Abstract

Using a fuzzy-set qualitative comparison analysis, we identify and examine key conditions for success in early front-end phases of process innovation projects. We focus on the very initial stage of the innovation process—the front-end phase—and a selection of conditions for managing highly uncertain process innovation projects. In high-uncertainty projects coupled with high levels of equivocality, formalizing roles and processes should be consistently avoided; however, idea screening is beneficial. Moreover, in successful innovation projects formalized processes but not formalized roles are beneficial. The findings suggest that formalizing roles and processes, a success factor in prior studies of innovation, does not result in success of process innovation projects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Process innovation centers on creating and implementing new ideas and practices in firms’ manufacturing processes and is therefore critical to competiveness. Still, process innovation is one of the least studied phenomena in innovation management (Anderson and Tushman 1990; Greco et al. 2015). Rather, heavily one-sided attention has been placed on product innovation (Linton and Walsh 2008). This is surprising because improvements in the manufacturing process domain have been shown to enhance a firm’s ability to benefit from product innovation and vice versa (Ennen and Richter 2010; Kurkkio et al. 2011).

Process innovation is often characterized by high-uncertainty—the lack of reliable information to solve a particular task (Galbraith and Buck 1977), because many manufacturing firms want to take larger technology leaps in renewing their manufacturing processes (Kurkkio et al. 2011). They want to move beyond minor improvements and adjustments to make bolder changes, such as more radical process innovation, which increase the level of uncertainty in development projects (Gopalakrishnan and Damanpour 1994; Frishammar et al. 2012). Significant uncertainty and equivocality are encountered in mature process innovation industries where radical processes must be developed to gain competitive advantage.

Because process innovations require that firms create new ideas and concepts for new manufacturing processes, they result in higher uncertainty. Increasingly, process innovation efforts underscore the need for new knowledge about the front-end phases of these projects. Moreover, as firms conducting process innovation tend to be specialists in their production processes, process manufacturing technologies must be revamped significantly (i.e., machinery and equipment), thus further reinforcing uncertainty (Robertson et al. 2012). Although open innovation is used increasingly due to limited internal capability, process innovation conducted in joint projects still requires firms to internally retool their operations (Naqshbandi et al. 2015; Rönnberg-Sjödin et al. 2016). Although high-uncertainty process innovation projects are becoming a common occurrence and a major challenge for large manufacturing firms, limited studies to date have investigated how firms manage this challenge when uncertainty is high or when both uncertainty and equivocality are high.

The early phase of process innovation starts with an idea for a new process and finishes when the firm has developed a robust process innovation concept (Kim and Wilemon 2002; Cooper 2008). The three studies by Kurkkio et al. (2011), Frishammar et al. (2013), and Rönnberg-Sjödin et al. (2016) have focused specifically on challenges related with achieving robust process innovation concepts under uncertainty. However, although contributive, the first two studies are descriptive and highlight an array of organizational factors that may be important for managing high-uncertainty process innovation projects, whereas the last one do not focus specifically on high-uncertainty projects.

In the present study, we build on previous studies by examining interdependencies and interplay among diverse practices for managing high-uncertainty process innovations that are coupled with equivocality in the early phases. In particular, we focus on four different possible configurations of practices highlighted in prior literature for successful process innovation projects with uncertainty and at times coupled with high equivocality. These practices are: (1) formalized roles, (2) formalized processes, (3) idea screening, and (4) breadth of cooperation. To identify the successful configurations among these proposed organizational practices, we apply a novel methodological approach: a fuzzy-set qualitative comparative analysis (fsQCA) (Fiss 2011; Ragin 2008). fsQCA accounts for complex interactive effects of more than three contributing factors. This analysis is beneficial in the present study because it permits us to analyze a relatively small number of cases and allows configurational analysis of the four organizational factors across cases (Woodside 2013; Ragin 2008). Thus, the purpose of the present study is to investigate which configurations of practices are important for successful high-uncertainty process innovation projects, at times coupled with equivocality, in the early phases.

The present paper provides several contributions. First, we contribute to a better understanding of managing high-uncertainty process innovation projects that are also coupled with equivocality. With increasing pressure to secure and sustain competitiveness, large manufacturing firms are increasingly required to take larger technology leaps and achieve successful projects under conditions of uncertainty and equivocality to solve a particular task in process innovation. Thus, we shed light on the important but still understudied topic of managing uncertain and equivocal process innovation. Second, whereas prior studies have listed key organizational practices that are beneficial for managing process innovation projects in early phases (Kurkkio et al. 2011; Frishammar et al. 2013), they provide only limited insights on the configuration effects of these practices. We address this shortcoming by examining key organizational practices through use of fsQCA analysis. In doing so, we attempt to stimulate new dialogues in the process innovation literature. Finally, the study also provides several practical contributions for managers within large manufacturing companies that are responsible for process innovation projects and oversee activities executed during early phases. The results provide knowledge on how to manage highly uncertain and equivocal process innovation projects.

The remainder of this article is organized as follows. First, we discuss process innovation, reasons for the occurrence of high uncertainty, and its implications on the early phase of process innovation. This is followed by a set of arguments about key organizational practices of potential importance for successful high-uncertainty process innovation projects. In the third section, the methods employed in this research are described, including motivation for using fsQCA and the operationalization of constructs. We subsequently present the results before we discuss theoretical and managerial implications and offer limitations and suggestions for future research.

