Abstract

In this work, the photocatalytic degradation of the neonicotinoid insecticide acetamiprid was investigated using a UVA-LED radiation source and TiO2 nanoparticles in a batch slurry system. All experiments were performed with the same initial acetamiprid concentration, amount of TiO2, and solution pH. The influences of three parameters such as mixing rate, radiation intensity and hydrogen peroxide concentration were studied using response surface methodology. An experimental design was prepared using the software package Design-Expert. The obtained experimental results were tested with the kinetic model for the pseudo-first order reaction and showed a good fit. The ANOVA analysis was used to obtain a linear model for predicting the system behavior and to identify significant parameters. The experimental results showed that the radiation intensity had the greatest influence on the efficiency of the photocatalytic degradation of acetamiprid. The acetamiprid conversions increase with increasing radiation intensity and hydrogen peroxide concentration and with decreasing mixing rate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid growth of the world’s population is increasing the demand for food and thus the need to make agriculture more efficient. Since the presence of pests reduces agricultural food production, there is a need to use pesticides for pest control and elimination. Pesticides are chemical substances or mixtures of substances used in agriculture, forestry, horticulture, and health care to prevent, destroy, repel, or alleviate various types of pests such as insects, rodents, weeds, and disease-carrying microorganisms such as fungi, bacteria, and viruses [1]. In addition, they can be used as plant growth regulators, defoliants, desiccants and nitrogen stabilizers to inhibit the process of nitrification, denitrification and evaporation of ammonia [2]. Globally, the production and consumption of pesticides are increasing rapidly, resulting in increased pollution, especially in water. Adverse effects of pesticides on the environment arise from their toxicity, high mobility and stability in an aqueous medium. The problem occurs because farmers often use very high doses of pesticides to increase profits, but only a small percentage of the applied dose can protect the agricultural product, while most of it is lost to the environment through evaporation, hydrolysis, photolysis or microorganisms [3].

Neonicotinoids are a group of organic compounds used as insecticides or pesticides to kill and repel insect pests. They have been in use since 1990 when imidacloprid, the first neonicotinoid insecticide, was synthesized. The need for their development arose in response to the growing resistance of pests to previously used pesticides and due to concerns about high environmental concentrations and the harmful effects of organophosphorus and carbamate insecticides [4]. Since then, their development and use have increased rapidly due to their high selectivity for target organisms, longevity of protection, ease of application, efficacy in controlling arthropods, and relatively low toxicity to fish and mammals. Neonicotinoids now account for about 25% of the global insecticide market and are used in more than 120 countries worldwide [5]. Besides imidacloprid, acetamiprid, thiacloprid, thiamethoxam, clothianidin, dinotefuran, and nitenpyram are the most commonly used. Neonicotinoids are systemic insecticides, which means that the plant takes them up mainly through the roots, after which they spread to all parts of the plant through xylem and phloem transport [6]. Insects then take these compounds into their bodies by sucking plant juices or biting the leaves, where they have neurotoxic effects. They affect nicotinic acetylcholine receptors (nAChRs), which are responsible for the rapid transmission of neurons in the central nervous system and play an important role in learning and memory [7]. They inhibit neuronal transmission, resulting in neurobehavioral disorders that eventually lead to death.

Neonicotinoids have many properties that make them effective insecticides, but those same properties also make them dangerous pollutants. After application, they remain in plants and soil for a very long time, which provides long-term protection, but also makes them more likely to spread in the environment and enter the food chain [8]. The use of neonicotinoids particularly threatens populations of pollinating insects such as bees and bumblebees. Although pollinators such as bees are not pests and are necessary for normal ecosystem functioning, neonicotinoids have the same neurotoxic effect on them as they do on target organisms. Because they remain in the soil and plant tissues for long periods of time, large numbers of pollinators encounter neonicotinoids over time. Direct exposure of bees can lead to acute toxicity, but also to chronic effects on the nervous and immune systems or on energy distribution. Neurotoxicity can affect their memory, orientation, and ability to learn and adapt [9]. Bees become disoriented and less active, making it difficult for them to gather food. At imidacloprid concentrations of 0.5 μg kg−1, bees have been shown to fly much shorter distances and generally remain in the hive in the feeding area, with fewer interactions between bees in the colony [6]. Although not directly leading to bee death, the behavioural changes make it more difficult for bees to forage and maintain the hive, eventually leading to colony collapse. Research has also shown that the number of microsporidium infections in the digestive system of bees increases when hives are treated with neonicotinoids, and interactions between pesticides and pathogens have long been considered a major cause of global bee mortality [10]. A recent study found that acetamiprid can have synergistic effects when combined with most other pesticides, which then leads to lower expression of memory-related genes in honey bees and subsequently causes memory loss [11, 12]. In addition to bees, neonicotinoids may also pose a threat to some aquatic organisms. They are easily washed out of the soil by rain and enter surface waters, where they have neurotoxic effects on aquatic invertebrates such as crayfish and aquatic insects [4].

