Qiu S, Wang Q, Peng X, Yuan H, Wang X (2020) Construction of Zn0.5Cd0.5S nanosheets and the hybridization with onion-like carbon for enhanced photocatalytic hydrogen production. Appl Surf Sci 525:146586. https://doi.org/10.1016/j.apsusc.2020.146586

Peng S, An R, Li Y, Lu G, Li S (2012) Remarkable enhancement of photocatalytic hydrogen evolution over Cd0.5Zn0.5S by bismuth-doping. Int J Hydrog Energy 37:1366–1374. https://doi.org/10.1016/j.ijhydene.2011.09.140

Ong W-J, Yeong J-J, Tan L-L, Goh BT, Yong S-T, Chai S-P (2014) Synergistic effect of graphene as a co-catalyst for enhanced daylight-induced photocatalytic activity of Zn0.5Cd0.5S synthesized via an improved one-pot co-precipitation-hydrothermal strategy. RSC Adv 4:59676–59685. https://doi.org/10.1039/C4RA10467F

Du H, Xie X, Zhu Q, Lin L, Jiang YF, Yang ZK, Zhou X, Xu AW (2015) Metallic MoO2 cocatalyst significantly enhances visible-light photocatalytic hydrogen production over Mo2/Zn0.5Cd0.5S heterojunction. Nanoscale 7:5752–5759. https://doi.org/10.1039/c4nr06949h

Lebedeva MA, Chamberlain TW, Khlobystov AN (2015) Harnessing the synergistic and complementary properties of fullerene and transition-metal compounds for nanomaterial applications. Chem Rev 115:11301–11351. https://doi.org/10.1021/acs.chemrev.5b00005

Chai B, Liao X, Song F, Zhou H (2014) Fullerene modified C3N4 composites with enhanced photocatalytic activity under visible light irradiation. Dalton Trans 43:982–989. https://doi.org/10.1039/c3dt52454j

Krätschmer W, Lamb LD, Fostiropoulos K, Huffman DR (1990) Solid C60: a new form of carbon. Nature 347:354–358. https://doi.org/10.1038/347354a0

Qi K, Selvaraj R, Al Fahdi T, Al-Kindy S, Kim Y, Wang G-C, Tai C-W, Sillanpää M (2016) Enhanced photocatalytic activity of anatase-TiO2 nanoparticles by fullerene modification: a theoretical and experimental study. Appl Surf Sci 387:750–758. https://doi.org/10.1016/j.apsusc.2016.06.134

Guo W, Tian Y, Jiang L (2013) Asymmetric ion transport through ion-channel-mimetic solid-state nanopores. Acc Chem Res 46:2834–2846. https://doi.org/10.1021/ar400024p

Zhu S, Xu T, Fu H, Zhao J, Zhu Y (2007) Synergetic effect of Bi2WO6 photocatalyst with C60 and enhanced photoactivity under visible irradiation. Environ Sci Technol 41:6234–6239. https://doi.org/10.1021/es070953y

Wang S, Liu C, Dai K, Cai P, Chen H, Yang C, Huang Q (2015) Fullerene C70–TiO2 hybrids with enhanced photocatalytic activity under visible light irradiation. J Mater Chem A 3:21090–21098. https://doi.org/10.1039/C5TA03229F

Lente G (2015) Deterministic kinetics in chemistry and system biology: the dynamics of complex reaction networks. Springer, Berlin

Yu J, Ma T, Liu G, Cheng B (2011) Enhanced photocatalytic activity of bimodal mesoporous titania powders by C60 modification. Dalton Trans 40:6635–6644. https://doi.org/10.1039/c1dt10274e

Sahoo PP, Maggard PA (2013) Crystal chemistry, band engineering, and photocatalytic activity of the LiNb3O8-CuNb3O8 solid solution. Inorg Chem 52:4443–4450. https://doi.org/10.1021/ic302649s

Ge L, Liu J (2011) Efficient visible light-induced photocatalytic degradation of methyl orange by QDs sensitized CdS-Bi2WO6. Appl Catal B 105:289–297. https://doi.org/10.1016/j.apcatb.2011.04.016

Xu Y, Zhang W-D (2015) CdS/g-C3N4 hybrids with improved photostability and visible light photocatalytic activity. Eur J Inorg Chem 10:1744–1751. https://doi.org/10.1002/ejic.201403193

Sun Y-J, Jiang J-Z, Cao Y, Liu Y, Wu S-L, Zou J (2018) Facile fabrication of g-C3N4/ZnS/CuS heterojunctions with enhanced photocatalytic performances and photoconduction. Mater Lett 212:288–291. https://doi.org/10.1016/j.matlet.2017.10.111

Chen A, Zhang J, Zhou Y, Tang H-Q (2021) Preparation of a zinc-based metal-organicframework (MOF-5)/BiOBr heterojunction for photodegradation of Rhodamine B. Reac Kinet Mech Cat 134:1003–1015. https://doi.org/10.1007/s11144-021-02107-4

Premalatha N, Rajalakshmi P, Miranda LR (2022) Photocatalytic degradation of Rhodamine B over TiO2/g-C3N4 and immobilized TiO2/g-C3N4 on stainless steel wire gauze under UV and visible light: a detailed kinetic analysis and mechanism of degradation. Reac Kinet Mech Cat. https://doi.org/10.1007/s11144-022-02154-5

Martínez-de la Cruz A, Hernández-Uresti DB, Torres-Martínez LM et al (2012) Photocatalyticproperties of PbMoO4 synthesized by a hydrothermal reaction. Reac Kinet Mech Cat 107:467–475. https://doi.org/10.1007/s11144-012-0482-9

Qi S-Y, Wang D-P, Zhao Y-D, Xu H-Y (2019) Core-shell g-C3N4@Zn0.5Cd0.5S heterojunction photocatalysts with high photocatalytic activity for the degradation of organic dyes. J Mater Sci: Mater Electron 30:5284–5296. https://doi.org/10.1007/s10854-019-00828-w

Li Q, Li X, Wageh S, Al-Ghamdi A, Yu J (2015) CdS/graphene nanocomposite photocatalysts. Adv Eng Mater. https://doi.org/10.1002/aenm.201500010

Hu Z, Liu G, Chen X-Q, Shen Z, Yu J (2016) Enhancing charge separation in metallic photocatalysts: a case study of the conducting molybdenum dioxide. Adv Funct Mater. https://doi.org/10.1002/adfm.201600239

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by HZ, CD, ZX and JY. The first draft of the manuscript was written by HZ and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Duan, C., Xu, Z. et al. Synthesis of C60/Cd0.5Zn0.5S nanocomposite with high photocatalytic activity for the degradation of Rhodamine B. Reac Kinet Mech Cat 135, 1099–1111 (2022). https://doi.org/10.1007/s11144-022-02187-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02187-w