2 Theoretical background

2.1 Defining high-uncertainty process innovation

Process innovation is deliberate and systemic development related mainly to production objectives, aimed toward introducing new elements into the production process. Its purpose is to create or improve methods of production (Baer and Frese 2003; Lager 2002; Kurkkio et al. 2011). To contrast, if product innovation concerns what is done (i.e., a new innovative product sold to external customers), process innovation focuses on how work is done (i.e., innovation related to manufacturing processes) (Utterback and Abernathy 1975). Process innovation implies more than mere improvements to existing processes to achieve marginally improved efficiency. That is, process innovation “…presupposes wider and more encompassing changes to the manufacturing process, such as the launch of a next-generation process for a new product” (Pisano 1997, p. 34). The outcome of process innovation varies depending on the specific focus on the process innovation project. However, common examples center on reducing costs, increasing production volumes, increasing production quality and reliability, reducing time to market, and engaging in more environmentally friendly production (Pisano 1997; Lager 2002). These types of innovations in production and manufacturing have been characterized to secure competitiveness for firms as it represents a superior operational competence (Teece 2009). In fact, prior studies associate process innovation to positively influence not only efficiency improvements but also financial performance (Hendricks and Singhal 2001; Ittner and Larcker 1997; Frishammar et al. 2013).

Recent studies on process innovation projects have highlighted uncertainty (Kurkkio et al. 2011; Frishammar et al. 2013; Naghizadeh et al. 2015; Lin 2010; Rönnberg-Sjödin et al. 2016). An analysis of these and related studies provides several reasons why uncertainty needs be better understood, comprehended, and managed. First, process innovation is systemic in nature, which means it is characterized by interconnected and coordinated functions (Gopalakrishnan et al. 1999). Pisano (1997) provides an example related to production development, manufacturing strategy, and operation strategy. A complex web of interconnection in process innovation means information and knowledge necessary for decision-making may not always be accessible when needed.

Second, Kurkkio et al. (2011) highlighted that a major problem for process innovation projects relates to managing process innovation proactively toward addressing future challenges rather than reactive problem solving of daily production issues. As firms increasingly strive to pioneer advantages to meet new customer demands, process innovation efforts nowadays are exposed to significantly more uncertainty than what has been highlighted in previous discussions (Greco et al. 2015).

Finally, manufacturing firms tend to be specialized in executing their processes but typically possess limited competence in underlying process technologies, such as machinery and equipment (Robertson et al. 2012). This requires them to establish joint projects with external partners and then coordinate a multitude of development activities across organizational boundaries. Such projects tend to require integrative development processes in which a variety of members with different backgrounds interact and share relevant information and knowledge (Rönnberg-Sjödin et al. 2016). Thus, process innovation projects are increasingly manifested by high-uncertainty, but insights on how to manage such projects successfully is still limited. Such projects are also often coupled with significant equivocality.

2.2 Organization practices on high-uncertain process innovation in early phases

The front-end phase has been proposed to be vital to the success of process innovation projects (Kurkkio et al. 2011; Frishammar et al. 2013). Because process innovation tends to entail large investments in R&D spending (Lager 2002), executing activities proficiently in this early phase can provide a clear direction toward forthcoming innovation challenges. Typical activities undertaken during the early phases of process innovation include refining ideas, preliminary testing, and laboratory and pilot testing (Kurkkio et al. 2011). Prior studies from the product innovation domain highlight that deficiencies in performing activities in the early phase can result in costly and fatal problems at later phases (Cooper 1988), a logic that is applicable for process innovation (Frishammar et al. 2013). For example, lack of sufficient information may lead to ad-hoc decision-making and investments into inferior technologies or process concepts.

Although prior studies have acknowledged the early phases of process innovation to be of utmost importance (Lager 2000; Lim et al. 2006; Pisano 1997), we know of only three studies that specifically focus on the early phases of the process innovation. The study by Kurkkio et al. (2011) addressed the issues related to describing sub-phases and associated key activities that constitute the early phase. Frishammar et al. (2013) attempted to conceptualize the “process equivalent” of product definition, which they term as a process definition. Moreover, (Rönnberg-Sjödin et al. 2016) highlighted organizational practices that are important for achieving project success. We draw on these and other related studies to identify key practices relevant to the early phases of process innovation. Although these provide a better understanding of early phases of process innovation, how they impact success remains unexplored and under-investigated. First, these studies highlight the emergence of high-uncertainty in process innovation projects and suggest that high uncertainty has major implications on how activities and practices in the early phase need to be executed. However, they do not explicitly examine the effects of multiple organizational practices on successful high-uncertainty process innovation projects in the early phases. Second and more important, the interplay and interdependencies among organizational practices toward high-uncertainty process innovation projects success need further attantion. This calls for a more configuration-based examination of organizational practices, because they may have enhancing or suppressing effects. Thus, in the present study we apply fsQCA analysis on a set of commonly discussed key organizational practices from process innovation literature: (1) formalized roles, (2) formalized processes, (3) idea screening, and (4) breadth of cooperation. Each is briefly described, motivated, and tested. But before elaborating these four organizational practices, we define the concept of equivocality as it applies to process innovation projects and is a key concept in our subsequent analysis.

2.2.1 Equivocality in process innovation projects

Equivocality refers to multiple and conflicting interpretations of a situation, task, or goal (Daft and Lengel 1986; Weick 1979). Although the concept of uncertainty centers on a lack of information or knowledge, equivocality centers on a lack of clear interpretations of whatever information or knowledge is available (Frishammar et al. 2011). That is, whereas uncertainty implies the absence of a clear interpretation because information was missing, equivocality implies a situation in which multiple clear interpretations are present. In the front-end of high-uncertainty process innovation projects, participants (e.g., marketing department, R&D department) are more likely to come to fundamentally different conclusions of the future viability of a new process innovation concept. Equivocality is especially problematic during early innovation efforts, and at times, it is inextricably linked to uncertainty, because it makes identifying and solving problems more difficult—activities that are critical to moving a project forward in the front end (Frishammar et al. 2011). Indeed, diverging interpretations and misunderstandings is a poor basis for developing consensus and paving a joint way forward to success.