Since conventional water treatment techniques are unable to completely remove pesticides, work must be done to develop new, more efficient treatment techniques. Advanced oxidation processes (AOPs) stand out as an effective solution for the degradation of organic materials in wastewater. Among them, photocatalysis stands out as an environmentally friendly technique that uses light energy and a semiconductor photocatalyst to generate reactive hydroxyl radicals that can completely mineralize organic materials [13]. The most used photocatalyst is TiO2. Nowadays, intensive work is being done to study and improve photocatalytic processes as they have many properties that make them desirable for widespread use in water treatment: complete mineralization of organic molecules to CO2 and H2O, avoidance of secondary waste, operation at room temperature, and low operating costs [14].

The selection of the appropriate radiation source is crucial for photocatalytic processes and their efficiency. The most used photocatalysts such as TiO2 and ZnO have a band gap energy corresponding to the wavelength of the UV part of the spectrum. This means that they can only absorb UV light and thus achieve photoactivation [15]. These photocatalysts can also absorb photons in the visible part of the spectrum, but only after certain chemical or structural modifications [16]. Light sources for heterogeneous photocatalysis can be divided into two categories: natural (solar radiation) and artificial (UV lamps and LED sources). The use of solar radiation for photocatalysis is inexpensive compared to the use of expensive artificial sources that also consume electricity. The main disadvantage is that the sun is an unreliable source of radiation as weather conditions change and solar radiation is not equally available in all parts of the world. It also requires a large area and installation of quite expensive equipment to be efficient [17]. Therefore, artificial sources are usually used. Artificial sources of radiation used in heterogeneous photocatalysis use UV radiation to excite photocatalysts, since most semiconductor materials absorb light in the UV part of the spectrum.

Of the conventional UV light sources, commercially available mercury lamps are the most commonly used in practice. Although their use is widespread, conventional mercury lamps have many disadvantages: they are relatively fragile, energy inefficient, contain highly toxic mercury, medium- and high-pressure lamps pose a risk of explosion due to high operating temperatures, and cooling requires additional energy consumption. They also have a short life span (500–2000 h), which makes their use quite unprofitable despite their relatively low price [18]. Therefore, attention is now turning to safer and more energy-efficient sources of radiation, such as LED sources.

LEDs (light emitting diodes) are now increasingly used in photocatalysis in place of conventional lamps. They are based on the principle of electroluminescence of semiconductors. Inside the LED there is a mounted semiconductor chip which is connected with two wires. The semiconductor chip consists of two regions: the n region dominated by negative charge and the p region dominated by positive charge. When a sufficient voltage is applied, the current through the wire reaches the semiconductor. The electrons in the semiconductor move in only one direction, from the n region to the p region. During the transition, the electron falls to a lower energy level and the excess energy is released in the form of photons whose energy corresponds to the distance between the energy levels [16]. UV LED sources are most commonly used for heterogeneous photocatalysis.

LED modules have several key advantages over conventional lamps, most notably in energy efficiency, i.e., the more efficient conversion of electricity into light energy. Their service life is around 100000 h, which is up to 100 times longer than some standard mercury lamps. Their small size allows them to be incorporated into virtually any photoreactor configuration. Heat generation is significantly lower than conventional lamps and they contain no toxic substances, making them completely safe to use [19].

LED modules are a relatively new source of radiation in heterogeneous photocatalysis. The first documented use for these “purposes” dates to 2003, and since then their application for photocatalytic degradation of various compounds has increased significantly year by year. LED modules are effective for the degradation of organic compounds such as formaldehyde, bisphenol A, aniline, Cu-EDTA complexes, some intensively used pesticides such as 2,4-dichlorophenol, and the antibiotics sulfamethoxazole and trimethoprim [17, 20]. UVA-LED modules are also used in photocatalytic disinfection, but their use is mainly limited to E. coli [21]. Their major limitation is the low radiant power, which is why they can only be used at lower pollutant concentrations. When designing a photoreactor, it is necessary to pay special attention to the light distribution to ensure a homogeneous dispersal. The photocatalytic degradation efficiency of some compounds, such as methanol, can be lower than when using conventional mercury lamps if the irradiation within the reactor is not uniform [22]. Despite minor shortcomings, the use of LED radiation sources in photocatalysis is still relatively new and is expected to replace conventional lamps as the main radiation source in practice after some further development.