Equivocality can be reduced through the exchange of subjective interpretations and worldviews, activities aimed at consensus formation, thus creating a shared understanding. Managing equivocality and reducing uncertainty could be better conducted through practices the promote “rich media” (Daft and Lengel 1986), that is, through rapid communication cycles among people through face-to-face meetings and discussions, which allows participants to converge on the meaning of equivocal cues and define a common solution(Daft and Weick 1984; Weick 1979). This is of particular importance for the success of highly uncertain process innovation projects in the front end. Uncertainty and equivocality constitute two distinct types of knowledge problems in organizations (Zack 2001). High prevailing levels of equivocality in a highly uncertain front-end projects will create excessive information processing load. In other words, information processing demands will exceed the capabilities available to process information. For this reason, reducing equivocality may be even more important in highly uncertain projects than in projects with more modest degrees of uncertainty (Frishammar et al. 2011). Moreover, when uncertainty is high, as in high-uncertainty process innovation projects, there is simply more room for multiple interpretations and diverging views, when team members ground their perceptions in subjective opinions and worldviews rather than facts. This sets the stage for equivocality. When reliable information is absent, assessments of the right way ahead will be influenced by heuristic principles (Tversky and Kahneman 1974). In a situation of high uncertainty, this implies it will be more difficult for organizational members to assess predictability to develop future scenarios, reach consensus, and form a common confidence that their predictions rests on factors that are valid or that they have not developed spurious explanations of what is a valid process innovation (cf. Tversky and Kahneman 1973).

2.2.2 Formalized roles

Formalization of roles is the degree to which role expectations take place to distribute individual responsibility across individuals and functions in organizations (Rizzo et al. 1970). For innovation processes, formalized roles imply clear accountability throughout the innovation activities across roles, across individuals, and through any subgroups in the organization such as the marketing department, production, administration, or the R&D department. Through high formalization of roles, individuals are assigned formal role expectations and responsibilities (Griffiths-Hemans and Grover 2006). As failures in process innovation can lead to major product malfunctions and technology breakdowns (Anderson and Tushman 1990) formalized roles have often been used in low uncertainty projects, because they favor reliability and the capacity to manage outcomes effectively (Hervas-Oliver et al. 2014). As such, formalizing roles can be understood as mitigating the likelihood for failure throughout the innovation process (Goldenberg et al. 2001).

Historically, formalizing roles have been considered a natural part in certain and highly predictable projects, although there are clear restrictions in highly uncertain situations because too much formalization of roles risk hindering the flexibility needed in highly uncertain innovation work (Amburgey and Miner 1992; Gilbert 2005). The front-end phase of the innovation process starts when an early stage idea surfaces along with an initial semi-formal response to an opportunity of a possible and feasible solution to a problem (Griffiths-Hemans and Grover 2006). When confronted with high uncertainty, it is crucial to overcome potential status quo in the initial phases of the front-end. This is because dynamic teamwork that goes beyond formal role responsibilities is necessary to drive such innovation processes (Conway and McGuinness 1986). Although dynamic team work may be of less concerns in low uncertain projects that enter the initial phases of the innovation process, projects with high uncertainty requires dedication and passion beyond a role description where one or several committed individuals involved to manage project activities, and until a go/no go decision is taken in the initial innovation phase (Conway and McGuinness 1986). This means that formalizing roles and responsibilities may mitigate opportunities for environmental exploration, flexibility, and adaptation through process innovation by limiting the power of interconnecting multiple functions and persons working dynamically to experiment with solutions under high uncertainty. As formalized roles restrict process innovation by restricting expertise to be interconnected in new and different ways as well as ensuring diversity of approaching problems through new styles and experimentation in the processes (Gopalakrishnan et al. 1999), there will not be a constant flow of ideas, and it is difficult to develop these ideas further.

2.2.3 Formalized processes

Khurana and Rosenthal (1998) defined a formal front-end process to be explicit and characterized by clear goals and specific performance requirements. Formalization is argued to provide stability and predictability to front-end efforts. As such, a formalized process builds on the use of standardized, written rules and procedures to govern activities in the innovation process and to help clearly outline and institutionalize process innovation routines (Ettlie and Reza 1992).

In De Brentani’s (2001) study, high-performing companies often implemented a formal process. Nevertheless, although formalization is important, there is also the danger that processes and practices are shared and implemented may become rigid rapidly. Acknowledging this trade-off, other authors, such as Boeddrich (2004), discussed something called the fantasy route to innovation versus the technocratic route to innovation and outlined conditions in which high potential and more radical ideas will be supported in less restricted and more chaotic environments without systematic and formal process direction. This suggests that formalization may be efficient for low-uncertainty projects that are more incremental in nature. This has advantages for reliability in terms of delivering products at expected quality levels and in a timely manner, as well as accountability and documentation of resource use and decision-making in the development process (Hannan et al. 2002).

2.2.4 Idea screening

Screening ideas is critical to any front-end project, because it assures relevance, accuracy, and value of what is being developed. In the case of process innovation projects in the front end, it implies assuring that the critical dimensions of the process concept are sufficiently clarified, including ensuring that the emerging idea and concept is sufficiently clear to be transferred into a production environment in a subsequent step (Frishammar et al. 2013). In brief, idea screening involves the activities or a project a firm undertakes to assure that an emerging idea, at its specific stage of refinement, should be further developed or not (Florén and Frishammar 2012). Overall, high-performing firms tend to deal with idea screening systematically to weed out poor or deficient ideas, that is, though a stage-gate process or equivalent (Cooper 2008). However, such processes are less well developed for the context of process innovation, in particular for the front-end of innovation, prior research has shown that the stage-gate logic may be less applicable because work is more informal, the team is smaller, there is less consensus about what and how to approach work, and development efforts center on developing and clarifying an idea rather than doing formal development (Kim and Wilemon 2002). Thus, early in the front end, formal screening is not very sophisticated. Still, there are a couple of reasons why idea screening is of particular importance to the success of highly uncertain process innovation projects in the front end.

First, when uncertainty is high, screening is even more important to determine whether an idea should be further developed or not. Although screening is increasingly challenging when information is missing, as in the context of high uncertainty, its importance is without doubts (Florén and Frishammar 2012). In the context of process innovation, this argument is further underscored by the fact that process innovation is systemic in the sense that changes to the production process frequently result in changes not only to end products, but also to many other things in a manufacturing company (Gopalakrishnan and Damanpour 1994). As such, costly disturbances need be kept to a minimum. Second, under conditions of high uncertainty, proficient screening allows effective use of resources (Yu and Hang 2010), thus allowing firms to weed out poor ideas and ensure the good ideas are not eliminated. Although there is a clear danger that companies lack routines to identify “false negatives,” screening is nevertheless critical to success (Chesbrough 2004, 2006). Finally, prior research shows that idea screening takes place in two domains: business analysis and feasibility analysis of an idea (Murphy and Kumar 1997). The first criterion is of less relevance here, because process innovation does not have a direct external customer as in product development. Rather, the “customer” is the firm’s production system (Lager et al. 2013). However, the second criterion is of utmost importance to the success of high-uncertainty process innovation projects. In particular, feasibility analysis by assessing technology carefully is absolutely necessary before investing formally in a project (Cooper and Kleinschmidt 1987). If the idea and concept are not technically viable, which is a key risk under high uncertainty when information is lacking, major disturbances in the production system is a commonly experienced aftermath (Rönnberg-Sjödin et al. 2016).

2.2.5 Breadth of cooperation

Cooperation with external parties such as equipment suppliers, research institutes, and universities has been widely recognized to be important for acquiring knowledge, expertise, or skills for process innovation (Frishammar et al. 2012). Therefore, suppliers are usually viewed as strategic partners because buyer–supplier cooperation forms the backbone of many process innovation-related development activities (Lager et al. 2013). In addition to suppliers, other important partners include research institutes, universities, and customers that are known for providing valuable knowledge in process innovation (Linton 2000). In sum, external cooperation may result in reduced development costs, reduced time to market, and lead to higher product quality (Kim and Wilemon 2002; Khurana and Rosenthal 1997). Thus, numerous studies have recognized the ability to gain knowledge from external partners valuable for the successful front-end of process innovation (Kurkkio et al. 2011).

We argue these findings are relevant in the context of highly uncertain process innovation, First, acquiring specialized knowledge through external cooperation can be an important way to fill current knowledge gaps and thus reduce uncertainty during the front-end of process innovation projects (Rönnberg-Sjödin et al. 2016). Process innovation often requires cross-functional expertise and is coupled with high technological uncertainty, which means that innovation projects are faced with limited information to take appropriate actions (Frishammar et al. 2012). Alliances with universities and research institutes can offset such information limitations. Second, Zack (2001) proposed a capability-based argument for how external cooperation can increase the ability to mitigate lack of information to complete a task. More specifically, joint problem-solving activities with external partners can enable mutual efforts where the collaborating partner helps overcome obstacles and achieve project effectiveness (Bstieler and Hemmert 2010). For example, involving suppliers in joint problem-solving sessions can provide a setting for experimentation and learning that results in better solutions or concept development (Uzzi 1997; McEvily and Marcus 2005). This is so because partners can provide alternative knowledge of the innovation problem and solutions, which provides opportunities for comparing and contrasting perspectives to reach better solutions under conditions of high uncertainty and equivocality.

2.2.6 A configuration model of organizational practices

The above arguments underscore the importance of identified organizational practices for high-uncertainty process innovation projects, where equivocality is also inextricably linked. However, the interplay and interdependencies among the studied organizational practices have not yet been explored and investigated. To provide such examination, we build on configuration theory, which provides the underlying logic of our empirical examination. Configuration theory (Ragin 2000) centers on complex, multidimensional phenomena at different levels (firms, groups, individuals) that tend to cluster into archetypes described by common patterns of coherent causal conditions (e.g., organizational practices). As its fundamental premise, configuration theory posits that the same set of causal factors can lead to different outcomes, depending on how the factors are arranged.

Due to a lack of prior research motivating such configuration effects, the present study proposes and tests the configurations of organizational practices as an explorative research question instead of explicating hypotheses or propositions:

Research question: Which configurations of organizational practices (formalized roles, formalized process, idea screening, and breadth of cooperation) explain whether high-uncertainty process innovation coupled with high equivocality in early phases will be successful?

3 Research method

3.1 Sample and measurement

Our sample consisted of four large Swedish companies with significant focus on process innovation in the metal and minerals industry. Company A develops metal powders for the global market. The company has 1600 employees and a long history of success in process innovation. Company B develops high strength steel, has about 9200 employees, and is active in 45 countries. Company C had 4600 employees when the study was conducted. Company D, which develops and produces industrial mineral products, employs 3800 individuals and is active in 15 countries.

These companies were selected for three reasons. First, prior relationships with these companies and an intimate understanding of their innovation activities provided a more informative platform for conducting qualitative data collection of innovation projects, furthermore, these prior relationships allowed us to have a better understanding of language, symbols, and understanding of innovation activities. Second, companies from the metal and mineral industries generally specialize in process innovation (Frishammar et al. 2011). Process innovations in metals and mineral industries are intensive in this mature industry. Because the basic manufacturing process is widely established at a global scale, process innovations are highly innovative and uncertain. Third, despite the smaller sample size for our cross-case analysis, it is important to note that these established firms have substantial innovation competence and routines, providing a viable setting to study uncertainty in process innovation.