In this work, the photocatalytic degradation of the insecticide acetamiprid was studied in a batch reactor using the UVA-LED chip as the radiation source and TiO2 in suspended form as the photocatalyst. H2O2 was used as an additional oxidant. A Design of Experiments (DoE) approach was used to gain a better insight into the process. The effects of the operating parameters (mixing rate, radiation intensity, and H2O2 concentration) were determined using response surface analysis to derive a mathematical model that predicts the system behavior. The required number of experiments was achieved by using the Box-Behnken experimental design.

Materials and methods

Materials

To prepare a starting solution, Mospilan 20 (a comercial product containing 20% acetamiprid as the active ingredient) was dissolved in ultrapure water. The initial concentration of acetamiprid was 10 ppm in all experiments. The pH of the initial solution was adjusted to pH = 6 with 0.1 M NaOH or HCl. Some experiments were performed with the addition of appropriate volumes of 30% H2O2 solution. Commercial TiO2 P-25 (75% anatase, 25% rutile), previously modified with UV-C light for 2 h, was used as the photocatalyst [23].

Experimental setup

Experimental measurements were performed in a 250 mL batch reactor. A magnet and a magnetic stirrer (MM—530) were used to achieve conditions for good mixing of the working medium during the measurement and uniform illumination of all parts of the suspended solution. A UVA -LED module connected to a voltage source (DC Power Supply, Uni -trend UTP 3303) was used as the radiation source. By adjusting the voltage applied to the module, the radiation intensity was controlled. The complete experimental setup is shown in Fig. 1.

All experiments were performed in a reaction mixture with a volume of 200 mL. After preparation, the initial solution was stirred for 30 min without the light source used to create conditions for equilibrium adsorption of acetamiprid on the photocatalyst surface. The change in acetamiprid concentration due to equilibrium adsorption was found to be insignificant in all experiments performed. Then the light source was adjusted to the expected radiation intensity and the photocatalytic reaction started. The duration of each experiment was 4 h. At defined time intervals, 1 mL samples were withdrawn from the reactor with a syringe and passed through a filter before being added to the vials to remove residual suspended photocatalyst particles. During the initial phase of photocatalytic degradation, when the greatest changes in acetamiprid concentration were expected, samples for analysis were taken at shorter time intervals (15 min) and after 1 h of reaction time, samples were taken every 30 min to minimize the change in the total volume of working medium. Before and after the reaction, the radiation intensity was measured using a radiometer (UVP) and the corresponding sensor. After completion of the reaction, the pH of the solution was determined again. The change in acetamiprid concentration during photocatalytic degradation was monitored by high performance liquid chromatography (HPLC) analysis.

Design of experiment (DoE)

Design of experiments (DoE) based on mathematics and statistics is a formal and structured technique for studying any process whose performance is influenced by several variables [24]. With this technique, it is possible to obtain useful information from a small number of experiments, such as the interactions of the variables under study and their optimal values. Moreover, DoE significantly reduces the number of experiments, reagent consumption and time. In this work, the effects of various experimental parameters on the photocatalytic degradation of acetamiprid were studied to determine their optimum values. Based on the study of related works in which the effect of various parameters on the process of heterogeneous photocatalysis were investigated, the stirring rate of the reaction mixture, the radiation intensity and the concentration of the added hydrogen peroxide were selected as the study parameters [21, 25]. To determine the optimum values of the studied parameters, the Box-Behnken factorial plan was used in combination with the response surface methodology (RSM). The response surface methodology consists of a set of empirical techniques used to determine the relationship between a set of controlled experimental parameters and a measured response. Using the software Design-Expert, a suitable experimental design was constructed with different combinations of parameter values as shown in Table 1.

Once the experimental design was established, the exact values of the cutoff values (− 1 and 1) and medians (0) for each parameter were chosen, as shown in Table 2, using existing data from the scientific literature and considering the capabilities of the experimental apparatus.

Results and discussion

Photocatalytic reaction kinetics

Knowledge of the kinetics of heterogeneous photocatalysis is essential for the design of an efficient photocatalytic process. It gives us insight into the reaction rate, which is one of the most important criteria for assessing photocatalytic activity. The kinetics of photocatalytic degradation is most commonly described by the Langmuir–Hinshelwood (L–H) kinetic model (Eq. 1). According to this model, the rate of photocatalytic degradation, rA is proportional to the coverage of the catalyst surface by molecules of the organic compound [3, 13].:

Here k is the reaction rate constant (mol dm−3 min−1), cA is the concentration of the organic compound (mol dm−3), and K is the Langmuir adsorption constant (dm3 mol−1).

If the initial concentration of the organic compound is very low, it can be neglected and Eq. (1) takes the classical form of

The kinetic model (Eq. 2) is fitted to the batch reactor model

The analytical solution of this ODE for the initial condition cA = A0 is given by:

Here k′ is the pseudo first order rate constant (kK, Eq. 1) and cA0 and cA are the concentrations of the organic compound at times 0 and t. The k′ is used to describe the rate of reaction under various experimental conditions.

A kinetic analysis of the results was performed assuming that the reactions can be described by pseudo first order kinetics. Using Eq. (4) derived from the Langmuir–Hinshelwood kinetic model, a reaction rate constant k′ (min−1) was estimated. The normalized root mean square deviation (RMSD) was calculated for each experiment as a criterion for the agreement of the experimental results with the assumed kinetic model (Eq. 5).

These values, as well as the conversion of acetamiprid obtained by HPLC analysis, are shown in Table 3.

Influence of the process parameters

In the next part of this paper, the influence of the process parameters will be explained.

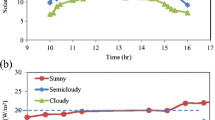

Two experiments were performed with the same mixing rates of the reaction mixture and added concentrations of hydrogen peroxide, while the third parameter studied (LED intensity) was different (R4 and R8, Table 3 and Fig. 2). LED intensity was controlled with the value of voltage applied to the source: the higher voltage means higher LED intensity at different voltage applied to the source. It can be seen that at higher radiation intensity, the decrease in acetamiprid concentration was significantly higher during the irradiation time of 4 h. This is confirmed by the large differences in the total conversions of acetamiprid. At a higher intensity of UVA irradiation, almost 40% of acetamiprid was degraded, while at a lower intensity the degradation was almost 5 times less efficient. The reaction rate constant is an order of magnitude higher in the higher intensity experiment. A higher rate constant also implies a higher rate of degradation of acetamiprid and thus a higher conversion in the observed time, which is consistent with the results obtained. The experimental values agree relatively well with the assumed model, so that the photocatalytic degradation of acetamiprid can be described as a pseudo-first order reaction. Based on the results presented in Table 3, it can be observed that in all four experiments carried out at the highest intensity or voltage (U = 31.5 V), large conversions of acetamiprid were obtained (53.41, 39.42, 38.36 and 23.01%), while they did not exceed 10% at the lowest intensity. It can be concluded that the radiation intensity is the most significant of the studied variables, i.e., it has the greatest influence on the rate and efficiency of photocatalytic degradation.

The reaction mixture was homogenised with a magnetic stirrer to ensure good mixing and uniform illumination of the solution. From the results presented in Table 3, lower mixing favours the photocatalytic degradation of acetamipride (R1 vs R11), which is surprising since one might expect that with more intense mixing, the external mass transfer resistance would be lower. At the lowest mixing rate, the highest conversion of acetamiprid was obtained (55.85%) and the reaction rate constant was 10 times higher than in the lowest rate experiment. It follows that in the observed system, external diffusion was not a limiting step affecting the overall rate of acetamipride photodegradation. It can be seen from Table 3 that in all experiments carried out at the highest mixing speed, a very low conversion was obtained, about 5%. The negative effect of high mixing speed on the degradation of acetamiprid can be attributed to the formation of a large vortex in the reaction mixture, which leads to a varying thickness of the aqueous layer through which the incident light must pass, resulting in uneven illumination of the solution. Due to the small size of the reactor (volume of 250 mL), the developing vortex occupied most of its volume. At lower mixing speeds, there was no large vortex, so the surface of the solution was better and more evenly illuminated. It may be inferred that although the purpose of mixing is to ensure an even distribution of radiation in all parts of the solution, too high mixing speed may have the opposite effect, so care should be taken to find the optimum mixing speed. It can also be assumed that in a reactor with a larger total volume (and diameter) or in reactors with a large, irradiated surface area, a faster mixing speed might prove more efficient.