The respondents for the study were senior management staff and engineers. This diverse respondent set was selected due to its breadth of knowledge about process innovation efforts within the company and depth of knowledge about successful projects. The data is representative of their experiences from managing 16 successful high-uncertainty process innovation projects during early phases. For the analysis we used fuzzy package in Stata 14.

3.2 Method

We start by describing the measures.

3.2.1 Uncertainty in innovation project

The respondents were asked to rate the level of uncertainty on a Likert scale ranging from 1 to 10 (1 = low uncertainty to 10 = high uncertainty). Uncertainty was captured and defined as the difference between the information that was available and the information needed in order to execute various tasks. Example scale items included “uncertainty in assessment of project feasibility” and “uncertainty in analysis of market and technology.”

3.2.2 Equivocality in innovation project

The respondents were asked to rate the level of equivocality in the process innovation projects. The scale was a 10-point three-item scale (1 = low equivocality to 10 = high equivocality). Equivocality was defined and specified as the situations where the task that was to be executed was heterogeneously interpreted, and where ideas and interpretations needed information or knowledge exchange in order to understand what the problem really entailed. Sample scale items for the tasks included to capture key activities in the initial fuzzy front-end phase were “equivocality in development of detailed specifications and design” and “equivocality in test of prototypes as well as validation.”

3.2.3 Idea screening

The respondents were asked to rate the extent of idea screening in reference to the initial phase of the innovation process for a recently successful process innovation project. The scale was three-item scale (1 = do not agree to 7 = fully agree). A sample scale item was, “The company needs to use mechanisms to separate the good ideas from the less good ideas,” and “to which extent it was necessary to evaluate ideas from the perspective of market potential and feasibility.”

3.2.4 Formalized roles

The extent of formalization in the early phase of the process innovation was based on a 5-item scale (1 = do not agree to 7 = fully agree). Sample scale items included, “We strive to that the early phase of process development projects should be explicit, that is, well known by involvement of people, and is characterized by clear decision and responsibility, and include specific performance measures.”

3.2.5 Formalized processes

The respondents were asked to rate the extent to which a formalized process was present in the process innovation. The scale was a 14-item scale with 1 = do not agree to 7 = fully agree. Sample scale items include “The process concept at my company demonstrates compliance with the company’s strategic direction” and “At my company, we assess the risk in developing new process concepts.”

3.2.6 Breadth of cooperation

The respondents were asked to rate the extent of cooperation in their firm in reference to the early phase of the process innovation. The scale included seven items (1 = do not agree to 7 = fully agree). Sample scale items include “Cooperation with external parties such as equipment suppliers, research institutes, and universities is important.”

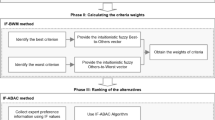

3.3 Preparing data for fuzzy set QCA analysis

We used fsQCA to derive possible means to identify configurations for successful process innovation with high uncertainty. The fsQCA approach allows for a holistic understanding of and possibly equifinal configuration of factors or elements on process innovation performance (Ragin 2008). As a configurational approach, fsQCA seeks to understand fit among various organizational structures and practices geared toward process innovation that are equally important. fsQCA is useful for understanding a configuration of conditions of highly complex phenomenon such as successful execution of process innovation processes (see Eng and Woodside 2012). By identifying how structures and practices that are necessary and sufficient (Ragin 2008) for managing uncertainty in successful process innovation projects, fsQCA contrasts significantly to other approaches to provide actionable knowledge about important combinations of factors. Our configurational approach is based on a cross-case analyses of how different organizational factors manifest into successful process innovations.

Broadly, QCA aims to identify a set of configurations from cases by identifying joint occurrences of characteristics (i.e., standardized ranked variables) for a given outcome. A truth table is created for each combination of attributes. In the current analysis, 2number of attributes = 25 = 32 configurations are created, and configurations without observations are dropped. Most parsimonious solutions are recognized after identifying a series of intermediate solutions. The intermediate solutions are screened for sufficiency and consistency (degree of conformity with necessity and sufficiency criteria). Raw coverage refers to the degree of coverage if only a given configuration was the solution. Unique coverage refers to the degree to which solution contributes beyond other combinations of attributes. Solution consistency is the degree of conformity with necessity and sufficiency hypothesis in the truth tables. The recommended cutoff for consistency is 0.8 or above.

We use the fuzzy routine in Stata 14, to conduct fsQCA analysis. Compared to crisp-set analysis that requires clear demarcation of membership, fsQCA allows for calibration of membership from continuous responses to ranked responses. Calibration refers to rank-order transformation of original responses on a continuous scale to an interval ranging from 0 to 1. In cases where values are tied, values are allocated to preserve the rank-sum order. The ranks are then standardized by subtracting minimum rank and dividing the result by the difference between the maximum and minimum rank. We use setgen function in Stata 14 to create standardized ranks. The resulting standardized rank-order values range from 0 to 1. Table 1 presents both the raw and transformed values.

4 Results

Table 2 shows the results of the analysis of causal configurations that affect uncertainty in successful process innovation projects. Table 2 represents a set of sufficient causal conditions along with unique coverage and consistency for each solution and overall solution coverage and solution consistency for four configurations. The results show that all four solutions have consistency above 0.8. Based on Ragin (2008) all the configurations above 0.8 meet the goodness-of-fit criteria. Adopting a notation similar to Fiss (2011) the black circles represent the high presence of a condition and blank circles indicate that low presence of condition. We now discuss each condition.

Configuration 1 indicates that both equivocality in innovation project and idea screening are important elements in success of uncertain process innovation projects. In other words, with high equivocality, having an idea screening process is important to ensuring success. Next, in configuration 2 (configuration 4), if equivocality is high, formalized processes (formalized roles) should be low. Finally, in projects with high formalized processes but low formalized roles are related to success (configuration 3).