The addition of a strong oxidant H2O2 to the reaction mixture can increase the number of hydroxyl radicals formed and thus enhance the photocatalytic degradation [25]. It can be seen from Fig. 2 and Table 3 (R8 and R13) that the addition of peroxide leads to better degradation of acetamiprid, but the improvement is not as pronounced as in the experiments in which the effect of radiation intensity and mixing rate were studied. Higher values of reaction rate constant and conversion were obtained in the presence of H2O2. Although the addition of peroxide improved the degradation efficiency to some extent, its influence in these experiments was not as pronounced as the influence of the other two parameters. One possible reason for this is that the added H2O2 concentrations (3 and 6 ppm) are too low to have a significant effect on the reaction efficiency. Since the addition of too much peroxide can inhibit the reaction due to the scavenger effect, further investigation is needed to find a suitable peroxide concentration to improve the process efficiency.

DoE analysis

Once the experiments were performed and the conversion values of acetamiprid for each experiment were obtained, the results were entered into the program Design-Expert to obtain the corresponding model and its 3D graphical representation from which the optima for each parameter can be read. The following linear model was obtained:

In addition, an analysis of variance (ANOVA) was performed, which is important for determining the significance of the obtained model. Table 4 summarizes the results of the ANOVA analysis. The results were evaluated using various descriptive statistics such as sum of squares, degree of freedom (df), mean sum of squares, F-value and p-value. The F-value of 5.67 implies that the model is significant. p-value of less than 0.05 indicates that the model is significant which is desirable as it indicates that the terms in the model have a significant effect on the response. From the p-values for each parameter presented in Table 4, it was concluded that the only significant parameter is radiation intensity. it is less than 0.05, which indicates that the model is significant, which is desirable as it indicates that the terms in the model have a significant effect on the response.

The graphical interpretation of the model describing the dependence of the conversion on the three process parameters is shown in Fig. 3.

Conclusion

Response surface methodology in combination with Box-Behnken experimental design was used to study the photocatalytic degradation of acetamiprid in a batch reactor in the presence of TiO2 under UVA -LED irradiation. The effects of various operating parameters such as radiation intensity, stirring rate and addition of H2O2 on the acetamiprid photodegradation were investigated. Of all three parameters tested, radiation intensity has the greatest effect on photodegradation, with the acetamipride degradation rate increasing with increasing radiation intensity. Higher mixing rate does not lead to better photocatalytic degradation. This can be explained by the formation of a strong vortex in the reactor and uneven illumination of the reaction mixture, which reduces the efficiency of photocatalysis. The addition of H2O2 as an additional oxidant improves the reaction rate, but this effect is not as pronounced as for the other parameters. To get a better insight into the effect of adding H2O2 as an additional oxidant, future experiments have to be performed in a larger concentration range.

References

John S, Soloman PA, Fasnabi PA (2016) Study on removal of acetamiprid from wastewater by electrocoagulation. Procedia Technol 24:619–630

De Souza RM, Seibert D, Quesada HB, de Jesus Bassetti F, Fagundes-Klen MR, Bergamasco R (2020) Occurrence, impacts and general aspects of pesticides in surface water: A review. Process Saf Environ Prot 135:22–37

Fiorenza R, Di Mauro A, Cantarella M, Iaria C, Scalisi EM, Brundo MV, Gulino A, Spitaleri L, Nicotra G, Dattilo S, Carrocio SC, Privitera V, Impellizzeri G (2020) Preferential removal of pesticides from water by molecular imprinting on TiO2 photocatalysts. Chem Eng J 379:1–13

Morrissey CA, Mineau P, Devries JH, Sanchez-Bayo F, Liess M, Cavallaro MC, Liber K (2015) Neonicotinoid contamination of global surface waters and associated risk to aquatic invertebrates: a review. Environ Int 74:291–303

Han W, Tian Y, Shen X (2018) Human exposure to neonicotinoid insecticides and the evaluation of their potential toxicity: an overview. Chemosphere 192:59–65

Van der Sluijs JP, Simon-Delso N, Goulson D, Maxim L, Bonmatin J-M, Belzunces LP (2013) Neonicotinoids, bee disorders and the sustainability of pollinator services. Curr Opin Environ Sustain 5:293–305

Taillebois E, Cartereau A, Jones AK, Thany SH (2018) Neonicotinoid insecticides mode of action on insect nicotinic acetylcholine receptors using binding studies. Pestic Biochem Physiol 151:59–66