To summarize, in successful process innovation projects when equivocality is high, idea screening is important; however, formalized roles or processes should be low. Formalized processes, but not formalized roles, are associated with successful process innovation projects.

5 Discussion

Our objective was to investigate key conditions for success in uncertain process innovation projects that are coupled with equivocality. Process innovations require systematic changes in an organization, and the early phase of process innovation is more critical in charting the path forward under equivocality and uncertainty. The findings indicate that idea screening is valuable when uncertainty and equivocality are both present. However, formalized roles are less useful, and formalized processes are only useful when uncertainty is greater but equivocality is less present. The breadth of cooperation is not important under any of the four configurations.

Understanding factors that help manage high-uncertainty and high-equivocality process innovation projects is crucial in an increasingly mature metals and minerals industry. Extending prior studies of early front-end phase process innovation (Kurkkio et al. 2011; Frishammar et al. 2013; Rönnberg Sjödin et al. 2016) have started to recognize that the level of uncertainty—a lack of reliable information to solve particular tasks in process innovation—is becoming a common occurrence. We add the equivocality component, which is linked with (but distinct from) uncertainty. This combination leads to a challenging situation for large firms executing process innovation projects in the early stages as they struggle to achieve robust process concepts (Kim and Wilemon 2002; Cooper 2008). In this direction, we focused on configurations of diverse organizational practices that could be influential to reduce high-uncertainty. Our results based on analyzing 16 successful process innovation projects from large firms showed evidence of four different organizational configurations. We explored the interdependences and interplay among (1) formalized roles, (2) formalized processes, (3) idea screening, and (4) breadth of cooperation.

While recent work has increasingly called for the relevance of open innovation in innovation pursuits, the results do not show that breadth of cooperation is relevant to managing uncertain and equivocal process innovation projects. It is plausible that the industry under study has strong tacit knowledge that may not be facilitated through open innovation. Mutual acquisition, assimilation, transformation, and exploitation of knowledge in process innovation may be difficult in a process innovation setting. Process innovation focused on depth (to tie systemic knowledge, tools, and processes) and breadth (seeking novel ways to reconfigure systemic knowledge, tools, and processes) is particularly challenging with increasing breadth of cooperation, where divergent knowledge bases must be presented.

Of interest is the critical role of idea screening considered in tandem with formalized roles and processes. Formalized roles could be particularly detrimental in an uncertain process innovation setting, whereas formalization could increase interaction costs and the costs of managing a fluid innovation process where knowledge combination dynamics are gestating. Whereas alternative work has shown that formalization is a facilitator under uncertainty (Sine et al. 2006), formalized roles are particularly detrimental to success of uncertain and/or equivocal process innovation projects.

However, it must be noted that formalized processes under the presence of uncertainty but absence of equivocality are beneficial. A potential rationale for this finding is that lower equivocality implies limited duality in interpreting information and knowledge, and formalized process could help individuals dabble through uncertainty. Past work has showed that perceptions of control (possibly facilitated by formalized process) are increased with perceptions of gain when the environment is uncertain (Thomas and McDaniel 1990).

Configuration with the presence of equivocality, idea screening practices were the most important. This pinpoints the importance of managing high equivocality to lower information processing loads (Frishammar et al. 2011). Idea screening allows one to limit the loci of possible combinations of ideas to consider, thus limiting the total amount information, innovation configurations, and experimentation efforts the firm pursues. Lacking idea screening, the number of possibilities considered would multiply significantly, which would exacerbate further under bounded rationality. In the absence of idea screening, diverging views would cause paralysis by analysis. Overall, developing improved idea screening capabilities is relevant and important for firms aiming to engage in process innovation under uncertain and/or equivocal conditions.

These findings are not without limitations. First, process innovation projects, as with any other innovation projects, are idiosyncratic and therefore less generalizable across projects. While we lack rich qualitative data on the nature of formalized roles and processes or on idea screening procedures, we collated responses from managers who were deeply embedded in the innovation process. We call on future research to further assess the qualitative nature of these rich processes to further assess the frictions in formalization efforts and efficiency and effectiveness resulting from idea screening.

Second, we relied on a sample of Swedish metal and mining firms. Not only are these findings less generalizable to other contexts but also firms in these industries, due to higher cost structure from transportation, have comparable processing cost structures. We call on future studies to assess whether variations in cost structures could affect innovation success or whether they could add additional factors. For example, we do not consider total factor productivity, underlying value of mineral deposits, or cyclicality of demand. We call on future studies to take these important predictors into account.

Third, we do not measure the economic implications of success in process innovations. It would be interesting to further assess if the identified factors driving success of process innovation projects continue to have long-term effects on returns from innovation. It is plausible that formalized roles and process may have short-term costs, but they could facilitate future implementation of process innovations. Because implementation of process innovations that are systemic are important for long-term economic returns, formalization could beneficial in the long-term despite the higher risk of failure in early stages. We focused on early-stage process innovation efforts. However, it is possible that efficacy of the identified conditions could vary in later stages of innovation development efforts. With decreasing uncertainty and equivocality, formalized processes may be more important in later stages.

Fourth, we draw on fsQCA and some literature has highlighted its drawbacks. We caution the readers that the proposed inferences are strictly exploratory and should not be construed as causal. Smaller sample sizes and configuration-based inferences render causal inferences less meaningful. We call on future studies to not only draw on a larger sample, but also draw on causal design approaches. For example, studies could draw on a quasi-natural experimental designs as follows. Different industries have different levels of productivity shocks that drive firms to invest in process innovations. This treatment of productivity shocks coupled with qualitative design could help understand exogenously driven characteristics of process innovation.