Gill K, Garg H (2014) Pesticides: environmental impacts and management strategies u: pesticides—toxic aspects, intechopen. pp 187–230

Fent K, Schmid M, Hettich T (2020) The neonicotinoid thiacloprid causes transcriptional alteration of genes associated with mitochondria at environmental concentrations in honey bees. Environ Pollut 266:1–11

Horáková M, Klementová Š, Kříž P, Balakrishna SK, Špatenka P, Golovko O, Hájková P, Exnar P (2014) The synergistic effect of advanced oxidation processes to eliminate resistant chemical compounds. Surf Coat Technol 241:154–158

Wang Y, Zhu YC, Li W (2020) Interaction patterns and combined toxic effects of acetamiprid in combination with seven pesticides on honey bee (Apis mellifera L.). Ecotoxicol Environ Saf 190:1–10

Shi J, Zhang R, Pei Y, Liao C, Wu X (2020) Exposure to acetamiprid influences the development and survival ability of worker bees (Apis mellifera L.) from larvae to adults. Environ Pollut 266:1–9

M’Arimi MM, Mecha CA, Kiprop AK, Ramkat R (2020) Recent trends in applications of advanced oxidation processes (AOPs) in bioenergy production: Review. Renew Sustain Energy Rev 121:1–18

Tassalit D, Chekir N, Benhabiles O, Mouzaoui O, Mahidine S, Merzouk NK, Bentahar F, Khalil A (2016) Effect and interaction study of acetamiprid photodegradation using experimental design. Water Sci Technol 74:1953–1963

Byrne C, Subramanian G, Pillai SC (2018) Recent advances in photocatalysis for environmental applications. J Environ Chem Eng 6:3531–3555

Tokode O, Prabhu R, Lawton LA, Robertson PKJ (2014) UV LED sources for heterogeneous photocatalysis u: environmental photochemistry part III. The Handbook of Environmental Chemistry, Springer, 35: 159–179

Jo W-K, Tayade RJ (2014) New generation energy-efficient light source for photocatalysis: leds for environmental applications. Ind Eng Chem Res 53:2073–2084

Kanmani S, Sundar KP (2019) Progression of photocatalytic reactors and it’s comparison: a review. Chem Eng Res Des 154:135–150

Casado C, Timmers R, Sergejevs A, Clarke CT, Allsopp DWE, Bowen CR, van Grieken R, Marugán J (2017) Design and validation of a LED-based high intensity photocatalytic reactor for quantifying activity measurements. Chem Eng J 327:1043–1055

Cai Q (2018) & Hu, J, Effect of UVA/LED/TiO2 photocatalysis treated sulfamethoxazole and trimethoprim containing wastewater on antibiotic resistance development in sequencing batch reactors. Water Res 140:251–260

Nyangaresi PO, Qin Y, Chen G, Zhang B, Lu Y (2018) Effects of single and combined UV-LEDs on inactivation and subsequent reactivation of E. coli in water disinfection. Water Res 147:331–341

Martín-Sómer M, Pablos C, van Grieken R, Marugán J (2017) Influence of light distribution on the performance of photocatalytic reactors: LED vs mercury lamps. Appl Catal B 215:1–7

Babić K, Tomašić V, Gilja V, LeCunff J, Gomzi V, Pintare A, Žerjave G, Kurajica S, Duplančić M, Zelić IE, Vukušić Pavičić T, Grčić I (2021) Photocatalytic degradation of imidacloprid in the flat-plate photoreactor under UVA and simulated solar irradiance conditions—The influence of operating conditions, kinetics and degradation pathway. J Environ Chem Eng 9:1–14

Lira JOB, Riella HG, Padoin N, Soares C (2020) CFD + DoE optimization of a flat plate photocatalytic reactor applied to NOx abatement. Chem Eng Process Process Intensif 154:1–40

Sahel K, Elsellami L, Mirali I, Dappozze F, Bouhent M, Guillard C (2016) Hydrogen peroxide and photocatalysis. Appl Catal B 188:106–112

Acknowledgements

This work has been supported by Croatian Science Foundation under the project IN-PhotoCat (IP-2018-01-8669).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competingfinancial interests or personal relationships that could haveappeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kosar, V., Kurt, F., Tomašić, V. et al. Analysis and modelling of photodegradation of neonicotinoid insecticides under the influence of UVA-LED radiation. Reac Kinet Mech Cat 134, 989–1001 (2021). https://doi.org/10.1007/s11144-021-02075-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-021-02075-9