In summary, process innovation, although rarely studied, is critical to economic growth. A significant amount of GDP growth in countries across the world comes from process innovation. However, due to their systemic expanse, process innovations are also marred by uncertainty and equivocality. Although formalized roles are detrimental and breadth of cooperation less meaningful, investing in idea screening capabilities seems to be related to success under uncertainty and equivocality in process innovation. We hope that this configurational approach using fsQCA adds to this area of research.

References

Amburgey, T.L., Miner, A.S.: Strategic momentum: the effects of repetitive, positional, and contextual momentum on merger activity. Strat. Manag. J. 13, 335–348 (1992)

Anderson, P., Tushman, M.L.: Technological discontinuities and dominant designs: a cyclical model of technological change. Adm. Sci. Quart. 35(4), 604–633 (1990)

Baer, M., Frese, M.: Innovation is not enough: climates for initiative and psychological safety, process innovations, and firm performance. J. Org. Behav. 24(1), 45–68 (2003)

Boeddrich, H.J.: Ideas in the workplace: a new approach towards organizing the fuzzy front end of the innovation process. Creat. Innov. Manag. 13(4), 274–285 (2004)

Brentani, U.: Innovative versus incremental new business services: different keys for achieving success. J. Prod. Innov. Manag. 18(3), 169–187 (2001)

Bstieler, L., Hemmert, M.: Increasing learning and time efficiency in interorganizational new product development teams. J. Prod. Innov. Manag. 27(4), 485–499 (2010)

Chesbrough, H.: Managing open innovation. Res. Technol. Manag. 47(1), 23 (2004)

Chesbrough, H.W.: Open innovation: the new imperative for creating and profiting from technology. Harvard Business Press, Boston (2006)

Conway, H.A., McGuinness, N.W.: Idea generation in technology-based firms. J. Prod. Innov. Manag. 3(4), 276–291 (1986)

Cooper, R.G.: Predevelopment activities determine new product success. Ind. Mark. Manag. 17(3), 237–247 (1988)

Cooper, R.G., Kleinschmidt, E.J.: New products: what separates winners from losers? J. Prod. Innov. Manag. 4(3), 169–184 (1987)

Cooper, R.G.: Perspective: the stage-gate® idea-to-launch process—Update, what’s new, and Nexgen systems. J. Prod. Innov. Manag. 25(3), 213–232 (2008)

Daft, R.L., Lengel, R.H.: Organizational information requirements, media richness and structural design. Manag. Sci. 32(5), 554–571 (1986)

Daft, R.L., Weick, K.E.: Toward a model of organizations as interpretation systems. Acad. Manage. Rev. 9(2), 284–295 (1984)

Eng, S., Woodside, A.G.: Configural analysis of the drinking man: fuzzy-set qualitative comparative analyses. Addict. Behav. 37(4), 541–543 (2012)

Ennen, E., Richter, A.: The whole is more than the sum of its parts—or is it? a review of the empirical literature on complementarities in organizations. J. Manag. 36(1), 207–233 (2010)

Ettlie, J.E., Reza, E.M.: Organizational integration and process innovation. Acad. Manag. J. 35, 795–827 (1992)

Fiss, P.C.: Building better causal theories: a fuzzy set approach to typologies in organization research. Acad. Manag. J. 54(2), 393–420 (2011)

Florén, H., Frishammar, J.: From preliminary ideas to corroborated product definitions. Calif. Manag. Rev. 54(4), 20–43 (2012)

Frishammar, J., Florén, H., Wincent, J.: Beyond managing uncertainty: insights from studying equivocality in the fuzzy front end of product and process innovation projects. IEEE Trans. Eng. Manag. 58(3), 551–563 (2011)

Frishammar, J., Kurkkio, M., Abrahamsson, L., Lichtenthaler, U.: Antecedents and consequences of firms’ process innovation capability: a literature review and a conceptual framework. IEEE Trans. Eng. Manag. 59(4), 519–529 (2012)

Frishammar, J., Lichtenthaler, U., Richtnér, A.: Managing process development: key issues and dimensions in the front end. R&D Manag. 43(3), 213–226 (2013)

Galbraith, J.K., Buck, B.: The age of uncertainty. Houghton Mifflin, Boston (1977)

Gilbert, C.G.: Unbundling the structure of inertia: resource versus routine rigidity. Acad. Manag. J. 48, 741–763 (2005)

Goldenberg, J., Lehmann, D.R., Mazursky, D.: The idea itself and the circumstances of its emergence as predictors of new product success. Manag. Sci. 47(1), 69–84 (2001)

Gopalakrishnan, S., Damanpour, F.: Patterns of generation and adoption of innovation in organizations: contingency models of innovation attributes. J. Eng. Technol. Manag. 11(2), 95–116 (1994)

Gopalakrishnan, S., Bierly, P., Kessler, E.H.: A reexamination of product and process innovations using a knowledge-based view. J. High Technol. Manag. Res. 10(1), 147–166 (1999)

Greco, M., Grimaldi, M., Cricelli, L.: Open innovation actions and innovation performance: a literature review of European empirical evidence. Euro. J. Innov. Manag. 18, 150–171 (2015)

Griffiths-Hemans, J., Grover, R.: Setting the stage for creative new products: investigating the idea fruition process. J. Acad. Mark. Sci. 34(1), 27–39 (2006)

Hannan, M.T., Pólos, L., Carroll, G.: Structural inertia and organizational change revisited: architecture, culture and cascading change. I. Graduate School of Business, Stanford University, California (2002)

Hendricks, K.B., Singhal, V.R.: Firm characteristics, total quality management, and financial performance. J. Op. manag. 19(3), 269–285 (2001)

Hervas-Oliver, J.L., Sempere-Ripoll, F., Boronat-Moll, C.: Process innovation strategy in SMEs, organizational innovation and performance: a misleading debate? Small Bus. Econ. 43, 873–886 (2014)

Ittner, C.D., Larcker, D.F.: The performance effects of process management techniques. Manag. Sci. 43(4), 522–534 (1997)

Kim, J., Wilemon, D.: Strategic issues in managing innovation’s fuzzy front-end. Eur. J. Innov. Manag. 5(1), 27–39 (2002)

Khurana, A., Rosenthal, S.R.: Integrating the fuzzy front end of new product development. MIT Sloan Manag. Rev. 38(2), 103–120 (1997)

Khurana, A., Rosenthal, S.R.: Towards holistic “front ends” in new product development. J. Prod. Innov. Manag. 15(1), 57–74 (1998)

Kurkkio, M., Frishammar, J., Lichtenthaler, U.: Where process development begins: a multiple case study of front end activities in process firms. Technovation 31(9), 490–504 (2011)

Lager, T.: A new conceptual model for the development of process technology in process industry. Int. J. Inno. Manag. 4(3), 319–346 (2000)

Lager, T.: Product and process development intensity in process industry: a conceptual and empirical analysis of the allocation of company resources for the development of process technology. Int. J. Innov. Manag. 6(02), 105–130 (2002)

Lager, T., Blanco, S., Frishammar, J.: Managing R&D and innovation in the process industries. R&D Manag. 43(3), 189–195 (2013)

Linton, J.D.: The role of relationships and reciprocity in the implementation of process innovation. Eng. Manag. J. 12(3), 34–38 (2000)

Linton, J.D., Walsh, S.T.: A theory of innovation for process-based innovations such as nanotechnology. Technol. Forecast. Soc. Ch. 75(5), 583–594 (2008)

Lim, L.P., Garnsey, E., Gregory, M.: Product and process innovation in biopharmaceuticals: a new perspective on development. R&D Manag. 36(1), 27–36 (2006)

Lin, T.T.: Assessment of decision-making regarding market entry/exit for technology innovation. Qual. Quant. 44(3), 447–457 (2010)

McEvily, B., Marcus, A.: Embedded ties and the acquisition of competitive capabilities. Strat. Manag. J. 26(11), 1033–1055 (2005)

Murphy, S.A., Kumar, V.: The front end of new product development: a Canadian survey. R&D Manag. 27(1), 5–15 (1997)

Naghizadeh, R., Elahi, S., Manteghi, M., Ghazinoory, S., Ranga, M.: Through the magnifying glass: an analysis of regional innovation models based on co-word and meta-synthesis methods. Qual. Quant. 49(6), 2481–2505 (2015)

Naqshbandi, M.M., Kaur, S., Ma, P.: What organizational culture types enable and retard open innovation? Qual. Quant. 49(5), 2123–2144 (2015)

Pisano, G.P.: The development factory: unlocking the potential of process innovation. Harvard Business Press, Boston (1997)

Ragin, C.C.: Fuzzy-set social science. University of Chicago Press, Chicago (2000)

Ragin, C.C.: Redesigning social inquiry: fuzzy sets and beyond (vol. 240). University of Chicago Press, Chicago (2008)

Rizzo, J.R., House, R.J., Lirtzman, S.I.: Role conflict and ambiguity in complex organizations. Adm. Sci. Quart. 15, 150–163 (1970)

Robertson, P.L., Casali, G.L., Jacobson, D.: Managing open incremental process innovation: absorptive capacity and distributed learning. Res. Policy 41(5), 822–832 (2012)

Sjödin, D.R., Frishammar, J., Eriksson, P.E.: Managing uncertainty and equivocality in joint process development projects. J. Eng. Technol. Manag. 39, 13–25 (2016)

Sine, W.D., Mitsuhashi, H., Kirsch, D.A.: Revisiting burns and stalker: formal structure and new venture performance in emerging economic sectors. Acad. Manag. J. 49(1), 121–132 (2006)

Teece, D.J.: Dynamic capabilities and strategic management: organizing for innovation and growth. OUP, Oxford (2009)

Thomas, J.B., McDaniel, R.R.: Interpreting strategic issues: effects of strategy and the information-processing structure of top management teams. Acad. Manag. J. 33(2), 286–306 (1990)

Tversky, A., Kahneman, D.: Availability: a heuristic for judging frequency and probability. Cognitive Psychol. 5, 207–232 (1973)

Tversky, A., Kahneman, D.: Judgment under uncertainty: heuristics and biases. Science 185, 1124–1131 (1974)

Utterback, J., Abernathy, W.: A dynamic model of process and product innovation. Omega 3, 639–656 (1975)

Uzzi, B.: Social structure and competition in interfirm networks: The paradox of embeddedness. Adm. Sci. Quart. 42(1), 35–67 (1997)

Weick, K.E.: Cognitive processes in organizations. Res. Org. Behav. 1(1), 41–74 (1979)

Woodside, A.G.: Moving beyond multiple regression analysis to algorithms: calling for adoption of a paradigm shift from symmetric to asymmetric thinking in data analysis and crafting theory. J. Bus. Res. 66(4), 463–472 (2013)

Yu, D., Hang, C.C.: A reflective review of disruptive innovation theory. Int. J. Manag. Rev. 12(4), 435–452 (2010)

Zack, M.H.: If managing knowledge is the solution, then what’s the problem. Knowl. Manag. Bus. Model Innov. (2001). doi:10.4018/978-1-878289-98-8.ch002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parida, V., Patel, P.C., Frishammar, J. et al. Managing the front-end phase of process innovation under conditions of high uncertainty. Qual Quant 51, 1983–2000 (2017). https://doi.org/10.1007/s11135-016-0376-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11135-016-0376-4